brick houses

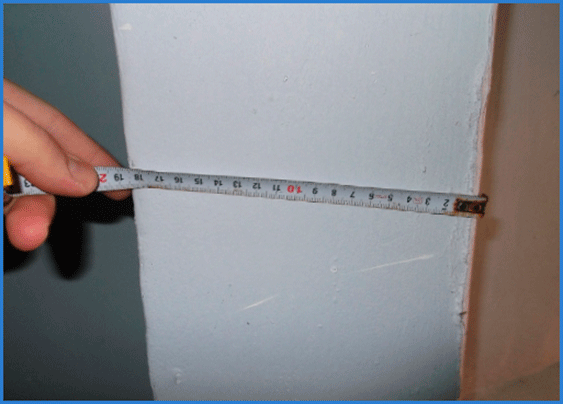

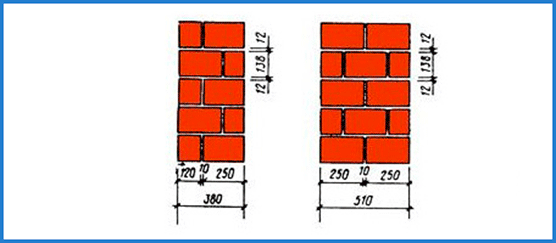

The thickness of the walls in brick buildings is formed during masonry. For example, a standard brick has a width of 120 mm. If the laying is carried out in two rows, then there is a seam of about 10 mm between them. Accordingly, the thickness of such a wall will be equal to 250 mm. If the wall is laid out in three rows, then its thickness will be 380 mm and so on.

The simplest method for determining a load-bearing wall is measurement. Walls 80, 120 or 250 mm are partitions. Accordingly, a wall thickness of 380, 520 mm and more is always a carrier. Also, be sure to take into account the layer of plaster and other finishing materials when measuring.

Partitions

Partitions are subjected to force effects from their own weight within one floor, minor random force effects during operation (when moving furniture, equipment, etc.), non-force acoustic effects. Partition structures, in accordance with the degree of fire resistance of the building, are designed with a fire resistance limit of 0.5-0.25 hours from non-combustible or slow-burning materials.

Such a low level of regulatory requirements for the fire resistance of partitions is due to the fact that their damage during a fire is usually local in nature and cannot affect the safety of the supporting structures of the building.

The low standard requirements for the strength and fire resistance of partitions allow them to be made from a wider range of materials than internal walls.

Partition structures are designed depending on the degree of fire resistance of a structure made of brick, stone, concrete, gypsum concrete, wood and other non-concrete materials. The soundproofing ability of partitions is provided according to the principle of acoustically homogeneous or separate structures, depending on the chosen material of the enclosing structure. The least industrial design of the partition is in the form of a thin wall, erected manually from bricks or small slabs, the most industrial is panel, single-row cutting. Partitions made of small-sized products are outdated and even in houses with brick walls give way to panel ones. In large-block and panel buildings, partitions are made of single-row cut panels (deaf or with openings) the size of a room. Partition panels are molded from heavy or lightweight concrete with a thickness of at least 60 mm or from gypsum concrete with a thickness of at least 80 mm. Inter-apartment partitions, as a rule, are designed acoustically separate, double with an air gap between the panels of at least 40 mm. The structures of the partition panels and the details of their fastening are shown in fig. 10.

Partitions made of non-concrete materials (Fig. 11) are designed, as a rule, layered in the form of frame or frameless (glued) panel-type structures or element-by-element assembly. The frame of such partitions is made of plank rails, aluminum or thin-walled galvanized steel rods of rectangular tubular or channel section with double-sided sheathing with gypsum dry plaster and filling the cavity with mineral or glass wool materials. Partitions are mounted on rails made of metal or wooden slats, fixed with dowels to the floor and ceiling. The vertical joints of the partition panels are carried out in a tongue on the laying rails included in the grooves of the vertical strapping. Partition panels are made floor-high with a main dimension in width of 1.2 m and additional elements with a width of 0.6 and 0.3 m.

In buildings with a layout that is transformed during operation, sliding partitions are used. Depending on the material used, a soft harmonious or rigid folded structure (Fig. 12) of a sliding partition is used.

Rice. 10.Partitions made of gypsum concrete panels - general view of the panel; b - adjoining the ceiling; c - adjoining the floor; 1 - lifting loop; 2 - wooden rack frame; 3 - door block; 4- lower wooden trim (support beam); 5 - metal clamp for docking with overlap

Rice. 11. Panel partitions made of non-concrete materials - adjoining the ceiling; 6 - adjoining the floor; in - adjoining to the wall; g - adjoining to the door frame; e - vertical joint; 1 - frame; 2 - sheathing; 3 - soundproof layer; 4 - plinth; 5 - strapping; 6 - butt rail

Varieties of foam blocks, their dimensions and thickness

In addition to the density, this material also differs in the method of manufacture. There are autoclave and non-autoclave methods. The latter is more often used by small enterprises that are not of good quality due to poorly debugged technical control.

The non-autoclave manufacturing method creates non-uniform porosity of the material. As a result, a partition made of such blocks shrinks about 3 millimeters on a 1 meter high section of the wall. Therefore, a partition made of autoclaved foam blocks will be much stronger.

This material also differs in the method of stamping. it can be cutting or shaping blocks. In the first case, blocks are cut from foam concrete with a special circular saw. The result of this manufacturing method is the geometric evenness of the edges and perfectly matching block sizes.

With the method of manufacturing by molding, liquid foam concrete solidifies in special forms. And although all forms are standard sizes, block sizes may vary. This is the disadvantage of molding.

Therefore, when purchasing material, it will be completely natural to give preference to foam blocks made by cutting.

Separately, it is worth highlighting the issue of the size of foam blocks for partitions. Typically, for the construction of interior partitions, blocks with the following parameters are used:

- thickness different 50, 75, 100 or 150 mm;

- height and length - standard 300 mm x 600 mm;

- weight depends on thickness and density 5.5 kg - 16.2 kg;

- optimal density D600.

Foam blocks with such parameters are suitable for partitions of any height.

Blocks with a thickness of 100 mm are most often used. Despite the small thickness, interior partitions made of foam blocks are durable, with good soundproofing and fire-resistant characteristics.

brick houses

At present, the percentage of brick houses built has noticeably decreased. This is due to the relatively high cost of materials and the duration of work, compared with other building methods. It takes 1.5-2 years to build a brick high-rise building (10-18 floors). This indicator is 30% higher than the construction of monolithic structures and 50% higher than panel ones. Modern brick apartment buildings are classified as premium housing.

Construction technology

Buildings made of bricks are the most suitable for living, in particular, if ceramic bricks were used in their construction. Ceramic material is considered environmentally friendly, capable of receiving and releasing moisture, as well as regulating the microclimate in the apartment. In addition, it is an excellent heat insulator, which allows you to reduce the cost of utility bills for heating.

Also in the construction of high-rise buildings, silicate bricks can be used. Its thermal insulation properties are not as high as those of ceramic, so the walls are additionally insulated.

At present, houses of only one brick are not often built.Developers prefer combined monolithic-brick structures. This design allows you to increase the operational period of the building and diversify its architecture.

Pros and cons of brick

- From an architectural point of view, it is possible to build any structures from brick.

- Designers are not limited by standard layouts.

- High confidence in the material from buyers.

- The best indicators of heat and sound insulation among all construction technologies.

- The material is able to absorb and release moisture. That eliminates such problems as the occurrence of mold and fungi due to the dampness of the room.

- Long service life - up to 150 years.

- The most pleasant indicators of the microclimate, that is, it is not cold indoors in winter, and not hot in summer.

The disadvantages of the material are much less than the advantages, but they are still present:

- Brick does not conduct sounds well, but is not a guaranteed protection against household noise.

- The high cost of apartments in brick buildings.

- Long construction period.

Do's and Don'ts

Monolithic houses are the most acceptable options for redevelopment. After all, almost all walls and partitions in the apartment are non-bearing. Therefore, a large number of changes are allowed based on the preferences of the owners, as well as in accordance with the requirements and norms of redevelopment of any residential premises.

This takes into account compliance with the following standards:

- construction;

- sanitary and hygienic;

- firemen.

Fire Safety Conclusion

It is worth remembering that prohibited actions are distinguished during redevelopment in a monolithic house.

These include:

- violation of the integrity of the supporting structures of the apartment;

- creation of residential premises without windows and heating, with an area of less than 9 square meters;

- changing the gasification, sewerage, heating or ventilation system without an appropriate permit;

- equipment of bathrooms, kitchen facilities above the living rooms of neighbors.

Redevelopment in a monolithic house opens up many prospects. However, it must also be done legally. Therefore, you need to coordinate your own actions in advance.

In disputable situations, after the reconstruction of the premises, redevelopment can be legalized through the court.

With what authorities it is necessary to coordinate the project of redevelopment of non-residential premises, read here.

- Due to frequent changes in legislation, information sometimes becomes outdated faster than we can update it on the site.

- All cases are very individual and depend on many factors. Basic information does not guarantee the solution of your specific problems.

Therefore, FREE expert consultants are working for you around the clock!

- Ask a question via the form (below) or via online chat

- Call the hotline:

- Moscow and the Region — +7 (499) 110-56-12

- St. Petersburg and the region — +7 (812) 317-50-97

- Regions — 8 (800) 222-69-48

APPLICATIONS AND CALLS ARE ACCEPTED 24/7 and 7 days a week.

How do you know if a wall is load bearing?

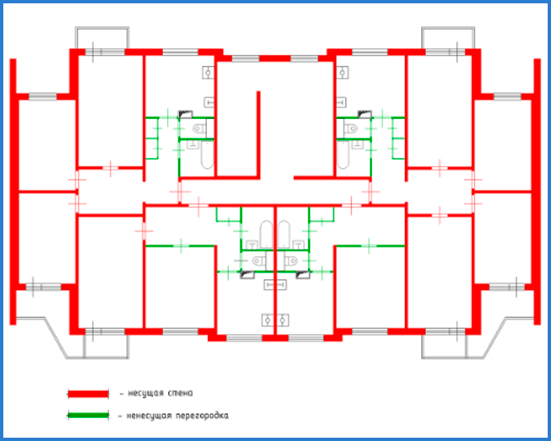

The easiest way is to look at the project of the house. All walls are clearly marked. The plan must be kept in the city administration, in the department of capital construction.

In addition, you can also use the plan of the apartment, which is located in those. passport or house book. However, for this you need to be able to read blueprints or have experience in construction.

Video: Olga Rozina: how to define a wall

If for some reason the plan cannot be found, then the appointment can be understood by some characteristic features. So, for example, if there is a neighboring apartment behind the wall, the entrance or street is load-bearing.

Another way to find out is by thickness. If you live in a brick house and the thickness of the partition is 38 cm, then it is load-bearing. In the panel, the thickness of the bearing walls is 14 cm or more.

In a brick house

In brick houses, the thickness of the exterior starts from 38 cm, between apartments from 25 cm, interior - 8 - 12 cm.The main material in the construction of such houses is silicate and red brick.

Gypsum boards can be used for partitions. By measuring the wall, for example, in the area of \u200b\u200bthe doorway, you can understand whether it is capital or a partition.

However, this method is not suitable for all houses. For example, in the 90s, houses were built according to individual projects, so if there is no plan, then only the author of the project can determine.

In the panel

Since the panel house consists almost entirely of carriers, it will be very difficult to implement the planned redevelopment. The load-bearing walls include - inter-apartment, external and adjacent to the external. In addition, the walls of the bathrooms can also be load-bearing.

Interior partitions have a thickness of 8 - 10 mm. There are partitions and 12 cm each, but this is a rare exception. To determine the purpose of the walls in this case, it is better to contact specialists who will draw a conclusion only after studying the design features of the building and decide whether redevelopment can be done.

In monolithic houses

It happens that the usual interior partition in monolithic buildings has a thickness of more than 20 cm. There are monolithic houses in which load-bearing walls are completely absent. They are replaced by reinforced concrete columns.

And in this case, you can’t do without a drawing and a plan. If they are not available, you will have to contact specialized companies.

The device of partitions from foam blocks

In recent years, a more modern and practical material has appeared in construction - foam concrete and foam blocks made from it, which are perfect for installing interior partitions. This building material has a whole list of priority qualities. he:

- relatively light with impressive dimensions;

- has good heat and sound insulation;

- easy to process, malleable for cutting holes, channels for pipes and electrical wiring;

- easy to saw with a hacksaw, ideal for implementing all kinds of design ideas, for creating arches and any configurations;

- has sufficient thickness to form a doorway in the wall;

- has a flat surface and is perfect for any decorative finish, primer, tiling, plastering, wallpapering;

- resistant to the effects of the sun, moisture, temperature extremes and active biochemical substances;

- has an affordable price.

Such excellent characteristics make foam blocks an indispensable building material for organizing partitions in houses, apartments, offices and industrial premises.

The only drawback of foam concrete blocks is not always the ideal shape. Therefore, it is preferable to purchase this material from large manufacturers, where product quality control is more thorough, and the geometric shape of the blocks meets standard standards.

And in this article it is said about the installation of corrugated board on the roof.

Methods for demolishing a load-bearing wall in a panel house

Today, there are two main options for the demolition of a load-bearing wall in a panel house.

Carrier beam tie-in

In the case when the dismantled section of the fence is located between the bearing walls, a crossbar (beam) is cut in, which is a powerful reinforced concrete beam or a metal profile of an I-section reinforced with stiffeners.

Installation of columns

Of course, it is impossible to undertake such work on your own.

Only professional workers can carry out the dismantling of load-bearing structures.

All changes that have taken place in the layout of the apartment must be included in the technical passport.

Bearing walls in panel houses are 14, 18 cm thick. In some series, from the first to the fifth floor, the thickness of the bearing wall in a panel house can be 22 cm. All load-bearing walls must have reinforcement. Diamond cutting of openings or widening openings in such walls is carried out with a hand-held diamond cutter, diamond cutting of walls is carried out on both sides to obtain a through seam in the wall. An ordinary 220V electrical outlet is enough. The use of a perforator is minimized, it is used only as an auxiliary tool. The time for cutting a standard opening in the wall of a panel house is from 1.5 to 5 hours, depending on the thickness of the wall and conditions at the workplace.

The thickness of the floors in panel houses is 14 cm. There are also multi-hollow floor slabs with a thickness of 22 cm.

Non-bearing partitions in prefabricated houses are 8 cm thick. They are both concrete and gypsum, but in both cases there is reinforcement inside the partition. Cutting the opening in the partition is also carried out with a hand-held diamond cutter, only on one side.

External walls in a panel house are 38 cm thick. They perform a heat-insulating function, so they are expanded clay or concrete sandwich with foam inside.

The demolition of the window sill block is carried out by diamond cutting on both sides, followed by grinding with a perforator. Inside there is reinforcement, sometimes quite thick. The use of a perforator in this case takes up to half of the work, that is, the work is loud.

The walls of the sanitary cabin, as well as non-load-bearing partitions, are 8 cm thick. They are made of either plaster, or aceid, or concrete. In most cases, the demolition of the bathroom is done with a hand tool and an ordinary grinder. This job takes 5 hours.

Comparison table.

partition type

Floor load from 1 m / n partition, kg

Estimated cost of 1 m / n partition, $

Strength

Deformation susceptibility

heat and sound insulation

fire resistance

Brick partitions in half a brick

580-620

Brick partitions in a quarter of a brick

cracks are possible if there is a heavy door in the partition

Partitions made of tongue-and-groove and simple gypsum slabs 8-12 cm thick

cracks are possible if there is a heavy door in the partition

Partitions made of foam concrete 9-12 cm thick

cracks are possible if there is a heavy door in the partition

Partitions with wooden frame

depends on the material of the skin and the frequency of the bars

depends on the thickness of the bars used and the frequency of their location, from low to high.

depends on the type of cladding, from very low to low

Partitions with metal frame

depends on the skin material and profile frequency

depends on the width of the profiles used and the frequency of their arrangement, from low to high

low to high

Glass block partitions

140-150

cracks are possible if there is a heavy door in the partition

Transformable partitions

20-150

low to very low

extraneous loads are not desirable

very low to medium

Notes:

- The weight of 1 m / p is indicated for a standard partition height of 2.5 m. For higher partitions, the weight will be more, for lower partitions - less.

- The floor loading does not include plaster or sheathing with drywall, plywood, chipboard or wall panels. 1 m / p of a plaster layer 1 cm thick will add about 37 kg to the indicated load.

- Floor slabs in residential buildings are designed for a load of up to 400 kg / m 2 without taking into account structural loads. The total load-bearing capacity of the floor depends on the structure of the house and averages around 600 kg/m 2 , but the existing screed or future furniture must not be forgotten.

I hope, dear reader, the information presented in this article has helped you at least a little to understand the problem you have.I also hope that you will help me get out of the difficult situation in which I recently found myself. Even 10 rubles of help will be of great help to me now. I don’t want to bore you with the details of my problems, especially since they are enough for a whole novel (in any case, it seems to me so, and I even started writing it under the working title “Tee”, there is a link on the main page), but if I was not mistaken in your conclusions, then the novel will be and you may well become one of its sponsors, and possibly heroes.

For terminals Yandex Wallet number 410012390761783

For Ukraine - hryvnia card number (Privatbank) 5168 7422 0121 5641

webmoney wallet: R158114101090

Categories:

- Design elements. Walls . Partitions

- Diagnosis and treatment

User rating:

Not

Comments:

Note: Perhaps your question, especially if it concerns the calculation of structures, will not appear in the general list or remain unanswered, even if you ask it 20 times in a row. Why, is explained in sufficient detail in the article “Make an appointment with a doctor” (link in the header of the site).

The thickness of the walls in panel houses is the main factor determining the load-bearing walls and partitions. In our time, the problem of redevelopment of apartments in such houses has not lost its relevance.

The demolition of internal fences in apartments of panel houses allows the owners of dwellings to change the layout of the living space in the direction of reducing the number of small "rooms" and getting a more spacious room.

The fact that it is impossible to demolish a load-bearing wall

Most often, redevelopment is associated with the demolition of interior partitions. But which walls can be touched, and which not - not everyone knows. Reckless demolition of structures leads to a change in the action of forces on the remaining surfaces and rooms located below. In addition, ceilings left without support may not withstand the load and collapse at any time. Since, in addition to separating different rooms, the wall elements serve as ceiling supports for all similar structural elements located above.

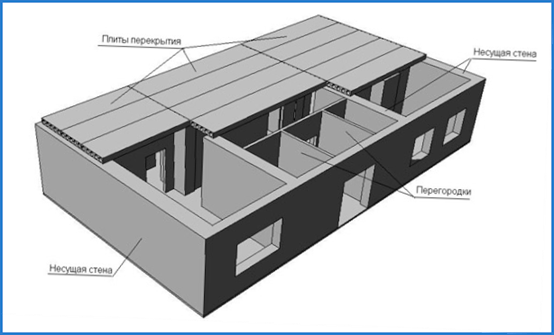

The main (bearing) walls in practice are perpendicular to the floor beams. If it is made of concrete slabs, then their ends rest on the surface of the supporting structure. Usually these are walls between apartments and blocks, or external. As a rule, only partitions are equipped inside the apartment.

General requirements

Internal walls and partitions are the main internal vertical enclosing structures in buildings. In addition, internal vertical enclosing structures form structural elements combined with engineering equipment: sanitary cabins, ventilation blocks and shafts, elevator shafts, etc. The relevant sections are devoted to consideration of these structural elements. (see rubricator)

Internal walls perform enclosing and load-bearing functions in the building, partitions are only enclosing. The structures of walls and partitions must meet the regulatory requirements for strength, stability, fire resistance, sound insulation, be vapor and gas tight, easy to erect and easy to clean. Partitions and walls of wet rooms, in addition, must be waterproof and watertight.

The design of walls and partitions, the choice of their design is carried out taking into account the above, as well as economic requirements, since up to 20% of the cost of building structures and 15% of the labor costs for its construction fall on the construction of walls and partitions.

The level of regulatory requirements for the strength and fire resistance of wall and partition structures is different due to the different role of these structures in the static operation of buildings.

The general enclosing function of internal walls and partitions is to provide sound insulation from airborne noise.In this regard, the level of requirements for the soundproofing qualities of these structures coincides and depends not on their static role in the building, but on their location in it. For inter-apartment and intersection walls and partitions, for fences separating living rooms from stairwells and elevator lobbies, the insulation index required by the head of SNiP "Noise Protection" must be at least 50 dB, for interior rooms - 41, for walls and partitions separating living rooms and sanitary premises of the apartment - 45, and for fences between living rooms and built-in shops or cafes - 55 and 60 dB, respectively.

To ensure sound insulation, acoustically homogeneous or heterogeneous structures are used. As acoustically homogeneous, massive single-layer enclosing structures of a solid or multi-hollow section are used, as heterogeneous - double walls and partitions, walls with a flexible screen, multi-layer lightweight partitions. The method of sound insulation is chosen based on the appropriate use of the properties of the materials used.

Panel houses

The construction of apartment buildings using panel technology dates back to the days of the Soviet Union. At the end of the 50s of the 20th century, large-scale construction of panel plants began to provide housing for Soviet citizens. Such buildings "survived" to this day.

Construction technology

The specifics of this type of construction is simple - the building is assembled from concrete slabs by the method of "assembling the constructor", and the joints between them are laid with a cement mortar.

At present, concrete panels have been replaced by sandwich structures, the core of which is made of noise and heat insulation materials. The dimensions of such panels are larger than those of their predecessors, therefore, in houses built using sandwich structures, the ceiling height and distance between load-bearing walls are increased compared to conventional concrete panels.

Pros and cons of panel structures

- The construction takes the least amount of time (from 3 to 12 months), compared with brick and monolithic ones.

- The most affordable cost of housing, due to the low cost of materials and low energy and labor costs.

- Design life of 40-50 years. The actual service life can be up to 1.5 times longer than the design one.

- Primary repairs do not require much effort. The panel has a smooth and even texture, which you can easily putty yourself.

The disadvantages of multi-apartment panel houses are:

- The layout is designed in such a way that it cannot be changed - most of the walls are load-bearing.

- Low level of sound insulation. Excessively high audibility is achieved due to the small thickness of the panels.

- Bad thermal insulation. The reasons for this shortcoming may be the small thickness of the panels or poorly sealed joints between them, which unscrupulous developers are often "famous for". You can increase the level of thermal insulation only by installing an additional layer of insulation yourself, which entails additional costs.

Modern panel-type buildings are superior to Soviet ones in the following indicators:

- Significantly improved layout of the room.

- It is possible to buy an apartment with an already glazed balcony and two bathrooms.

- Various facades of buildings.

- High-quality multilayer panels provide higher levels of noise and heat insulation.

Stages of redevelopment in a monolithic house

Due to the free planning of apartments in monolithic houses, it is possible to realize the most daring ideas of designers and architects.

If the redevelopment is carried out completely, then there are several stages of its implementation:

- From an ordinary kitchen you can make a studio. At the same time, it is allowed to change its size and location. After all, the area of \u200b\u200bthe zone for cooking and eating often does not meet the requirements of the owner. Therefore, the kitchen can be combined with the room.

- You can increase the area by combining a bathroom. Joint bath and toilet are played up by designers.This measure allows you to expand the space, rationally using the wet zone.

- Changes are noted in the number and area of living rooms. If there are not enough for each family member, there is an option to complete the construction of new premises. This can be achieved by dividing one bedroom into two, capturing part of the corridor or storage room.

- By taking the corridor area, you can make the living room more spacious.

- The owner can equip niches, dressing rooms, utility rooms. Also a great option would be zoning space.

We demolish walls during redevelopment, what can be demolished and what not

Many people, especially those living in Khrushchevs, are trying to remake their small and uncomfortable apartments using redevelopment. But it is one thing to complete it in an individual building, and quite another to change the doorway or move the partition in a high-rise building, where almost every wall is load-bearing. All this ensures the safety of residents in combination with the entire technical design of the house.

What is rescheduling? According to the housing code, this concept includes all changes in the configuration of the apartment that require them to be included in the technical passport. This:

- changing the location of load-bearing walls and partitions,

- moving window and door openings,

- re-equipment of vestibules and dark closets,

- arrangement of internal stairs,

- bathroom refurbishment,

- division of large rooms,

- expansion of living space due to household premises,

- glazing of a balcony or loggia,

- replacement of gas stoves with electric ones,

- relocation of a bathroom, kitchen or toilet.

All these types of changes in the apartment are redevelopment and require approval by the relevant authorities.

Tools and materials used for laying foam blocks

Before starting work on the construction of a partition from foam blocks, you need to prepare a set of necessary materials and tools:

- glue for foam blocks at the rate of 15 kg per 1 cu. meter (with a layer of 2 mm);

- cement mortar for laying the lower row;

- mounting foam for foaming the gap between the top row and the ceiling;

- foam gun;

- pins - self-tapping screws, metal embedded pins;

- spatulas and trowel;

- a drill with a mixer for mixing glue and cement mortar, a container for glue;

- a hammer with a rubber overlay for leveling blocks when laying;

- building laser or regular level;

- corner, hacksaw for sawing blocks;

- planer or grater for foam blocks to level the surface before finishing;

- electric cutter or wall chaser for making holes, grooves in the partition;

- large-width brush for sweeping concrete dust from rows before applying adhesive.

After preparing everything necessary for the construction of a wall partition from foam blocks, you can proceed directly to the start of work.

And here is an article about laying cork on the floor.

We demolish walls during redevelopment, what can be demolished and what not

Many people, especially those living in Khrushchevs, are trying to remake their small and uncomfortable apartments using redevelopment. But it is one thing to complete it in an individual building, and quite another to change the doorway or move the partition in a high-rise building, where almost every wall is load-bearing. All this ensures the safety of residents in combination with the entire technical design of the house.

What is rescheduling? According to the housing code, this concept includes all changes in the configuration of the apartment that require them to be included in the technical passport. This:

- changing the location of load-bearing walls and partitions,

- moving window and door openings,

- re-equipment of vestibules and dark closets,

- arrangement of internal stairs,

- bathroom refurbishment,

- division of large rooms,

- expansion of living space due to household premises,

- glazing of a balcony or loggia,

- replacement of gas stoves with electric ones,

- relocation of a bathroom, kitchen or toilet.

All these types of changes in the apartment are redevelopment and require approval by the relevant authorities.

What can not be demolished: load-bearing wall

Most often, redevelopment is associated with the demolition of interior partitions. But which walls can be touched, and which not - not everyone knows. Reckless demolition of structures leads to a change in the action of forces on the remaining surfaces and rooms located below.

In addition, ceilings left without support may not withstand the load and collapse at any time.

Since, in addition to separating different rooms, the wall elements serve as ceiling supports for all similar structural elements located above.

The main (bearing) walls in practice are perpendicular to the floor beams. If it is made of concrete slabs, then their ends rest on the surface of the supporting structure. Usually these are walls between apartments and blocks, or external. As a rule, only partitions are equipped inside the apartment.

How do you know which wall is load bearing?

Is it possible to determine the purpose of the wall yourself? Certainly. According to its thickness or the material from which it was built. In panel-type houses, indoor units are up to 120 mm thick. Therefore, they can be considered partitions (their thickness ranges from 80-120 mm).

The bearing surface must be at least 140 mm thick. Most often, in such houses, the outer walls are made with a thickness of 200 mm or more. In brick houses - external, load-bearing structures have a thickness of 380 mm or more, inter-apartment - 250 mm, and partitions 120 or 80 mm.

As a material for load-bearing walls in prefabricated houses, wall or inter-apartment blocks made of reinforced concrete with various additives are most often used to facilitate construction and increase thermal protection. Internal partitions in 90% of panel houses are made of gypsum concrete panels. In brick buildings, the main material for all walls is red and silicate brick, which differ in size. Gypsum concrete panels can also be used as partitions in them.

Of course, no one is going to demolish the outer walls, but the partitions can be removed after obtaining the appropriate permission. To accurately determine which of the walls is the carrier, it is best to use the BTI data - a detailed floor plan. There, thicker lines mark all the main walls, and partitions that do not have such functions are marked with thinner lines.

What is required for demolition?

In any case, before proceeding with the demolition of a particular wall and its transfer, you need to consult a qualified specialist. As well as a complete calculation, taking into account the distribution of loads that must be transferred from old structures to newly built ones.

In addition, you may have to change the power supply scheme. In addition, it must be borne in mind that the uncoordinated demolition of the walls of the premises may place it on sale or execution of donation documents, etc. But this is not all.

Such actions are considered illegal and entail penalties, subpoenas, and may even lead to the confiscation of the apartment.

Therefore, the coordination of the redevelopment project is necessary in any case. What is needed for that?

- A plan developed by the BTI service specifically for this type of redevelopment.

- Drawing up a technical report on the demolition of the wall.

- Obtaining a positive conclusion from the housing inspection at the place of registration.

Display all materials with a tag:

- construction works

- organizational matters