Progress does not stand still: nowadays, massive steel pipes are no longer in demand, and a reinforced polypropylene pipe or, more simply, plastic, has come in their place. These products are easy to store, transport and install, which is an important advantage for every craftsman, from beginner to professional.

General properties and scope

Let's look at the technical characteristics of polypropylene pipes. How do they stand out among similar products made from other materials?

Main advantages:

- polypropylene products are cheaper than their steel counterparts;

- low weight of polypropylene pipes;

- service life of polypropylene pipes - reaches 50 years;

- no need for special care (there is no need to paint or process them in any way, (it is enough to wipe occasionally with a damp cloth from dust);

- with the help of a huge selection of fittings, it is possible to design a wiring system of any complexity;

- resistance to corrosion;

- minimum possibility of pressure loss;

- high throughput;

- material safety (environmentally friendly non-toxic type of plastic);

- during long-term operation, no layers are formed on the inner surface of the product.

Application area:

- hot and cold water supply;

- water floor heating system;

- distribution of central heating;

- drinking water supply;

- sewerage;

- ventilation systems.

Polypropylene pipes have characteristics sufficient for transportation (in the pipeline system) of compressed air and chemically active liquids. Thus, there are practically no restrictions on the operation of polypropylene pipes, it is enough just to choose the right type, based on the designation and marking.

Classification and specifications

Types of polypropylene pipes are divided into single-layer and multi-layer. The classification of polypropylene pipes is more complex and is divided into chemical composition, structure and diameters. All these parameters determine the area of use and the overall life of the products.

Single layer products

According to the method and material of manufacture, single-layer polypropylene pipes are divided into several types:

Type 1 - PPH. Material - homopolypropylene. High hardness and resistance to bending, combined with low resistance to high and low temperatures determine the scope of their application: homopolypropylene communications are widely used in cold water supply and ventilation systems.

Type 2 - PPB - block copolymer of polypropylene. The improved chemical structure with polyethylene additive allows to increase the temperature resistance and flexibility of the material. This type of product is used for the installation of floor heating systems, cold water supply, ventilation and sewerage; it is not suitable for hot water supply due to the large thermal expansion of the material.

Type 3 - PPR - random copolymer of polypropylene, they are also called - polypropylene pipes and are designated PPRC. It is distinguished by increased resistance to high temperatures and the effects of acids and alkalis, surpasses even metal-plastic in strength. A product made of such a material is universal, and its scope is very wide, but its main purpose is heating systems. Polypropylene pipes have the following technical characteristics:

- absolute environmental friendliness;

- slight thermal expansion;

- high melting point (+170 °C);

- the ability to withstand temperature extremes at maximum values up to +130 ° C;

- frost resistance;

- high constant operating temperature (90°C).

Type 4 - PPS - special flame retardant polypropylene, capable of withstanding temperatures up to 95 ° C in continuous operation.

[smartcontrol_youtube_shortcode key="types of polypropylene pipes" cnt="4" col="2" shls="true"]Grades of single-layer pipes

Single-layer polypropylene products can be divided into several categories that differ in their technical characteristics and allowable working pressure.

- PN10 - thin-walled model, designed for cold water supply (up to 20 °C), installation of underfloor heating (up to 45 °C), as well as for the ventilation system.

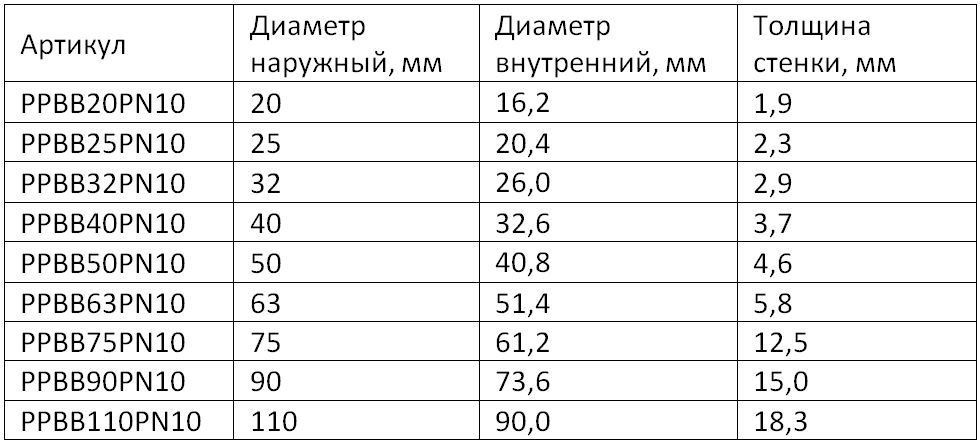

The dimensions of polypropylene products of this type are presented in the table:

- PN20 is a universal type of product designed for cold and hot water supply (up to 80°C).

For convenience, the parameters of the product of this brand, including the outer and inner diameter and wall thickness, are presented in the table:

- PN16 is an intermediate model. It is used less often than others, it is intended for cold and hot water supply (up to 60 ° C).

Multilayer polypropylene pipes

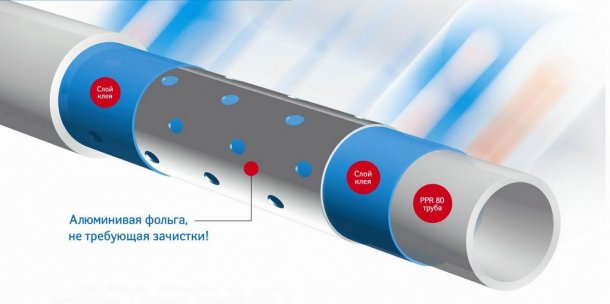

As the name implies, this type of pipe has 3 layers firmly fastened together. The middle layer may consist of aluminum foil, polyethylene or fiberglass. Such a product is marked PN25.

Models with aluminum spacer

Polypropylene pipes reinforced with aluminum Pn25 are used primarily for the installation of heating system wiring, although they are also used for laying cold and hot water supply systems. Polypropylene products of this class are the most popular among plumbers.

The aluminum layer in the composition of the PN25 pipe can be smooth or perforated. As practice shows, a smooth aluminum layer is not very convenient, since it needs to be cleaned before welding so that the aluminum does not come into contact with water or other medium that will be transported. The perforated layer in PN25 products is more practical: it is a mesh with holes into which melted polypropylene flows during welding, which makes the bonding more reliable and safe.

Products with a polyethylene layer

Polypropylene pipes with an inner polyethylene layer have a lot of disadvantages. For example, when welding with a fitting, only the outer layer is connected, which means that the inner one will come into contact with the transported media.

[smartcontrol_youtube_shortcode key="reinforced polypropylene pipes" cnt="2" col="2" shls="true"]Fiberglass reinforced pipes

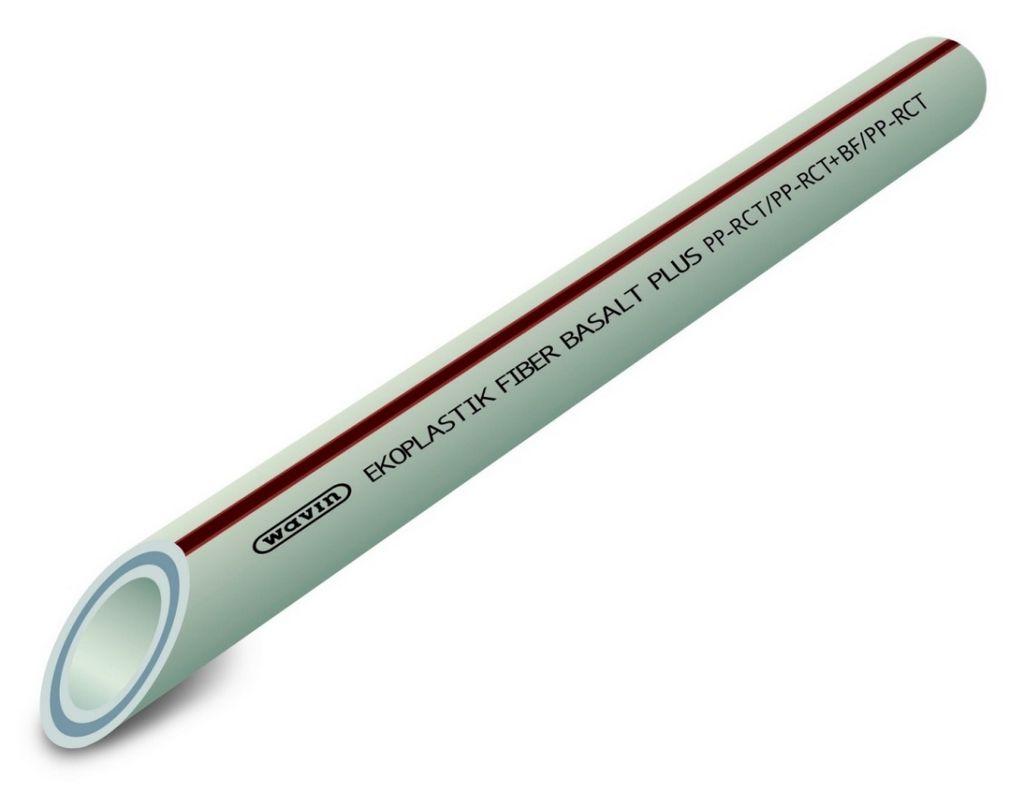

The most outstanding type of products in this classification are glass fiber reinforced polypropylene pipes. The visual feature of this type of product is a tinted layer with fiberglass - this is done so that it can be distinguished from other types. There are a lot of advantages to such products:

- due to the internal fiberglass layer, the pipeline elements become more rigid and turn into a monolithic structure;

- the coefficient of thermal expansion is almost 2 times less than that of non-reinforced products;

- high strength;

- the ability to maintain its properties at high temperatures;

- protection from hydraulic shocks;

- best throughput.

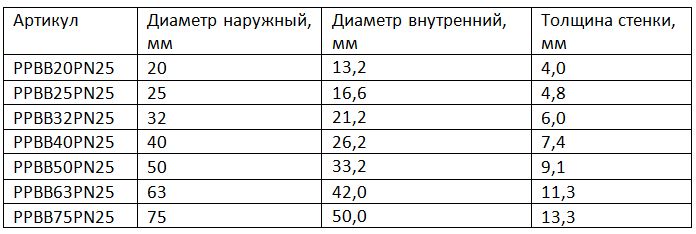

The marking of polypropylene pipes for heating of different diameters is presented in the table:

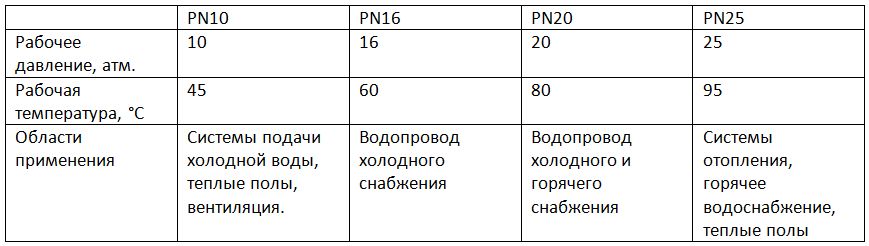

The type of product PN25 should be selected for a specific type of water supply or heating, taking into account the characteristics of operation. When choosing, you need to consider the following technical characteristics:

Pipe selection: what to look for

- The inner or passage diameter of polypropylene products is the most important value that you need to rely on when choosing pipes and fittings for them.

The standard outer diameter of products for a centralized heating system is 25 mm and 32 mm, the inner diameter is 16.6 mm and 21.2 mm, respectively. You can connect the radiator using a pipe with a diameter of 20 mm (outer) and 13.2 mm (inner). For underfloor heating, products with an internal diameter of up to 16 mm are suitable. For the distribution of water supply in an apartment, pipeline elements with a diameter within 20 mm are usually selected. A 40 mm polypropylene pipe is used for heating and plumbing risers, and a 63 mm polypropylene pipe for wiring lines in technical rooms.

- The working pressure, which can be found from the product labeling, is one of the main selection criteria. The operating temperature must also be taken into account, which can be found in the following table: