New company boiler Turbo

Neva Turbo boilers are, in fact, a modified version of the already familiar Lux modification, taking into account the shortcomings of previous versions. Models have the following specifications:

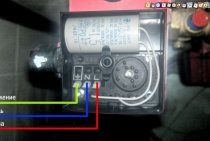

Turbo boilers are volatile. The power supply of the boiler is provided by connecting to a normal voltage network of 220 V. For stable operation, you will need to install a UPS and a generator.

Ease of maintenance and operation

It is enough to connect the unit to the heating and power supply system and start heating the house or apartment. In practice, under the condition of a ready-made heating system, all work takes about 3-4 hours.

After installation, there is no need to worry about the safety of the station. The sequence of automation completely eliminates the possibility of gas leakage, creating an emergency, even if an unplanned power outage occurs.

The main differences between the Neva boilers

The Turbo modification provides economical gas consumption and, subject to proper operation, fully pays off in a few years.

Calculation of power and temperature of a warm water floor

Russian wall-mounted gas double-circuit boilers Neva provide consumers with maximum comfort when switching to autonomous heating and hot water supply. This equipment is intended for operation in multi-apartment residential premises and in country houses. For the production of boilers, modern materials are used, as well as high-quality components from the best European suppliers. The company's designers conduct a constant scientific search, running prototypes of new models at the Gazapparat pilot plant before launching into serial production.

Thanks to this, it is possible to correct all the shortcomings, the manufacturability of production increases and, which is important for gas equipment, the degree of its reliability increases.

The domestic manufacturer BaltGaz implemented two design options in Neva Lux gas double-circuit boilers. So in boilers of the 72nd series, as well as in the BaltGaz 18 DBF boiler, a single bithermic heat exchanger is installed to work with heating and hot water circuits

This decision allowed to reduce production costs, which had a positive impact on the pricing of these products. In addition, the products of the 72nd series provide accurate temperature control with a tolerance of 1 0 C. The models of the 82nd and 86th series use the traditional layout with two heat exchangers - copper for the heating circuit and plate for the hot water circuit. The entire line of double-circuit boilers, with the exception of the Nevalux-8624 model, is equipped with a closed combustion chamber.

In addition to the above, Nevalux gas double-circuit boilers differ in thermal performance and minor details in the design:

- Nevalux-7211 - thermal power 11 kW, bithermic heat exchanger, maximum heating area - 110 m 2

- Nevalux-7218 - thermal power 18 kW, bithermic heat exchanger, maximum heating area - 180 m 2

- Nevalux-7224 - thermal power 24 kW, bithermic heat exchanger, maximum heating area - 240 m 2

- BaltGaz 18 DBF - thermal power 18 kW, bithermic heat exchanger, maximum heating area - 180 m 2

- Nevalux-8624 - thermal power 24 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 240 m 2

- Nevalux-8224 - thermal power 24 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 240 m 2

- Nevalux-8230 - thermal output 30 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 300 m 2

Wall-mounted gas boilers among consumers with a house or a small cottage are in great demand. This is due to the advantages of this type of equipment. Thus, the wall-mounted boiler is distinguished by its small external dimensions, due to which the equipment can be installed indoors with minimal loss of space. The equipment does not make noise during operation and is able to consistently perform the tasks, regardless of operating conditions. Many users choose the Neva Lux double-circuit gas wall-mounted boiler for installation in the heating systems of their homes, with the advantages and main technical characteristics of which we will get acquainted below.

Main technical characteristics and features of Neva equipment

Note that wall-mounted gas boilers are presented on the market with an open and closed combustion chamber. What does it mean? In the first case, the removal of combustion products is carried out in a natural way, through the chimney to which the device is connected. The intake of air necessary for the normal combustion of gas is carried out from the room.

In the second case, the gas boiler is connected to a coaxial chimney, the device of which is made according to the "pipe in pipe" principle. Through the inner pipe, the products of combustion are forced out, thanks to the built-in fan, and the air is supplied through the outer pipe, which comes from outside the room.

Double-circuit wall-mounted gas equipment is capable of performing two tasks aimed at heating the coolant and sanitary water. Heat exchangers are installed separately, one is designed for heating the coolant, the second for heating sanitary water.

Household appliances of this type are distinguished by a wide power range, which allows you to choose a unit for installation in an autonomous heating system for a house of any size.

When choosing a device, it is important to consider that 1 kW is needed for normal heating of 10 m 2. So, if a house, for example, has an area of 200 m 2

in which there is a need for hot water supply, then in order for the system to work stably, efficiently and economically, you will need to buy a double-circuit gas boiler Neva of any model with a capacity of 24 kW.

Design features of the Neva boiler

Despite the fact that the Neva wall-mounted boiler is small, its design contains everything necessary for the stable and high-quality operation of the equipment. Therefore, having opted for these heating boilers, you will not need to buy a separate circulation pump or expansion tank, the task of which is to remove air from the heating system in a timely manner. According to experts, the built-in expansion tank can significantly improve the safety, reliability and stability of the heating system.

The main advantage of the built-in expansion tank from a remote tank is that there is no need to constantly check the coolant level, the equipment will do it for you. In addition, since there is no need to install an expansion tank, it is possible to significantly save on the installation of the heating system.

All models of gas boilers presented by Neva are equipped with pressure gauges, which are installed on the equipment panel

It is important to know that as the temperature rises, the pressure in the system rises and vice versa. The system should be supplemented if the pressure drops below 1.5 atmospheres

Note that Neva wall-mounted appliances are able to continue to work effectively at reduced pressure of gas and water.

Let's return to the circuits of the device, namely the one that is responsible for heating sanitary water intended for everyday needs. So, for its manufacture, stainless steel is used, the advantage of which is high resistance to corrosion, which increases the durability of the device.

If you want to extend the operating life of your equipment, it is recommended to install a filter on the water supply pipe through which water is supplied to the boiler, with the help of which the water will be purified and softened. Shut-off valves should be installed in front of the filter and on the return line, which will allow you to carry out equipment maintenance and filter replacement without unnecessary difficulties.