1 Applications

The area of use of such material as mineral wool Izolight has fairly wide limits. This makes Izorok mineral wool better than Rockwool insulation.

Thermal insulation Isolight in most cases is used in order to effectively isolate all kinds of enclosing structures of buildings from the effects of cold.

Reviews about the presented insulation (as well as about the Rockwool material) are mostly positive. The density of this substance is very high, and therefore it exhibits high heat-retaining qualities.

Isolight can be used as a reliable heat insulator with a high density during the installation of pipelines and the construction of various industrial buildings.

This thermal insulation significantly increases not only the thermal performance of individual structural elements, but also affects such characteristics as:

- Soundproofing level;

- Fire hazard similar to Isospan A membrane;

- Foundation load;

- The density of additional layers of insulation.

It is best to use the most lightweight modifications, such as Isoroc with grades 75 and 50. The numerical value here indicates the density of the substance.

Reviews about it come across for the most part good. The technical characteristics of a material such as Isolight allow it to be actively used to provide thermal insulation of walls within low-rise buildings.

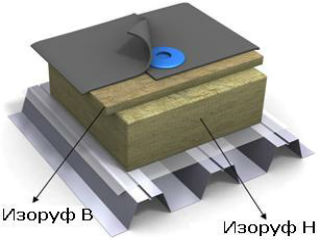

ISORUF B — ISOROC insulation

Features of mineral wool insulation

Rockwool mineral wool belongs to the category of environmentally friendly materials, for the manufacture of which durable rocks of basalt and gabbro were used without the inclusion of metallurgical waste. The final product is characterized by high thermal insulation characteristics, excellent performance properties.

To obtain basalt wool slabs, rocks are subjected to melting at elevated temperatures, followed by stretching into fibers, by analogy with how the material is formed in natural conditions.

Unlike previous generation mineral wool insulation, when the fibers were laid in a strict order in rows, Rockwool basalt wool slabs are created with the fibers laid in a chaotic manner, which favorably reflects the technical characteristics of the material, reducing the specific gravity.

An analysis of the characteristics of the insulation allows us to note its ability to cope with high temperatures - Rockwool boards can withstand temperatures above 1000 degrees Celsius. Insulation is used both in domestic construction and for thermal insulation of industrial facilities, where compliance with the characteristics of fire safety requirements is of fundamental importance.

Materials based on Rockwool mineral wool are versatile and practical, helping to create and maintain a comfortable microclimate in the room, regardless of the season.

glass wool

The cheaper and more commonly used Izover glass wool is represented in the product line:

· Warm Roof;

· Warm walls;

· Warm house;

· Quiet house;

Izover Classic (classic Izover);

· Pro;

· Pitched roof;

· Sound protection;

Frame P;

Frame M;

· Sauna;

Facade Light;

OL;

· VentFacade;

· Floating Floor;

· Sandwich Life;

Quiet and warm roof;

· Uteplyaev (Universal, only for Siberia).

Let's focus on three popular types of materials:

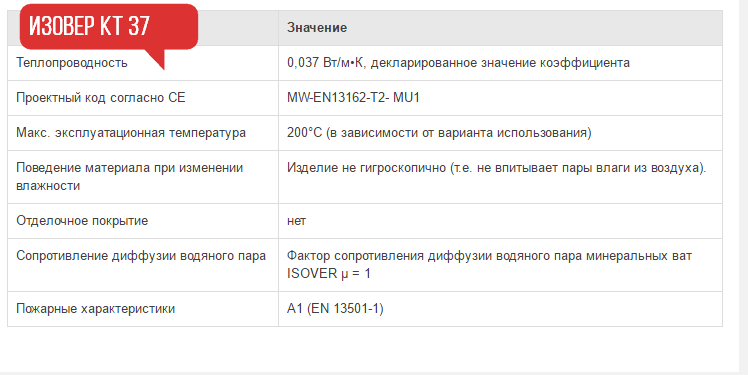

· Isover KT 37;

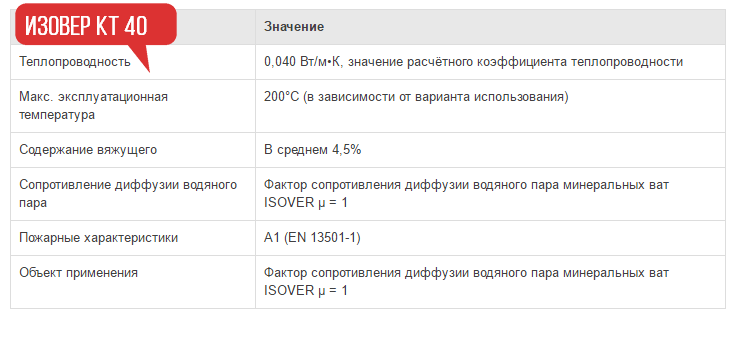

· Isover KT 40;

Isover KT 37.

Description of materials. Both of the first materials are soft fiberglass roll mats. However, the numbers in the index refer Isover KT 37 to the corresponding thermal insulation class 37, and Isover KT 40 provides a twin insulation - two mats are stacked on top of each other. The total thickness is 50 and 75 mm.

The thermal conductivity of Izover KT 37 and 40 is corresponding - 0.037 and 0.040 0.040 W / m•K. The width of the rolls in both cases is the same 1220 mm. For both, it is necessary to build a crate and materials are used for internal wall insulation and other internal work. Density is about 15 kg per cubic meter. Sometimes you can also find the marking Isover KT Special (KT Special) - this is a heater in rolls of the same series. Below is the data in more detail.

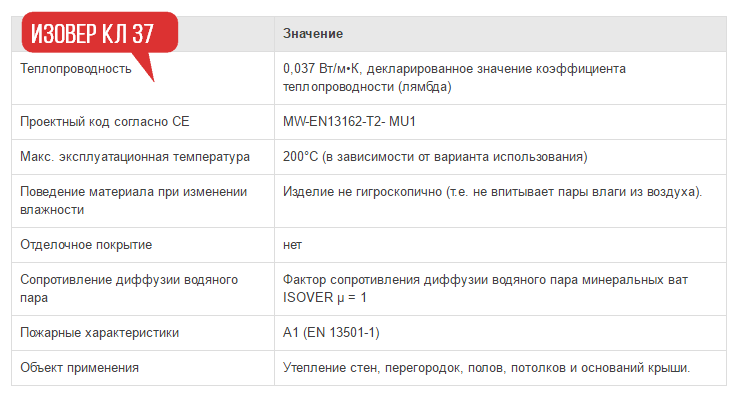

Insulation Izover 37 and 40 specifications and dimensions:

Isover KL 37 material in the form of mats (Isover soft plates have a density of 16 kg / m3). This series is intended for isolation:

Roofs;

Sten;

Paul,

In those places where there will be no load on the insulation (that is, in the frame and along the logs).

Below in the table you can see the characteristics of Isover kl 37

Model KL 34 has a lower thermal conductivity than the 37th.

For the sauna, there are separate types of foil material. One side of the mat is covered with foil, which prevents it from getting wet.

The density and dimensions of Izover correspond to GOSTs. The declared parameters of Izover insulation and technical characteristics correspond to the market as a whole.

Product line

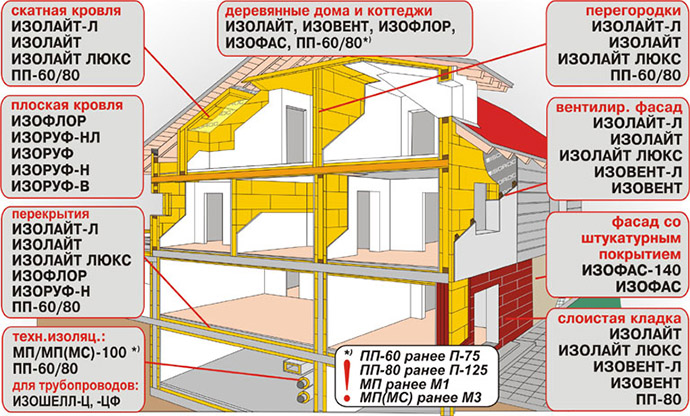

The line of insulation for walls Izorok contains several subspecies, focused on the features of the protected surfaces and various areas of application. It includes the following titles:

- Isolight-L;

- Isovent;

- Isofrol;

- Isoruf in packs;

- Izorok in slabs (in cylindrical shapes).

Samples of Izolight-Lux products have a density of 60 kg / cu. meter and are used to isolate surfaces of various orientations. At the same time, large loads and deformation stresses in the layers of products of this type are unacceptable. The next model in the series, Isovent-L, has a much higher density (up to 90 kg / cubic meter) and is used in the arrangement of ventilation of building facades.

In the Isoflor modification, the density indicator declared by the manufacturer is close to 140 kg / cu. m. This insulation is used as an intermediate link in three-layer reinforced concrete structures. It is allowed to use in sandwich panels. For thermal insulation of roofs and concrete floors, another type of insulation material is used, called Isoruf. It is available with markings H, B or NL, and its average density is 110 kg / cu. meter. Blanks of this material or mats without a piercing shell are marked as "MP", and if it is available - "MP (ST)".

Izorok insulation in plates has two modifications with a material density of 75 and 100 kg / cu. per meter, respectively. They are optimally suited for protecting any horizontal surfaces, but do not allow the load to be exceeded above the limit level. As a separate category of heat insulators, Izorok Cylinders are considered, which are labeled TsF. Various samples of these products differ in the diameter of cylindrical blanks (within 18-273 mm) and are used to insulate cold water and hot water pipes.

Information about the manufacturer Izorok

The date of the appearance of the Russian brand "Izorok" is considered to be 2000, when a large association was created on the basis of the Tambov plant of mineral heaters. Further development of this production was supported by investments coming from a number of foreign companies.

Over time, Izorok mineral wool has become a very popular product, in demand in most areas of building technology.

To expand the output of mineral wool, the association needed:

- significantly expand their production areas;

- acquire modern equipment that allows you to automate the workflow;

- master new technologies for non-waste production of insulating products.

Izorok thermal insulation is made on the basis of the finest fibers from a melt of mineral rocks, the individual components of which are held together by a special binder. The need to comply with all the subtleties of the technological chain stimulated the concern's engineers to constantly improve this process. Today he belongs to the undisputed leaders of the Russian market of insulation materials.

Minvata Izorok characteristics and benefits of use

Developed on the basis of the latest world innovative achievements, the insulation is several times superior to similar materials.

Izorok thermal insulation has such advantages as:

- low thermal conductivity;

- high fire resistance;

- resistance to chemical compounds;

- strength at deformation and on a separation of layers;

- soundproofing ability;

- vapor permeability, etc.

Izorok thermal insulation is widely used in civil and industrial construction. It is in demand where it is required to ensure fire safety, create sound insulation, and reduce the load on the foundation.

Environmentally friendly material, developed on the basis of natural materials, makes it possible to create favorable conditions indoors.

Properties of mineral wool sandwich panels

In construction, mineral wool sandwich panels are quite popular. The thermal conductivity coefficient of this material is equal to the limit from 0.20 to 0.82 W / m * K. The degree of sound insulation of the material is 24 dB. The shear strength is 100 kPa, as is the compressive strength. The density of products can be equal to the limit from 105 to 125 kg/m3.

The structures do not provide for the need to use special equipment for construction work, they easily undergo exposure to ultraviolet radiation, as well as temperature changes. Sandwich panels are not susceptible to rust, they are resistant to fire and have excellent heat and sound insulation qualities. If the panels are damaged, they can be partially replaced. Such structures do not create an extra load on the foundation. By visiting the store, you can choose any shade of panels, which allows you to achieve an excellent aesthetic result.

The coefficient of thermal conductivity of wool Ursa

The table of thermal conductivity and other qualities of the material quite often allows consumers to make the right choice. This is also true when it comes to Ursa mineral wool. If you need insulation for thermal insulation of the roof, floor and walls, then you can choose Ursa Geo M-11 with a thermal conductivity coefficient within 0.040 W / m * K. Slabs, presented in rolls and produced under the name URSA GEO, are designed for pitched roofs. The thermal conductivity coefficient in this case is 0.035 W / m * K.

For insulation of floors, acoustic ceilings and ceilings, URSA GEO Light rolls are used, in which the described characteristic is equal to the limit of 0.044 W / m * K. As practice shows, the properties of mineral wool insulation under the Ursa brand are among the best. With the help of this insulation, you can reliably insulate the house, as a result, it is possible to achieve the formation of a breathable surface with air gaps. Using a unique recipe and environmentally friendly technology, Ursa Geo is produced, which deserves special attention.

Universal thermal insulation ISOLIGHT

The Isolight series is a slab of basalt moisture-resistant wool. Available in 3 types, differing in density. It is used in residential, non-residential and industrial structures as an unloaded heat and sound insulation. Scope - universal (external and internal walls, partitions, roofing, ceilings, basements), for any type of surface and slope.

Technical characteristics of Izoroc Isolight:

| Indicators | Isolight-L | Isolight | Isolight-Lux |

| Density, kg/m3 | 40 | 50 | 60 |

| Length cm | 100 | 100 | 100 |

| Width, cm | 50 | 50 | 50 |

| Thickness cm | 5-20 | 5-20 | 5-20 |

| TOthermal conductivityt=+10 °С, W/mK | 0,036 | 0,034 | 0,034 |

| TOthermal conductivityt=+25 °С, W/mK | 0,038 | 0,036 | 0,038 |

| Water absorption by volume, % up to | 1,5 | 1 | 1,5 |

| Humidity by weight, % up to | 0,5 | 0,5 | 0,5 |

| Content of organic substances, by mass, % up to | 2,5 | 2,5 | 2,5 |

| Compressibility, % up to | 30 | 15 | 7 |

Reviews of Izorocom insulation of the ISOLIGHT series are mostly positive, although there are some complaints:

“The thermal insulation of Izorok Isolight walls does not require special skills, although it must be handled with care. According to subjective sensations - very warm material

However, in the hands it partially exfoliates, the flaps can be torn off with a slight tension. For the same reason, it is necessary to cut to size with a very sharp knife or a file with small hardened teeth, otherwise the cut will be uneven, with breaks.

Pivovarov Mikhail, Moscow.

“I really liked ISOROC, warm, dense insulation, packed perfectly. On the day of purchase, it was raining, they were transported in an open car, but not a single drop leaked inside. At the same time, it is cut, crushed and installed easily.

Golubev Boris, Samara.

Universal insulation ISOVENT

The Izoroq Isovent complex is non-combustible slabs made of moisture-resistant mineral wool. Available in 2 types, they are used for thermal and sound insulation of enclosing devices of all types (horizontal, vertical, inclined), hinged facades. A special condition is the presence of an air gap between the finish coating (ventilated facades, siding) and the base.

Specifications ISOVENT:

| Indicators | Isovent-L | Isovent |

| Density, kg/m3 | 80 | 90 |

| Length cm | 100 | 100 |

| Width, cm | 50 | 50 |

| Thickness cm | 5-16 | 4-16 |

| TOthermal conductivityt=+10 °С, W/mK | 0,034 | 0,034 |

| TOthermal conductivityt=+25 °С, W/mK | 0,036 | 0,036 |

| Water absorption by volume, % no more | 1 | 1 |

| Humidity by weight, % no more | 0,5 | 0,5 |

| Content of organic substances, by mass, % up to | 4 | 4 |

| Compressibility, % no more | 10 | 20 |

Prices for mineral wool Izorok Isovent start from 180 rubles / m2.

Customers speak favorably about the ISOVENT series:

“I chose the right thermal insulator for a long time, until I settled on Izorok Isovent. It is easy to install, gives decent thermal insulation, can be used for residential and non-residential premises, does not weigh down the structure. As it turned out empirically, in addition, it is also a sound insulator. The only thing is that the dealer immediately warned that the material is not suitable for wet facades (plaster), since the degree of peel strength of the layers is insufficient.”

Lukin Egor, Petrozavodsk.

Universal insulation ISOFLOOR

Thermal insulation material Izorok Isoflor is a non-combustible moisture-resistant stone wool in the form of plates. Provides a reduction in the level of heat loss in almost all types of bases: in structures of concrete, reinforced concrete and other floors, self-leveling, electric and water floors, wall sandwich panels and similar structures. It is used for residential and industrial buildings, structures.

Specifications ISOFLOOR:

| Indicators | Isovent |

| Density, kg/m3 | 110 |

| Length cm | 100 |

| Width, cm | 50 |

| Thickness cm | 3-15 |

| TOthermal conductivityt=+10 °С, W/mK | 0,034 |

| TOthermal conductivityt=+25 °С, W/mK | 0,038 |

| Water absorption by volume, % no more | 1 |

| Humidity by weight, % up to | 0,5 |

| Content of organic substances, by mass, % up to | 4 |

| Compressibility, % no more | 25 |

The price of Isoflor insulation in Moscow and the Moscow region starts from 130 rubles / m2.

Feedback on Izoroq Isoflor products is generally positive:

“They planned to lay a cork underlay under the laminate for good heat and sound insulation, but it turned out to be very expensive. We chose a more economical option - ISOROC Isoflor, and did not regret it. It is pleasant to walk, in winter the legs do not get cold. The interlaminar bonding is a bit weak, but this disadvantage is compensated by the price and good properties.”

Valery, Omsk.

Izorok product features

A review of Isoroc brand basalt insulation reveals some differences from products from other manufacturers. The main thing is a fairly high density of light series mats. This approach partly solves the eternal problem of loose insulation - bald spots and uneven weaving of fibers practically do not occur here.

It is also interesting that the Izorok line includes mini-plates of type P and PP, although in terms of their characteristics they have something in common with the already considered types of insulation:

- PP-60 corresponds to Isolight-Lux.

- P-75 is a transitional form to Isovent with a density of 80 kg / m3.

- In PP-80, it is easy to recognize the insulation for ventilated facades.

- P-125 - external insulation for walls, flat roofs, as well as floors that are under load.

In fact, the difference in Isoroc insulation grades is due only to regulatory documents, according to which all these twin heaters are produced. The considered P and PP slabs are manufactured in accordance with GOST 9573-2012 and GOST 21880-2011, and all other types of Izorok are manufactured according to separately developed specifications. However, it should be borne in mind here that mineral wool, which meets all the requirements of industry standards, is not designed for direct contact with wet solutions, since it has a higher moisture absorption. That is, it is impossible to plaster such plates on the facade. And when insulating horizontal surfaces under the screed, it is necessary to first lay a waterproofing material.

“I, as an inexperienced builder, spent quite a lot of time studying reviews of various materials that I will need next year. As for the insulation, I could not decide on the brand for a long time. So I just went to the store to look and feel everything. Of the inexpensive series, I liked Isolight-L, although the layers held on to each other somehow uncertainly, but the "fluff" did not come out, as from Rocklight.

Fedor, Moscow region.

“I have already used Izorocom, but Ultralight came across to me for the first time. Perhaps the most unfortunate isolation of this brand, since the bundle is still present. When laid, the mats simply fall apart into bundles of fibers. I had to come up with a new technology: they threw the plates on a substrate made of a dense film and, like on a stretcher, they transferred them one at a time (they insulated the attic). Very convenient - you tamp the Ultralight between the lags, and then carefully pull out the film.

“Isolight is really not very convenient to use if the density is less than 50 kg/m3. I have not tried Ultra, but the related L series, although it does not fall apart in the hands, requires accuracy when cutting. If the knife is dull, the edges will tear and tear out the fibers. Once I had to deal with this material, and the impressions were enough to buy dense mats Izorok Lux next time. There are no problems with them at all - they write correctly in the reviews.

Vladimir Gubarev, Moscow.

In principle, with the right type of insulation for certain jobs, Izorok does not cause any complaints. Like other types of basalt wool, it has a standard set of positive qualities:

- Fire resistance and high temperature resistance up to +400 °С, and in some models up to +700 °С.

- Sufficient elasticity and ability to restore shape after removal of the load.

- Excellent thermal insulation properties, coupled with vapor permeability, which allows you to create the most comfortable microclimate in the premises.

- Durability, thanks to the biological and chemical resistance of both the basalt fibers themselves and the resins that hold them together.

Of the serious disadvantages, judging by the reviews, there is a weak adhesion of fibers in ultralight series of thermal insulation, but this problem occurs only in Ultralight mats. But the cost per package or cube of any of the Isoroc products presented in the review is pleasantly surprising. With the same quality, it turns out to be lower than that of the famous analogues such as Rockwool or Parok.

Isoroc basalt wool is produced by a Russian company of the same name. All products, including Izorok stone wool, are made using a mineral base.

Izoroq Isofas 90-110

The presented thermal insulation Izolight has several modifications, each of which has a number of features and distinctive properties. Installation of such products is simple if you use a calculator for calculating the thermal insulation of pipelines.

Thermal insulation production

The raw materials for the manufacture of heat-insulating plates are basalt rocks. Under the influence of a temperature of 1500 degrees, the material melts, after which it is pulled out with a centrifuge into thin fibers. During the manufacturing process, impurities are added to the raw materials, including water-repellent components. An automated stacker weaves the fibers into a web of various thicknesses, which is then pressed and cut into slabs of predetermined dimensions.

The production technology is built in such a way that the resulting thermal insulation fully complies with the manufacturer's specifications and is environmentally friendly and safe for human health.

The dimensions of the thermal insulation material vary depending on the type and purpose of the product. So, the thickness of the plates varies from 20 to 200 mm, length - 500 or 600 mm, width - 1000 or 1200 mm.

Mounting Features

Features of the installation of Izorok plates and rolls for surfaces of various classes are manifested in the requirement to adhere to certain rules. They depend on the conditions in which it is supposed to use this material as a heat insulator. However, in any case, its use is permissible only in combination with vapor and waterproofing.

Cement floor screed

Installation of insulation on the floor begins with preparatory operations, including the following steps:

- The screed is cleaned of accumulated layers of dirt.

- All cracks found on the floor are sealed, followed by leveling its surface.

- A waterproofing layer is mounted, on top of which Izoroq mats are laid.

When laying them, you will need to ensure that the workpieces are located right next to each other without noticeable gaps.

Another waterproofing layer is laid on top of the thermal insulation, on which a reinforcing mesh is then placed. The laid reinforcement is poured with cement screed

When carrying out these works, it is important to take into account that the total thickness of the coating increases markedly

Insulation of the outer walls of frame structures

Before purchasing Izoroq boards, their total volume is calculated based on the fact that two layers of protective material are formed. Work on their laying is carried out in the following sequence:

- A crate based on wooden slats or a metal profile is attached to the walls.

- During installation, the distance between the individual elements must match the dimensions of the insulation boards.

- Laying is organized in such a way that the slabs in the layers are staggered, the blanks of the second row completely overlap the joints of the previous one.

Flat roof insulation

For roof insulation, Izorok material with a high density index is selected, laid on a base of reinforced concrete slabs or a metal profile. Work order:

- A vapor barrier layer is installed to prevent moisture from entering between the layers of the heat insulator.

- The edges of the protective film must be folded under the insulation, which does not allow vapors to penetrate into it.

- With multi-layer installation, the joints of the plates are located with a slight offset.

- For the upper layer, a material of greater density is selected than for the lower coating.

- Waterproofing is installed on top of the insulation.