How to deal with a complex roof shape

Let's be honest with you: metal tiles are far from the best roofing material for a roof with a complex shape. And therefore, since there is already one and it needs to be insulated, be sure to think over the ventilation of all its parts. Definitely everyone!

The fact is that certain areas without ventilation will be warmer, snow will melt on them and flow down to the eaves, where there is ventilation and the roofing has a lower temperature (especially on the overhang, under which there is no insulation). And in a metal tile for water, it is not difficult to find an entrance to the under-roof space.

Further, melted snow will stumble upon non-melted snow and remain there, eventually turning into ice. And they put it on - this is not only a danger to people living in the house when they go outside at the wrong time - it is also a constant destruction of the drain.

This is why the ventilation of a complex roof must be 100% without missing a single section. For this, an intermittent counter-lattice is equipped, which allows air flows to move not only in one specific direction, but also in different directions, reaching all zones. Also, a couple of additional aerators will not be superfluous.

And at the end of the insulation, also make sure that the air intake hole in the cornice is always open. It cannot be hemmed with a board, but it can be covered with a slightly bent gutter drip.

In extreme cases, we advise you to insulate such a roof from the inside and with the help of polyurethane foam, which penetrates into all cracks and hard-to-reach places (and a complex roof always has them), and is not afraid of moisture:

How to take care of your roof

The polymeric covering of a metal tile protects it from a rust, but itself is exposed to influence of temperatures, an ultraviolet and weather cataclysms.

Regular cleaning consists of the following simple steps:

- Dried leaves and ordinary dirt are removed with a damp brush with a hard bristle;

- Snow is cleared with conventional soft snow plows;

- For washing gutters, a jet of water is used under pressure, which is directed from the roof ridge towards the cornices;

- Severe contamination is removed with gentle means for polymer surfaces;

- Aggressive household chemicals should not be used: it can destroy the protective layer of the roof.

Installing additional items

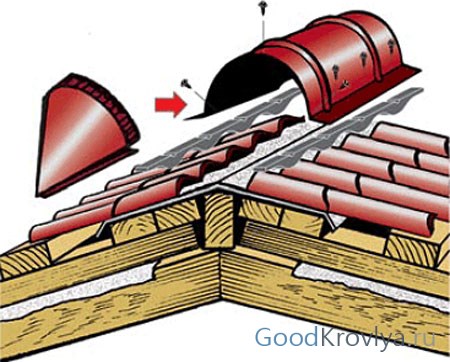

Valley installation: constructive advice

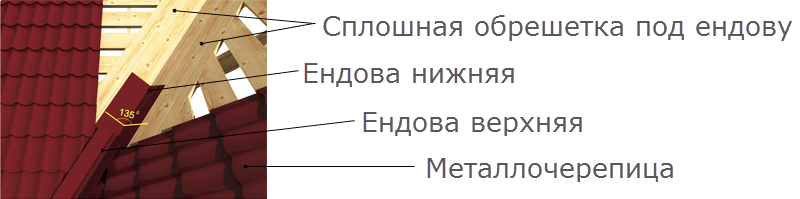

It is installed at the junction of the slope to the slope, but always with the overlays. The slats of the lower valley are laid on the crate so that its lower edges are on top of the cornice slats. Then, a sealant must be laid on the planks of the lower valley - it ensures a snug fit of the sheet to the planks. By the way, the valley is attached at the top of the profile wave with a step of 300 mm.

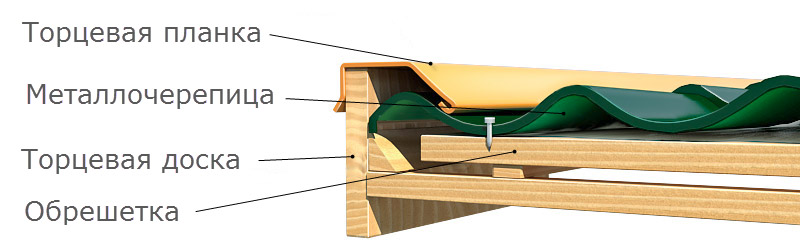

End plate

Here it is necessary to use the “bottom-up” scheme, and the overlap of the planks is at least 10 cm in length. The end plate is mounted on self-tapping screws in increments of 40 cm.

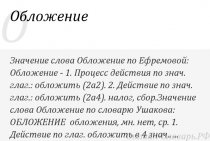

Something about the cornice plank: proper water drainage

The cornice strip for metal tiles is a longitudinal structural element, the main function of which is to protect the frontal board from destructive wetting, from the penetration of moisture into the interior. The essence of its fastening lies in such moments: the cornice strip is nailed to the frontal board in a checkerboard pattern (300 mm step); first one plank is nailed, then the other is overlapped.

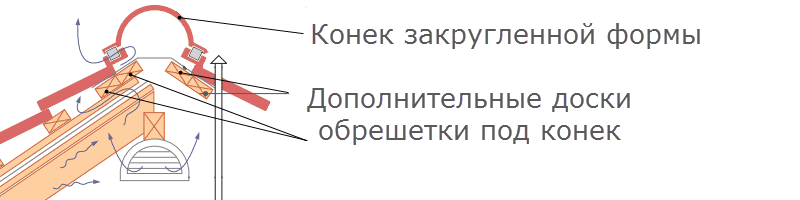

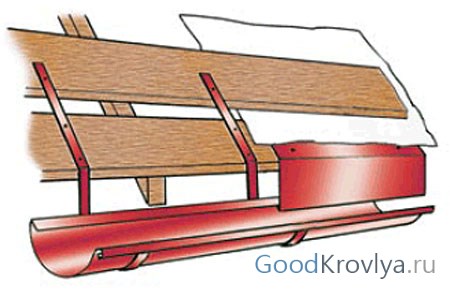

Skate - say "no" to the flow

At the junction of the ridge, it is necessary to leave small gaps. A sealant is firmly glued along the upper edges of the sheets, the ridge is fixed with self-tapping screws at the top points through the wave.

Snow guards - such components should not be neglected

The planks are fastened under the second transverse steps of the profile sheets, between them at the top of each wave a support bar is attached. In addition, the installation of protective snow retainers can be carried out directly to the crate: naturally, then it is advisable to use long roofing screws.

In general, all of the above can be summarized unambiguously: the installation of metal tiles is a complex process that requires skills, knowledge, and experience. You can’t master it on your own, so it’s better to immediately turn to professional craftsmen, because then the final result will be excellent, pleasing to the eye!

How to insulate the roof tips on the device

We can say that in the end, the maximum provision of heat preservation depends on the filling of the pie. Properly selected and installed, it prevents the attic and attic living quarters from cooling down, does not allow moisture to penetrate from the outside and ensures its removal directly from the cake itself.

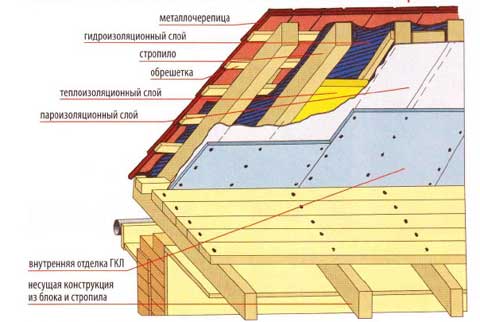

The main layers of the roofing cake

It is impossible not to note the roofing material itself - metal tiles. The extent to which the roof and the elements of the "stuffing" of its roofing pie will be protected from the aggressive effects and physical exertion of natural phenomena, snow, rain, and wind largely depends on the observance of its laying technology. The safety, lack of wetting and efficiency of the heat-insulating layer is ensured by a waterproofing film, one or two ventilated gaps (depending on the type of waterproofing material) and a vapor barrier material.

The waterproofing of a roof made of metal is designed to prevent the penetration of moisture from the outside. Depending on the purpose of the attic, it can be both vapor-tight and vapor-permeable.

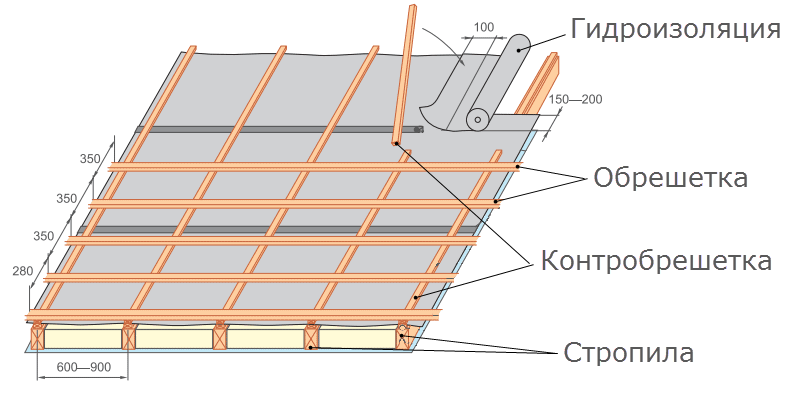

On top of the waterproofing layer along the rafters, bars of the counter-lattice are laid, and the bars of the crate are laid across. The height of the bars of the counter-lattice is chosen based on the length of the roof slope and the size of the required ventilation gap, and the step of the batten is selected in accordance with the length of the horizontal wave of the metal tile, since roofing material will be attached to it.

For a roof made of metal, it is especially important to have ventilation for the under-roof space. In its absence, condensate, which is formed when the difference between internal and external temperatures on the inside of the metal tile, can lead to disastrous consequences for the roof structure.

For metal roofs, including those made of metal tiles, it is necessary to use special membranes - anti-condensation.

This material is one-sided, and it should be laid with the rough side to the insulation.

Heat-insulating layer of a roof from a metal tile it is recommended to arrange from breathable materials, as a rule, with a fibrous structure. They are based on basalt or fiberglass. These heaters have good thermal insulation characteristics and perfectly dampen noise. Another advantage is that they are not flammable. The total thickness of mineral wool layers under the metal roof of an energy-efficient house is at least 20 cm. Fiberglass insulation, due to its structure, has many air gaps, which ensures their low thermal conductivity.

In general, the performance characteristics of mineral wool and glass fiber are similar, although the thermal conductivity of glass fiber is lower.

Penoizol is also used as a heater - liquid foam, a heat-insulating material of a new generation.

The thermal insulation mats or boards must be semi-rigid. So they will hold well in vertical and inclined planes.

Metal roof vapor barrier protects the insulation from moisture that comes from the inside. It is also attached to the rafters, only from below, using galvanized nails or staples. Similar to laying a waterproofing film, an overlap is performed. In order to ensure tightness, all “dangerous” adjoining areas, for example, to walls, pipes, windows, are glued with special adhesive tape.

The device of the roof, insulation and other elements is carried out without deflections, gaps and irregularities with a snug fit to each other, with the exception of ventilation ducts.

2019 stylekrov.ru

Materials for thermal insulation of a pitched roof

Roof insulation technology involves the use of various materials. The most popular heat insulators include mineral wool and glass wool (in slabs or rolls), plate polymer materials - polyurethane foam, expanded polystyrene. The principles of their installation are similar, but it is worth noting that it is much easier and more convenient to mount plate material.

As a waterproofing, roofing felt or a waterproofing membrane is usually used, impervious to water, but capable of removing moisture from the insulation. The vapor barrier can be made from :

- roofing material;

- polyethylene film;

- parchment;

- foil materials laid with foil towards the attic.

To create a roofing pie with high functional characteristics, it is recommended to use a special vapor barrier membrane to create a vapor barrier: it removes condensate outward from the insulation and does not let steam and moisture into the roofing pie.

Calculation of the amount of metal tiles

To calculate the required number of sheets of material, you first need to determine the type of profile and the manufacturer of the metal tile - you will need the exact dimensions of the material itself, and each profile has its own. Then it is necessary to make accurate measurements of the slopes - the length, height, if any, it is necessary to measure all the protrusions or other decorative elements that will need to be sheathed with roofing material. If the roof has a complex shape, it is better to draw its plan, put down all the dimensions and then sit down for the calculations.

Number of rows

It is best to look for metal tiles not in stores or markets. It is advisable to go directly to the manufacturer. It's not just the price - it may not differ very much, but the fact that many workshops / factories offer to cut sheets of the required dimensions. The minimum sheet height is 0.7 m, the maximum is 8 m.That is, you can order the required number of sheets covering the roof slope from the ridge to the overhang (including the ledge).

This option is good because the metal roof will not have horizontal joints, which means there will be less chance of a leak. The second plus is the minimum amount of waste and a smaller amount of the material itself (due to the absence of horizontal overlaps, several square meters are saved). Cons - difficulties with delivery, lifting long sheets upstairs, inconvenient installation.

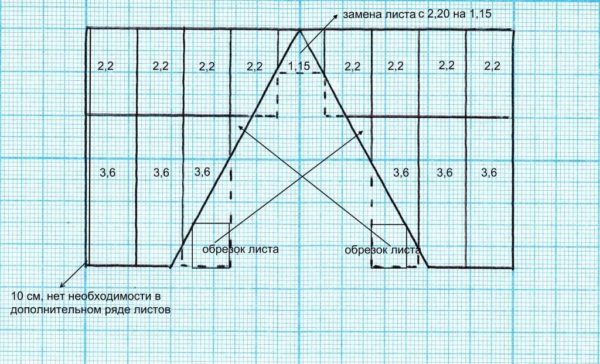

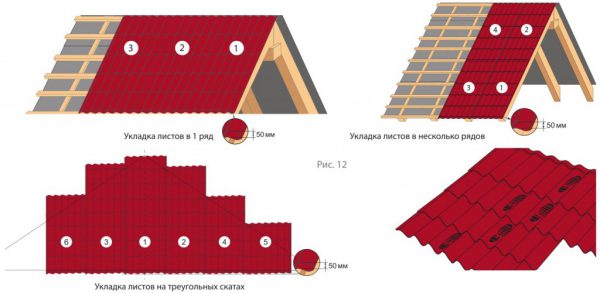

Calculation of a rectangular roof slope

When using sheets of standard sizes, the height of the roof slope is divided by the useful length of the sheet. The resulting figure is always rounded up. The useful length is obtained after the horizontal overlap is subtracted from the total length - from 100 to 200 mm. The flatter the slope, the greater the overlap of the sheets is necessary so that precipitation cannot enter the under-roof space. On roofs with an angle of inclination up to 12°, one sheet overlaps another by at least 200 mm, with an inclination of 12° to 30°, the overlap is 150-200 mm, more than 30° - 100-150 mm. The specified amount of overlap is subtracted from the total length of the sheet, this will be the “usable length”.

An example of calculating the number of rows of metal tiles on the roof. Let the length of the slope be 4.5 m, the useful length of the sheet is 2.3 m. Divide 4.5 by 2.3, we get 1.95, round to an integer - we get 2 rows. In this case, only a small part of one sheet will go to waste, but there are times when more than half is cut off. This is very unprofitable, since you can’t use this piece anywhere else.

Number of sheets in a row

Take the length of the slope and divide by the useful width of the sheet. This parameter is indicated in the technical specifications for the metal tile. Most often it is 110 cm (1.1 m). The resulting number is rounded up, we get the number of sheets in a row.

An example of the calculation of sheets of metal tiles in a row. Let the length of the overhang be 8 m, the useful width of the sheet is 1.1 m. When dividing, we get 7.27 pieces, but we round up to a larger integer and get 8 pieces in one row. Moreover, more than 2/3 of one sheet will go to waste.

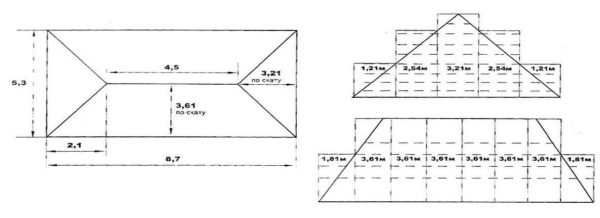

Features of hip roofs

In hip roofs, the slopes have a triangular or trapezoidal shape. Here it is necessary to select the length of the sheet - to minimize the amount of waste.

An example of the layout of sheets of metal tiles on a hip roof

The height is chosen so that no more than half goes to waste. It is quite difficult to do this manually, and still there is a solid error - there will be 20-25% more waste than when calculating using programs. They are usually available from vendors and manufacturers. It is better to provide them with an accurate calculation, and at home to pre-measure the parameters of the roof (or call a measurer), and then try to choose the dimensions yourself. Then it will be possible to compare the amount of material needed, calculated by you and proposed.

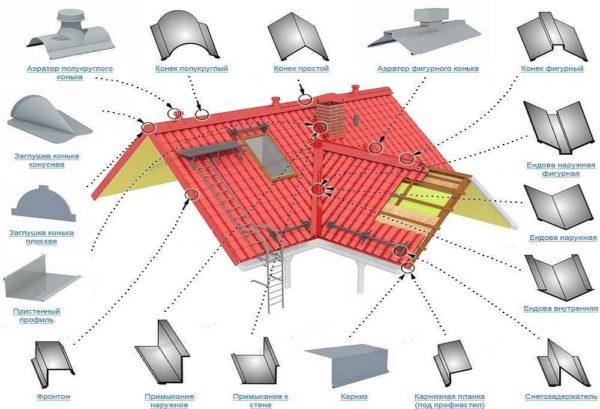

Determination of the number of additional elements

Roofing from a metal tile requires a large number of various additional elements (additions) that form the ridge, the edge of the overhang, the sides of the slope, the passage of the pipe, the valley (the junction of two adjacent roof slopes). With a simple gable roof, ridge elements and plugs, cornice and gable strips will be needed. That's all.

What are the additional elements for a roof made of metal and why are they needed

Despite the wide variety of extensions, they are all considered the same. Take the length of the surface on which you want to mount and divide by the useful length of the element. It is usually standard and is 1.9 m (total length 2 m). The result is rounded up.

The device of safety elements and their purpose

Stairs

To climb to the roof, you need a stable ladder.It consists of wall and roof ladders with brackets. Brackets are required in 4 pieces per section, they are placed in the place of the lower wave bend, where the crate is solid. Both the brackets and the top of the roof ladder are fixed with bolt screws. The wall ladder is installed so that the uppermost step is opposite the edge of the eaves. At the same time, the wall staircase itself must be aligned with the roof staircase.

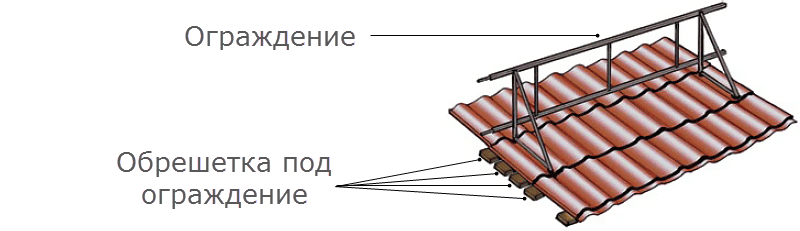

roof fencing

These metal elements are a necessary condition for work on the roof. They are fixed with the help of special supports to a continuous crate through the lower part of the wave, sealing with a rubber gasket. See photo above.

transition bridge

Walkways are needed for safe walking on the roof from the attic window, hatch or stairs. They are fixed in the same way as the fences, only a continuous crate is not required.

Snow guards

Snow guards have a tubular design, are made of metal, painted in black, brown, red or green. They are installed along the entire perimeter of the roof, above the cornice overhang. In addition, they must be placed above the entrance to the house, attic windows, as well as above each level of a multi-tiered roof.

>Scheme of the roofing system Metal Profile

Below is a diagram of the roofing system of Metal Profile. On it, all the nodes discussed above are connected into a whole roof.

flat roof insulation

What should be used

- Bearing base.

- Vapor barrier.

- Roll material (roofing material).

- Insulation.

The bulk layer on a flat roof consists of a cement-sand mixture and a drainage layer.

The order of the layers in the "roofing cake" depends on the type of roofing. In the traditional type, the insulation is protected by a waterproofing carpet, and in the inverse type, vice versa.

How to insulate the roof

Flat roof insulation.

To begin with, the roof should be thoroughly cleaned of excess moisture, foreign objects and dirt.

This item should be given special attention, excess moisture will saturate the space in the sub-roofing layer with wet steam and penetrate into the open pores of the insulation

As a result, it can even lead to swelling of the roofing and the formation of air pockets, which can significantly affect the insulation.

Next, a waterproofing coating should be applied to the insulation, it is important to do this immediately, avoiding any water ingress on a flat surface

To evenly distribute the load, during installation, workers must move strictly along the inventory walkways. It is important to carry out the laying of thermal insulation “toward yourself”, starting from the edge opposite from the exit to the roof.

These simple rules require very careful study, but your work will not be in vain, and in return you will receive high quality thermal insulation.

Often, when installing roofing material, big problems arise, and as a result, it is necessary to change the truss system, which has become soaked and completely deteriorated due to insulation that was previously done incorrectly.

Therefore, the insulation of the roof must be approached with all caution. At the roof of a private wooden house, the rafters can also get wet, the crate can become unusable, and all this is literally in just 5 years.

Therefore, it must be mounted correctly and on time, as soon as the team makes the truss system. and insulation can be installed after the installation of the roof.

Share this helpful article:

Stages of work on the insulation of pitched roofs

The scheme of roof insulation is quite simple. First of all, you need to measure the distance between the rafters. Cotton wool insulation boards should be cut according to the results obtained, adding 1 centimeter. This will allow you to fix the heat insulator by surprise between the rafters. This stage of work is greatly simplified if the roofing system is initially designed and installed for the use of plate heaters of a certain width.

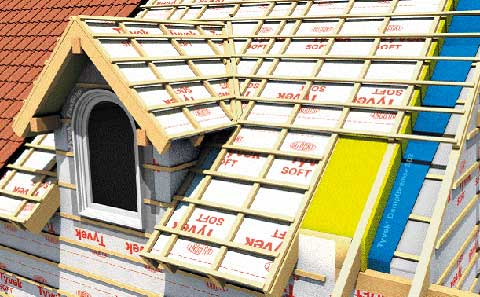

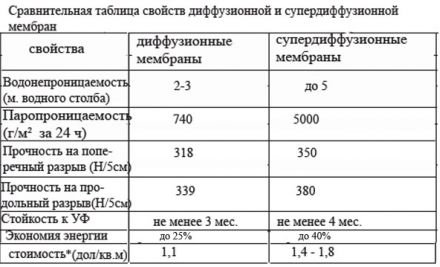

If there is no waterproofing between the rafters and the already installed roofing, the hydro-barrier must first be fixed. The membrane should envelop the rafters, it is most convenient to fix it with a construction stapler to the rafters themselves and to the roofing sheathing in the openings between them. The waterproofing must be led under the overhang at the bottom of the roof to ensure the removal of moisture.It should be borne in mind that with this method of attaching the hydrobarrier, the insulation has to be mounted without the necessary air gap. For this reason, it is recommended to use a superdiffusion membrane as a waterproofing.

If there is a waterproofing layer under the roofing, nails are stuffed onto the rafters in increments of about 10 cm. The nails should be located at a distance of 3-5 cm from the waterproofing layer. Between the nails it is necessary to stretch the polyethylene thread or cord, knocking them to the end. This will help create an air gap between the hydrobarrier and the insulation. If the heat insulator is planned to be fixed with a cord, and not with a sheathing for the inner lining, nails must also be stuffed along the outer edge of the rafters.

If, when determining how to insulate the roof of the house, a cotton slab insulation was chosen, then the prepared elements must be slightly squeezed and inserted between the rafters

When using stiffer foam boards and similar materials, it is important that they are accurately sized so that the boards fit snugly into the opening. Warming is recommended to be carried out in two layers.

If it is necessary to mount in the opening not solid sheets, but narrower fragments, joining them in length or width, it is necessary to ensure that the joints of the second layer do not coincide with the joints of the first. The heat insulator should not protrude beyond the plane of the rafter legs. If the rafters are not wide enough to mount two layers of insulation, an additional beam is nailed to them.

The heat insulator is fixed between the rafters with a stretched cord fixed on pre-stuffed nails. Or, as a fastener, a crate of slats is used, designed for mounting the interior cladding of the room. The slats are nailed to the rafters in increments of 30-40 cm. In this case, the vapor barrier is fastened with a stapler to the rafters before the lathing is installed: the thickness of the slats allows you to create the necessary air gap between the vapor barrier and the sheathing.

When installing the vapor barrier, special attention is paid to the tightness of the layer. The panel is laid with an overlap of at least 10 cm, the joints should be glued with adhesive tape in two layers

It is necessary to install the vapor barrier around the chimney and at the junctions with the walls with the highest quality. At the final stage, the cladding is installed using wood-containing or gypsum boards.

How to insulate the roof of the house, you can learn in detail from the video.

Laying technology

The laying of the metal tile is carried out after the completion of the assembly of the truss frame and the crate. To avoid wetting the wooden frame elements, installation must be carried out in dry weather. For safety reasons, it is forbidden to work at height in windy weather. To qualitatively lay the metal profile. There is the following instruction:

- A waterproofing material is laid on top of the rafter legs, starting from the roof overhang. Laying is done with a slight sag so that the waterproofing does not burst under water pressure. The film is attached to the rafters with a stapler, the overlap between the strips is 10-15 cm, gluing it with adhesive tape.

- Along the rafters, right on top of the waterproofing, counter-battens are installed, which form the ventilation gap necessary to protect the roofing material from condensate.

- Then, perpendicular to the rafter legs of the frame, the crate is fixed to the counter-lattice with a step equal to the wavelength of the metal profile.

- Carry out cutting sheets of metal tiles to the dimensions of the slope. If you buy material directly from the manufacturer, then the cutting is carried out at the factory, so there will be no horizontal joints between the sheets. You can cut a metal profile outside of production with a circular saw, electric jigsaw or hacksaw.

- Start laying from the lower right edge of the slope.If laying is carried out in one row, then the sheets are attached one after another. If the installation is in 2 rows, then first the outermost sheet is laid from the bottom of the slope, then the sheet is fixed above it, then the 2nd sheet of the first row, and so on.

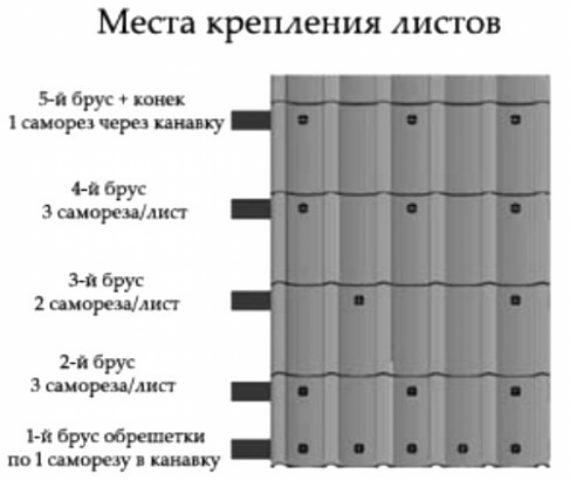

- The sheet is fastened to the crate using roofing screws with a rubber press washer, which closes the mounting hole from water penetration. Self-tapping screws are screwed strictly at right angles to the surface of the roofing material, leaving a gap of 1-2 mm so as not to deform it. To fix 1 sheet, 10-15 screws are required.

- During installation, the metal tile overlaps each other for 1 wave. The place of overlapping sheets is fixed by self-tapping screws through a capillary groove.

Note! When fixing the metal tile, it is important not to twist the self-tapping screw in order to avoid deformation of the material and chips on the polymer coating. To do this, it is better to work with a screwdriver at low speeds.

Material laying technology

Sheet fastening scheme

Location of attachment points

Styrofoam

This material plays a fairly significant role in any construction. Not every heater, with such excellent characteristics, also has such an affordable price. When performing thermal insulation measures with your own hands, you can significantly reduce the cash costs during the operation of the building, and the selection of high-quality insulation will help save electricity that is not cheap at the present time, and roof insulation will help in this. A metal tile is a material that will be quite profitable in economic terms due to the price-quality ratio.

An important element of the roofing crate

To create the crate, bars with a section of 50/50 mm and an edged board with a size of 32/100 and 50/100 mm are used. At the bottom of the roof slope, along the cornice overhang, two 50/100 boards are nailed. Then, a counter-lattice of 50/50 mm bars is stuffed over the waterproofing. The bars are nailed along the rafters, from the ridge to the bottom. On top of this counter-lattice with a certain step, the boards of the crate are horizontally fixed. The step of fastening these boards will depend on the type of metal tile profile which is planned to cover the roof.

Skate deck

The uppermost part of the roof needs to be reinforced. To do this, you need to nail a pair of boards on each side of the ridge bar.

From the end of the roof, you need to nail boards larger than the main crate, to the height of the metal tile profile.

A valley is an internal junction of two roof slopes. In places where the valley passes, the crate is made continuous.

roof fencing

It simply has to be reliable, therefore it is made above the overhang of the eaves. For reference, you can take the height of the bearing wall. The crate in these places needs to be solid. Therefore, additional boards are added between the ordinary crate and a solid base is made.

Types of waterproofing substrates

Condensation formation depends on whether the roof is warm or cold. Its intensity and volume are directly related to the temperature above and below the substrate.

In total, there are three types of films:

classic film

It is important to observe ventilation in two circuits:

- Between roofing material and waterproofing

- Between waterproofing and insulation

The choice of thermal insulation material

For thermal insulation of a roof with a cover made of metal tiles, it is better to use heat insulators with a fibrous structure. The most common of them:

- glass wool;

- mineral wool.

mineral wool

Mineral wool and similar materials with a fibrous structure have remarkable thermal insulation properties.They very effectively remove excess moisture from under the roof space to the external environment. A specific film of membrane fabric will not allow condensate to stay inside the building.

When performing work on the insulation of the roof from the inside of the attic room, the mineral wool must be cut in advance into fragments that have the required dimensions with an allowance of 2 or 3 centimeters. Before mounting the insulation material in the gaps between the rafters, it needs to be compressed a little. At the end of the installation work, the insulation will straighten out again and completely occupy the space intended for it.

Styrofoam

As a material that is easy to self-install and affordable, you can use the well-known foam. It weighs little, is produced in the form of plates and does not create additional load on the roof structure.

Styrofoam also has its flaws:

- insignificant steam conductivity, which threatens with accumulation of condensate under the roof and dampness in the house;

- the material attracts rodents who like to build their nests in it, which will significantly harm the insulation of the attic.

polyurethane foam

This material can be applied in foam form to any machined surface, regardless of its shape and design complexity. The process takes place using a specific portable installation with a sprayer, from which the substance is supplied under considerable pressure. Thus, it is possible to carry out the insulation of the plane, regardless of its angle of inclination.

In addition, the use of polyurethane foam eliminates the need to lay a vapor barrier layer that would protect elements of the decorative finish of the living space from the penetration of condensate. The cost of such material is less economical than other materials used for heat insulation.

Ecowool

This building material is made in a compressed form, and it will need to be loosened before being used for its intended purpose. Often, in order to return the material to its original shape, make it more voluminous and apply it to the surface to be insulated, special blowing equipment is used.

The technology of laying polyurethane foam and ecowool is not too complicated; work can be done without involving a structure to help. The use of insulation materials in rolls or panels will require stricter adherence to the rules of installation technology.

This is interesting: Types of alarm for giving - we explain in detail

Rules for working with heat insulators

When working with a heat insulator, you must follow a number of rules so that it performs its functions, and the insulated roof will serve you for many years.

Storage and installation

Firstly, moisture should not get on the surface of the materials either during storage or during installation, therefore, it is necessary to store the insulation in a room well protected from moisture.

Prevention of moisture ingress during installation is carried out by arranging a waterproofing layer

It reliably protects the material from getting wet, preventing it from soaking in water - this is an especially important condition for the normal use of mineral wool.

Instruction

Read the instructions for the isolator carefully before using. Many people believe that all the same type of heaters are the same, but this opinion is erroneous. Only goals are the same for such materials, and the installation process, storage conditions and other important points are often different.

improvised tools

Never neglect the reliability of improvised tools. No matter how high-quality the materials for insulating a metal roofing roof are, if you cut them with a dull knife, nothing good will come of it, just ruin the insulator.

Safety regulations

Remember the elementary safety rules regarding not only the thermal insulation of roof structures, but also any other construction activities.

We are talking about wearing goggles, durable gloves, a respirator, etc. Even a small metal crumb that accidentally gets into the eye can cause serious injury.

Material characteristics

A metal tile is a roofing covering based on galvanized steel with a polymer or paint layer, used for the construction of a cold or warm roof. It is produced by cold rolling from steel billets. The strengths of metal tiles are:

- A light weight. One square meter of metal tiles weighs 5.5-6.5 kg, which allows laying on a sparse crate without reinforcing the roof truss frame.

- Long service life. High-quality metal tiles, as well as additional elements made of galvanized steel, have been in operation for more than 20-25 years with proper maintenance and timely repairs.

- Corrosion resistance. Zinc layer, polymer coating reliably protect steel from water, because the metal tile does not corrode.

- High bearing capacity. Due to the wavy profile, the metal tile has a high bearing capacity and does not deform under the influence of intense loads.

- Resistant to temperature changes. Temperature drops do not affect the strength properties, the integrity of the material, so it is used in all climatic zones.

Important! It is recommended to lay the metal profile coating on single-pitched and multi-pitched roofs with a slope of at least 12 degrees. For the installation of a cold roof, you will need directly roofing material, as well as additional elements: valleys, ridges, eaves or gable strips, drainage elements, spotlights for filing cornices, lightning protection, snow retainers

The design of a warm roof implies the additional use of insulation and vapor barrier.

The structure of a sheet of metal

Possible sizes of sheets of metal