Schemes and types of executions of mixing units UTK

By default, a mixing unit for thermal control UTK version 0 without fittings, flexible pipes and thermomanometers is proposed for implementation. It is possible to manufacture non-standard strapping units according to the sketches and technical specifications of the customer.

The mixing unit is built according to a three-way control scheme

- Ball valves 1 are used to disconnect the node from the heating network.

- There is a filter 2 for hot water on the unit's supply line. As it becomes dirty, it is necessary to clean the filter element of the filter.

- A three-way control valve with proportional actuator 3 is installed on the unit's supply line. Inlet B of the valve is bypassed to the return line of the assembly.

- A non-return valve 5 is installed on the bypass to prevent the coolant from flowing into the return line bypassing the air heater.

- A circulation pump 4 is installed on the supply line of the unit to ensure the circulation of the coolant along the "small" circuit.

Operating principle

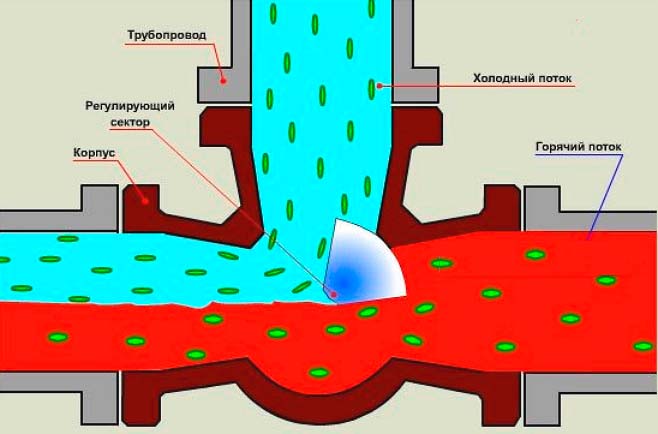

A typical mixing unit operates according to the standard scheme. The coolant, heated to a hot state, approaches the collector of water floors. On his way, he encounters an obstacle in the form of a safety valve equipped with a thermostat. If the water temperature exceeds the required value, the valve is activated, which opens the supply of cooled coolant from the return and mixes both liquids. As a result, hot and cold water are connected and when the temperature reaches the required value, the valve is activated again, blocking the flow of hot water.

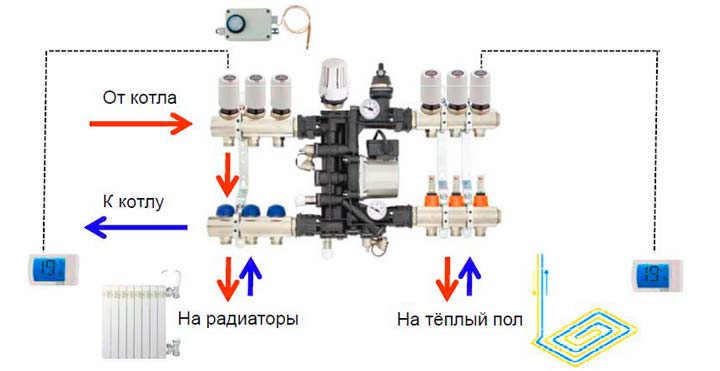

The mixing unit in the underfloor heating system not only regulates the temperature of the liquid, but also ensures its circulation inside the circuit. For these purposes, the device provides the following elements:

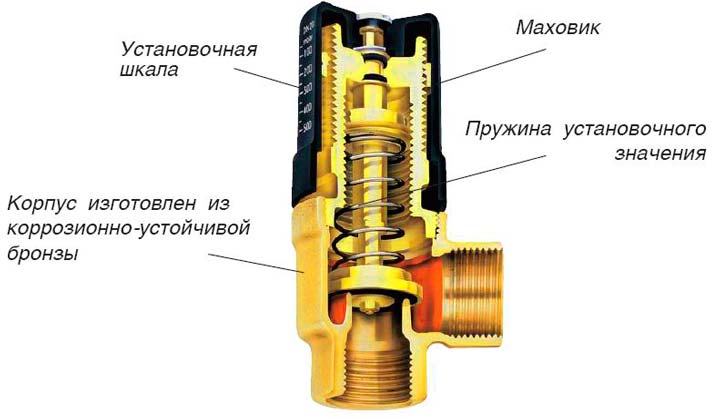

- Safety valve. With its help, the heating circuit is replenished with hot water in the required volume. At the same time, the inlet temperature is monitored.

- Circulation pump. After turning it on, the water in the circuit begins to move at the set speed. As a result, the entire area of underfloor heating is heated evenly.

The operation of the mixing unit is also provided by additional elements: a bypass that protects against overloads, air vents, and various types of drain and shut-off valves. Therefore, a do-it-yourself mixing unit for underfloor heating can be made in different ways, in accordance with its functions and operating conditions.

Installation of equipment is always carried out before the heating circuit. The direct installation site is selected based on the specific conditions for the use of underfloor heating. If there are several heated rooms, the mixing unit is placed in a separate manifold cabinet or mounted separately in each room.

Information about sources

The heat supply of the designed buildings and structures in the operating mode is carried out from heat pipelines of own needs.

The heat carrier for the heating, ventilation and heating circuit of the anti-icing system of the complex air-cleaning device is superheated water after the waste heat boilers with the following parameters:

- temperature T1 = 150 °C, T2 = 70°C;

- pressure Р1 = 8.0 kgf/cm2, Р2 = 2.0 kgf/cm2.

During the period of installation and commissioning or shutdown of waste heat boilers, temporary heat supply is provided from the existing heating network with a temperature schedule of 150-70 ° C, a pressure of 4.0-3.5 / 3.0-2.5 kgf / cm2.

The device of the mixing unit warm floor

The main element of the mixing unit for heating is the valve, which is responsible for mixing the heat carriers. It is either two-way or three-way.

The two-way valve consists of a thermostatic head, inside which a liquid sensor is placed. This sensor, when the coolant is supplied, fixes its temperature. If it exceeds the norm, then the head turns, thereby closing the entrance to the account. Normally, the cooled liquid from the return is always open. The hot coolant is passed to the pipes only when the temperature of the warm floor drops. The two-way valve copes well with the system of a small room, because it passes the coolant into only one circuit.

If the air temperature rises, the cold water supply may increase.

With a decrease in temperature in frost, the flow of hot water can increase its intensity.

An important part of the system is the balancing valve of the secondary circuit. It mixes hot water from the supply pipe and cold return water in the proportions necessary for heating.

The scale on the valve indicates the capacity of the valve. In order not to accidentally change the position of the balancing valve, it is fixed with a clamping key. The hex wrench can be used to change the valve setting.

Its purpose is to maintain water pressure. When it falls, the valve is activated. As a result, hot water goes through the bypass (backup path in an emergency) to the central heating radiators.

The principle of operation of the mixing unit

The water boiler heats the liquid to a temperature of 95 degrees. Water of this temperature is used only in central heating radiators. For warm floors, it is very hot.

Under the influence of water at elevated temperatures, harmful substances can be released from floor coverings. In addition, the surface of the finishing material from hot water can rise, the coating will deteriorate. And a person on such a floor is uncomfortable.

Therefore, a water mixing unit is needed to help cool the hot liquid.

Purpose of heating automation

Many manufacturers unanimously say that their automation allows you to save energy, whether it be gas, diesel fuel or electricity. This is a little different. Of course, there is a saving factor, but the system itself was designed primarily to maintain the microclimate in the house.

The principle of operation of the system depends on the ambient temperature and the temperature inside the room. Information on the lower and upper temperature limits is entered into the system in advance. In case of deviations, the automation decides to turn on or turn off the heat sources.

The control is carried out by thermometers. Data from these sensors enters the control unit, which analyzes many parameters. Modern automatic systems are able to regulate the daily air temperature.

According to the programmed program, the boiler is started, when the boiler is heated to the desired temperature, the circulation pump is turned on. After a short time, the entire heating system of the house is heated to operating temperatures and the heating field of the house, the system goes into either sleep mode or keep warm mode.

Any modern automation allows you to work:

Home systems management automation system

- in manual mode;

- in automatic mode;

- in remote control mode.

With the first two modes of the system, everything is clear, but the remote mode is a revolutionary solution that has become available recently. With the introduction of the GSM module, the exchange of information wirelessly became available. Now, thanks to the GSM channel, the following features have become available:

- remote monitoring of the state of your home;

- control of the heating system through mobile devices;

- receiving signals from the system to you about the occurrence of emergencies.