We prepare warm perlite plaster with our own hands

You probably noticed that all compositions for warm plaster contain components that determine their thermal insulation properties. Most often it is perlite or vermiculite, there are mixtures with polystyrene foam. It is their low thermal conductivity coefficients that make it possible, on average, to obtain good values for finished coatings. By using these additives in conjunction with or in place of certain fillers such as sand, as well as binders such as gypsum or cement, you can be sure to mix the mixture with the desired properties.

Unfortunately, the prices for ready mixes do not inspire confidence. What if you make your own solution? Moreover, individual components, such as cement, perlite, lime, are relatively inexpensive. For example, a ton of M500 cement can be bought for 3000-4000 rubles, 20 kg bags of slaked lime - according to 170 rubles, perlite (grades M75 or M100) - about 1500-2000 rubles. per cube If the amount of work is large, and the budget for the implementation is limited, then it's time to "chemize". We offer you several recipes for making warm perlite plaster with your own hands.

- 1 part of cement per 1 part of sand and 4 parts of perlite (calculated by volume) is mixed with water until the desired consistency is obtained (thick sour cream);

- the proportions of cement and perlite by volume are 1 to 4. So, for 375 kg of cement, approximately 1 cubic meter of perlite sand will be required. The mixture is mixed with 300 liters of water; PVA glue in a volume of 4-5 liters can be used as a plasticizing additive. The glue is kneaded in water, where a dry mixture of perlite and cement is subsequently added;

- volumetric ratios of cement and perlite - 1 to 5. For 290 liters of water, 4-4.5 liters of PVA, 300 kg of cement and a cube of perlite are used;

- by volume: 1 portion of cement, 2 portions of sand and 3 - perlite. As an additive, liquid soap or PVA can be used in an amount of not more than 1% by weight of cement; - 270 liters of water will require a cube of perlite and 190 kg of cement;

- 1 volume of cement, 4 volumes of perlite, approximately 0.1% by weight of cement PVA glue;

- volumetric ratio of cement to perlite in the range of 1:4÷1:8. The additive can be liquid soap, dish detergent, PVA - up to 1% by weight of cement;

- pre-prepare a solution for mixing (hereinafter RZ): in a measured volume of water, the sodium salt of carboxymethyl cellulose (CMC) is dissolved in a volume of 0.5% of the estimated volume of warm plaster, as well as plasticizers - 0.5% by weight of cement subsequently added. All components are thoroughly mixed and the solution is allowed to settle until the viscosity of the CMC increases. Further variations are possible depending on the density of the plaster to be obtained (bucket - 10 l). For example, 12 liters of cement, 2 buckets of perlite, 2.5 buckets of sand are added to 12 liters of RZ (the density of the resulting solution is approximately 1500 kg per cubic meter). For the same volume of RH, 1.5 buckets of sand, 3 buckets of perlite, 1 bucket of cement are poured - a mixture with a density of 1200 kg in a cube is obtained. For 20 liters, you can mix about 5 buckets of perlite, 1 bucket of sand, 12 liters of cement - we get a solution with a density of about 800-900 kg per cubic meter

All these PVA and liquid soap can be replaced with superplasticizers, for example, from Polyplast. This component is very important, because it determines the behavior of the solution and the need for the mixture in the volume of mixing water.

You should understand that any recipes are given for guidance only. To succeed, you will have to experiment with the ratio of components, check the resulting solutions in work

And only after the mixture is ideally suited specifically for your finishing conditions, you can knead large volumes. Pay special attention to the water absorption capacity of the thermal insulation components. They actively retain moisture, which, if there is a lack of mixing water, can affect the technology of cement mixture hardening.

Finally

If you do not perceive warm plaster as the only solution for warming a residential building, but only as an opportunity to bring the thermal performance of the building to the desired values, then the result will not be long in coming.Using such a solution, you can simultaneously level the base and give it new properties. And do not be afraid to experiment with making your own plaster - it will be cheaper than buying ready-made mixtures!

Advantages and disadvantages of stucco insulation from the inside

Warm plaster has unique properties. Using only it, it is possible to solve the issue of waterproofing, insulation and final wall decoration with one technological procedure. Especially pronounced are the advantages of plasters that have rock particles as fillers - perlite, expanded vermiculite, that is, mixtures of the most "advanced" type.

Thanks to the polymer additives included in the mixture, this plaster has excellent adhesion to any wall materials: aerated concrete, metal, ceramics and others.

Warm plaster easily passes air, while retaining water without soaking. Therefore, walls covered with this material are protected from mold. In addition, warm plaster is biologically resistant, so the formation of microflora in it is excluded. By processing the walls of the room from the inside with this material, you can not only insulate it, but also make it more environmentally friendly.

The effectiveness of insulation using such plaster is high not only due to the low thermal conductivity of the material, but also because of its close contact with the surface of the walls over their entire area without the formation of any cold bridges.

Another great property of warm plaster is its fire resistance. Unlike expanded polystyrene and other similar heaters, insulating plaster coatings perfectly protect walls, without collapsing, from intense heat and open flames. Moreover, the layer of plaster does not have to be thick.

According to manufacturers promoting warm plaster mixtures on the market, this material, applied to walls with a layer of 2 cm, is equivalent in its thermal insulation qualities to laying 2 bricks or a concrete wall about 1 m thick

Taking this fact into account, it is easy to calculate how much the weight of the building will decrease and how much material can be saved thanks to warm plaster. However, other experts consider this opinion rather controversial in terms of the approved ratios.

Simply applying this material is much easier than traditional insulation with their fastening, primer and top coat. By the way, during a work shift, a team of plasterers of three people can process more than 80 m 2 of walls with a warm mixture.

In addition to the above advantages, warm plaster has other unique properties: the complete absence of toxic inclusions, the material is made from natural components that have undergone heat treatment; at any temperature, the plaster is environmentally friendly, it does not decompose, does not burn or freeze.

The disadvantages of the material include the following:

- Warm plaster, made on the basis of foam plastic granules, needs a top coat. This does not apply to mixtures that include rock fillers.

The high price of plasters based on perlite, pumice and vermiculite.

The need for layer-by-layer application of material on the walls. A thick coating applied in one layer is more likely to slide off the wall under its own weight.

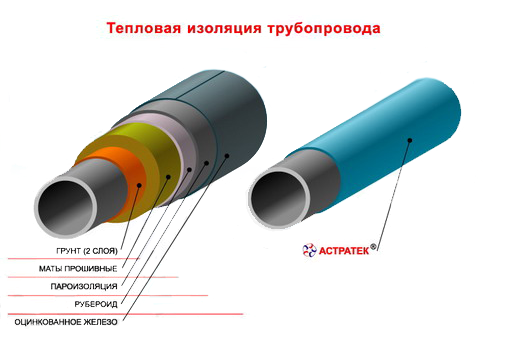

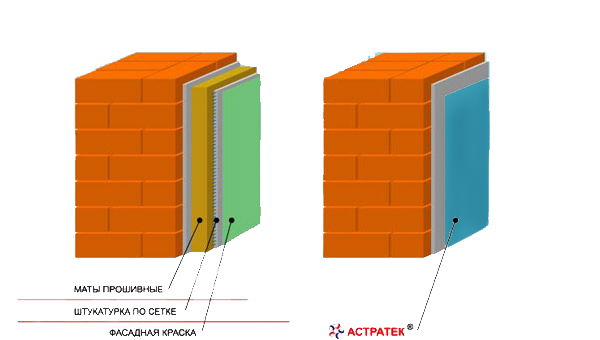

SUPER-THIN LIQUID THERMAL INSULATION ASTRATEK

ASTRATEK heat-insulating polymer coatings are modern multifunctional composite materials based on a polymer binder, special fillers and targeted additives. ASTRATEK coatings combine high thermal and operational characteristics with economic efficiency.

ASTRATEK is a highly porous heat-insulating material that works by implementing a blocking mechanism (creating high thermal resistance) of 3 types of heat transfer - convection, conduction and radiation. The microporous structure of ASTRATEK during heat transfer reflects and dissipates more than 76% of the input thermal radiation. Due to the low thermal conductivity, there is a “weakening” of the heat flow in the thickness of the material, a low emissivity reduces the level of the output heat flow and reduces heat loss.

Line of heat-insulating polymer coatings ASTRATEK:

ASTRATEK metal is a special composition with enhanced adhesion and anticorrosion characteristics, resistant to UV radiation and chemicals (solutions of salts, acids, alkalis, some types of petroleum products). The coating increases the service life of the insulated surface and protects against corrosion.

Water-dispersion paints and primers:

Universal primer - has a high penetrating power and increased adhesion, facilitates subsequent painting, reduces paint consumption. Contains additives to kill and prevent the development of fungi and mold. Specially designed to prepare for the application of ASTRATEK facade polymer coating and GROSS paints.

Metal Primer - Environmentally friendly replacement for traditional metal primers. Operating temperature up to +200°С. Specially designed to prepare for the application of ASTRATEK polymer coatings.

Water-dispersion paints - Decorative and protective coatings for high-quality painting of building facades on plastered, concrete, brick surfaces. Are intended for external and internal works. Material color - white base A, base C. Tinted according to the RAL catalog. Packing - buckets 14 kg; 4.2 kg; 1.4 kg.

The recipe for making heat-insulating plaster with your own hands

The insulating layer for interior decoration and warm plaster for the facade have a different recipe. Here are some options for preparing the solution.

Warm plaster for interior work, dry components will be required for indoor work: 3 hours of sawdust, 1 hour of cement, 2 hours of crushed paper, mix well, add water, bring a drill with a nozzle to a homogeneous plastic mass.

For outdoor and indoor use, a universal solution: 1 tsp of cement, 4 tsp of perlite or vermiculite, plasticizers according to the manufacturer's recommendation, can be replaced with PVA glue (approximately 0.05 g per 1 bucket of cement), water.

From natural materials: 0.2 hours of cement, 1 hour of clay, 2 hours of shredded paper soaked in water to a pasty state, 3 hours. sawdust, water.

Heat-insulating plaster for outdoor use: 1 hour of cement, 3 hours of perlite, plasticizer as recommended, 1 hour of expanded polystyrene, crushed into grains not more than 3 mm, foam fiber - 0.5 g per bucket of cement, water.

For your information: When applying a layer of 50 mm, the average consumption is 18-25 kg of mortar / m2, depending on the filler.

We offer you a video tutorial on how to properly apply insulating plaster for outdoor work in a mechanized way.

Purpose

Although the thermal insulation properties of this material are higher than those of ordinary plaster, it cannot replace the full insulation of the house with mineral wool or polystyrene foam, but it will be a good addition.

We give recommendations from manufacturers on how to use warm plaster. It is used as:

- facade insulation;

- heat and sound insulating material for interior and exterior walls;

- insulation of balconies, verandas, slopes of doors and windows, stairwells, etc.;

- sealing joints of ceilings, cracks and cracks;

- heat insulator for well masonry;

- material for finishing work in the premises;

- insulation of water supply pipes;

- thermal insulation of floors and ceilings.

Stucco facade is durable, practical and beautiful

Recently, plastering of wall insulation has become the most demanded technology, both for urban and suburban buildings.

Today it is already difficult to find any building that would not decorate its facade with decorative plaster.

This type of finishing work has become truly massive, and all thanks to the following qualities:

- Significant reduction in heating costs;

- No internal wall insulation required;

- Insulation under plaster can be mounted on any type of facade;

- Relatively inexpensive and simple type of work;

- A huge variety of plaster materials, which makes it possible to radically change the appearance of buildings;

- Reliable coating that is resistant to sudden changes in temperature;

- Perfectly solves the problem of sealing.

But most importantly, the plaster on the facade insulation does not create an additional load on the building structure and at the same time provides it with complete protection from the destructive effects of the environment.

Heat-insulating plaster mixture

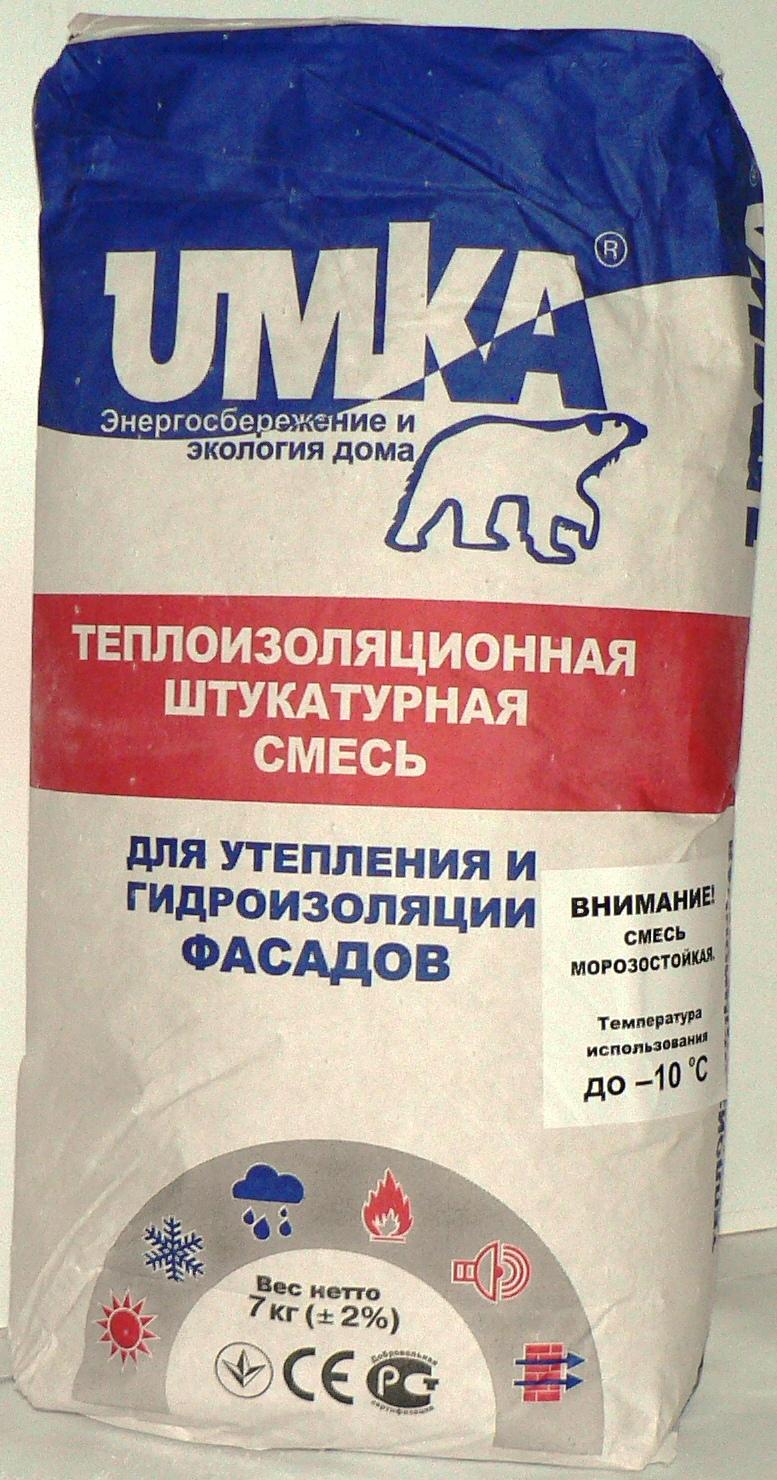

Umka heat-insulating mixes are ready-to-use dry mixes,

Heat-insulating plaster is a material that is created using the latest technologies and developments in the field of building thermal physics. When insulating buildings with heat-insulating plaster, additional insulation with materials such as mineral wool or foam plastic is not required, it is enough just to apply the plaster on a dry, clean wall. It is applied on all types of solid base (brickwork, concrete, aerated concrete, ceramic block, shell rock, etc.). The material is used as a decorative finish, finishing layer for the surface of a wall made of aerated concrete, foam concrete, ceramic block, thermoblock, etc., which meet the requirements of building thermal physics for wall material, but require additional insulation.

The use of heat-insulating plasters can increase heat savings up to 40%. Heat-insulating plaster mixes "Umka" consist of 98% inorganic substances, which makes them environmentally friendly and safe. This allows you to use them not only for external, but also for internal work. They are non-combustible material.

Umka heat-insulating plaster mixtures protect buildings from the effects of rain, sun, wind and other natural factors, prevent heat from escaping to the outside during the cold season, thereby reducing heating costs and keeping the room cool in summer.

The effective thermal insulation filler of warm plasters is based on granular vacuum expanded silicon. After a rather complex technological process, very light and durable balls are obtained. Their structure is a set of small pores, the size of which is larger than an air molecule, but smaller than a water molecule. This gives this material unique properties - it does not absorb water, but allows air to pass through, which allows the walls to "breathe" while maintaining waterproofing properties.Warm plasters based on expanded materials have a very small coefficient of thermal expansion - 0.000014, which means that the plaster layer on the building will not crack after winter frosts. Such materials retain their properties in the temperature range of -260…+1200 °C.

Due to their water-repellent and "breathing" properties, Umka heat-insulating mixtures contribute to the timely removal of moisture, and thereby prevent the appearance of mold and fungus on the surface of the walls and in the middle structures, creating a healthy, safe living environment. Complete environmental cleanliness - a key requirement for modern housing, is 100% implemented in the material "Umka", because. it does not contain carcinogenic substances, so it is safe for humans.

structures, creating a healthy, safe living environment. Complete environmental cleanliness - a key requirement for modern housing, is 100% implemented in the material "Umka", because. it does not contain carcinogenic substances, so it is safe for humans.

"Umka" has a perfectly white color on the wall, the material is technological when applied to any kind of wall surfaces without preliminary priming and reinforcing with a mesh, it can be applied both manually and by machine. A wall covered with Umka heat-insulating material, like a thermal fur coat, does not have a single cold bridge.

The use of Umka material increases the total thermal resistance of the wall by 40% of the calculated value due to the complete drying of the wall material and waterproofing protection from the external environment. Thus, the load-bearing wall remains dry throughout the year without absorbing dry moisture from the outside, which is not achieved when using insulation systems based on expanded polystyrene and mineral wool.

Umka heat-insulating plaster mixes meet all sanitary and hygienic requirements accepted in Russia and are recommended for use in housing and civil construction.

The main characteristics of thermal insulation

Issue price

In conclusion, let's say, the insulation for the facade under the plaster can be either ordinary expanded polystyrene, or extruded, or mineral wool. There are no better or worse materials, each insulation suits you relatively. Knowing the properties of each material, it is necessary to think about how to compensate for the shortcomings

If it is important for you to live in a house with natural ventilation, a good indoor climate, then it is better to use vapor-permeable mineral wool than polystyrene foam. If you want to save money, but are ready to lose quality, use polystyrene foam, but consider forced ventilation in the house

Extruded styrofoam is denser and lasts longer, but regular styrofoam is cheaper and may be easier for you to replace when it wears out.

Mineral wool is vapor permeable and does not burn, but costs three times as much and can absorb water if installed incorrectly. If stone wool gets wet, it will lose all of its energy-saving features.

- Ordinary expanded polystyrene PSB-S 25 costs 1500 rubles / m3;

- Extruded polystyrene foam costs 2800/m3;

- Mineral wool of high density (not less than 120kg/m3) costs 4800/m3.

Each insulation is certified for use, and can be used in plaster facade systems. Now you know the properties of each, choose according to the set of characteristics you need.

Thermal insulation of the facade with mineral wool under plaster involves the creation of a multi-layer "fur coat", which includes. insulation under siding.

Similar publications. insulation for house walls outside under plaster. Do-it-yourself siding installation: instructions for dummies.

To plaster facade according to insulation had a beautiful appearance, apply the next ball of plaster mixture. The task is.

under insulation suitable trim and siding, and plaster. As you can see, it is difficult to find the exact answer to the question of which is better - a wet facade or siding.

Wet insulation loses up to 90% of the energy saving characteristics declared by the manufacturer.

Such a porous lightweight material is used as insulation under plaster for walls both inside and outside the house.

Heat-insulating plaster types and features

In warm plaster formulations, some of the components of conventional leveling compounds are replaced by materials that can be used to enhance the thermal insulation properties of the cured mortar. For example, quartz sand or part of it is exchanged for perlite, vermiculite, polystyrene foam, etc. loose additives. Cement or gypsum can be used as a binder. In the first case, the finished composition is suitable for exterior and interior decoration, in the second - only for interior work due to the high hygroscopicity of gypsum.

The main part of dry mixes presented on the domestic market is perlite plaster. Expanded perlite is used as a filler, which outwardly may resemble coarse sand or fine gravel of a grayish-white color. The material is quite light - bulk density in the region of 200-400 kg per cubic meter. m. depending on the grain size. It is somewhat lower for expanded vermiculite. The density of this additive in plaster is approximately 100 kg per cubic meter. m. (bulk). Another property that must be taken into account when using heat-insulating solutions is the high hygroscopicity of the hardened coatings. The hygroscopicity of the material is up to 5 volumes of water per 1 volume of the expanded component.

Despite the high water absorption coefficients, vermiculite and perlite plasters can be used for external insulation of buildings. The main thing is that they are not under the direct influence of precipitation, and the steam passing through the walls of the house does not linger in the coating.

| Plaster | Price* | Note |

|---|---|---|

| Perel Teplorob | 240 rub. for 20 kg. | — |

| HAGAST FS-402 | 215 rub. for 15 kg. | |

| HAGAST FSW-402 | 240 rub. for 15 kg. | the same, but for winter application |

| Glims Velur | 225 rub. for 15 kg. | — |

| ExtraGips Iso | 270 rub. for 30 kg. | based on gypsum |

The low density of the solution components provides a reduction in the mass of the finished coating, which can be taken into account when designing a house. It becomes possible to reduce the load on the foundation and rely on a cheaper foundation for construction.

A short video about plaster based on polystyrene foam.

Two videos on how to prepare warm vermiculite plaster.

Types of liquid insulation for walls

Modern heat insulators can be divided into groups according to different indicators. We will give the most common classification.

liquid foam

Today, the construction market offers several types of such heaters.

Polyurethane foam (PPU)

The material is developed on the basis of liquefied urethanes, which, under the influence of a chemical reaction, form a foamy substance, while increasing by almost 50 times. After 24 hours, the mixture finally solidifies, forming a durable finely porous layer, resembling mounting foam in structure. Polyurethane insulation is applied using a special spraying machine that delivers the contents to the surface under high pressure.

Polyurethane insulation is applied using a special spraying machine

Penoizol

Penoizol differs from the previous thermal insulator by a lower price, lower density and poor thermal conductivity. This option is made budgetary by urethanes, which belong to the urea-formaldehyde group. In terms of efficiency, it can be compared with traditional insulation (foam or mineral wool). The material is also applied under high pressure using a spray gun. The finished volume, as a rule, does not exceed more than 30 times the original mixture.

Polynor

Another heat insulator based on heterochain polymers. Produced in small bottles. One container is enough to finish 1 sq. m when applying a layer with a thickness of about 60 mm. Compared to other materials, Polynor is much more expensive, and therefore it is unprofitable to use it for large rooms.A convenient bottle with a nozzle allows you to apply insulation without prior preparation of the material.

Thermal paints

They contain ready-made additives that do not need pre-foaming.

"Corundum"

The Russian brand that produces this insulation gives a guarantee on its products for up to 15 years. The material has a uniform viscous texture with high adhesion to various surfaces. Apply "Korund" with a spatula or paint brush. It can also be sprayed, but must first be diluted with water.

The manufacturer offers several variations of thermal insulation:

- "Facade";

- "Winter";

- "Anticor";

- "Fire protection";

- "Lotus";

- "Classic";

- "Waterproofing";

- "Sanitary";

- "Foundation".

"Armor"

This thermal insulation is produced by a Vologda company that owns copyright on the composition of the insulation. The paint has a fairly thick consistency, allowing it to fit well on any surface. It is water repellent and can also be used as a waterproofing coating. Like the previous mixture, "Armor" is available in several versions:

- "Classic";

- "Light";

- "Standard";

- "Universal";

- "Facade";

- "Metal";

- "Wall";

- "Fire protection";

- "Volcano";

- "North";

- "Winter";

- "Anticor".

Akterm

The country of origin of this thermal insulator is Russia. The company produces paints designed for two types of work: insulation and waterproofing. The Akterm product line is represented by 13 compositions with different technical characteristics:

- "Concrete";

- "Metal";

- "Anticor";

- "Facade";

- "Standard";

- "North";

- "Volcano";

- "Akterm - paint NG";

- "Anti-condensate";

- "Fire protection";

- "Water repellent";

- "Zinc";

- "Plast".

When using Akterm thermal paints for walls or facades, various colors can be added to them.

"Astratek"

Another Russian brand that occupies the first place among the manufacturers of modern liquid insulation. The paint has a uniform texture, the consistency resembles a suspension. Such a liquefied structure allows it to be applied not only with a paint brush, but also with a spray gun. The manufacturer produces several variations of the compositions:

- "Facade";

- "Metal";

- "Universal";

- "Anticondensation".

-

- "Corundum"

- "Armor"

-

- Akterm

-

- "Astratek"

Ecowool

The composition of this ecological material includes several components:

- processed cellulose;

- minerals;

- boric acid;

- wood;

- waste paper.

The thermal insulator is well suited for insulating floors, as well as wall sections where condensation often forms. The ecowool market is represented by several brands:

- Greenfiber - has heat and waterproofing properties, absorbs noise;

- Ekovilla is a heat insulator with high technical performance and a long service life;

- Termex - is characterized by increased environmental friendliness;

- "Ecowool Extra" - used mainly for residential buildings or apartments;

- "Equator" - is made according to European technologies, observing international standards.

Ecowool is well suited for wall insulation