Thermal heads for underfloor heating

Chinese automation for warm water floors! Test!

Heating in a private house has already been done. But we decided to add a warm floor in the washing room. Room area

Proper connection of the underfloor heating to the boiler.

Underfloor heating (principle of operation)

Those who have been following my work for a long time know that I am not a stranger to any simple ways to adjust the floor.

Automation of water floor heating. After watching the video, you will learn: - how to choose a room regulator, - which ones.

How to make a warm floor from heating? I connect a warm floor to a heating system without a collector

How to make a warm floor from heating with your own hands? In the house I made 3 contours with warm floors: in the kitchen, a bathroom.

How to assemble a three-way mixing unit for underfloor heating yourself. Crimping Underfloor heating own.

Water floor thermostat sensors

Before using the control device, you need to know how to regulate the temperature of the warm floor and what elements the system consists of.

Thermostat sensors monitor temperature:

- heated floors;

- air in the room.

The fact is that when installing a thermostat, a number of conditions must be observed:

- in the immediate vicinity of the device should not be sources of cold or warm air;

- sunlight cannot fall on it;

- lack of drafts;

- it must be placed so that the device can accurately display the temperature in a given room, which means that it must be installed at a height of 1 to 1.5 meters from the floor surface.

The remote floor temperature sensor is a small device attached to the end of a long cable. This device must be fixed to the floor at a distance of at least 50 centimeters from the walls. It must be installed at an equal distance in relation to the nearest pipes with a heat carrier. The opposite end of the cable is brought to the thermostat and connected to the desired terminals (read: "Correct installation of the floor heating thermostat and operating conditions").

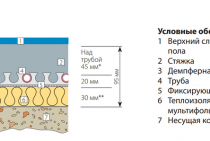

Mount the floor sensor before pouring the screed when laying the heating circuit. But since the devices can break, it is desirable to place them in a special corrugated sleeve to ensure the possibility of replacement. The end of the hose in the screed must be insulated, otherwise cement mortar may get into it.

The second end is placed in a strobe on the wall and led to the mounting box of the device. Such a sequence of mounting water floor sensors is not an easy task, but if the device breaks down, it can be changed quickly and easily.

In the case when a floor heating system was used, the installation method is similar. In this case, the corrugated sleeve must be attached to the system and must not be pinched.

Variety of floor water structure regulators

The fundamental difference between different control devices lies in the way the required temperature is set:

- mechanical modifications. These devices rarely break down and are affordable. This type of water floor heating regulator has a simple scale that makes the setting process easy and understandable. The required temperature is set using a rotating disk. Sometimes on the front panel of thermostats for a heated water floor there is a lever designed to turn it on / off. There are no other functions for such devices. The average price for them is 15 euros.

- Electronic devices. Their functionality is similar to the mechanical version, but it is implemented differently.The electronic model provides for a digital screen that displays the current or set parameters. You can also see several buttons on the devices. They may have arrows with the signs “up” and “down”, which serve to gradually change the temperature regime. Estimated cost is 20 euros.

- programming models. Adjusting the temperature of the warm floor with the help of such a device allows you to both maintain stable heating and change it automatically depending on the time. Models are sold that have the ability to program the temperature regime during the day and on the days of the week. This feature allows you to save energy, and therefore money, and at the same time live in comfortable conditions. For example, the temperature can be lowered when all family members are away from home, and raised before they return. Some modifications, in addition to a stationary unit located on the wall, are equipped with portable control panels. Now on sale there are models that correct the work through a computer or tablet. The simplest modification, which provides for the possibility of setting the floor temperature over time, will cost no less than 40 euros, and a sophisticated device can cost more than one thousand.

- Multizone modifications. Such thermostats control several circuits and maintain individual parameters in each of them.

- sensory models. The list of functions performed by these devices is the same as that of electronic models. But they are equipped with touch buttons, not tactile ones. The cost is higher.

- Radio thermostats and controllers. Similar systems supplied by European manufacturers are new on the domestic market. For example, Uponor systems consist of radio-controlled servos, a radio thermostat that monitors sensor readings, and a radio controller that receives data from the thermostat and forwards it to the servos. The kit also includes an SMS module that allows you to control the system via mobile communications and monitor its status.

Adjustment of water floor heating

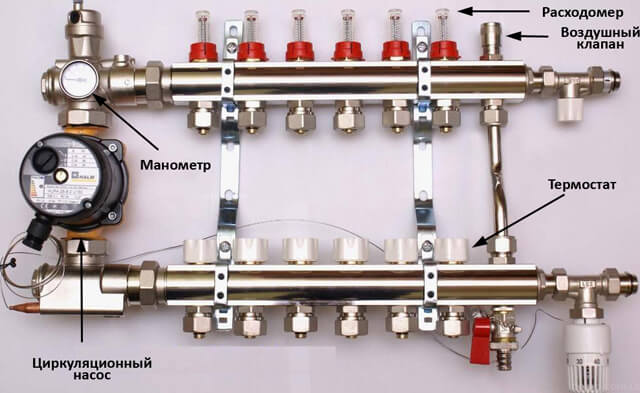

Most often, for arranging water heating of the floor, they use the connection of heating circuits by means of a collector, into which both ends of the pipeline enter: one of them supplies the coolant, and the second returns it back. Hot water at the same temperature enters each of the heating circuits.

Since the length of the pipelines is different, each of the rooms is heated to a different temperature. For example, for a bathroom, this parameter should be 25 degrees, and for living rooms it cannot exceed 22 degrees. To add or reduce the degree of space heating, you need to change the amount of heat carrier supplied to the circuit.

The easiest way to regulate the temperature of a water heated floor is to equip the collector with special valves for inlet and outlet (for more details: “Heat floor collector diagram - how everything should work”). By turning their heads, you can adjust the amount of heat carrier supplied to each of the circuits. In this case, you have to focus only on your own feelings, and this method of adjusting the heating cannot be called convenient.

The sequence of actions in this case is as follows:

- adjusting valves are tightened;

- wait for some time until the floor warms up;

- evaluate the result;

- tighten the valves again, etc.

Since the temperature outside is almost never the same for even one day, the owners of the house have to turn the valves very often, and manually.

The thermostats shown in the photo are usually placed in each room where a floor covering with water heating is installed.In turn, each circuit on the heat carrier supply comb is equipped with servo drives. They, according to the signals, increase or decrease the amount of water supplied to the circuit. Thermostats are associated with specific servos and give them control commands.

Regulators control either the temperature of the warm water floor or the air mass in the room. At the same time, it is necessary to monitor the temperature regime of the air in the room when heating the floor surface is the only way to heat the house.

The principle of operation of the floor heating regulator:

- The desired temperature is set on the equipment case (floor surface or air, depending on the specific model).

- If the parameter deviates in one direction or another, a signal is sent to the servomotors, after which the supply of heat carrier either increases or decreases. As a result, after a certain time period, the temperature returns to normal.

When the pipes are filled with screed, it takes time for the entire concrete mass to heat up or cool down. In the presence of a floor heating system, the inertia is less and then the changes come faster.

Servo drives for underfloor heating systems

There is no way to adjust underfloor heating in automatic mode without a servo drive (another name for a servomotor). This is an electrothermal device, the main purpose of which is to open and close the supply of hot coolant.

The main element of the servo drive is an elastic bellows, which has the shape of a sealed cylinder. It is filled with a substance that can change volume depending on temperature.

Around the bellows there is an electric heating element, which is energized after a signal from the thermostat. When he started to work, the substance in the cylinder begins to heat up and expand. The bellows, which has increased in size, puts pressure on the stem located below, and it shuts off the coolant supply. Since only thermal energy and electricity are used in the operation of these devices, they are usually called thermoelectric.

Servo drives are normally closed and normally open. Their name indicates the position of the valve during a power failure. In the first case, the valve is normally open, and after receiving the signal, it closes. In the second case, everything happens the other way around, first it closes, and then opens.

Varieties of valves according to the principle of the function performed

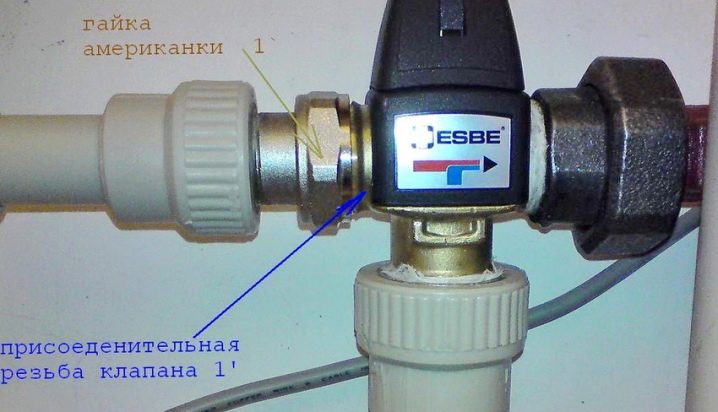

All options for three-way valves, depending on their design, can be divided into types:

As the name suggests, the first type mixes two different streams into one common one. The second type divides one common stream into a couple of different ones, and the third type simply redirects the stream to different directions. It is quite simple to determine which type in appearance, there is a marking on the tap, in the form of a pattern with arrows. It shows one outgoing and two incoming arrows, or vice versa - two outgoing and one incoming. Redirecting cranes may not have a designation, but they have noticeable differences in appearance.

Mixing or separation of coolant flows is used to maintain a predetermined temperature in warm floors, as well as to dilute high-temperature coolant flows to different elements of the heating system. Redirect valves are mainly used in boilers with a double-circuit heater, where the hot coolant is alternately redirected to different circuits.

Other types of devices with which you can adjust the temperature of the warm floor

- For a room whose area does not exceed 10 square meters. conventional valves can be used.It is enough to install two such devices, one at a time, for the water supply and for the return flow, and carry out the adjustment in the same way as it is done on a conventional radiator: screw the valve - lower the temperature, you need to increase it - open the valve harder. The disadvantage of such a mixing device compared to a thermostatic three-way valve is manual adjustment. There are no devices that will show you what temperature is obtained at the outlet, the actions take place by the “poke” method.

- Thermostatic mixers are not only three-way. but also two-way. Such a valve can be installed instead of one of the manual valves (the method of adjustment using a valve described above), and it will already maintain the set temperature automatically.

- For underfloor heating, which will occupy large areas. use a mix node. This device is a whole system of a supply and return manifold, a circulation pump and a thermostatic mixer.

Faucets for underfloor heating systems

Among the Lovato accessories that we offer are various types of three-way mixers with servomotors and thermostats. Three-way mixer "MK3", thermostatic mixer for underfloor heating (fixed point) in two versions and 3-way valve MV3. This selection of shut-off valves guarantees stable temperature indicators of the coolant in the circuits of heating systems (including the heating circuits of the “warm floor” system).

The Vivateks-m company offers a thermostatic mixer for underfloor heating from Lovato in two versions - DN20 - 3/4 "HVTC" and DN25 - 1 "MKTC". The principle of operation of both devices is approximately the same. When the upper bypass is fully open (from the side of the circuit), a significant part of the return heat carrier is taken in, after which it is mixed with the supply water. The thermal valve opens only when it is required to ensure the supply of coolant to the system itself. The lower mixer bypass is normally open when the unit is installed in a system equipped with a boiler and a pump. The thermostat valve is closed if the system does not require hot water, and therefore all water is returned. The three-way mixer DN32 - 1 1/4″ "MK3" from Lovato is presented in a right-handed version, which can be changed to left-handed by simply changing the position of the internal elements. The principle of operation of the device is as follows - the bypass takes a significant amount of return water and ensures its launch for supply. This maintains the supply water temperature balance. DN32 - 1 1/4" "MK3" can also be used as a mixer for underfloor heating.

Three-way mixers DN20 - 3/4″ "HV3" and DN25 - 1" "MK" are produced in versions with servomotor and thermostat. This valve is designed for right hand flow, however, as in the case of DN32 - 1 1/4″ "MK3", the valve can be easily switched to the left hand version by changing the position of the internal elements of the mixer. 2 bypasses (upper and lower) provide the ability to operate devices in systems of various types. Three-way mixers DN20 - 3/4" "HV3" and DN25 - 1" "MK" are attached to the wall using a special bracket. Another device, presented among the accessories from Lovato, is a three-way valve DN20 MV3, which has not only a set of unique technical characteristics, but also a high operational potential. This type of valves is used as a faucet or mixer. The scope of its application depends on what exactly is connected to the device - an electric actuator or a thermostatic head.

All products of the Italian brand Lovato, supplied by our company, are fully certified and adapted to existing Russian standards and norms.

Three way hydraulic valve

This hydraulic valve has three passages. Of these, two serve to supply water flows, the third leads the boiler into the design of the water circuit. In order to prevent metal corrosion, the block body is made of stainless steel. During operation, the thermal floor perfectly responds to the environment, changing the position of the axle boxes and controlling the degree of heating of the liquid at the outlet. The thermal head is equipped with a meter that transmits signals to the actuator (close or open the valve).

Three way valve features:

- it is easy to install;

- mechanical and automatic adjustment is possible in it;

- it is durable;

- it has an average price;

- it contains chemical and hydroprotection.

How to choose a thermostat for a water heated floor

A water heated floor is a concrete screed in which a circuit of heating elements is poured. In this case, a circuit means a pipe through which hot water moves. The coolant is supplied from the heating system and returned to it.

The installation of the circuit can be carried out both in the screed layer and on top of it. Both options have their advantages. But most often, builders prefer to relieve the horizontal water heating system from the physical load of the screed.

The principle of operation is cyclic. First, water from the heating radiator enters the beginning of the warm floor and, passing along the contour, gives off its heat to the surface of the screed. After that, the coolant returns to the central heating and is reheated in order to pass through the circuit again.

The elementary principle of operation and the minimum cost of electricity make this type of heating extremely popular. Cycling, thus, allows the screed to warm up to 36 degrees.

Installation involves its own complexity and algorithm. One of the most important aspects can be called the installation of a limiter if the final floor covering is a laminate or linoleum. These floor coverings should not be heated above 27 degrees. The thermostat (thermostat) allows you to adjust the "climate" in the house with an accuracy of up to a degree, so its presence is mandatory.

Meaning and functions

A thermostat is a device that is designed to control the temperature. This device determines the temperature at a given point in time and compares it with the default value. Thus, the thermostat either turns on the heating in order to reach the desired temperature, or, on the contrary, turns it off if the indicator is reached.

In the case specifically with a water-heated floor, the thermostat performs its functions in stages. With the help of servomotors, this device gives a command to slightly open or, conversely, partially shut off the supply of hot water from the central heating. Such control allows the floor to retain a certain degree of "warmth".

If the electric floor heating is able to heat up to the desired level in a matter of minutes, then the water floor, due to the consistent operation of the regulator, performs its task in a longer amount of time.

A thermostat for a water heated floor is an indispensable attribute and, thanks to its advantages, there is no doubt about its need:

After installation, you will need to understand the control method and some of the nuances. In order to get comfortable in this matter, you only need to spend time once to figure out the keys and menu of the thermostat.

Varieties of thermostats

On the modern market, you can see a whole range of thermostats, which can be divided into four types:

Mechanical devices resemble dimmers - dimmers. Management occurs with the help of a single wheel. As you rotate clockwise, the device turns on and adjusts to maintain a certain degree. The cost of such devices is the lowest when compared with other varieties.They do not have a shutdown function when the required temperature is reached, and this is a significant minus. Despite this, the device performs the control function properly.

The digital analog has a screen with which you can set the temperature to the nearest degree. There is a temporary shutdown function. Management is carried out by three keys. Most of these devices have a memory function that allows you to save the settings you have made even after a power failure.

Software thermostats or programmers appeared relatively recently. With their help, you can create a full-fledged schedule for the operation of a warm floor. Thanks to the time setting, it is possible to designate the exact time when water supply from the heating system starts and stops. Thanks to this function, the floor will heat the room only during those hours when the household is at home. This is a huge energy saving. The cost of such a device is high, but during operation it inevitably pays off in bills for light.

The touch thermostat can be called an innovative invention in this field. It has all the functions of a programmer, but the control is carried out using the touch screen. The convenience of setting is undeniable, but because of the sensor, the cost of such a device is quite impressive.

The thermostat is a necessary component of a water heated floor, without which it is not easy to do. Thanks to the range of devices, you can choose the most optimal option.

Thermostat for water and electric underfloor heating

Thermostat - what is it?

Such a question can be asked by those people who have never encountered it. In principle, it can not be used. No one bothers to connect the warm floor to the outlet, and that's it, it's already working. But it will only last a very short time, and the cost will be expensive. The thermostat (thermostat) for underfloor heating (and not only) will also provide a comfortable temperature in the room

What is important, it will be in it for a long time and it will all cost much cheaper.

These useful gadgets can be classified according to different principles - by placement, by sensors used, by type. However, the most understandable can be called a classification according to the principle of action.

- Electronic-mechanical. This is the simplest type of thermostat. According to the principles of its work, it is similar to a thermostat on an iron. It is not possible to set a specific temperature value. You can only put the wheel in the position you need, and according to the sensations, increase and decrease it. Of the advantages of such a device - simplicity and low price.

- Digital (electronic). According to the principle of operation, it is similar to mechanical. Only the temperature is set using sensors or buttons. You can set a specific temperature value.

- Programmable. These devices not only maintain a certain temperature in the room, but also go further. For example, they can turn off in the absence of the owners or start heating the room for a certain time before their arrival.

Where can thermostats be located?

Thermostats for water and electric underfloor heating can be located both inside and outside the room

There is only one important limitation in their use - they cannot work in a humid environment. Therefore, if you want to install a thermostat in the bathroom, be sure to place it outside

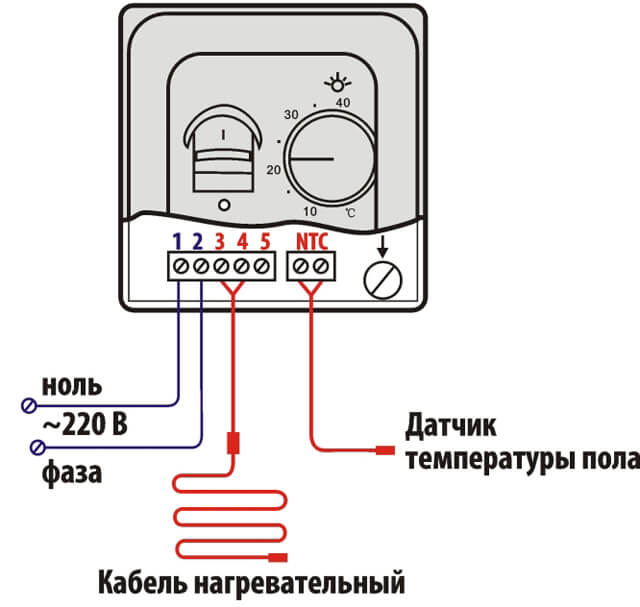

It is on where the thermostat for the warm floor is located that its installation depends. If it will be built into the wall, you need to prepare a niche in which it will be placed. All elements of the underfloor heating must be connected to the thermostat. Usually the wiring diagram is located on the back of the thermostat.

You can connect thermostats for water and electric underfloor heating to the network either directly from the outlet or using a special cable. In the second case, you need to install additional RCDs.

Connecting the temperature controller sensor

This issue deserves separate consideration, because. the control of the operation of the entire underfloor heating largely depends on the signals of the sensors. They also significantly affect the efficiency of the entire underfloor heating system as a whole.

For any configuration, a corrugated tube is used to mount the sensor. In order to place it on the wall, you need to break through the strobe. In this tube, you need to place the wires to the regulator and the sensor itself. Why should this be done? To be able to replace it if the thermostat fails. In this case, all elements are very easy to remove, even if the tube feeds a warm floor filled with cement.

The sensor should be placed between the cable spirals (i.e. directly between the heating elements), and not far from the regulator. The sensor cannot be used separately, so if you decide to buy a thermostat, do not forget to purchase a floor heating sensor as well.

There are no special requirements for these devices, except for safety requirements. That is, you can use, for example, a conventional thermostat for a film floor.

In general, we sorted out all the important issues on thermostats for water and electric underfloor heating.