Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branching in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

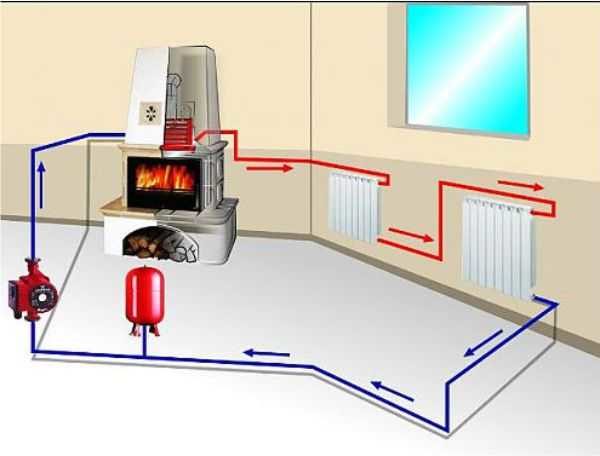

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

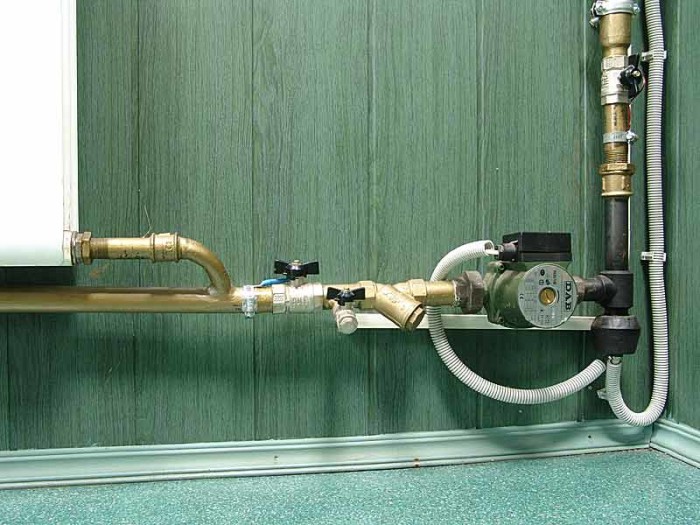

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

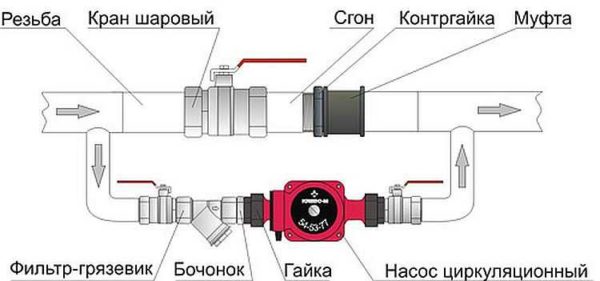

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer-mud filter is necessarily placed in front of the unit.

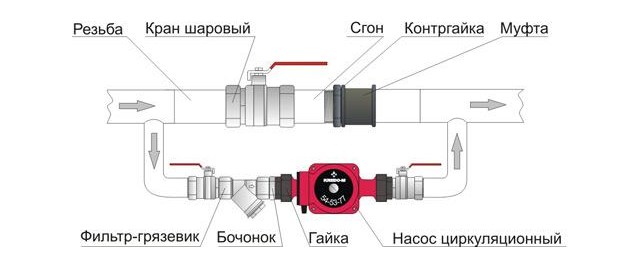

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Principles of installation and connection of the pump

To prepare the heating system for pump installation, the heating fluid is first drained and the entire system is cleaned if it is contaminated. The system is filled with water only after the pipes are fixed, after which they are carefully checked for faults for their further elimination. Using the central screw, excess air is removed from the system.

In order for the installed pump to interact with the cooled coolant, and to extend its service life, the unit is mounted in the return line pipeline. When installing in a forced circulation system, the connection of the expansion tank should not be made to the main riser, but to the return pipeline.

Having placed the pump strictly horizontally, it is attached to the pipes. As an additional device, the circulation pump can be mounted in a natural circulation system. In this case, the pump must be equipped with a filter and a detachable thread. The filter diameter must match the pump diameter. The operation of the pressurized system must be supported by a conventional valve that matches the thread diameter of the unit. When using an open system, it is not required.

After the pump is mounted, a valve should be installed on the main and return pipelines. To allow air to be bled from the system, a special device is installed on the bypass.

Where it is planned to install the pump, a pipe is cut off and a special connection for shutoff valves is welded to it, it is installed before and after the pump unit. This must be done for ease of removal, cleaning and repair of the device. Having blocked the water with taps on the outlet and inlet pipes of the pump, the heating boiler is turned off, then the nuts are unscrewed, on which the pump is attached to the pipes.

It is necessary to connect the pump after starting the entire system and filling the pipes with water. Air should not remain in the pipes, so it is released every time before starting the pumping unit. To release air manually, use special valves installed on both sides of the pumping unit.

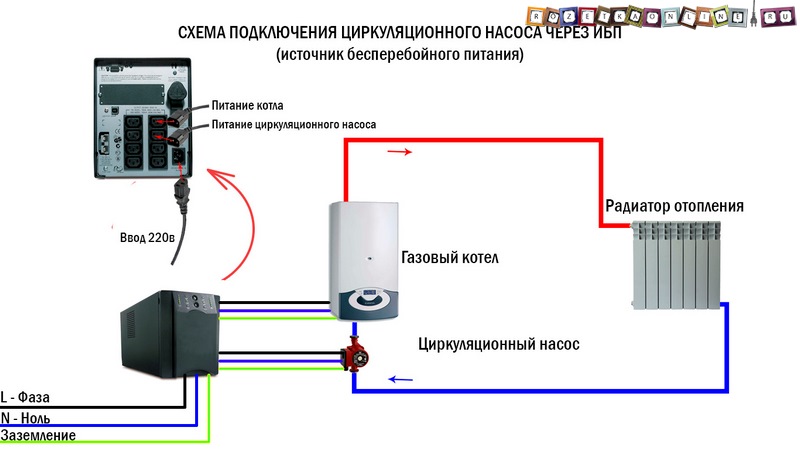

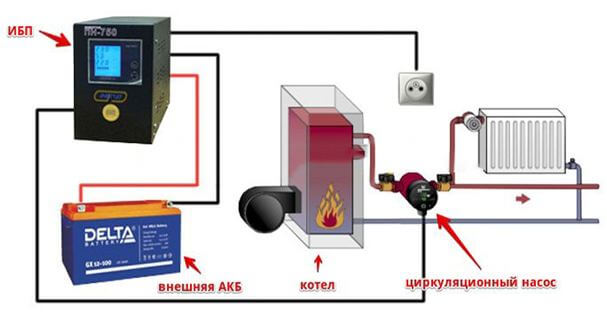

The circuit for connecting a circulation pump through an uninterruptible power supply UPS is as follows

The general principle of connecting a pump through a UPS is as follows. the power supply of the home network is connected to the uninterruptible power supply, and the circulation pump and, in this case, the gas boiler are already powered from it. Now, when there is a power outage, the house will continue to heat in the same mode for as long as the battery in the UPS lasts.

The uninterruptible power supply is selected depending on the installed equipment, its quantity, power consumption and some other factors. In heating systems consisting of a large number of electricity consumers or in systems that require a sufficiently long battery life, it is allowed to use both several UPSs at once, and one, but with additional batteries in the circuit, for example, automobile ones.

This UPS connection scheme can be combined with the circulation pump connection scheme through a thermostat, then the house heating system will be most efficient.

Power connection

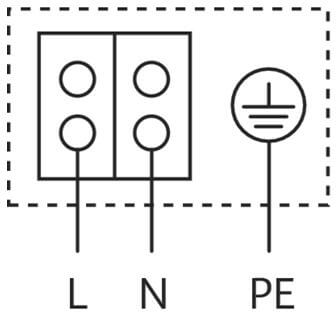

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable.Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors. They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

how to properly connect the pump to natural circulation heating for the selection of coolant for euro batteries

Hello. My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Hello. Is it better to put two pumps in series one after another or should there be some distance between them?

It makes more sense if the two circulation pumps are separated. The movement of the coolant will be more uniform.

I have 2 pumps near the boiler, one in the supply, the other in the return. The total length is about 150 m. They have been working for 8 years.

Nobody said that you can't bet one after the other. You can and they work without problems. But you can break it down.

I have a house of 2 floors before there was heating: pipes throughout the house f80 floor tones of water Boiler Dani now redid the heating pipe f25 batteries metal flat pump for some reason cut into the return line although it used to be cut into the supply the far wing of the upper floor does not heat it may depend on the installation of the pump ?

You need to look at the whole diagram.

In principle, a circulation pump is installed in the return or in the supply - it does not matter. The main thing is that it has enough power

But due to a lack of power, the far wing may not heat up.

Criterias of choice

The first important indicator when choosing a pump is its power. For high-quality heating, you should choose a device with exactly the power that will be enough for heating. Pumps that are more expensive and powerful are not needed for an ordinary residential building - they still will not turn on at full load.

To calculate the optimal power, the following parameters should be taken into account: the temperature of the coolant at the inlet and outlet, pressure, throughput, performance of the heating boiler. The flow rate of the heat carrier can be equated to the power of the boiler

For example, a heating unit with a power of 30 kW drives 30 liters of coolant in 1 minute

The flow rate of the coolant can be equated to the power of the boiler. For example, a heating unit with a power of 30 kW drives 30 liters of coolant in 1 minute.

The simplest formula for calculating the optimal pump power is as follows: Q = N / (T2 - T1), in this formula, N is the boiler power, and T2 and T1 are the difference in water temperatures at the outlet of the tank and in the return.

The pressure is calculated based on the footage of the heated area. According to generally accepted standards, a pump power of about 100 W is required per 100 m2 of a residential building.

Installation of the circulation pump is carried out as follows. First you need to carefully study the instructions and the diagram according to which it should be connected. The boiler and all heating equipment needs regular inspection and prevention, so you need to prepare an approach to the main components of the devices in advance. Then it is necessary to drain all the coolant and clean the pipeline, after which you can decide on the installation site.

So, experts recommend installing this equipment near the boiler, on the return pipe. This position is explained by two reasons: the pump installed in this place will allow more even distribution of the coolant in the boiler, which means increasing the efficiency of the entire heating system. In addition, on the return line, the circulation pump will operate at a lower operating temperature, which will increase its service life.

Bypass installation

A bypass (bypass) is performed on the sector selected for installation. This operation is necessary so that the system continues to circulate even when the power is turned off or the pumping equipment breaks down.

The diameter of the pipe of the bypass system must be less than the diameter of the pipes of the main gas pipeline. Only after the installation of the bypass proceed to the installation of the unit.

A drawing with the technology for installing a circulation pump is shown in this diagram:

Installation Features

It must be remembered that the shaft must be located horizontally. If installed incorrectly, the circulation pump loses up to 30% of its performance, and can fail within a short time. The terminal box must be installed at the top of the system.

Ball valves must be inserted on both sides of the unit - they will definitely be needed in the future, with regular technical inspections and scheduled repairs.

In the heating system, filters must also be provided to purify water in pipelines from various solid particles. The latter, when they enter the pumping equipment, lead to its serious damage.

A valve is mounted on top of the bypass pipe to bleed air from the heating system. When mounting the motor shaft, it is necessary to provide for the rotation of the box along the axis with little effort. An expansion tank must be installed in an open heating system.

What is important to know

The wiring diagram and methods of connecting a device such as a circulation pump to electricity can have different versions. The choice of a particular option is determined by the characteristics of the heated object, as well as the place where the device is located. There are two possibilities to connect it:

- direct connection to the mains 220 V;

- connection to an uninterruptible power supply, which, in turn, is connected to a 220 V or 220/380 V network (in the case of a three-phase UPS).

Choosing the first method, the consumer runs the risk of being left without heating in the event of a long power outage. This option can be considered justified only with a high degree of power supply reliability, which reduces the likelihood of a long power outage to a minimum, and also if there is a backup source of electrical energy at the facility. The second method is preferable, although it requires additional costs.

What is a circulation pump and why is it needed

A circulation pump is a device that changes the speed of movement of a liquid medium without changing the pressure. In heating systems, it is placed for more efficient heating.In systems with forced circulation, it is an indispensable element, in gravitational systems it can be set if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the temperature outside, thus maintaining a stable temperature in the room.

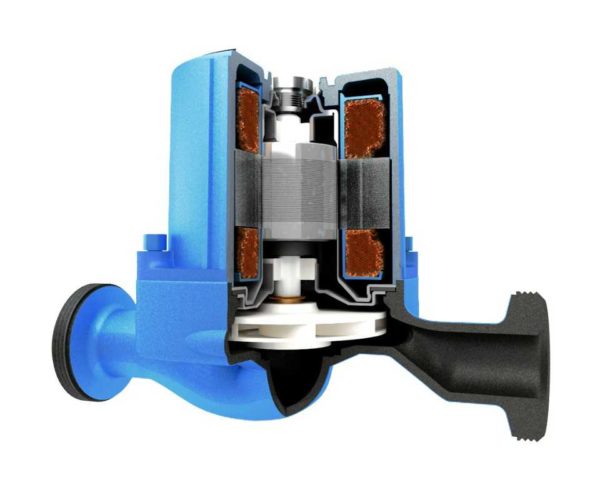

Sectional view of a wet rotor circulation pump

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but they are very noisy and require regular maintenance. Wet rotor units operate almost silently, with normal coolant quality, they can pump water without failures for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than enough to heat any private house.

Connection methods

Connection to the mains using a plug and socket. This method involves installing an electrical outlet in close proximity to the place where the circulation pump is mounted. Sometimes they can be supplied with a cable connected and a plug included, as in the photo:

In this case, you can simply plug the appliance into the mains using the socket located within the reach of the cable. You just need to make sure that there is a third, grounding contact in the outlet.

In the absence of a cord with a plug, they must be purchased in addition, or removed from an unused electrical appliance

You should pay attention to the cross-section of the conductors of the cord. It should be in the range from 1.5 mm 2 to 2.5 mm 2

The wires must be stranded copper, providing resistance to repeated bending. A cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, it is necessary to find out which of the three wires of the cord is connected to the grounding contact of the plug. This can be done with an ohmmeter, at the same time checking the integrity of the remaining wires.

Open the cover of the terminal box. Inside the box there are three terminals designed to connect the device to the network, marked as in the picture:

We unscrew the clamp of the cable sleeve (in the first photo it is a plastic nut into which the cable is inserted), we put it on our cord, we put the cord into the sleeve. If there is a cable tie inside the box, we pass the cord through it. We connect the ends of the cord wires, previously stripped of insulation, to the terminals.

To the terminals L and N, you need to connect the wires connected to the plugs of the plug (do not be afraid to mix them up, this is not critical), to the terminal PE you should connect the wire of the ground contact of the plug (but you can’t make a mistake here). The instruction attached to the product prohibits its operation without protective grounding. Next, tighten the clamp (if any), tighten the clamp of the cable gland tightly, and bury the cover of the terminal box. The pump is ready to be connected to the mains.

Fixed connection. The connection diagram of the circulation pump to the mains with grounding is provided below:

The requirements for the wire cross section are the same as in the previous version. The cable for this installation can be used both flexible and inflexible, copper, brand VVG. or aluminum, AVVG. If the cable is inflexible, the installation must ensure its immobility. To do this, the cable along the entire route is fixed with clamps.

In this embodiment, a residual current device (differential circuit breaker) is used. Instead, you can use a conventional single-pole machine, passing only the phase wire through it. If the machine is installed in a panel with a PE bus, then the cable from the pump to the machine must be three-core. In the absence of such a bus, the PE terminal should be connected to a grounding device. Such a connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting the pump to the UPS. It is most preferable and ensures the independence of the functioning of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power of the UPS should be selected based on the power of the pump motor. The battery capacity is determined by the estimated autonomous power supply time of the circulation pump, that is, the time when the power supply is turned off. We talked about how to choose a UPS for a boiler in a separate article. The cable cross-sectional requirements as well as the presence of protective earthing apply to all connection options.

Finally, we recommend watching video instructions for connecting various models of pumps to the electrical network:

Scheme for connecting the circulation pump to the thermostat

So we examined how the circulation pump is connected to the mains correctly. The diagram and video examples helped to consolidate the material and clearly see the nuances of the installation!

It will be helpful to read:

Scheme for connecting the circulation pump to the thermostat

Selecting the right unit

When choosing a pump, attention is paid to two main parameters: the force of the coolant flow and the hydraulic resistance that it overcomes when creating pressure. At the same time, the characteristics of the purchased circulation pump should be 10-15% lower than the calculated values

If you install a powerful pump in the heating system, you may encounter the problem of increasing power consumption, excessive noise, and rapid wear of equipment parts. A low-power pump will not be able to provide the pumping of the coolant in the required volume. Many models of modern circulation pumps are equipped with electronic or manual motor shaft speed controllers. The highest efficiency value is achieved at maximum shaft speed.

Thermal valves, installed in many heating systems, regulate the temperature in the room in accordance with the set parameters. The valve closes when the temperature rises. This increases the hydraulic resistance and, accordingly, the pressure increases. These processes are accompanied by the appearance of noise, which can be eliminated by switching the pump to low speeds. Pumps with built-in electronics that can smoothly regulate pressure drops depending on changes in the amount of water cope with this task more efficiently.

Which pumps are suitable for installation in residential premises

Installation of a circulation pump.

The optimal temperature of the heating system of a country house is achieved using built-in thermal valves. If the set temperature parameters of the heating system are exceeded, this may lead to the fact that the valve will be closed, and the hydraulic resistance and pressure will increase.

Using pumps with an electronic control system helps to prevent noise, as the devices will automatically follow all changes in water volumes. The pumps will provide smooth adjustment of pressure drops.

To automate the operation of the pump, a model of an automatic type unit is used. This helps protect it from misuse.

The pumps used may differ according to the type of application. For example, dry ones do not come into contact with the coolant during operation. Wet pumps pump water when they are submerged. Dry types of pumps are noisy, and the installation scheme of the pump in the heating system is more suitable for enterprises rather than residential premises.

For country houses and cottages, pumps designed to work in water, having special bronze or brass cases, are suitable.The parts used in the housings are stainless, so the system will not be damaged by water. Thus, these structures are protected from moisture, high and low temperatures. Installation of such a design is possible on the return and supply pipelines. The whole system will require a certain approach in its maintenance.

In order to increase the degree of pressure attributable to the suction section, you can install the pump so that the expansion tank is nearby. The heating piping must be descending at the point where the unit is to be connected. It will be necessary to make sure that the pump can withstand strong pressures of hot water.

Tip 3 How to connect underfloor heating to the boiler

The most economical and convenient option for underfloor heating - water floors with connection to boiler . Such a system allows you to save a large amount of electricity and makes it possible to independently regulate the heating temperature. In addition, it is easier to install.

- - wall-mounted boiler for underfloor heating;

- - manifold cabinet;

- - shut-off valves;

- - compression fittings;

- - circulation pump;

- - thermostat (preferably, but not required).

Install underfloor heating in a sand-cement screed. To do this, prepare all the components of the system. Remove the existing screed and distribute all the underfloor heating elements over the area where they are planned to be installed.

Then hang the boiler for underfloor heating in a convenient place - so that the water pipe loops come from the collector. If you install floors in your own home, then it is advisable to place the equipment in a specially designated room. Regarding the installation of the boiler in the apartment, it is better to consult with an experienced master.

Install the manifold cabinet. Its task is to carry out the circulation of water in pipes and to combine floor heating with other domestic heating.

Lead the supply and return pipes into the installed manifold cabinet. The first will supply hot water to the water floors. the second is to take the cooled liquid and return it back to the boiler. Install a shut-off valve on each pipe so that you can turn off the water if necessary.

Using a compression fitting, connect the pipe from the boiler to the metal valve, and connect the manifold inlet to the valve. Connect the underfloor heating circuits to the collector with fittings.

In the collector, install a circulation pump designed for continuous water circulation. It is mounted on the supply pipe. It is better to purchase a pump with a thermostat. which will allow you to control the temperature of the floor heating.

After that, turn on the system, check its operation.

The final installation of underfloor heating is carried out only after the operation of the heating system has been checked. It should function for at least 10-12 hours. And, if everything is in order, the floor surface is laid above the pipes. Otherwise, there is a risk of flooding your own house due to a minor mistake. If the pipes are laid in a sand-cement screed, the system can only be turned on after the solution has completely hardened.

To avoid problems with connecting a variety of various control devices, you can purchase a pump mixing circuit for wall-mounted boilers, which includes a circulation pump and almost the entire set of equipment.

- Installation of a water heated floor

- how to connect underfloor heating