In conditions of space shortage, a balcony or loggia often becomes an additional fully functional room. Thanks to insulation, finishing materials and glazing technologies, comfortable conditions are created throughout the year. Often, insulation and finishing work is carried out by homeowners on their own, without complying with building standards. This affects the fire safety of the apartment, part of which is the fire protection of the balcony.

Causes of fires on the balcony

The lion's share of such fires is associated with external factors. This may be a "gift" from the neighbors from above in the form of an unextinguished cigarette butt. The means of festive illumination pose a great threat: salutes, firecrackers, Chinese lanterns. They are available and popular, and the rules for their safe use are often ignored. Even glazed loggias are not immune from the ingress of ignition sources from the outside: in hot weather, the windows open for ventilation.

The owners also contribute by storing flammable materials, old things on the balconies and carelessly handling fire.

Another source of ignition is short circuits in electrical wiring laid without observing fire safety rules. In a spacious loggia, household appliances of considerable power, such as refrigerators or freezers, are often placed. Errors in calculations and installation of wiring are costly for apartment owners.

To reduce the risk of fire, we recommend:

- When finishing, give preference to non-combustible and hardly flammable materials.

- Carry out the processing of structural elements with the help of fire-retardant impregnations, varnishes and paints.

- Enclose all elements of electrical wiring in non-combustible shells: corrugations, pipes, boxes. Installation is more reliable to entrust to specialists.

- Observe fire safety rules: do not litter the balcony, do not store flammable substances and liquids, handle fire and electrical appliances carefully.

Material selection

When modifying a balcony, it is preferable to use non-combustible materials. These include:

- For the device of the parapet - a strapping from a metal corner, walls from a foam block. Brick or cinder blocks are also completely fireproof, but are rarely used on loggias due to their heavy weight.

- Insulation - mineral wool, its derivatives. A good option is penofol, which only melts when in contact with fire.

- Wall, floor and ceiling cladding - plaster, ceramics, natural stone. Good fire safety indicators for drywall and non-combustible panels on a calcium silicate or glass-magnesite basis.

The use of such materials will not only protect against fires, but also make the balcony comfortable, cozy and beautiful. True, there are certain stereotypes that affect their use. For example, a tile floor is considered cold. However, when artificial heating is installed, it will not yield in terms of comfort to laminate or other popular floor coverings.

In stores there are "fireproof" coatings - laminate, linoleum, carpet. However, they cannot be classified as safe: although they do not burn on contact with an open flame, they melt at high temperatures, releasing hazardous substances and smoky the room. In addition, they cost an order of magnitude more expensive than their combustible counterparts.

For engineering or aesthetic reasons, it is not always possible to use only non-combustible materials. Therefore, when choosing them, the following recommendations are observed:

- Other things being equal, the choice is made in favor of a safer material. For example, vinyl tile is preferable to ordinary linoleum.

- The fire hazard is reduced by combining combustible and non-combustible materials.So, the flammability of the laminate is reduced if it is laid on foamed polyethylene.

- Combustible materials based on wood, as well as plastic and vinyl, are treated with special protective compounds.

The flammability of the material is determined by its class, indicated on the packaging by the abbreviation: from non-combustible (KM0) to flammable (KM5).

Some manufacturers indicate on the packaging all the characteristics by which the fire safety class is determined:

- G - combustibility;

- B - degree of flammability;

- D - smoke formation;

- T - toxicity;

- RP - flame propagation.

The lower the number after each characteristic, the safer the material.

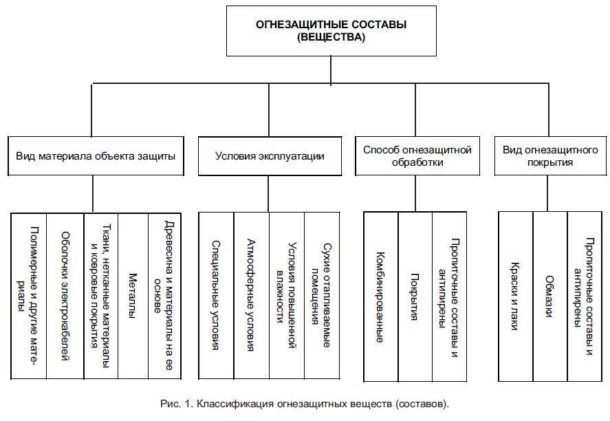

Types of fire-fighting impregnations and compounds for wood

Flame retardants or flame retardants are available in the form of varnishes, paints or impregnations. Most often, impregnations are used, since they penetrate deep into the material, while maintaining its structure.

By type of impregnation solvent are:

- Organic-soluble - used only for outdoor work due to its toxicity.

- Water-soluble - used for the treatment of internal surfaces.

To protect wooden structures from fire, acid, alkali and salt compounds are used. Each type has its own advantages and disadvantages:

- Acid impregnations are the most popular option. They penetrate deep into the wood without changing its structure, appearance and properties. Allow the material to "breathe", increase the strength of the element.

- Alkaline compounds are not used to treat visible areas of the coating, as they violate the structure of the wood. Their main advantage: they are cheaper than acid ones.

- Salt solutions are less effective and are mainly used for deep processing even at the stage of manufacturing wooden elements by soaking them in special containers. In industrial production, deep impregnation is carried out using autoclaves.

fire retardant paints

They create a layer on the surface that prevents heating and further ignition of the structure. According to the principle of action are:

- Intumescent paints. When ignited, they crack, forming a coke-like layer that reflects heat. In parallel, an inert gas that does not support combustion is released from the pores. Able to resist fire for 2-2.5 hours. Recommended for application outside.

- Non-intumescent paints based on silicate. Liquid glass, as well as other flame retardants included in their composition, immediately after application form a protective layer on wooden surfaces that can withstand flame exposure for up to two hours. They are suitable only for interior work, as they quickly decompose and lose their properties on the street.

The disadvantage of fire retardant paints is that the layer they form hides the texture of the wood.

Fire retardant varnishes

A decorative coating that protects against fire and preserves the structure of wood. Due to this, they cover not only constructive, but also decorative elements of decoration. The exception is surfaces painted with water-based paints. Form a matte or shiny protective layer.

Apply in several steps at a temperature above +5˚С. Each subsequent layer is formed after the previous one dries.

Combined compositions of fire protection

Most wood preservatives have antiseptic additives. Thanks to this, they not only protect against fire, but also protect the elements from microorganisms. They prevent the appearance of mold, fungus, fight larvae and adults of carpenter insects.

Antiseptics are part of refractory impregnations, paints and varnishes.

Stages of processing wooden elements of the balcony

The impregnation order is determined by the assembly sequence:

- Frame elements - strapping beams, load-bearing beams of the floor and ceiling.

- Crate.

- Finishing - lining, imitation of timber, various types of wood-based boards.

Fine finish is covered with a protective layer from top to bottom, from ceiling to floor. This will avoid the appearance of drops and smudges on the already treated surface.

Requirements for applying protective compositions:

- Humidity of wood - no more than 30%.

- Air humidity - up to 70%.

- The temperature is above +5˚С.

The compositions are applied to the surface with a paint brush, roller or pneumatic spraying. Observance of safety regulations is mandatory: no open flame and heaters, use of a respirator and protective clothing.

The number of layers, the time interval between their application is determined by the manufacturer's recommendations indicated on the package. The total drying time of the composition is also indicated there.

Fire retardant varnishes dry the fastest, paints and impregnations dry the slowest.

The compositions are applied to the previously prepared wood surface.

Lathing processing

The appearance of these elements does not matter: they are hidden under the finish. Therefore, the treatment is carried out with refractory impregnations.

Surface preparation:

- Remove old paintwork, if present.

- Clean off dirt and dust.

- Remove grease and oil stains with white spirit.

- All elements are processed with fine emery. Dust is blown off with a vacuum cleaner.

Ideally, the parts of the crate fitted to each other are impregnated before installation. But in practice, processing is often carried out twice:

- First, the material is coated with a protective compound before assembly (after installation, some surfaces cannot be reached).

- Then, the places where the integrity of the protective layer has been violated (joints, grooves, cut ends) are additionally processed.

Impregnation is applied with a paint brush. The number of layers and their drying time is determined by the manufacturer.

Processing of lining, imitation of timber, boards

Wooden elements of the balcony, located outside, are painted with weather-resistant intumescent refractory paints.

For interior decoration, in order to preserve the beauty of the wood texture, you should choose a fire-retardant varnish. It is recommended to use it in combination with fire impregnation.

Lining processing:

- wipe the boards with a rag moistened with a solution of soda;

- remove mold, treat dark spots with bleach;

- apply impregnation, dry;

- mount the lining on the crate;

- sand with fine sandpaper;

- prime the surface;

- following the manufacturer's recommendations, apply a protective varnish.

The compatibility of the solutions is checked using an unnecessary piece of material. All layers are successively applied to it. After drying, evaluate the result.

Professionals recommend using formulations from one manufacturer, produced in one line. Then there will be no compatibility issues.

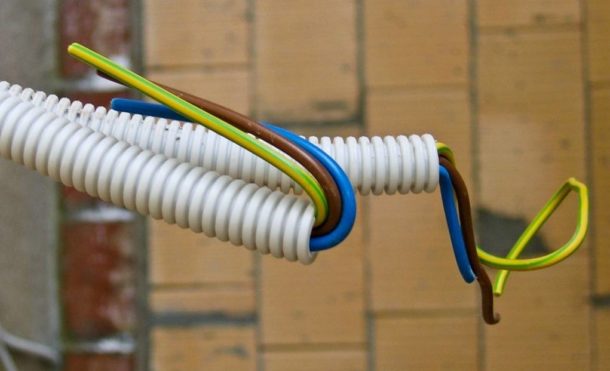

Fire protection wiring

Proper installation will prevent the possibility of fire due to electrical wiring faults:

- Wires marked NG are used. This is how a non-combustible cable is marked.

- Hidden parts are placed in corrugations, which exclude the contact of lines with insulation or combustible finishing materials. Plastic corrugations are used on the balcony.

- Open areas are enclosed in cable channels made of non-combustible plastic.

- Branchings are located in junction boxes that do not support combustion.

- When passing floors and walls, the cable is enclosed in a metal pipe filled with a fire retardant composition: mastic or sealant.

- To supply electricity to the balcony, it is recommended to lay a separate line connected to the switchboard.

Vinyl, plastic, fabric processing

For interior cladding, it is better to use non-combustible panels.These include:

- Gypsum vinyl - the basis of their drywall, covered with a decorative vinyl film.

- Glass-magnesite - with a decorative layer of acrylic paint and a protective varnish coating.

- Silicate-calcium plates.

The basis of these panels is incapable of burning, which reduces the likelihood of fire spreading.

Conventional PVC panels do not lend themselves well to fire treatment. Their smooth outer layer has low adhesion, and impregnation is generally impossible. To reduce flammability, a special paint is used. It consists of heat-resistant, gas- and foam-forming fillers. It is applied in two or three layers. Dries completely within a day.

There are fire-prevention impregnations for materials on a woven basis. Apply by brush, roller, spraying or dipping. During operation, such coatings are subjected only to dry cleaning: after each wash, the impregnation will have to be repeated.

Additional fire protection measures for the balcony

Self-acting fire extinguishers can be a good insurance in case of fire. These are containers filled with fire extinguishing powder. When the temperature rises, the sensor is triggered, starting the reaction of the thermally active substance. It quickly expands in volume, building up pressure inside the case. As a result, it collapses, and the powder is thrown out with force, covering the area around the fire extinguisher with a diameter of 2-3 meters.

The area of the balcony is small. Two or three of these fire extinguishers, evenly distributed, will suffice for him. This is good insurance in the event of a fire.