How to seal the plastic parts of a car radiator

Let us consider in more detail the adhesive method of repairing a damaged radiator using the example of the use of Hosch two-component industrial adhesive.

To seal the radiator tank, you should prepare the following materials and tools:

- powder welding granulate and liquid component of glue-welding;

- sandpaper;

- acetone for degreasing surfaces;

- gloves;

- cotton swabs.

Stages of work:

- Training . Both surfaces to be bonded must be free of grease and other contaminants. If traces of other glue remain on the parts, they must be completely removed. In most cases, ordinary acetone is suitable for cleaning;

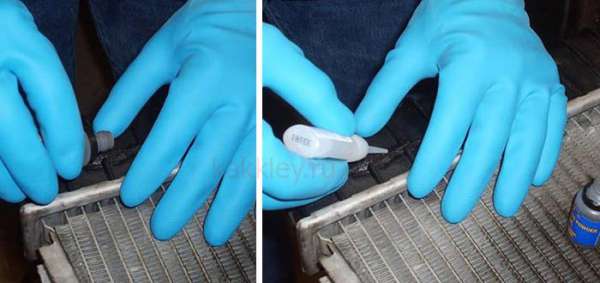

- Applying glue. The minimum amount of adhesive welding is applied directly to the crack. To fill the void or in the absence of body fragments, a powdered adhesive component is sprinkled onto the liquid base. If it is necessary to restore a large depression, gluing is recommended to be carried out in several stages (several layers are applied sequentially with an interval of 10 minutes). After the gap is filled with dry granulate, it must be evenly impregnated with the liquid component.

- Seam processing. After 10-15 minutes after completion of the work, you can start machining the seam with a grinder or fine-grained sandpaper to give the seam an aesthetic appearance.

VIDEO INSTRUCTION

Instructions - how to solder the plastic parts of a car cooling radiator

For soldering (welding) a plastic radiator, the following materials and tools should be prepared:

- Special building hair dryer for heating the place of soldering;

- Soldering iron with a sharp tip and precise temperature control;

- Solder for plastic - special welding rods. The marking on them must match the marking on the radiator housing. As a rule, it is "PA" - polyamide (nylon) or "PP" - polypropylene. Instead of purchased welding rods, you can use pre-prepared strips cut from a similar plastic tank;

- Acetone.

Work order:

- Degrease the repair site with acetone;

- While the soldering iron is heating up, we heat the junction with a building hair dryer;

- We connect the seam and gradually draw along it with a heated soldering iron, forming a groove equal in width to the thickness of the welding rod;

- We apply a welding rod and, heating it with a soldering iron, put it into the groove of the seam;

- We check the radiator for leaks, and then install it on the car.

The welding temperature (heating of the soldering iron) is selected in accordance with the brand of plastic. For PP, this is about 250 degrees.

An article on how to repair a car cooling radiator - causes of malfunctions, troubleshooting methods. At the end of the article - a video about professional radiator repair.

- Causes of malfunctions of the cooling radiator

- Typical malfunctions

- How to accurately determine the location of a radiator leak

- Repair methods

- Video about professional radiator repair

After the combustion of fuel in the engine, about 70% of the generated energy is converted into heat. Some of the heat escapes through the exhaust pipe, but most of it stays inside the engine, heating it to a high temperature.

To prevent the engine from overheating and dissipate heat into the environment, a cooling radiator (heat exchanger) is used, which is the main component of the vehicle's cooling system. A healthy and well-maintained (clean) radiator keeps the engine at optimum operating temperature, allowing it to run at full power.

However, the radiator, like all other elements of the car, can fail and stop performing its function. But at the same time, it is not at all necessary to immediately contact a car service for repairs.As practice shows, in most cases, the malfunction of the heat exchanger can be eliminated independently. To do this, you just need to identify the cause of the breakdown and know how to eliminate it.

Step by step start instructions

At the start, it is not necessary to have a legal permit to conduct business. If we are not talking about opening a full-fledged service, but about self-repair, then you can do without an individual entrepreneur or LLC. Because the beginning of the path never gives a large flow of customers, it will be an additional small income, but after a while, you can think about expanding. Then official documents are required.

- Finding a room. As already mentioned, the repair site must have high ceilings so that KAMAZ can be driven. Very often, this particular vehicle requires such services, because modern manufacturing technology for this engine part does not provide for future repairs. If you can afford to rent a box for several cars, then you can spend money. The radiator will be removed and repaired in the room, it must be borne in mind that there should be enough space for the vehicle itself. Therefore, an area of 50 square meters can be considered the initial one.

- Equipment.

- Search for clients. Internet advertising, the site will be of little use, so you need to put up ads. If desired, you can hire a couple of workers who will perform the tasks. But these are extra costs.

How to solder the plastic of a car cooling radiator

Soldering an engine cooling radiator is considered a fairly simple task. However, not everyone can cope with it due to insufficient knowledge of how to solder a car radiator on their own. Most car owners prefer to drive their car to a service station.

Surface preparation

Before sticking the plastic on the radiator of the car, you will need to fully prepare the surface for this process. To this end, we need to clean it from grease, dust and dirt. Slightly dampen a rag, and very gently wipe the areas of plastic around the resulting crack.

In order to achieve a better effect, it is recommended to use an alcohol solution

It is important that in no case should you overdo it. The fact is that too active mechanical action on the damaged area or excessive pressure on it during cleaning is fraught with the fact that the heat exchanger will be damaged even more

Preparing the adhesive mixture

Now you need to take care of how to seal the crack on the car radiator. So, let's prepare the adhesive mixture. If it is decided to use exclusively glue specially designed for such purposes, then its use will be as simple as possible.

A small amount of adhesive should be applied directly to the damaged area. When a certain piece of the body is missing on the part or there is no gap between the two halves that are formed due to a crack, it is recommended to sprinkle the liquid base with a powdered adhesive component.

So, if the crack itself is too deep or a sufficiently large part of the body is missing, it is necessary to perform gluing in several stages. Apply the adhesive two or three times to the defective area, waiting until each of the layers is almost completely dry. When the resulting gap can be completely filled with a dry gradulant, it is recommended to impregnate it with a liquid composition. So you can be completely sure that it will perfectly fix on the surface of the part.

Cold welding

In addition, you can seal the car radiator using cold welding. Since it comes in the form of a fairly thick putty, it will be enough to apply it to the seam and wait for it to cool completely.

It is important that this same putty should be applied in a neat and even layer so that the seam is of the highest quality.

Cold welding is required to be used as:

- the main method of recovery;

- an additional means of fixing the result obtained by soldering or gluing.

A layer of cold welding applied over the adhesive layer will allow for a long time to maintain the quality of the repair of auto parts and extend the operational life of the part.

Final stage

When the glue has finally hardened and all the main working steps have been completed, it is necessary to perform the final surface treatment. It should be ensured that the resulting seam becomes neat and smooth. For such purposes, the place of soldering will need to be processed with fine-grained sandpaper, and ideally with a grinder.

Thus, it will be possible to get rid of all minor flaws that will not have the best effect on the further operation of the product. After this treatment has been carried out, install the heat exchanger back in its place.

How to quickly fix a leak

First you need to determine the location of the leak. You can do this in several ways:

- We carefully and in detail examine the line along which the movement of the liquid is carried out. A wet spot will be present at the site of the leak. This method does not always give a positive result, for example, in the case of microcracks.

- The compressor allows you to quickly find all the problem areas that will need repair. All outlets are closed on the radiator, only one is left, the system is filled with water and air is supplied through the compressor. A pressure of 1 atmosphere will be sufficient. In places with drops of water, the cooling radiator just flows. This method does not require the dismantling of a faulty part, which is appreciated by many drivers.

- If the radiator has leaked in the car, and there are no wet spots on its structure and there is also no compressor at hand, then it must be dismantled. The design is placed in a container with water, a bath is best suited, and air is supplied. At the place where the bubbles appear, there are just problems.

Often, leaks occur simply on the road, away from home and even any settlement. It is not worth continuing to move, it is dangerous for the car and the driver. We will tell you how you can repair a car radiator with your own hands using improvised means.

- A piece of an old car camera and a clamp will allow you to close the leak for a while and get to the nearest settlement or car shop. We cover the leak with rubber, and compress it with a clamp.

- Pliers are certainly in the travel kit of any driver. They are needed to plug a damaged tube. There should be no more than 5 such tubes, otherwise, the cooling will be significantly reduced and the system will not cope with the task assigned to it.

- Sealant is a very useful tool that can help out at the most unexpected moment. Sealants are different and the principle of their use can vary significantly. Instructions for use are always indicated on the packaging. We study it and act in accordance with the manufacturer's recommendations.

In the case of aluminum

If, nevertheless, it became necessary to solder aluminum, you can use a flux specially prepared for this. It is a rosin, in which metal filings are added during solidification. It is necessary to use such a flux quickly and skillfully. You can buy a special flux for aluminum and a suitable solder, such as castolin.The flux composition is applied to a preheated damaged surface and then melted with a soldering iron.

Carrying out translational movements, they clean the aluminum surface with a sting. At the same time, metal shavings and sawdust, which are part of the flux, act as an abrasive, removing pollution and an oxide film. At the same time, rosin immediately covers the cleaned area, preventing oxygen from reaching it. Further soldering occurs in the same way as in the case of copper parts.

Choice of repair and adhesive methods

Radiators in trucks and cars are the most important part that helps to cool the mechanism and remove excess heat from the engine. Inside the device, cool liquid circulates through pipes and hoses, and the convenient location of the upper part under the hood allows it to be blown with air.

Most cars are equipped with aluminum radiators. This material is ideal for this purpose - it is light, durable, not subject to corrosion, its thermal conductivity is high (it gives off heat, and the parts will not overheat). Aluminum and plastic cooling batteries have replaced brass and copper products, which are much more expensive. But due to chemical characteristics, such tanks are much more difficult to repair, although nothing is impossible. The radiator is capable of cracking even from a small impact, and if it is made of plastic, even a major defect may appear.

How to seal a radiator, and what other method can be used at home? Here are the main ones:

- Soldering. Heat-resistant plastic, from which radiators are made, as well as aluminum parts, can be fastened with a conventional soldering iron.

- Repair by cold welding. The method is based on the use of special adhesives that melt the edges of the material and tightly seal the crack with a heat-resistant seam. Suitable if the radiator is plastic.

- Use of adhesive sealant. Only very small cracks in plastic radiators can be sealed. Like other measures, this one is temporary.

3M DP8005 Two-Part Adhesive is an effective leak stopper. The composition contains acrylic, which can glue even the most complex types of plastic, such as polypropylene. If the radiator burst, this material will be ideal. The seam created by him is not destroyed by the action of moisture, aggressive chemicals, temperature changes. But the price of such a tool is very high (up to 1,500 rubles), so you need to think about the advisability of buying it compared to replacing a radiator.

Choice of repair and adhesive methods

There are several ways to restore the integrity and tightness of the cooling radiator:

- Soldering. Housing elements of modern car radiators, made of heat-resistant plastic, are perfectly soldered using a conventional soldering iron (we will consider this process in more detail below).

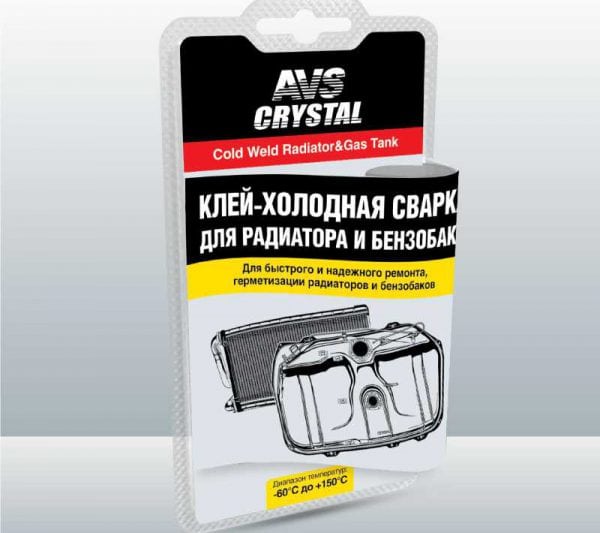

- Cold welding. This is the fastest way to join plastic parts without heating. A special plastic mass, which includes polymer resins, metal filler and chemical additives, connects the surfaces to be glued, forming a heat-resistant seam.

This process does not require special equipment, but such repairs cannot be called durable.

Due to the low adhesion of plastic, cold welding is very weak. This method allows you to only temporarily solve the problem (for example, to get to the nearest car service).

Application of glue. If the damage is small, special glue will help restore the tightness of the case.

Such compositions have proven themselves well, such as:

3M DP8005 Two-Part Adhesive is a specialized acrylic-based compound designed for bonding difficult-to-bond plastics, polyethylene, and polypropylene.

Great for repairing a cracked radiator. The adhesive seam formed by DP8005 adhesive from the 3M trademark is resistant to aggressive solutions and high temperatures.

The only drawback of this glue is the high price (1300-1500 rubles per pack of 38 grams).

Adhesive welding for Hosch plastics. This two-component industrial adhesive effectively repairs cracks and other damage in all plastic products.

The adhesive seam is able to withstand exposure to high and low temperatures, as well as pressure up to 12 atmospheres, so they can easily glue a plastic radiator with it.

Often the junction is stronger than the plastic being glued. The average cost of a set of two complementary components is 1500-1700 rubles.

Repair of copper radiators

It is enough to have a fairly powerful soldering iron, tin-lead solder POS-60 or ZIL-2 (for brass you can use POS-40) and flux (rosin diluted with alcohol).

An electrical device is hardly suitable for soldering pipes or soldering brass fittings to radiator tanks. Most often, devices are used that are heated in an oven or in the flame of a blowtorch. The method of soldering with such a soldering iron is peculiar:

- parts that need to be soldered must first be cleaned and heated with a hairdryer, blowtorch or oven;

- the hot part must be well treated with flux to remove oxide films from its surface;

- solder to the place of the seam is delivered not on the tip of the soldering iron, but directly by feeding a tin rod;

- with a heated soldering iron, it is distributed at the place of soldering.

If a leak is found in one of the cooling tubes, a gas burner can be used to fix the problem. To get close to the damaged area and do the job efficiently, you need to carefully remove the finning plates. This can be done by applying a special abrasive nozzle to a portable drill. You can immediately clean the damaged area.

When heating the tube with a torch, it is necessary to cover as large an area as possible in order to provide sufficient temperature for suturing and not overheat the copper tube. Solder in the form of a rod or solder wire is introduced into the soldering zone when the part is heated to the desired temperature and treated with flux.

Soldering car air conditioner radiators is carried out in a similar way, with the only difference being that you need to bleed the refrigerant from the system, observing safety precautions. In general, it is better to entrust the repair of pipes and radiators to specialists if there is no experience in soldering

Financial calculations

Start-up capital

At the start, you do not need to spend a lot of money, it all depends on the existing components. If there is a garage, then you don’t need to spend money on rent, the same is the case with equipment. In the absence of everything, the costs will look like this:

- garage rental - from 10 thousand rubles;

- purchase of equipment - from 5 thousand rubles;

- advertising - 2,000 rubles;

- with official registration - 4,000 rubles for opening an IP.

The final minimum amount is 17,000 rubles.

Monthly expenses

Every month the costs will be different depending on the work done. How much cold welding, solder is spent? You have to pay for a lot of electricity.

You can conclude the monthly costs:

- purchase of consumables - from 3,000 rubles;

- garage rental - from 10,000 rubles;

- payment for electricity - from 5,000 rubles;

- advertising - from 1,000.

If it is planned to gather workers, then everyone will need to pay from 15,000 rubles every month. That is, the amount of costs will be from 19 to 34 thousand rubles.

How much can you earn?

Earnings can vary greatly, because it depends not only on the number of customers, but also on the extent of the radiator defect. Large deformations will cost the client from 5,000 to 10,000 rubles. Small cracks in pipes can be repaired for 1,000-3,000 rubles.If you serve from 15 people monthly, then you can easily generate revenue from 40,000 rubles, where the net profit on hand will be about 21 thousand rubles or more. It will be possible to recoup the costs in the first 2-3 weeks of work with high productivity.

Is it always possible to repair

It is not always advisable to repair the radiator. In some cases it will be easier and even cheaper to install a new one. But how to understand that this is exactly the situation before you and not waste time on recovery? We'll help you figure it out.

- Leaks that are located at the junction of the radiator with a plastic pipe cannot be repaired. You can fix the leak, but only for a temporary effect. It is better to use epoxy glue or sealant.

- From corrosion, which caused the depressurization of the system, nothing will save. It is not worth spending time, money, or materials on such a radiator. It is recyclable.

- Structural damage resulting from an accident is often beyond repair. Even if there is a chance of success, the cost of repairs will be considerable.

Any leak starts with a small crack, which will be much easier and faster to fix. With timely repair, the radiator can serve for a long time and properly cope with its duties. Remember, not all defects can be eliminated; in some, especially advanced cases, you will have to replace the part.

The best prices and conditions for the purchase of new cars

Loan 6.5% / Installment / Trade-in / 98% approval / Gifts in the salon

Mas Motors

Determining the location of damage

Less commonly, air conditioner radiators are repaired, which are used as condensers and evaporators. But such cases also happen. It is very unpleasant when the climate control suddenly stops working in a luxury car during the hot season.

One of the most effective and affordable repair methods is soldering radiators.

If a car radiator is damaged, it is very important to identify the malfunction in a timely manner and try to fix it.

The autoradiator, which is part of the engine cooling system, is a very important component of it. Structurally, this device consists of two vertical tanks connected by a large number of thin horizontal tubes. The coolant circulating in them, through natural heat exchange, gives off heat to the air and cools down. To improve heat transfer, the surfaces of the tubes in contact with the surrounding air are increased. To do this, thin metal plates are soldered to them - fins.

Signs of radiator damage are an increase in engine temperature during operation, as well as a decrease in coolant level. Of course, fluid loss can occur not only through the radiator, but most often this node is the cause. Visually, major damage can be determined by observing a coolant leak. But on a hot engine, this will be quite difficult to do, since the antifreeze will immediately evaporate. Some compounds are painted with special pigments that remain on the surface of the part after drying, which helps to identify the damage site.

If it is established that the leak occurred in the radiator, and no damage is visible, it is necessary to remove the device from the car, after draining the coolant. After that, it is necessary to close all the holes, leaving one, and supply air into it under slight pressure, lowering the radiator into a container of water. From the emerging air bubbles, it will be possible to determine the location of the hole.

Internal radiator repair with chemicals

Repair of the radiator can be performed by folk methods.So, when all kinds of chemicals had simply not yet been invented, ordinary mustard was considered the most effective way to deal with a broken car heat exchanger. It was simply poured into the car radiator. Since hot water circulates there, the mustard swells quickly enough and closes all the small cracks in the pipes.

So, at any time you can buy chemicals that operate on approximately the same principle. They are often sold under the names "powder reductant", "repair agents", or "radiator sealants".

The main disadvantage of using such chemicals is that it is unlikely that it will be possible to know their exact composition or the exact place of production. Just like with regular mustard, the use of certain types of these chemicals can lead to clogging of the heat exchanger. Moreover, sometimes these substances can disable the entire cooling system of the motor.