When and why to change the filter on HBO

timely replacement or cleaning HBO filters

a very important procedure, since clogging leads to the creation of a high resistance to the gas flow.

The result is a rapid overheating of the engine. Besides, when clogged HBO filter, contaminated cardboard may tear due to the accumulation of dirt and enter the equipment, resulting in breakage.

For the design to work properly, purchase only original and proven spare parts. Devices of non-original production often do not meet the requirements and standards and can lead to a quick breakdown of the equipment.

Replacing the filter on HBO 4 generations - instructions

HBO 4th generation involves the use of two filters.

The first is installed between the nozzles and the reducer, and the second is located directly in the gas reducer.

The room in which the replacement will be carried out must be well ventilated, since even a small gas leak cannot be avoided, it is important to exclude proximity to any sources of sparks or fire

Required tools:

- screwdriver,

- octahedron,

- soap solution

- two filters.

VIDEO INSTRUCTION

HBO filter replacement procedure:

- Tighten the gas cylinder valve tightly, preferably half empty.

- Relieve pressure by starting the engine. This will start the consumption of the remaining gas in the system and the car will start running on gasoline. If possible, it is better to drive a few kilometers on gasoline before replacing.

- Unscrew the gearbox with an octagon.

- Remove the cover, dismantle the old device without touching the nearby rubber tubes (after analyzing the mud accumulations, you can understand how worn out the installation is, how it worked, what are the shortcomings of its work).

- Remove dust near the filter installation site with a vacuum cleaner. Treat the installation site of the new filter with a special liquid.

- Lay a rubber ring on the bottom, then a new filter, then another sealing ring.

- Close the cover, turn the screws.

- Loosen the two clamps with a screwdriver, remove the second old filter.

- Put a new one in its place so that the arrow points to the injectors.

- Open the valve on the bottle.

- Then, with a soap solution, check all unscrewed connections to identify possible gas leaks.

The cost of a new device starts from 1000 rubles. When buying it directly from the service, you can save on installation, as you can be offered free installation or a good discount.

A gas filter is a device that is needed in order to clean the gas supplied through the pipeline from various contaminants: rust, dust, tar and other harmful impurities. By cleaning the gas, the tightness of the locking devices can be improved. In addition, the service life is increased. Wear resistance and accuracy of counters and other measuring instruments become many times better. The most commonly used gas filter for gas equipment. There are also models for cars.

We use a filter for a gas boiler

The gas filter for the boiler is a small structure that is installed in the gas pipeline. Its function is to collect dust particles and other debris in order to prevent it from entering the boiler system.

A filter for a gas boiler is a necessary addition to a traditional unit that will protect the main components of the structure from premature wear. If you want your boiler to serve you for decades, you should not ignore the need to purchase a filter element for the gas pipeline.

What does such a filter collect? The natural gas that enters our homes through the pipeline system contains all sorts of foreign particles. It can be resins, sand, the smallest elements of corrosion and much more.With the help of a complete purification of the gas entering the system, the tightness of the locking devices improves and their reliability increases. Moreover, devices such as meters will show the most accurate data without errors. As for the design of the unit itself, when using gas filters for the boiler, there is less wear on its main components, especially those that are extremely negatively affected by erosion.

Choosing a filter for a gas boiler is a responsible task, since your decision depends on how reliable and safe your gas supply system will be. Today, a variety of filter units are presented on the market for heating equipment and components, which can be classified according to a number of criteria. In particular, there are direct-flow and rotary filters, which differ from each other in the direction of gas movement. Depending on the design features, angular and linear devices are distinguished. They are usually made from steel or aluminium. Moreover, it can be both welded-type structures and components produced by casting.

If you decide to purchase a filter for a gas boiler, start by evaluating the filter material. There are two main types of material - mesh and hair.

In the first case, a special metal woven mesh is used as a filter element, which effectively traps small dust particles. The hair filter is a cassette with pressed horsehair or nylon thread impregnated with viscin oil.

Consider popular products that are in demand in Russia in order to learn more about what a gas filter is.

Compact Gas Filter (70600 Series)

This model, produced by the Italian company Giuliani-Anello s.r.l., is made of aluminum. It is completed with a cover made of galvanized steel. The design is robust and according to UNI-EN161 this model is group 1 in terms of mechanical strength.

The filter is designed for a maximum incoming pressure of 0.5 bar and for operation in a temperature range from -10 to +80 degrees Celsius. The filter element is made of special material Viledon P15/500S, which has a high dust absorption rate and a long service life. Viledon P15/500S complies with the international standard DIN EN779, which says a lot.

The compact cleaner of the 70600 series will delight the owner with its small dimensions. It has been designed for operation with gas boilers and water heaters.

When purchasing this filter, you must follow the recommendations below:

- Make sure it is suitable for your heating system by checking the specifications;

- Do not install the filter in direct contact with plastered walls;

- During installation, use the appropriate tool;

- Mount the device in such a way that you have easy access to its cover;

- The direction of gas movement must correspond to the direction of the corresponding arrow located on the body of the unit;

- Mount the filter after the gas reducer.

The 70600 Series Compact Gas Filter can be used in both horizontal and vertical pipelines, making it a versatile solution for incoming gas filtration.

A filter for a gas boiler is a necessary option that will extend the life of your water heating equipment. A huge number of design variations in various price ranges will allow you to choose the optimal installation that will fully justify the money spent on it.

Car gas filter replacement

The gas filters used for fine cleaning of the fuel systems of the car are disposable, for coarse cleaning they are used several times.For the latter, it is regularly necessary to dismantle it. Often the liquid phase device is located under the hood. The list of its functions also includes the capture of small fractions from metal.

The filter should be replaced either once a year or every 10 thousand km - less often it is not worth it. How does this process take place?

First you need to close the balloon. Next, you need to remove the nuts from the gas line, inlet and outlet. The filter should be left for a while to allow the gas to escape from it. After that, the “backcloth” of the device is removed. It is usually mounted on a bracket.

Now you should disassemble the filter. This is done as carefully as possible, since there are many elastic bands and magnets in the case. After the space in the filter has been cleaned, a new cartridge should be installed. Now it remains to assemble the device and install it in place.

This completes the replacement of the gas filter. This process, as is already clear, can be done quickly and without any effort. The only caveat: you should eliminate the elastic bands that have already lost their elasticity.

LPG installations are becoming more and more popular in our country. If the HBO setting is technically correct, there are no complaints about the work: fuel consumption is less, and gas is cheaper, and there is minimal harm to the engine. Periodic inspection is one of the main conditions for maintaining gas equipment in working order. One of the main points of maintenance of HBO is the need to change filters.

How to replace the HBO filter

It's very important to do removal and installation filters in a ventilated area, since gas leakage will occur in any case, and of course, away from open sources of flame.

Next, they turn off the car, after switching it to gasoline. By the way, in order for even the best filter to slowly overgrow with dirt, you need to always drive the last 2-3 kilometers before a long parking lot on gasoline.

The car mechanic must tightly close the valve on the gas cylinder

It doesn’t matter whether it is full or not, but for safety, drivers are usually asked to come with a half-empty cylinder to replace the LPG filter.

The master dismantles the filter, trying not to touch the rubber tubes passing nearby and not damage them. By the nature of mud accumulations, any master can draw up an approximate picture of the health, wear and tear and shortcomings in the functioning of a gas installation.

A special liquid cleans the place where the old one stood and a new filter will be installed. You can continue to work only when everything is dry.

A new cleaning device is installed along with all gaskets. The air filter is often installed at the same time.

What to do if there is a breakdown of the gas boiler

If the boiler breaks down before the start of the heating season, this is not so bad, but what to do if it breaks down in the midst of the heating season? The most important thing is not to panic. However, it is also impossible to take the problem lightly, since even a minor breakdown can lead to the failure of the entire boiler or the entire heating system. If the breakdown is not too serious and you can fix it yourself, then you should not waste time. However, if you do not know what the matter is, it is better to entrust the repair to a specialist from this field.

The performance of the boiler depends largely on your choice even at the moment when you purchase it in the store.

You should also pay attention to such a moment as the availability of service in your area. It is best that the same company is engaged in maintenance, inspection, repair of electric heating boilers

Service maintenance of a gas boiler

Some companies keep special statistics on those devices that break down most often. Most often, the cause of the breakdown is a violation of the requirements and standards established by the boiler manufacturer.This happens in 65% of cases. In 25% of cases, the cause of equipment failure is its improper operation. The probability of a factory defect is only 1%, and an error in the documentation occurs in 4% of cases.

Filter selection criteria for gas boilers for water

The choice of a cleaning filter must be approached with all responsibility, because the further operation of the equipment depends on it. If you have any doubts about the purchase of a particular device, it is better to consult with knowledgeable people or be guided by the general rules of choice.

- Focus on water quality and frequency of filter use. For regular use, an electromagnetic cleaner is suitable, which does not require disassembly and replacement of main parts. Complete with an expensive boiler, it will show maximum efficiency.

- With a very hard and dirty coolant, it is better to use double protection and softening, focusing on different degrees of water purification.

- If the budget is limited, you can give preference to a polyphosphate filter or a cartridge filter.

- Consider the dimensions of the filter so that there is enough space for its installation.

- Buy products from trusted sellers who provide a quality guarantee and the possibility of warranty service for their products.

- Focus on well-known manufacturers, because. they are more difficult to fake, and in the event of a breakdown, parts for such devices will be easier to find.

If you do not ignore these recommendations, then you can purchase a quality filter with a good price-quality ratio.

Gas filter for boiler

Any gas system must have a gas filter, including a gas boiler. The device is mounted on a horizontal section of the pipe. The filter for a gas boiler cleans the gas passing through it. This improves the error-free operation of flow meters and prevents gas equipment from failing.

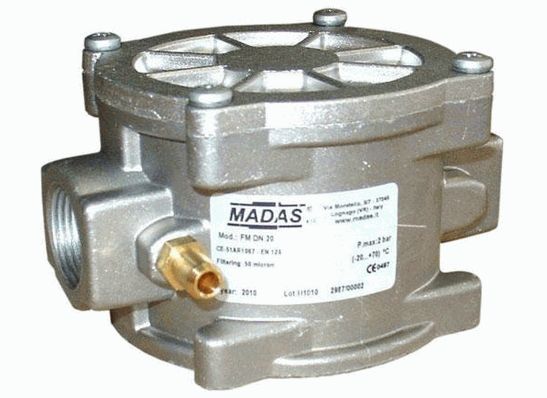

Gas filter MADAS threaded

Functions and purpose

A gas filter for a boiler is an addition to boiler equipment that is necessary to protect components from early wear. If you intend to contribute to the long life of the boiler, then do not ignore the purchase of a gas filtration device.

The function of the filter is to collect excess particles (tar, sand, small pieces of rust) that come with the gas through the pipeline system. With the help of high-quality cleaning of the gas that enters the system, the tightness values \u200b\u200bof the shut-off valves become much higher, reliability is ensured. Plus, devices such as meters will show high-precision data without errors. The boiler room itself, using gas filters, will not fail so quickly, and the main components of the heating unit will not corrode.

Installed gas filter

Types and how to choose

The gas filter for the boiler must be chosen with full responsibility, because the level of reliability and safety of the gas supply system will depend on the choice. Currently, on the market for heating devices and components, you can see a variety of filtration units, classified according to some criteria.

Based on the direction of gas movement, gas filters can be distinguished:

Based on their design parameters:

Devices can be made from different materials, they distinguish:

Brass mesh filter for gas with a magnet

There may also be filters:

To select a gas filter, you need to evaluate the filter material. He can be:

- Reticulate. Here, the filtration element is a special woven metal mesh, which perfectly traps small dust particles.

- Hair. It is a cassette with pressed horsehair or nylon thread, which is impregnated with viscin oil.

Popular Models

Gas filters for boilers are quite popular in the Russian market. A popular model is a small device of the 70600 series.

The product is manufactured by Giuliani-Anello s.r.l. and made of aluminum alloy. The lid is made of galvanized steel. The advantage of the filter is high reliability, in accordance with UNI-EN161 the model has the first group in terms of mechanical strength.

Characteristics of the gas filter for the boiler series 70600 Giuliani-Anello.

Viledon P15\500S material is characterized by excellent and high-quality absorption of dust particles and a long service life. It meets the general standard DIN EN779.

Compact gas filter Giuliani Anello 70600

When buying this gas filter for the boiler, you need to remember the following rules:

- It is worth making sure that the filter element is combined with your heating system by examining those parameters.

- It is not necessary to install the device next to the walls on which plaster is applied.

- For installation work, use the appropriate tool.

- It is desirable to install the filter so that you can easily get close to its cover.

- The gas flow must correspond to the direction indicated by the arrow on the unit body.

- It is necessary to install the filter element after the gas reducer.

The 70600 series gas boiler filter is designed for installation on vertical and horizontal pipes, which ensures the versatility of the device.

The gas filter for the boiler is a small but very useful device for extending the operating period of the heating unit. A variety of design solutions and a variety of prices make it possible to choose the best device that fully justifies the money invested in it.

Features of installing a water filter on a gas boiler

A gas boiler, like the entire heating system, will not tolerate amateurism, so a person who understands this should install the filter element. The general procedure depends on the type of device selected.

Before starting the installation, you need to prepare the necessary tools and materials. For work you will need:

- brush for cleaning pipes leading to the boiler;

- a device for cutting and sealing pipes, if the pipeline is plastic;

- a device for threading, if the pipeline is metal;

- pliers;

- tow;

- sealing tape.

Preparatory work is mandatory. Pipes are cleaned of plaque and scale. To do this, the heating system is washed, the pipes themselves are cleaned with a special brush or brush.

It is necessary to make sure that the purchased filter fits the gas boiler in terms of the diameter of the pipes, taps, and whether there is enough space for its installation. It is recommended to mount the device in an easily accessible place so that it can be serviced later. As a rule, this is the place before the pipe enters the heating boiler. When using an electromagnetic cleaning device, it is necessary to consider the connection and install the device based on the presence of an electrical outlet.

Usually, manufacturers complete their product with installation and operation manuals, so read the instructions carefully. Installing a filter involves several steps.

- At the place where the filter is installed, the pipe is cut.

- The first shut-off valve is installed and soldered. It is fixed on tow or sealing tape.

- The filter itself is installed and fixed.

- The second flowing valve is mounted according to the same principle as the first one.

For reliability, it is recommended to install filters for gas boilers for water on special brackets on which they will be held.

After completing the installation work, you need to start and check the system's performance. First you need to turn on the water and see if there are any leaks. If everything is dry, turn on the gas.

Whether or not an electromagnetic device works, it will be clear right away, because. it is connected to the network. If filters of a different type were used, then some time must pass to check them.

The duration and efficiency of the filter for gas boilers for water directly depends on the periodic and scheduled maintenance of the device. During the heating season, it is recommended to clean the appliance at least once a month. To do this, turn off the water in the area where the filter is installed. The coolant is poured into a previously prepared container, the inner mesh is removed from the device and cleaned well under running water. After that, the structure is going to place us, the valves open and the liquid is launched into the circuit. In order to avoid mistakes at any stage, it is better to invite an experienced specialist.