All major error codes and their interpretation and solution

Consider the main errors of Ferroli gas boilers and options for their elimination:

| The code | Decryption | Ways to solve the problem |

| A01 | No flame (unsuccessful ignition attempt) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False presence of flame (voltage detected on the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of drops of condensate on the control board |

| A03 | Boiler overheating | Flush the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Failure of the coolant temperature sensor | Replace element |

| A09 | Gas valve failure | Check operation, replace element |

| F04 | Overheat flue gas thermostat | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke exhaust system, fan shutdown | Replace fan |

| F08 | Overheating of the primary heat exchanger | Flush the heat exchanger, if necessary, replace it |

| F10 | Breakage or short circuit of the temperature sensor OB | Repair contact or replace sensor |

| F11 | Break or short circuit of the DHW temperature sensor | Repair contact or replace sensor |

| F14 | Malfunction of the sensor No. 2 of the direct line of the heating circuit | Repair contact or replace sensor |

| F34 | Supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible |

| F37 | RH pressure drop | Detect an RH leak and fix it |

| F40 | Excessive RH pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit pressure switch OB | Repair or replace relay |

| F50 | Malfunctions in the control board | Replace control board |

Ferroli boiler errors are divided into critical (A) and non-critical (F). Those with the letter A lead to an independent blocking of the boiler, and those with the letter F do not lead.

The main malfunctions of Ferroli gas boilers

The design of Ferroli boilers is distinguished by a well-thought-out and high-quality study of all components and details.

However, any system has weaknesses, and gas boilers are no exception.

The operating conditions of some parts of the units are very difficult, temperature loads contribute to the occurrence of the phenomenon of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There can be different causes and ways to fix them, one of the most common problems.

- Pressure drops or rises. This is a serious problem that results in either leakage of the heating medium, which causes overheating and blockage of the boiler, or overpressure and blockage. Especially dangerous is the increase in pressure, from which the parts of the unit can burst.

- Failure of the fan or circulation pump. The loss of both functions means the system is unable to function - the inability to remove smoke causes sudden overheating and blocking, and the lack of liquid movement has the same consequences, only detected by other sensors.

- Malfunctions of the electronic control board. The cause of these problems is most often an unstable supply voltage or lack of good grounding. The boiler electronics are very sensitive to any changes in the operating mode. When drops or jumps appear, it starts to issue a continuous series of errors that do not repeat when restarted. Often there is an accumulation of static charge on the case, which is transferred through the mass to the control board and ionization electrode, which causes the appearance of an A02 error (the system sees a flame when there is none).The solution to the problem is to completely disconnect the boiler from the power system for a while and restore (or create) high-quality grounding.

In addition to the above, there are a lot of problems with the combustion mode:

- Too little flame.

- Spontaneous start of combustion.

- No DHW heating.

- A sharp flash of flame with a pop.

All these problems are associated with a deterioration in the gas supply due to clogging of the nozzles, failure of the thermocouple or fuel valve coil.

Instruction manual how to start

The operation of Ferroli boilers is not distinguished by any specific actions and procedures.

The owner is only required to organize periodic maintenance, cleaning the body and insides of the boiler, and maintaining the burner nozzles in proper order.

The boiler start-up procedure resembles the method of ignition of other gas units.

A feature is the need to maintain a pause between start attempts, during which the code D3 or D4 appears on the display (50 or 30 seconds).

The first code occurs after a critical error occurs and the unit is blocked.

Until the required time interval is met, a restart is not possible.

The second code appears between attempts to start normally, if the previous one was unsuccessful.

This is usually due to the presence of air in the pump, piping or heat exchanger. Attempts are repeated until the air is removed from the boiler.

Accessories

For each category of boilers, the manufacturer also provides additional accessories. In particular, wall-mounted double-circuit models can be supplemented with a kit for smoke exhaust systems and devices that allow the equipment to operate on liquefied gas. In turn, the Ferroli floor standing gas boiler can be equipped with boilers, hot water priority systems, turbo nozzles and devices for cascade control. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic switches, a mounting manifold frame, as well as special sets of fittings for connecting boilers.

Why does pressure drop

The pressure drop in the boiler can be the result of three reasons:

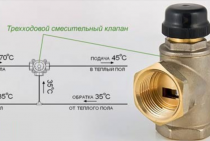

- The appearance of a leak in the heating circuit (including in the boiler itself). A feature of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is fed. In this case, you need to find the place of the leak. First of all, you need to check the condition of the drain cock or valve, whether it is open or out of order. If no malfunctions are found in this node, the entire heating circuit is sequentially checked. Sometimes they forget to close the discharge valve on the radiators, fistulas appear on the pipelines, connections fail. It is most difficult to detect a leak if the faucet feeds a water-heated floor system poured into a concrete screed. You can detect a problem by a wet spot on the floor or on the ceiling of the lower floor, and for this you often have to remove the floor covering or stretch ceiling.

- Failure of the circulation pump. This problem is immediately detected by the self-diagnosis system, and it is easy to check the operation of the pump. It is enough to make a visual inspection of the element, and take appropriate measures.

- Expansion tank diaphragm rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intensive with an increase in the temperature of the RH. If it turns out that the problematic element is precisely the expansion tank, urgent measures must be taken to repair or replace the assembly.Otherwise, with the thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repair and restoration of the boiler.

The boiler does not start, the burner does not turn on

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board failed.

- The boiler is blocked due to a malfunction of any node.

Most of the possible causes are detected by the self-diagnosis system, and the corresponding code is displayed on the display.

However, some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure that you are ready for work. In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the shield after the connections are made, the wires are mixed up.

Ferroli wall mounted gas boilers

Wall heater Italian company Ferroli.

Ferroli wall-mounted boilers are available in different configurations and capacities, so you can choose a unit according to your requirements and budget. The first characteristic is the number of circuits. So, heaters can work not only to heat water in the heating system, but also simultaneously supply the house with hot water. Accordingly, single-circuit and double-circuit boilers are distinguished.

The second aspect is the type of combustion chamber and its configuration. The combustion chamber may be open or sealed. Open combustion chambers, like a conventional stove burner, burn the air out of the room (there is no fire without oxygen). Sealed chambers draw air from the street through a special chimney pipe called a coaxial chimney.

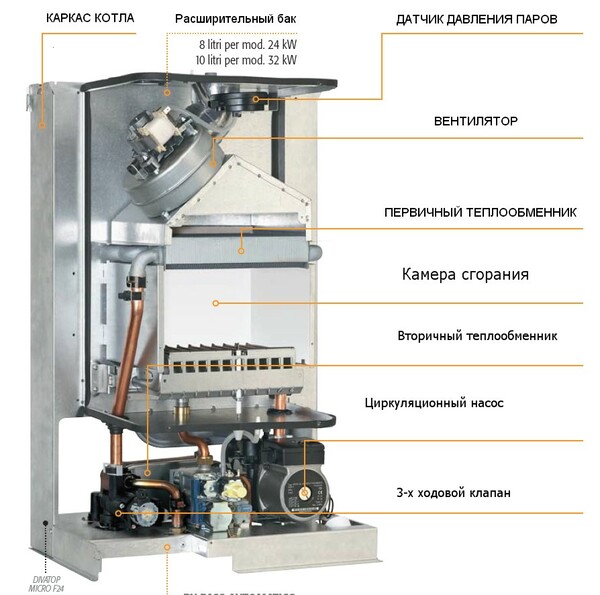

A heat exchanger (one or two) is installed in the combustion chamber. One heat exchanger (bithermic) is a pipe in a pipe, into which pipes are cut for separate smoke removal. The heat exchanger is made of copper. If there are two heat exchangers, then they are separated from each other. The primary is made of copper and the secondary is made of stainless steel.

Complete set of Ferroli gas boilers according to the instructions:

- heat exchanger (one or two);

- gas valve - Siemens or HoneyWell;

- three-speed circulation pump Wilo;

- branch pipes for smoke removal - separate smoke exhaust system;

- bypass;

- Control block.

There are models with and without LCD display. The display shows information about the parameters of the heater and errors that occur during operation. The display lights up blue. The DivaTop 60 model is available with a built-in 60 liter boiler.

The efficiency of the Ferroli wall-mounted heating boiler of any model is approximately 93%. The minimum power is 7.2 kW, the maximum is 40 kW. The heat carrier for high-temperature heating systems, the unit heats up to 85 degrees, and water for hot water supply - up to 55 degrees. Boilers operate on natural and liquefied gas. The nominal energy consumption is indicated in the passport for each model. The inlet gas pressure must be at least 20 mbar for natural gas and 37 mbar for liquefied gas.

How effective is vermiculite for ceiling insulation, read here.

Conclusion

Equipment that can work forever and not fail does not exist.

The most valuable devices are those that can help the owner or repairman in determining the problem that has arisen, to demonstrate to him the source or cause of a particular problem.

Ferroli gas boilers have this capability, directly indicating a defective or questionable part using an error code on the display.

This makes it as easy as possible to find the reasons for the failure of a particular node, saves time and allows you to more accurately detect problems.

In some situations, the presence of a self-diagnosis system literally saves the life of the owner and his family members, turning off the boiler in the event of a serious danger.

Protection provides an increase in the service life of the boiler, saves money on expensive repairs and allows you to create a comfortable and cozy environment in the house.

Today we will consider the types of gas heaters of the Italian manufacturer Ferroli. So, there are two types of Ferroli boilers: wall and floor. Units that are suspended are also divided into two groups - conventional and condensing. The latter are characterized by high efficiency.