Simple electric cutter

Considering How to Make a Styrofoam Cutter

, you should study the design of the simplest equipment of this class, which is powered by electricity. In this case, you will need to prepare a thin guitar string and several batteries (for example, from a flashlight).

The principle of operation of this equipment is simple. Battery construction forms a single unit. A guitar string is connected to it. When electric current passes through the circuit, it will heat up. It is in this state that the string can easily cut the foam sheet.

When using such a tool, the material will melt. The string heats up to 120 ºС and even more. In this case, it is quite possible to cut several large foam plates. If you need to perform a large amount of work, this option is not suitable. Batteries run out quickly. You will have to provide for the option of connecting the system to a household network.

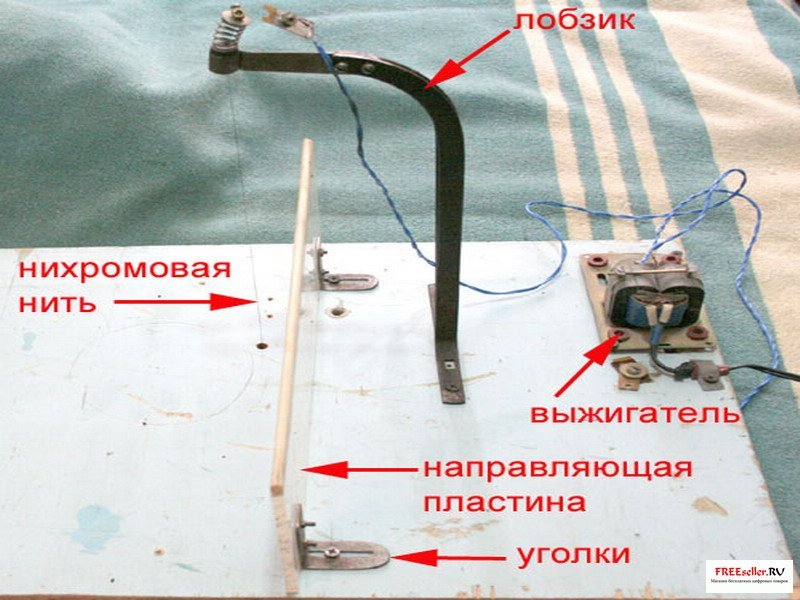

Cutter for linear cutting

Do-it-yourself line cutter for foam plastic

allows you to create blocks of material of the required dimensions. This greatly speeds up the work of the wizard. If necessary, this tool can cut circles, triangles or squares in the foam.

Two racks are vertically mounted on the surface of the table. Two insulators are attached to them. A nichrome thread is stretched between them. This alloy heats up quickly, providing sufficient cutting temperatures. A freely hanging load is passed through one of the racks. Contacts from the transformer are connected to the thread.

Passing the current will heat it up. It will be taut all the time due to the weight hanging from one side. This is necessary because the string can sag when heated. If desired, the design can be modified by adding a spring instead of a load. However, the original version is easier to implement.

Do-it-yourself foam cutting device

Styrofoam can be cut not only with a nichrome thread, but also with a metal plate. As a basis, you should take a regular soldering iron with a power of 60 watts. It will need to be reconstructed - instead of a sting, place a knife plate. A thermofusible synthetic is also used as the main material.

The wooden leg must be additionally equipped with support legs. Beforehand, a slot should be made in the board and a knife should be placed in it. Additionally, the device should be equipped with a rack with brackets

Equally important is the safety screen, which in the future will protect a person from burns.

In the process of cutting, the thermal knife must be placed at an angle to the surface. The blade is also sharpened on both sides at once. You should first hone your skills on unnecessary scraps of material. In this case, a smooth and beautiful surface is guaranteed to be obtained.

How to choose cutting wire

A suitable cutter can be made from nichrome wire (X20H80), which is used in the design of most household appliances as a heating element. In terms of mechanical characteristics, nichrome is comparable to ordinary steel, while it has a high resistivity and a heating limit up to temperatures of +1200 ºC. Wire diameters up to 10 mm are available for the manufacture of cutting fixtures.

Precise and smooth foam carving is possible when the cutting line is heated to a temperature that is two to three times the melting threshold (+270 ºC). It should be borne in mind that such a process involves the consumption of energy and the absorption of heat by the material itself in proportion to its density. Therefore, for efficient and safe cutting, it is necessary to select a wire of suitable thickness in order to prevent metal melting at maximum heating.

Calculation and preparation of the electrical part

The voltage is proportional to the resistance and is calculated using formulas or tables. But on average, with a wire diameter of 0.8 mm, a length of 500 mm and a resistance of 2.2 ohms, you will need a 12 V current source with a load current of 12 A. Changing the length up or down will require a similar increase or decrease in voltage at the same strength current.

Power sources and connection diagram

Safe cutting is ensured by connecting to a regular 220 V household network through a car transformer. To adjust the voltage in a single primary winding, a handle is provided, with which the graphite wheel is moved and the voltage is removed from the corresponding section. This parameter can be changed within the range from 0 to 240 V. Connection to the current source is carried out through the terminal box.

When connecting a homemade foam cutting machine to the mains, you need to make sure that the phase does not fall on a common wire. All the necessary parameters and connection diagram can be found on the transformer housing. Before connecting to the network, you need to check the operation of the device using a multimeter.

A simpler option for supplying current to the wire is to use conventional step-down transformers with taps from the secondary windings. In this case you don't have to adjust the voltage

, since this value is always constant and sufficient to heat the wire to the desired temperature. You can select the desired value during the initial setup of the transformer, providing a certain number of turns of windings in the circuit.

You can also heat the wire for cutting polystyrene using household appliances. In this case, the following nuances are taken into account:

To make a thermal knife for polystyrene or foam rubber, it will not take a significant investment of time and effort. For this, a wire of almost any diameter is suitable, but with unknown parameters (diameter, resistance), you need to increase the power gradually, connecting first low-power current sources. Of great importance is the reliable isolation of the contacts and the control of the position of the phase, which cannot be connected to the wire.

Standard construction is a thing of the past. Today, every owner strives to make his home functional and individual.

At the same time, attention is paid not only to design

Equally important is sound insulation, heat preservation and proper ventilation. With the help of foam, you can perform a large number of works

However, manufacturers pack the material in large sheets. That is why it is important to choose a reliable and comfortable tool for cutting them.

With the help of foam, you can perform a large number of works. However, manufacturers pack the material in large sheets

That is why it is important to choose a reliable and comfortable tool for cutting them.

Application

If you think that for all the above actions it will be enough for you to use a thermal knife, or a hacksaw is enough, then you are mistaken.

After all, a hacksaw will not make the edges even and not torn, as is the case with a cutter.

Polyfoam is used in many construction works. It has good thermal insulation. However, this is a rather fragile and crumbling material. Therefore, when cutting it, special equipment is used.Otherwise, the edges will be uneven, and the material itself will lose its thermal insulation qualities at the joints.

Special equipment is on sale. However, the foam cutter

you can do it yourself. This will significantly save the family budget. How to create different options for a tool for cutting foam, it will be interesting for every craftsman to know.

How to do it yourself

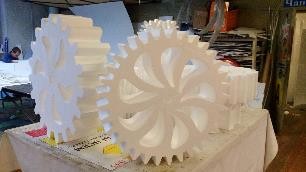

And to accomplish this, you will need a piece of foam. For example, you can use foam from the packaging of the TV. It is necessary to draw on it with a ruler, a compass and a ballpoint pen the places where holes will need to be made in the future.

This is where the need for an electric cutter comes in. After all, it will be difficult to perform this action without damaging the foam sheet without such a tool. Consider one of the options for how to make a device of this type at home.

A homemade cutting device can be of various designs. It is from her and the type of cutting that will depend on how exactly the cutter copes with its goals.

Step-by-step production of a thermal cutter

-

-

Sleeve.

Initially, you need to do the main and most difficult thing - the sleeve. So, for this, the plate must be bent, machined. Further, a hole must be made in the sleeve, a thread will be inserted there in the future. -

Burner.

You need to cut off the wire that leads to the hole, and take the appropriate connectors, then solder to the gap.

-

Sleeve.

Note:

such areas must be isolated

After everything is done, you can connect the thermal cutter.

Cut the old jigsaw in half. In the upper part it is necessary to attach a pre-prepared plate-foot to the screws

But we attach the bottom to the base using self-tapping screws.

Insert the sleeve into the foot.

Now, with special attention, it is necessary to mark a point under the bushing hole from the hole along a plumb line or square. Next, drill a hole in the base

The diameter of the hole in the base should be about 5 mm.

Thermal cutter.

So, when everything is ready, you need to straighten the nichrome wire. To do this, you should turn on the burner at full power and touch the nichrome with wires from it. Everything must be done in such a way that between the wires there is a distance equal to the height of the device. If the thread does not heat up, but the burner starts to buzz, find a thinner wire. This is necessary because the resistance you have chosen does not have enough resistance.

Take note:

nichrome should be hot, but should not heat up to red. If the string has turned red, it is necessary to reduce its heating by means of the regulator. In the event that nichrome is red even at a minimum, then a compensator should be left 5-10-15 cm above the spring of nichrome wire. And only after that you can pick up the contact.

-

Device operation.

With a pre-installed guide, you need to cut the styrofoam dies to the desired thickness, you can also make the shape curly.

Features of work

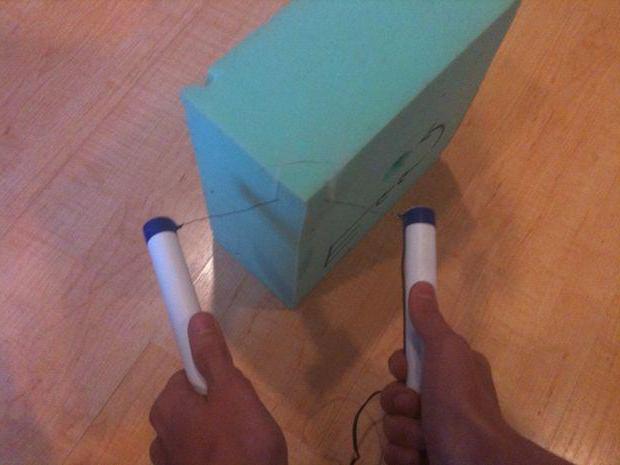

Learning how to make a hand held foam cutter

, it is also necessary to consider the features of the functioning of such equipment. As mentioned above, such an instrument has a string. It heats up and melts the surface of the foam.

Such material reacts badly enough to heat.

Therefore, it is important to maintain the technology of the entire process. Cutting with a hot thread is fast

This allows you to achieve a high quality cut.

Checking the heat level of the string is easy. To do this, a test is carried out on a test piece of foam. If, when the thread is immersed, long pieces of material remain on it, it has not yet warmed up enough. If there is no foam on the string at all, then the temperature is too high. In this case, you will have to cool the tool a little. With the right heat, it is possible to perform fast, accurate cutting.

Necessary tools and materials

Styrofoam is a lightweight material that can be cut with a variety of tools.

In some cases, accuracy and cleanliness of the cut are of no small importance. You can provide these properties using the following tools:

- ordinary sharp knife;

- small stove or hacksaw;

- strong string;

- knife with thermal effect;

- thermal cutter;

- cutter with laser beam.

Each builder has his own preferences regarding the choice of one of the tools. All tools allow you to qualitatively process the foam and form a straight line. Styrofoam has low resistance to mechanical stress - this should not be forgotten in the process of choosing a tool.

Do-it-yourself foam cutting methods using nichrome

If the electrical parameters of the nichrome wire are not known, then you must first try to connect a low-power electrical appliance, for example, a 200W electric light bulb (a current of about 1A will flow), then a 1kW (1A) heater, and so increase the power of the connected devices until the nichrome wire of the foam cutting machine heat up to the desired temperature. Electrical appliances can also be connected in parallel.

cutting with nichrome wire: option 1.

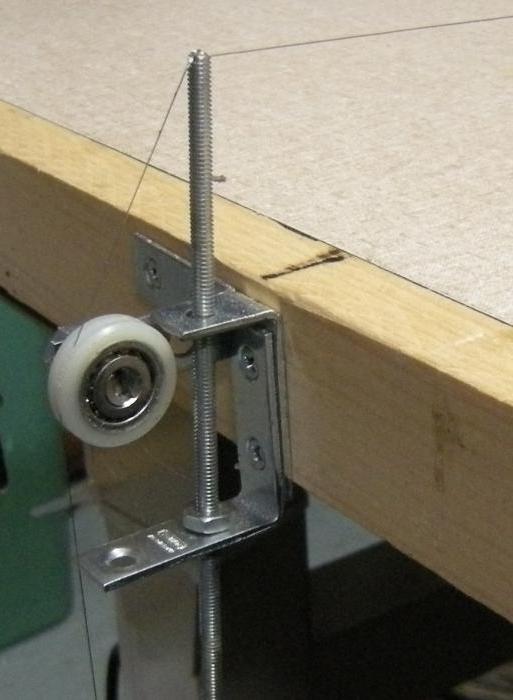

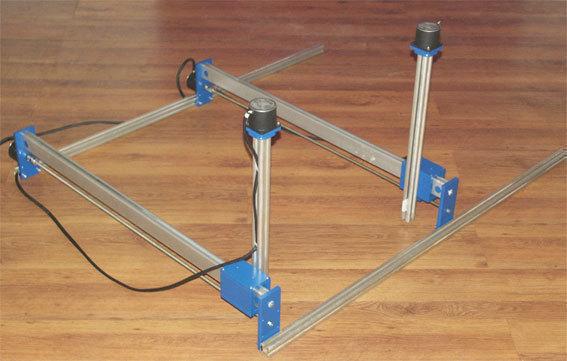

A simple foam cutting machine can be assembled by hand. In addition to the nichrome string, you will need: a step-down transformer for 12 or 24 volts, a piece of any pipe, a spring for string tension, a small table. The most difficult thing is to find nichrome. But here an old hair dryer can help out. The wire can be taken in it. The principle of operation of the device is as follows: with the help of a step-down transformer, nichrome is heated to a certain temperature, a foam plastic is brought to it, which, when melted, is cut. In this way, you can get various figured products from this material.

The assembly of the device is simple: you need to fix a wooden block on the table, in which we will drill a hole and install a piece of pipe in it. We thread the wire into it and with the help of a spring fixed on the back of the table, we stretch the nichrome wire. We connect it to the transformer, and it to the mains. Slowly moving a piece of foam with your hand to the wire, cut it.

cutting with nichrome wire: option 2.

To make this device you will need:

- Hardboard, in which you will need to make holes for perforation (using a drill and a thin drill).

- Aluminum rod 0.5 m long.

- Fast fix adhesive.

- Pieces of wire with "crocodiles".

- Small wooden blocks, 5-7 cm thick.

- Sheet of cardboard.

- Scotch.

- Power Supply.

- Nichrome wire.

- Bolt and 4 nuts.

The sequence of work on the assembly of the apparatus for cutting foam

In fact, this is the same hot string, but brought to perfection. A professional tool allows you to achieve high cutting speed, it is possible to use curly nozzles.

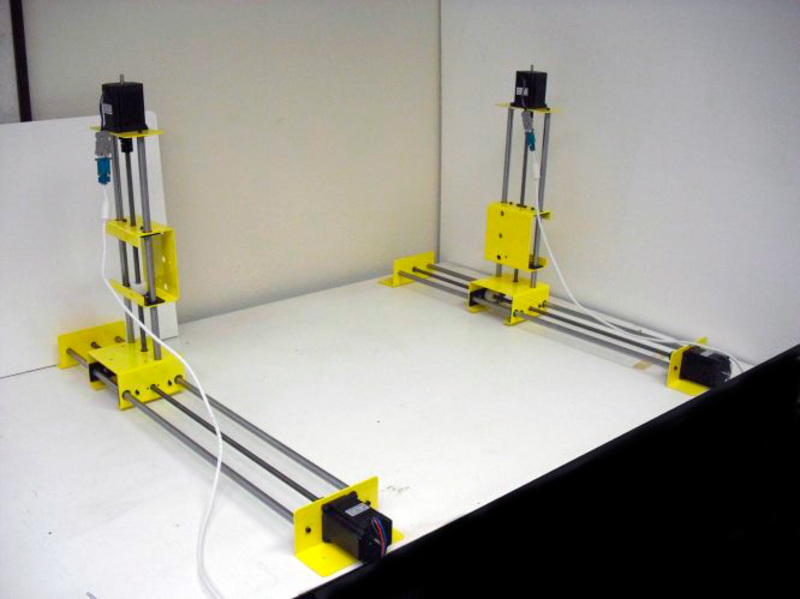

Making the base for the device. It is a square piece of hardboard (rib length 40-45 cm), which must be fixed with screws or nails to two wooden blocks. They will act as "legs". Thus, you get a fairly solid stand with a perforated surface. In one of the bars, you need to drill such a hole so that the aluminum bar prepared in advance is firmly inserted into it. We measure 30 cm on an aluminum bar and at this point we bend it at an angle of 90 °. We insert the rod into the hole drilled in the bar. We find on the hardboard the hole closest to the free end of the bar and mark it with a marker.We cut the aluminum rod with metal scissors so that its tip is exactly above the marked hole. To prevent the rod from rotating, we drill a hole through it and the support and drive a nail into it. We install a wire from nichrome. First of all, screw 2 nuts onto the bolt. Wrap the wire around it, tie it up and screw 2 more nuts on top. They should be well tightened. We put the bolt with nuts on the base and fix the nuts on it with glue

It is important to make sure that the nuts do not rotate

Pay attention to the hole opposite the tip of the aluminum rod. We marked it with a marker

We pass the wire into it and, having made a loop, throw it on the bar and tighten it

We connect the power: with the help of "crocodiles" we connect "+" with an aluminum bar, and "-" with a bolt. On the power supply, you need to make such an adjustment that the nichrome heats up by no more than 100 °. When working with the device, you must not forget about the safety of your hands.

Other ways to cut foam

- cutting foam is possible with a grinder and the thinnest disc. But in this case, it will not be possible to obtain a smooth edge;

- it is possible to cut foam with a sharp knife, but this method is very difficult due to chipping of the material;

- some craftsmen suggest using fine-toothed wood files when cutting foam. But this method is also dubious;

- in building materials stores you can buy a special thermal knife for working with foam. The working temperature of this tool is 600°C, and the heating rate is no more than 10 seconds. But this is quite an expensive purchase. Therefore, if you are not going to open a workshop for cutting this material, it is easier and more profitable to assemble a free home-made machine with your own hands.

Cutter with metal plate

There is a foam cutter,

in the design of which it is used To create this equipment, you can remake a soldering iron. Suitable equipment with a power of 60 watts. Remove the heating element from the device. Instead, a plate is installed here.

One side of the copper blank needs to be sharpened. This will allow you to create a more precise cut. The sharpening angle should not be made too large. Cutting will be done by heating. To find its required level, you will have to experiment on a test piece of foam.

This method is also used by masters of various skill levels and profiles. If necessary, the copper plate can be replaced with a steel billet. This option will require more effort when sharpening. But with the help of such a tool, you can also cut denser polymeric materials.

Choosing Which Styrofoam Cutter

more suitable for the work of the master, you should take into account the recommendations of professional builders. The greater the amount of work performed, the more complex the design will be. A simple battery-operated cutter is fine for cutting a few blocks. However, to perform a large amount of work, you should give preference to network types of equipment.

When cutting, the foam is heated. At this point, substances unsafe for human health are released from it into the environment. Therefore, work is performed in a well-ventilated room or on the street.

In order not to make a mistake with the cutting configuration, you should mark all the lines with a pencil before starting the action. This will help avoid cutting errors. These simple recommendations will allow you to do the job quickly, correctly and safely.

Having considered what options for foam cutters can be made with your own hands, each craftsman will be able to choose the best option for himself.

Styrofoam (extruded polystyrene foam) is used as thermal insulation for exterior and interior decoration, used for packaging goods or manufacturing prefabricated structures. The material is produced in the form of sheets, which are cut on the spot and adjusted to the dimensions of the surfaces.For quick cutting of foam, you will need a special device that allows you to make a straight or curly cut.

Manual processing of foam plastic is possible at home and in small workshops using a simple device assembled from improvised materials. Extruded polystyrene foam has a fairly dense structure, so you can cut the plates with a metal tool

heated to a certain temperature. As a cutting surface, a wire that supplies electric current is suitable, with the supply of which the main difficulty in assembly is associated.

To cut foam at home, you will need a structure that can be assembled from simple materials available at any hardware store. First you need to determine the parameters of each element, taking into account the dimensions of the foam plates that will have to be processed. In most cases, the following details will suffice:

- The basis from dense plywood, a chipboard or the massif. You can order new parts or use elements of old furniture (doors, walls, shelves). A base of 400 x 600 mm is sufficient for working with foam.

- A string or wire in the form of a thermal knife for polystyrene.

- Metal posts, screws, springs or ordinary nails to fix the wire. The installation height of the cutter depends on the expected thickness of the finished boards.

- Fixings for parts on the base. A few self-tapping screws are enough to fix the structural elements.