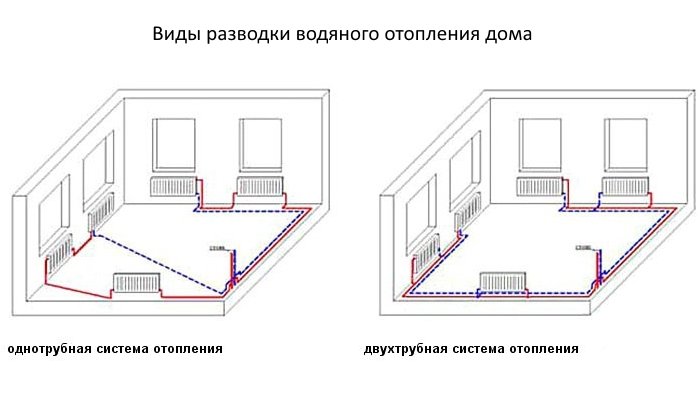

When designing a new house or dwelling, it is very important to choose the right heating system from polypropylene pipes, since the consumption of electricity or fuel during subsequent operation, as well as the appearance of the room, depend on it. Installation of heating from polypropylene pipes is carried out according to three types of schemes:

- single pipe;

- two-pipe;

- collector.

The heating system used in these installation schemes can be with forced movement of water or antifreeze and gravity. With vertical mounting and horizontal.

Pros and cons of single pipe wiring

A single-pipe system is a type of connection in which liquids, moving from one radiator to the next, lose temperature. With this scheme, there is no movement of the fluid in the opposite direction. It is mainly mounted vertically, but sometimes a horizontal one is used. It is used for heating equipment in multi-storey and private houses. The radiators can be connected from above or below.

Cons of this layout

- the inability to regulate the heating temperature in different parts of the wiring. It is generally difficult to regulate it, since a decrease in the temperature regime at the beginning of the wiring will lead to a minimum temperature at the end;

- if the temperature difference between the top point of the wiring and the bottom of the riser is large, then at the bottom it may be necessary to install heating batteries with a larger number of sections and area than at the beginning of the riser.

- strong pumps are needed for normal operation, heating costs for boilers increase, operational wear increases, there is a need for frequent replenishment with water.

Advantages of single-pipe heating distribution with polypropylene pipes

- gives great savings when laying in consumables and labor hours;

- more acceptable appearance (less pipes are laid);

- today there are many possibilities to correct the functional shortcomings of this system with the help of radiator regulators, thermostatic sensors.

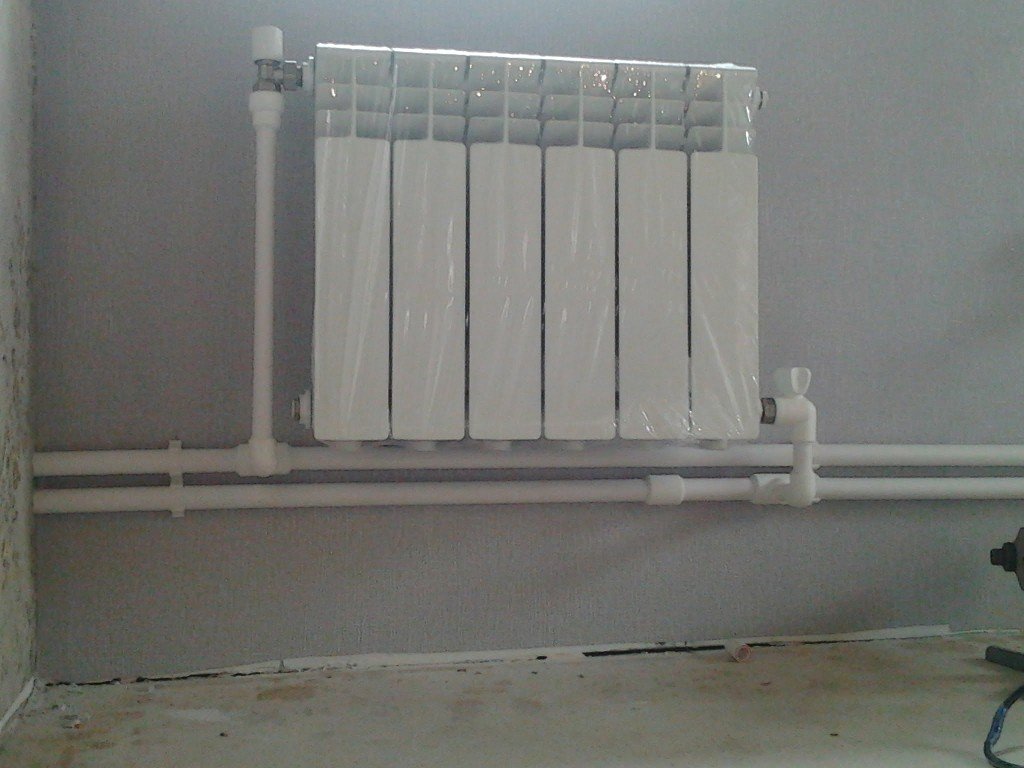

The difference between two-pipe wiring

With a two-pipe heating distribution, a heat agent (water, antifreeze, steam, gas) with the same heating temperature is evenly distributed throughout the equipment. Radiators are connected both from above and from below at the same time. From the common riser, a hot heat agent enters each radiator through the upper connection, circulates in the heating battery and leaves through the lower connection through a common return line to the boiler for new heating. The advantage of such a system is that with the help of a thermostatic head or a servo drive, the temperature of any radiator can be adjusted separately, and this will not affect the rest of the heating system. With this installation, the use polypropylene pipes larger than DN 20x3.4. as well as a radiator valve over 1.2 does not make sense, it will not get warmer. The length of the polypropylene pipe supplying the heat agent should be no more than 25 meters.

The disadvantage of the scheme is the high cost of laying the return pipe system.

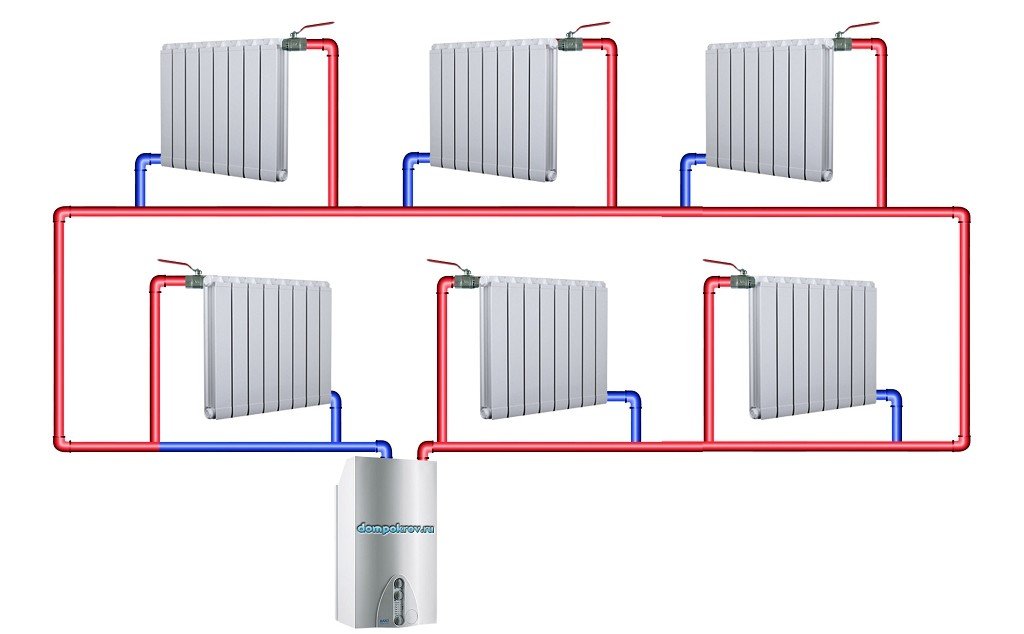

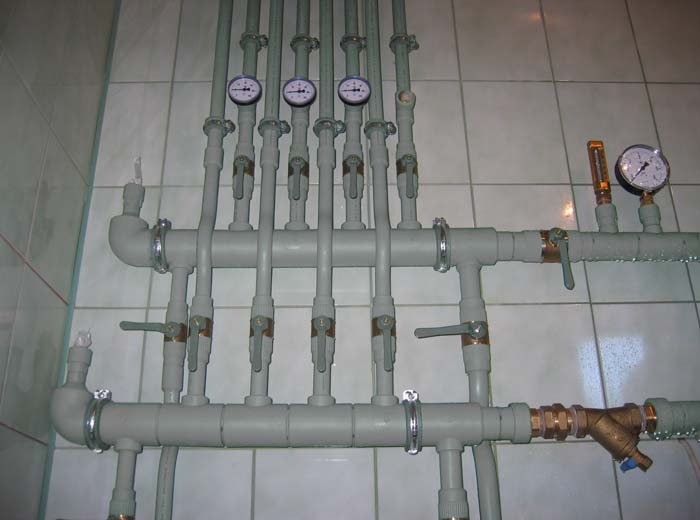

Heating from polypropylene pipes - collector scheme

Such a system is different in that each radiator is connected directly to the collector. Radiators are connected from two sides. On one line, the heat agent supplies heat to the heating battery, on the other hand, the cooled agent returns to the collector. With this scheme, polypropylene pipes, as a rule, are carried out in a straight line and laid inside the screed. Their length is quite large. But it is easier to manage this system, the heat will spread evenly. With the help of a hydraulic arrow, it is possible to draw circuits with different temperatures and pressure drops.The collector scheme is not suitable for multi-storey buildings.

Disadvantages of the collector circuit

- high pipe consumption, compared with single-pipe wiring;

- complication of work, since there should be no connections;

- the heating system is only forced;

- installation of the same number of pumps as autonomous circuits, distributed throughout the premises.

Polypropylene pipes are not afraid of defrosting. But keep in mind that defrosting can damage the boiler and expansion tanks. Soldering polypropylene pipes requires a special tool. The nodes are soldered separately, and in finished form they are installed in the place where they will stand.

You also need to know that when connecting metal-plastic pipe and polypropylene pipes should be selected that meet the following requirements:

| Metal-plastic pipes, size: | Polypropylene pipes, size: |

| 20 x 2 | DN 25 x 4.2 |

| 16 x 2 | DN 20 x 3.4 |

| 26 x 3 | DN 32 x 5.4 |

After weighing all the pros and cons, it is worth choosing a scheme that is most suitable for specific conditions.