Stage one

This includes an aerodynamic calculation of mechanical air conditioning or ventilation systems, which includes a number of sequential operations. A perspective diagram is drawn up, which includes ventilation: both supply and exhaust, and is prepared for calculation.

The dimensions of the cross-sectional area of the air ducts are determined depending on their type: round or rectangular.

Schema formation

The scheme is drawn up in axonometry with a scale of 1:100. It indicates the points with located ventilation devices and the consumption of air passing through them.

When building a highway, you should pay attention to which system is being designed: supply or exhaust

Supply

Here the calculation line is built from the most remote air distributor with the highest consumption. It passes through supply elements such as air ducts and ventilation unit up to the place where the air is taken. If the system must serve several floors, then the air distributor is located on the last one.

exhaust

A line is built from the most remote exhaust device, which consumes the air flow to the maximum, through the main line to the installation of the hood and further to the shaft through which air is released.

If ventilation is planned for several levels and the installation of the hood is located on the roof or attic, then the calculation line should begin with the air distribution device of the lowest floor or basement, which is also included in the system. If the hood installation is located in the basement, then from the air distribution device of the last floor.

The entire calculation line is divided into segments, each of them is a section of the duct with the following characteristics:

- air duct of the same section size;

- from one material;

- with constant air consumption.

The next step is the numbering of the segments. It starts with the most distant exhaust device or air distributor, each is assigned a separate number. The main direction - the highway is highlighted with a thick line.

Further, on the basis of the axonometric scheme for each segment, its length is determined, taking into account the scale and air consumption. The latter is the sum of all the values of the consumed air flow flowing through the branches that are adjacent to the highway. The value of the indicator, which is obtained as a result of sequential summation, should gradually increase.

Determination of dimensional values of air duct sections

It is made on the basis of such indicators as:

- air consumption in the segment;

- normative recommended values for the speed of air flow are: on highways - 6 m / s, in mines where air is taken in - 5 m / s.

The preliminary dimensional value of the duct is calculated on the segment, which is reduced to the nearest standard. If a rectangular duct is selected, then the values are selected based on the dimensions of the sides, the ratio between which is not more than 1 to 3.

Initial data for calculations

When the scheme of the ventilation system is known, the dimensions of all air ducts are selected and additional equipment is determined, the scheme is depicted in a frontal isometric projection, that is, axonometry. If it is performed in accordance with current standards, then all the information necessary for the calculation will be visible on the drawings (or sketches).

- With the help of floor plans, you can determine the length of the horizontal sections of air ducts. If on the axonometric diagram there are marks of the heights at which the channels pass, then the length of the horizontal sections will also become known.Otherwise, sections of the building with laid air duct routes will be required. And in the extreme case, when there is not enough information, these lengths will have to be determined using measurements at the installation site.

- The diagram should show with the help of symbols all additional equipment installed in the channels. These can be diaphragms, motorized dampers, fire dampers, as well as devices for distributing or extracting air (grilles, panels, umbrellas, diffusers). Each unit of this equipment creates resistance in the path of the air flow, which must be taken into account in the calculation.

- In accordance with the regulations on the diagram, near the conditional images of the air ducts, the air flow rates and the dimensions of the channels should be affixed. These are the defining parameters for calculations.

- All shaped and branching elements must also be reflected in the diagram.

If such a scheme does not exist on paper or in electronic form, then you will have to draw it at least in a draft version, you cannot do without it in calculations.

2. Calculation of friction losses

Losses

flow energies are calculated proportionally

so-called

"dynamic" head, magnitude

pW2/2,

where p is the density

air at flow temperature

(determined according to table (1)

and (2)), a

W

- speed in a particular section of the contour

air circulation.

The fall

air pressure due to the action

friction calculate

according to the Weisbach formula:

wherel

— length of the section of the circulation circuit, m,

deq-equivalent

section cross section diameter,

m,

deqv=

friction resistance.

Coefficient

friction is determined by the air flow regime

in the considered section of the contour

circulation, or the value

Reynolds criterion:

Re=

where

Wideq

- speed and equivalent diameter

channel

and

kinematic viscosity coefficient

air (determined according to the tables

/1/ and /2/,

m

/With.

Meaning

interval 105

-108

(developed

turbulent

value) is determined by the formula

Nikuradze:

.

10-3—

0,231 .Re-0,231

More

selection details

/5/

a diagram for finding

values

facilitating

calculations.

Computed values

V

table 3 summarizes the values of the initial

data for each channel

speed,

length, cross section,

equivalent diameter,

magnitude

Reynolds criterion, coefficient

resistance,

dynamic

head and the value of the calculated losses on

friction.

|

Table 3 |

||||||||

|

channel number |

W, m/s |

F, m2 |

deq M |

l, |

|

Re |

|

|

|

1 |

15 |

0.8 |

0,77 |

1,0 |

76,5 |

3,5 |

0,015 |

1,5 |

|

2 |

25 |

0,87 |

0,88 |

1,75 |

212,5 |

6,7 |

0,013 |

5,5 |

|

3 |

21,7 |

1,0 |

0,60 |

3,0 |

160,1 |

3,9 |

0,014 |

11,2 |

|

4 |

28,9 |

0,75 |

0,60 |

1,75 |

283,9 |

5,3 |

0,0135 |

11,2 |

Calculations

friction resistance in the furnace channels

5.3.

"Local" losses

- this term refers to losses

energy in those

places where the air flow suddenly

expands or narrows, undergoes

turns, etc.

V

there are enough such places for the designed furnace

many - heaters, turns

channels, expanding or narrowing channels

and etc.

These

losses are calculated in the same way as the share

dynamic head p=W2/2,

multiplying

it on the so-called "coefficient

local resistance"

Sum

29.4Pa

29.4Pa

=

Coefficient

local resistance is determined

but tables /1/ and /5/ depending on the type

local resistance, and overall

characteristics. For example, in

this furnace local resistance type

sudden narrowing takes place

in channel 1-2 (see Fig. 7). Section ratio

(narrow to wide). By

application /1 / find

= 160Pa,

Absolutely

other local

losses. Necessary

note that in some cases local

losses are due

the action of two types of resistance at once.

For example, has

place the channel turn and at the same time

change in its cross section (narrowing

or extension) should be carried out

loss calculation for

both cases and add up the results.

Results of Local Loss Calculations

summarized in table 4

|

№ |

A type |

W, m/s |

|

|

Note. |

|

sudden |

43,4 |

0,125 |

160 |

Nah. according to the table |

|

|

1-1 |

Turn |

25 |

1,5 |

318 |

~ |

|

2-3 |

rounded |

25 |

O,1 |

21,3 |

~ |

|

3 |

Aperture in

stream |

35,8 |

3,6 |

601 |

~ |

|

3-4 |

rounded |

21,7 |

0,28 |

44,8 |

~ |

|

4-1 |

Turn |

28,9 |

0,85 |

241 |

~ |

|

4-1 |

sudden |

28,9 |

0,09 |

25,5 |

~ |

Sum

=1411.6 Pa

=1411.6 Pa

Total

losses:

=30 + 1410 =1440 Pa

=30 + 1410 =1440 Pa

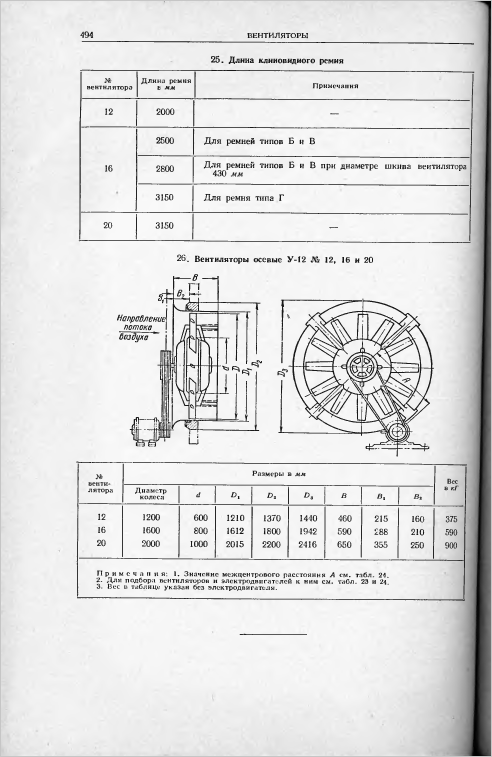

Fans

choose according to features

centrifugal

fans

, presumably for VRS type No. 10

(working

wheel

diameter 1000

mm).

For

performance 21,5

m3/With

and the required pressure H>1440

Pa..

We get: n=550

rpm;

Nmouth

kW.

Drive unit

fan from asynchronous motor,

power 30

kW

type

JSC

at 720

rpm,

through a V-belt drive.

Stage two

Here, aerodynamic drag indicators are calculated. After choosing the standard sections of the air ducts, the value of the air flow velocity in the system is specified.

Friction Pressure Loss Calculation

The next step is to determine the specific friction pressure loss based on tabular data or nomograms. In some cases, a calculator can be useful to determine indicators based on a formula that allows you to calculate with an error of 0.5 percent. To calculate the total value of the indicator characterizing the pressure loss in the entire section, you need to multiply its specific indicator by the length. At this stage, a correction factor for roughness should also be taken into account. It depends on the magnitude of the absolute roughness of a particular duct material, as well as the speed.

Calculation of the dynamic pressure index on the segment

Here, an indicator characterizing the dynamic pressure in each section is determined based on the values:

- air flow rate in the system;

- air mass density under standard conditions, which is 1.2 kg/m3.

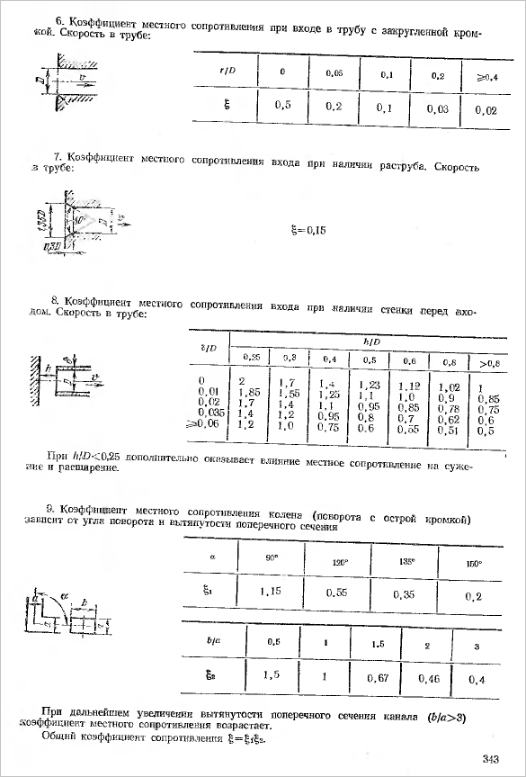

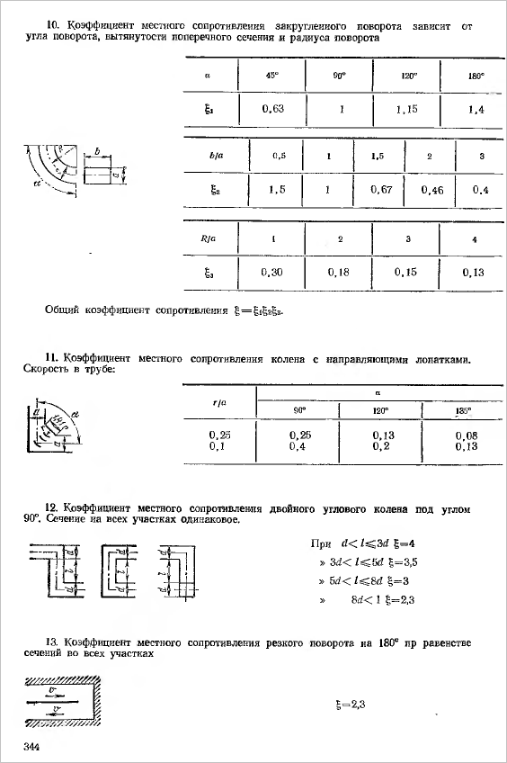

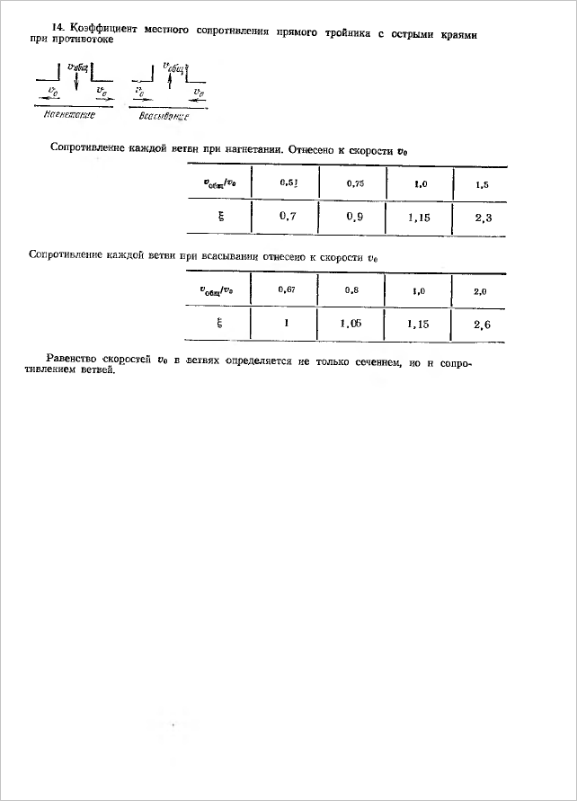

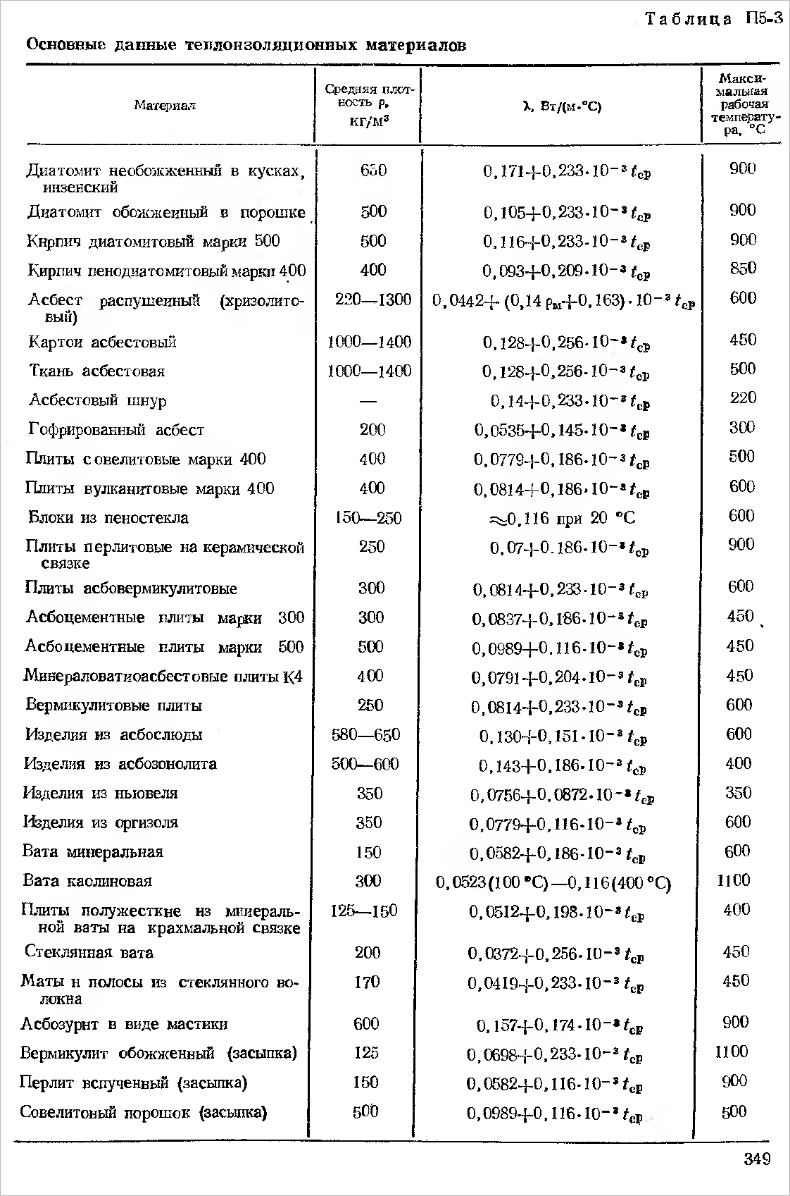

Determination of local resistance values in sections

They can be calculated from local resistance coefficients. The obtained values are summarized in a tabular form, which includes data from all sections, and not only straight segments, but also several shaped parts. The name of each element is entered in the table, the corresponding values \u200b\u200band characteristics are also indicated there, by which the coefficient of local resistance is determined. These indicators can be found in the relevant reference materials for the selection of equipment for ventilation installations.

In the presence of a large number of elements in the system or in the absence of certain values of the coefficients, a program is used that allows you to quickly carry out cumbersome operations and optimize the calculation as a whole. The total resistance value is defined as the sum of the coefficients of all segment elements.

Calculation of pressure losses on local resistances

Having calculated the final total value of the indicator, they proceed to the calculation of pressure losses in the analyzed areas. After calculating all segments of the main line, the obtained numbers are summed up and the total resistance value of the ventilation system is determined.

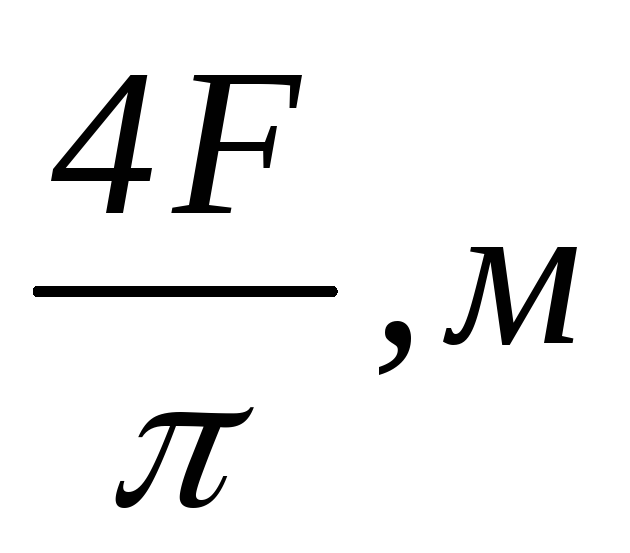

Calculation of air ducts for supply and exhaust systems of mechanical and natural ventilation

Aerodynamic

calculation of air ducts is usually reduced

to determine the dimensions of their transverse

section,

as well as pressure losses on individual

plots

and in the system as a whole. Can be determined

costs

air for given dimensions of air ducts

and known differential pressure in the system.

At

aerodynamic calculation of air ducts

ventilation systems are usually neglected

compressibility

moving air and enjoy

overpressure values, assuming

for a conditional

zero atmospheric pressure.

At

movement of air through the duct in any

transverse

flow cross section there are three types

pressure:

static,

dynamic

and complete.

static

pressure

determines the potential

energy 1 m3

air in the section under consideration (pst

equal to the pressure on the walls of the duct).

dynamic

pressure

is the kinetic energy of the flow,

related to 1 m3

air, determined

according to the formula:

(1)

where

– density

air, kg/m3;

- speed

air movement in the section, m/s.

Complete

pressure

equal to the sum of static and dynamic

pressure.

(2)

Traditionally

when calculating the duct network, it is used

the term "loss

pressure”

("losses

flow energy”).

Losses

pressure (full) in the ventilation system

are made up of friction losses and

losses in local

resistances (see: Heating and

ventilation, part 2.1 “Ventilation”

ed. V.N. Bogoslovsky, M., 1976).

Losses

friction pressures are determined by

formula

Darcy:

(3)

where

- coefficient

friction resistance, which

calculated by the universal formula

HELL. Altshulya:

(4)

where

– Reynolds criterion; K - height

roughness projections (absolute

roughness).

engineering pressure loss calculations

friction

,

Pa (kg/m2),

in an air duct with a length /, m, are determined

by expression

(5)

where

– losses

pressure per 1 mm of duct length,

Pa/m [kg/(m2

* m)].

For

definitions Rdrawn up

tables and nomograms. Nomograms (Fig.

1 and 2) are built for the conditions: section shape

duct circle diameter,

air pressure 98 kPa (1 atm), temperature

20°C, roughness = 0.1 mm.

For

calculation of air ducts and channels

rectangular sections are used

tables and nomograms

for round ducts, introducing at

this

equivalent diameter of a rectangular

duct, in which the pressure loss

for friction in

round

and rectangular

~

air ducts are equal.

V

design practice received

Spread

three types of equivalent diameters:

■ by speed

at

parity of speeds

■ by

consumption

at

cost equity

■ by

cross-sectional area

if equal

cross-sectional areas

At

calculation of air ducts with roughness

walls,

different from that provided for in

tables or nomograms (K = OD mm),

make a correction to

tabular value of specific losses

pressure on

friction:

(6)

where

- tabular

specific pressure loss value

for friction;

- coefficient

taking into account the roughness of the walls (Table 8.6).

Losses

pressure in local resistances. V

places of rotation of the duct, when dividing

and merger

flows in tees, when changing

sizes

air duct (expansion - in the diffuser,

constriction - in the confuser), at the entrance to

air duct or

canal and exit from it, as well as in places

installations

control devices (throttles,

gates, diaphragms) there is a drop

flow pressure

moving air. In the specified

places going on

restructuring of air velocity fields in

air duct and the formation of vortex zones

at the walls, which is accompanied

loss of flow energy. alignment

flow occurs at some distance

after passing

these places. Conditionally, for convenience

aerodynamic calculation, loss

pressure in local

resistances are considered concentrated.

Losses

pressure in local resistance

determined

according to the formula

(7)

where

–

local resistance coefficient

(usually,

in some cases there is

negative value, when calculating

should

take into account the sign).

Ratio refers to

to top speed

in the narrow section of the section or speed

in section

section with a lower flow rate (in a tee).

In tables

local resistance coefficients

indicates which speed it refers to.

Losses

pressure in local resistances

plot, z,

calculated by the formula

(8)

where

- sum

local resistance coefficients

Location on.

Are common

pressure loss in the duct section

length,

m, in the presence of local resistances:

(9)

where

– losses

pressure per 1 m of duct length;

– losses

pressure in local resistances

site.

W2/2

W2/2

,

,

Pa

Pa