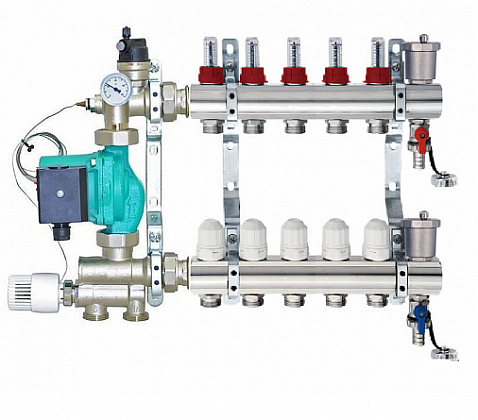

Two pumping and mixing units for underfloor heating in one heating system.

I got two underfloor heating mixers in one heating system.

I made one right away at the first stage of the repair and installed it temporarily.

While this mixer controlled one branch of the warm floor. Then he planned to move it to other rooms at the end of the repair. I laid pipes in the floor in order to connect this branch to the mixer in a new place.

But nothing is more permanent than temporary.

And in a new place installed another of the same mixer.

Someday I will remove the first mixing unit - the collector of the second mixing unit has fittings for connecting this branch and pipes have already been laid.

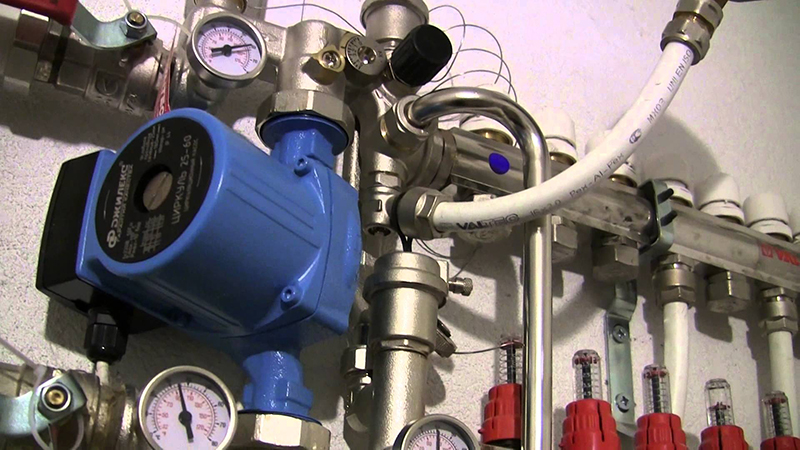

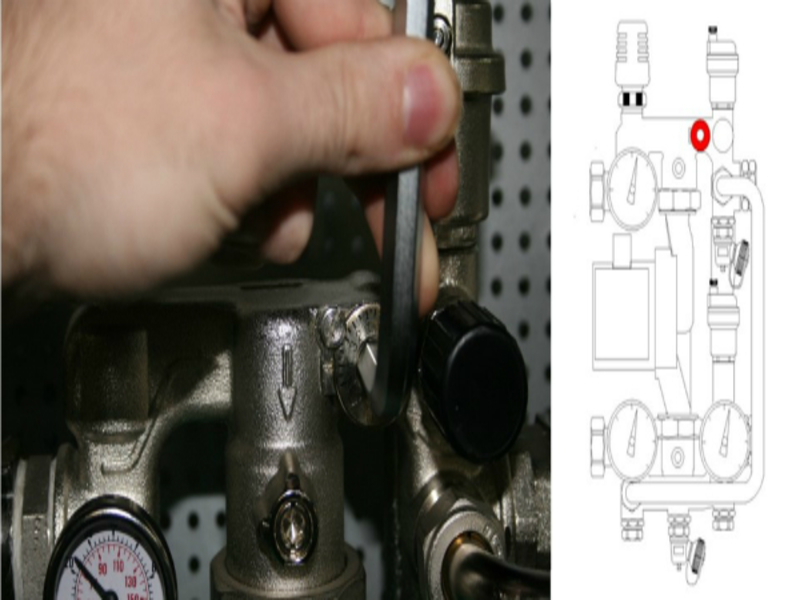

Please note that the mixer in the first photo is not capable of providing a coolant supply temperature of more than 25 degrees at a temperature set on the boiler, 50 degrees. The photo shows a coolant temperature of 30 degrees, achieved at a boiler temperature of 60 degrees and setting the thermostatic mixer head to 40 degrees

The photo shows a coolant temperature of 30 degrees, achieved at a boiler temperature of 60 degrees and setting the thermostatic mixer head to 40 degrees.

This is just understandable with such a connection.

The paradox is that this (25 degrees) is enough to heat the room relatively quickly by a couple of degrees, maintaining the set temperature.

Final debugging

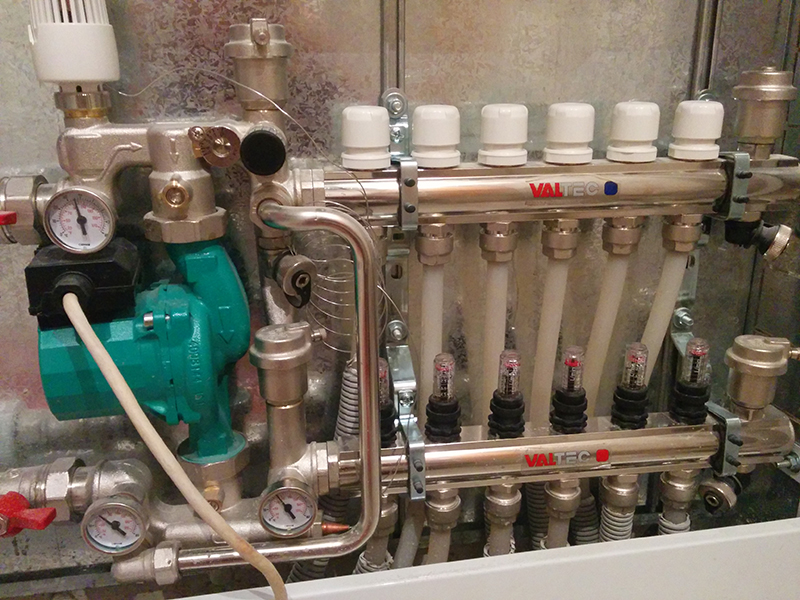

Adjusting the Valtek underfloor heating mixing unit requires linking the equipment with other heating devices. The main task: to adjust the movement of the coolant through each unit so that it corresponds to the project. If errors are made at this stage, some devices may not heat up enough, while others, on the contrary, will overheat. There are several ways to balance the collector for Valtec underfloor heating. The manual for the equipment describes this process in detail.

Next, we have to adjust the bypass valve. You can do this in one of two ways. When we know the resistance of the most loaded branch, the same value is set. If the indicator is unknown, they are guided by the pump. In the latter case, the value for the valve should be 90-95% of the maximum pump pressure for the speed at which it is set. The instruction for Valtek underfloor heating also indicates these parameters.

The process ends with a system check. The task is to ensure that all branches are heated evenly, and the correct balance of temperatures of the liquid flowing through all pipelines is maintained. If you are convinced that the Valtec floor heating mixing unit is set up correctly, you can put on the thermostatic head of the control valve, as well as other protective nozzles. Now the equipment is completely ready for operation. As you can see, the process is not so complicated that it is necessary to resort to the help of professionals.

What regulates the bypass of the mixing unit TIM JH-1036.

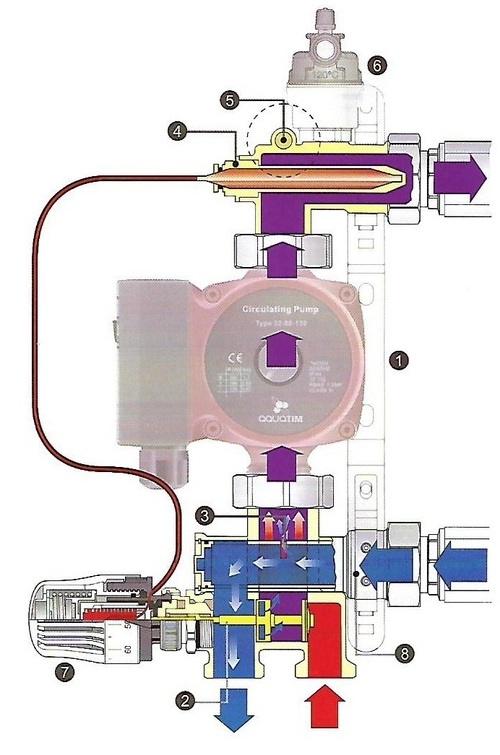

The mixing unit has a conditional mixing chamber through which the underfloor heating circuit and the boiler heating circuit pass.

Usually, the underfloor heating mixing unit has one adjustment parameter - the water temperature in the underfloor heating circuit. The mixing unit TIM JH-1036 has some kind of bypass, and even with the ability to adjust. And this is not the bypass balancing bypass, which is triggered by the excessive pressure developed by the pump.

balancing pressure bypass can be seen in the photo - the rightmost personal belongings.

I need it, because it is possible to block all directions of underfloor heating as a result of automatic regulation. By the way, I still haven’t figured out how to adjust the balancing bypass TIM M307-4 - maybe someone will tell you.

As for the bypass of the mixing chamber, you can find the following graphical explanation of the operation of the bypass of the mixing unit:

Little is known from these diagrams.

Moreover, it is not clear what the numbers on the scale mean and what the current value is attached to. All this can be found out only by holding the TIM JH-1036 mixing unit in your hands:

It turns out that the adjusting screw turns the cylinder, in which there is a slot that overlaps when turned. Through this slot, water can be pumped by a circulation pump, bypassing the conditional mixing chamber.

Keep in mind that a sticker with a scale from 0 to 5 can be pasted arbitrarily.

The maximum slot opening (pictured above) corresponds to setting the adjusting screw to position 5 (pictured below).

For a conditional reading point of the scale value, you can take a technological ledge on the body of the mixing chamber. When the scale value is 0, the gap is maximally closed. In this position, all the water pumped by the circulation pump through the underfloor heating circuits passes through the mixing chamber.

When the bypass is completely closed, the thermal power of energy extraction by the mixing unit from the heating system is maximum.

If the bypass is fully open, then part of the water circulates through the heating circuits without entering the mixing chamber - and the heat extraction power is minimal.

But in practice it turned out that not only the thermal power is regulated by the bypass.

Connection

The connection process can be divided into several stages:

- Adjustment of the balancing valve VK.

- Pump speed setting.

- Branch balancing.

- Linking compatibility with other elements that make up the system.

- Bypass valve adjustment.

- Checking the correct operation of the equipment.

Setting up a Valtec underfloor heating collector begins with assembly. Pipes are connected by means of a threaded connection G1. To connect the collectors of the secondary circuit, special connectors are used. The circulation pump is installed with the ball valves closed. Before turning on the device, they must be opened. Before starting the test, make sure that all elements are securely fastened in accordance with the instructions.

At the next stage of adjusting the Valtek underfloor heating, the pump parameters are adjusted. First of all, we should calculate the pressure drops in the subsequent circuits, as well as the coolant costs for the VC. The calculation formulas are indicated in the instructions for the Valtek mixing unit for underfloor heating. If there is no application to the equipment, you can get out of the situation by setting the pump to the minimum mark. If during commissioning it turns out that this pressure is not enough, just increase the speed.

The balancing of the branches begins with the closing of the PC valve BZ. Remove the cover and tighten the screw until it stops, using the appropriate key.The direction is reverse clockwise. If the adjustment of the Valtec floor heating collector provides for connection to only one circuit, no additional devices are required. If there are several branches, you need to buy additional valves or flow regulators.

The process is as follows. We open the valves / regulators to the maximum and select the branch where the actual flow rate does not correspond to the one indicated in the instructions for the Valtec underfloor heating collector the most. Adjust this valve to the required level. We do the same with the rest. It is recommended to use the VT.FLC15.0.0 instrument for flow indication. If this indicator is not available, refer to the temperature of the warm liquid return carrier or the degree of heating of the system sections. If it is not possible to organize the correct flow of the coolant, increase the pump speed.