With the advent of materials such as gypsum fiber sheets, many interior finishing processes have received new options. In particular, it became possible to lay GVL on the floor, which greatly simplified the process of leveling the floors.

What is GVL?

Gypsum fiber sheet at first glance, it is very similar to the usual GKL. But if the latter has a layer of gypsum enclosed between two layers of cardboard according to the sandwich principle, then GVL is reinforced throughout its entire thickness. To do this, manufacturers add split cellulose to the gypsum mortar. GVL significantly exceed conventional drywall in strength, but also weigh much more.

With the help of special additives, moisture-resistant gypsum fiber sheets are obtained, which can be used not only for wall decoration in wet rooms, but also to be laid on the floor in ordinary rooms.

Benefits of GVL flooring

Traditionally, for the arrangement of floors, a concrete screed or a wooden covering laid on a lag structure was used. Both methods have significant disadvantages:

- The cement screed has a considerable weight, and it takes several weeks for it to dry completely. Ceramic tiles laid on such a base are not appropriate in all rooms.

- Wooden floors can dry out over time, leading to cracks or an unpleasant squeak. In addition, they are susceptible to rotting and attack by various microorganisms.

Installing floors with GVL has many advantages over traditional methods:

- No thorough preparation of the subfloor associated with mixing or applying various solutions is required.

- The assembly of the GVL coating can be carried out even in a cold, unheated room. The only condition for the microclimate is the absence of high humidity.

- Installation of such a floor does not require special building skills and will not take much time.

- Any floor material can be laid on GVL to create a finishing coating: linoleum, laminate, parquet or carpet.

- The operation of the floor can be started immediately after laying the gypsum boards.

The base obtained with the help of GVL complies with all building codes, is resistant to fire and is environmentally safe. It is not as massive as a cement screed, which is important for flooring in old houses or balconies. And it is less prone to defects after a certain period of time, when compared with lag wooden floors.

GVL also has certain disadvantages:

- In the process of unloading, carrying and installing GVL, some care must be taken, since the material is rather brittle.

- The GVL used for the floor, for example, the moisture-resistant Knauf Superpol 1200 x 600 x 20 mm, have a considerable weight, about 20 kg.

- Relatively high price moisture resistant GVL noted by many ordinary people as a serious drawback of this material. But if you calculate all the costs of arranging a cement screed or a wooden floor, take into account the work of specialists, without whom it is often impossible to do, and the loss of time, then this drawback will not be so significant.

GVL from Knauf

In any finishing or repair work, it is important to use high-quality materials. For the arrangement of floors, many experts recommend using GVL for the floor, moisture resistant 1200 x 600 x 20 mm, manufactured by the German company Knauf. Over the years of work on the Russian market, it has confirmed the high quality of its products.

The manufacturer obtains individual floor elements by gluing two moisture-resistant sheets. At the same time, they are slightly shifted relative to each other in two directions, which leads to the formation of folds 50 mm wide along the entire perimeter of the sheet.This design greatly simplifies the assembly of the flooring, reduces the consumption of fasteners, and facilitates adaptation to structures with a complex surface shape.

Each floor element has a size of 1200 x 600 x 20, a weight of about 18 kg and a usable area of 0.75 m2.

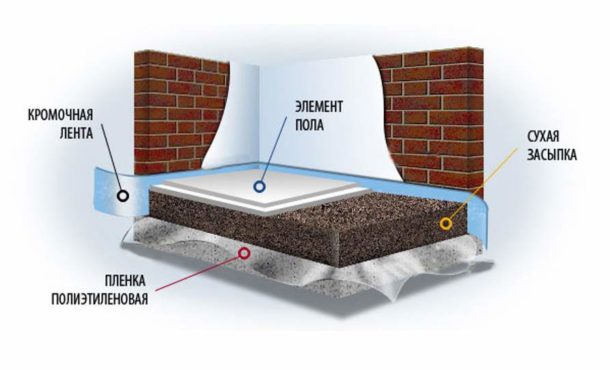

In addition to GVL, to equip the floor using Knauf technology, you will need:

- Vapor barrier. Usually it is a polyethylene film.

- Knauf special edge tape for soundproofing floors.

- Dry backfill. It can be fine expanded clay, sand or other material that does not shrink.

Before installation, all materials must be allowed to acclimatize to the room for several days. At the same time, they must be stored flat on a flat surface to avoid breakage of the material under its own weight.

Installation of GVL floors

The process of installing a GVL floor is quite simple.

- The base is thoroughly cleaned of debris (you can use a construction vacuum cleaner for this purpose), small cracks are repaired, and then the base floor is covered with a deep penetration primer.

- The floor level is marked. It must be strictly horizontal. Lines are drawn along the entire perimeter, limiting the backfill layer.

- A waterproofing layer is laid. Polyethylene film or other materials can be used. All joints must be glued with adhesive tape, vapor barrier is brought to the walls to the marked level.

- Knauf edge tape is laid around the entire perimeter. It will not only provide sound insulation, but also prevent the destruction of GVL during thermal expansion. The tape is attached with a stapler or tape.

- Expanded clay, sand or other dry screed material is backfilled. It is easier to backfill according to pre-set special beacons, mounted on gypsum stakes. By moving the metal rule along two adjacent beacons, the backfill is leveled, after which the beacons are taken out. Material is carefully added to the recesses remaining after them and finally leveled.

- Produce cutting sheets. Cut GVL You can use different tools, from a conventional wood saw to a jigsaw.

- Lay GVL. Usually they start from the door and cut off the folds adjacent to the wall at the first sheets. Sheets are placed in a checkerboard pattern, gluing the joints. After laying the GVL, they are additionally connected through the folds using self-tapping screws, placing them in increments of 10-15 cm.