How to bend rebar, sheet metal, etc. without a special tool

If you have already started a major overhaul with your own hands, regardless of where it is carried out: at home or in an apartment, then you need to be prepared for many tests.

In particular, a number of issues may arise that are very difficult to solve without proper experience and special equipment. For example, not everyone knows how to bend a sheet of metal, rebar, profile, corner, etc. while getting good results. In this article, we will try to answer the "inflexible" questions, while getting by with a minimum amount of tools.

How to bend a sheet of metal, galvanizing, profile

Very often, when mounting metal structures, it is necessary not only to cut steel sheets, but also to give them a curved shape.

You can do this at home without spending money on third-party services. For example, how to bend a sheet of metal? To do this, we need a wooden or rubber hammer, tongs, a table.

If a 90 degree curvature is expected, then this set of tools should be enough. The sheet simply hangs from the edge of the table, after which the desired curvature is achieved by uniform tapping in the bend area.

How to bend a pipe without preheating

It is possible to bend the profile pipe yourself, without preheating it, both with and without filler. Do not require filling with sand or rosin pipes, the profile height of which does not exceed 10 mm.

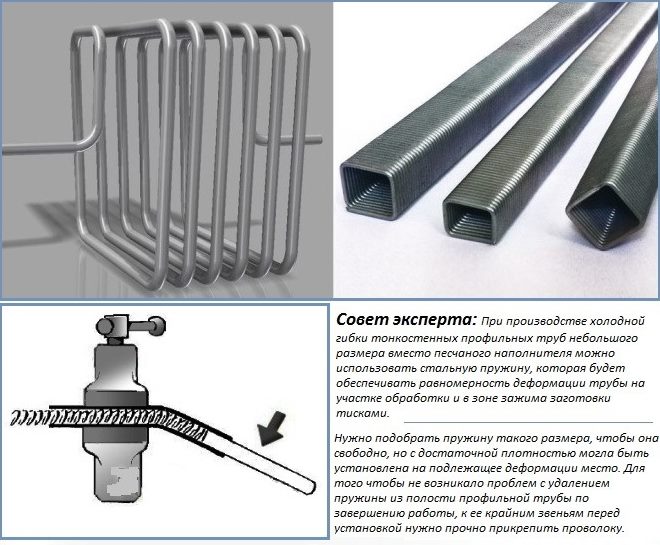

There is another technique that involves the use of a spring with a dense coil of coils instead of a filler, which is inserted into the internal cavity of the professional pipe and protects the product walls from deformation, as well as from excessive changes in their thickness during the bending process.

The design of an elementary pipe bender is simple and affordable for self-production.

For those who need to bend profile pipes with their own hands, without first heating them, you can use the training video and the following simple recommendations.

- It is possible to obtain the required bend on profile pipes using the simplest devices - a vice, mandrels, bending plates.

- You can use a manual pipe bender for products with a round profile. In this device, it is necessary to redo the working rollers, the shape of the recess in which must correspond to the pipe profile.

- You can bend pipes most efficiently and accurately using a roll forming machine, which you can purchase or make yourself.

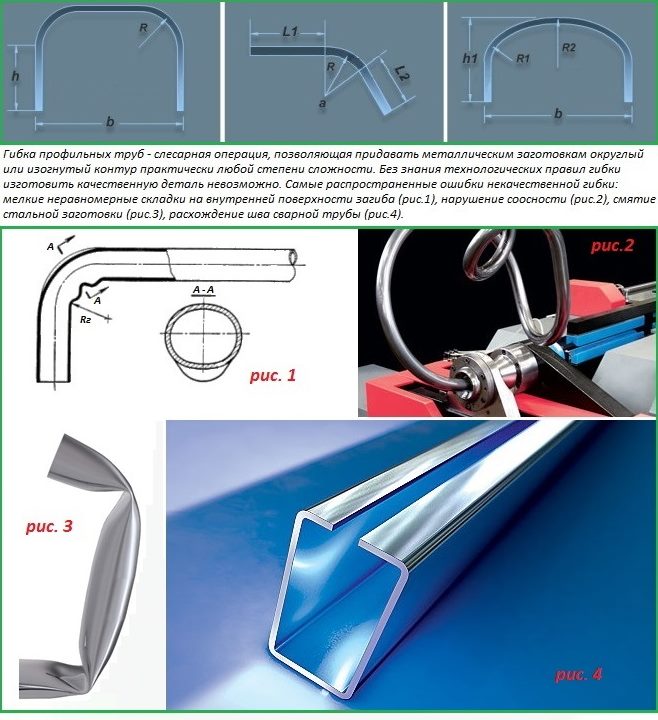

What is the complexity of profile bending

The essence of bending rolled metal, regardless of the shape of its profile, is that the profile pipes are given a partial or complete bend. Such a technological operation is performed in two ways: by acting on the bent pipe only by pressure or by additionally heating the section of the pipe in the area of which the bend is performed. During the bending, two forces simultaneously act on a metal pipe:

- compression force (from the inside of the bend);

- tensile force (from the outer part of the bent section).

It is the impact of such multidirectional forces that causes difficulties characteristic of the bending process of any profile pipes.

- Segments of the material of the pipe, which changes its shape during the bending process, may lose the coaxiality of their location, which leads to the fact that individual sections of the pipe will be located in different planes;

- The wall of the pipe, located on the outer side of the bend and subjected to tension, may not withstand the load and burst.

- The inner wall of the pipe, subjected to compression, may become covered with folds that resemble corrugations.

Technical characteristics of profile pipes

To prevent this from happening, it is necessary to take into account not only the characteristics of the pipe material, but also its geometric parameters - section dimensions, wall thickness, radius to which it is necessary to bend. Knowledge of the above will allow you to choose the appropriate technology and bend the corrugated pipe correctly without crushing it and without getting a corrugated surface.

Industrial cold bending methods

Depending on the diameter of the element and the amount of work, hand tools (pipe benders) or devices with an electromechanical drive can be used.

The main industrial cold bending methods are:

- Winding method. This technique allows you to bend a pipe with a cross section in the range of 1.0-4.26 cm in different planes. To maintain the shape of the section, composite or rod mandrels are used - calibrating plugs.

- With a twist. This method is suitable for bending tubular elements with a diameter of not more than 15 cm. In this case, the wall thickness should be impressive. The essence of the method: a rolling roller moves around a static bending roller of a given size. He presses the pipe and bends it.

- Roller. This method allows you to bend the workpiece in a spiral or ring. On the rollers, the element is moved by rollers and acquires the curvature specified by the position of the rollers.

- Drawing. The method is suitable for bending thin-walled seamless products. For bending, a template is made from a tubular element of a larger diameter. Then the template is threaded into the die and fixed with a clamp. Due to the rotation of the template, the workpiece is pulled through the die and bent.

- By stretching. This technique minimizes the risk of metal deformations. To do this, the workpiece is fixed at the edges, stretched and bent at the same time through the use of a bending template.

- On supports. Usually two supports are used on which the workpiece is placed. As the support bends, it rotates around its axis. The template is connected to the jack rod so that the force is applied in the center of the workpiece. The method is suitable for bending tubular products with a diameter of no more than 35.1 cm. The equipment allows bending directly on the construction site.

- With hydrostatic pressure inside. To do this, liquid is injected into the tubular element. Plugs are installed at the ends. Due to the resulting stresses, the metal reaches an almost plastic state. Then a template is brought to the place of bending and the workpiece is bent.

- With push. The method is suitable for bending elements with a diameter of three inches. The workpiece is pushed through a fixed and movable die. Due to the displacement of the matrices relative to each other, it is possible to adjust the curvature of the bend. Using this technique, one workpiece can be bent several times in different planes.

As for the use of mandrels, the simplest plug for pipes with a cross section of no more than 3.2 cm can be a steel cable. One end of this cable is fixed in the handle. The other end is connected to the wire to perform pulling into the lumen. In this case, the diameter of the calibrating plug should be slightly smaller than the cross section of the tubular product - by about 0.1-0.5 mm.

During the use of calibration plugs, unwanted scratches and notches may occur on the inner surface of the workpiece. This usually happens when bending stainless steel products. To protect against such undesirable consequences, you need to choose the right cork material, as well as use lubricant and thoroughly clean the surface.

Pipe bending features

All methods of bending workpieces can be divided into manual and mechanical, as well as hot and cold.Sometimes the bending process is accompanied by undesirable consequences for the tubular product, which have a significant impact on the subsequent operation of the element. The degree of manifestation of these consequences depends on the material from which the pipe is made, its diameter, bending radius, as well as the method by which the bending procedure was performed.

The negative consequences of bending include the following points:

- Reducing the wall thickness of the workpiece located along the outer radius of the bend.

- The formation of creases and folds on the wall, which is located along the inner radius of the bend.

- Changing the configuration of the section (reducing the size of the lumen and its shape - ovalization).

- Change in the bending radius due to the spring effect of the material.

The most common drawback of bending is a change in the configuration of the section and wall thickness. Due to the stresses of the metal, the outer wall becomes thinner at the bend, while the inner wall, on the contrary, thickens. This results in a noticeable weakening of the tubular element. This phenomenon is dangerous by rupture of the outer wall of the pipe, since it is it that is subjected to greater pressure of the transported medium.

Ovalization also significantly weakens the workpiece. This phenomenon is especially dangerous when bending a pipeline designed to transport a substance under conditions of a pulsating load. If such elements are used as building structures, then ovalization will affect the appearance of the element. That is why in the process of bending, they strive to minimize such phenomena as much as possible.

If folds form on the inner wall due to thickening of the material, then they will entail not only a decrease in the cross section, but will also create resistance to the moving flow. This in turn increases the likelihood of corrosion. In addition, the bearing capacity of the structural tubular element will decrease.

Pipe bending tools

The question of how to bend a pipe without a pipe bender will not cause difficulties if you use the simplest devices to perform this operation. You can perform cold bending of pipes using the following devices.

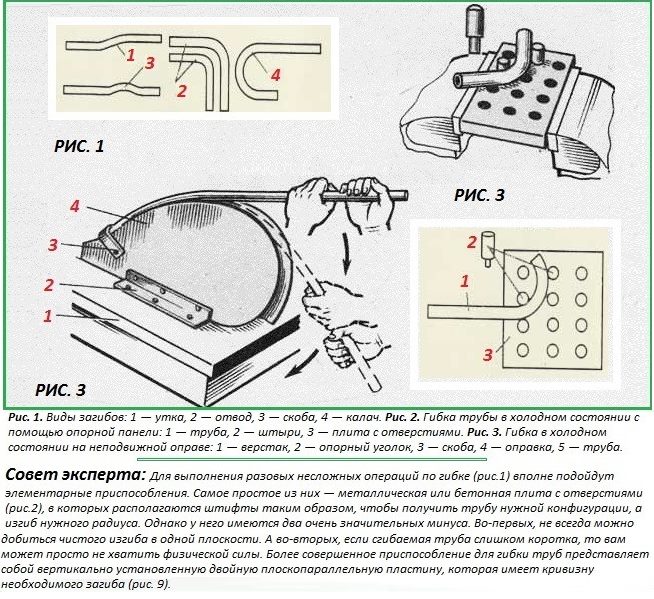

- In cases where it is necessary to bend a soft (aluminum) or steel pipe with a profile height of not more than 10 mm, a horizontal plate with holes is used, into which stops are inserted - metal pins. With the help of these pins, products are bent according to the required parameters. This method has two serious drawbacks: the low accuracy of bending, as well as the fact that when using it, it is necessary to apply significant physical effort.

- Products with a profile height of 25 mm are best bent using roller fixtures. The pipe is securely fixed in a vice, and a force is applied to that part of it that needs to be bent using a special roller. This device allows you to get a better bend, but also requires the application of physical effort.

Option, as they say, in haste. The long lever of this extremely simple device allows you to cope with rather thick pipes.

Elementary devices will help to make a one-time pipe bend

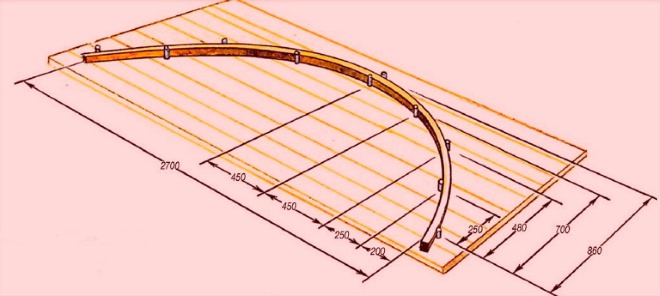

To form a bend with a large radius of curvature on steel or aluminum corrugated pipes, fixed rounded templates are used, on which special clamps are mounted to fix the product. On such a device, the pipe is also bent manually, with force laying it in the groove of the template, the shape of which exactly corresponds to the required bending radius.

Plywood and metal staples are all you need to make a bending template

bending plate

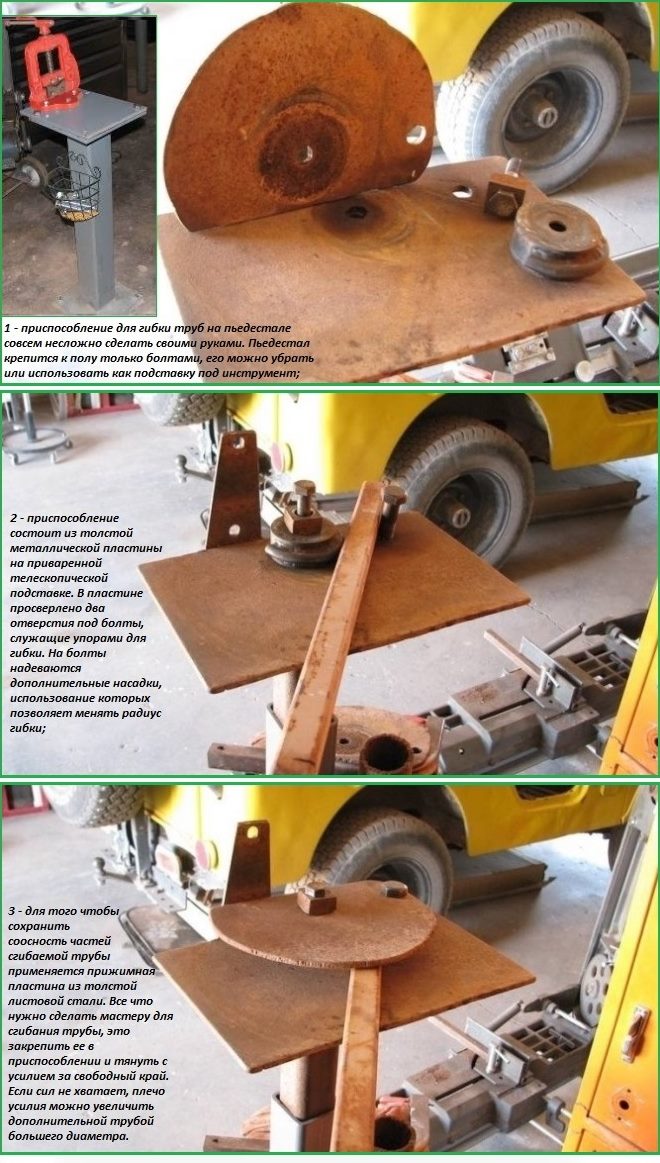

To effectively bend steel or aluminum pipes at home, you can make an upgraded bending plate using the following guidelines.

- The role of such a plate is played by a panel, which is cut out of sheet metal of great thickness.

- The panel, made in this way, is welded to the rack, which is installed on a special pedestal.

- Two holes are drilled in the panel, necessary for installing bolts that serve as stops for the profile pipe.

- A special nozzle is installed on one of the stop bolts, with the help of which the bending radius is adjusted.

- To ensure the alignment of the pipe sections adjacent to the bend, a metal plate is placed above the workpiece, fixed with bolts.

Scheme of the stand for bending profile pipes

The principle of manufacturing a simple home-made bending device

Mandrel bending

For bending profile pipe products at home, the wall height of which does not exceed 25 mm, a special mandrel can be made. For these purposes, it is better to use an overall workbench, on the surface of which there will be enough space for such a device. To select the optimal location of the element that fixes the bendable pipe, often located holes are made at one end of the workbench. A special template is responsible for ensuring the required bending radius of the corrugated pipe, which can be made from thick plywood or a metal corner if you are going to use it often.

Bending a profile pipe with a mandrel

Profile bending application

Of course, if you have a significant amount of work on bending profile pipes, it is better to make a special machine for this, the drawings of which are easy to find on the Internet. We will not analyze this issue here, since it is considered in more than detail in the articles on the links below.

One of the many options for a homemade profile bender

You can not do without such a machine even if you need to bend pipes with a large profile section. The main working bodies of such a machine, which is characterized by wide versatility, are three rolls, two of which are fixed motionless, and by changing the position of the third, the bending radius of the product is adjusted. As a drive for such a device, a chain drive and a handle that is rotated by the operator are used.

Oval protection

The main methods of cold bending of a galvanized pipe provide for measures that allow you to bend the workpiece, preserving the shape of its cross section as much as possible. This is usually done in one of two ways:

- Use of measures to preserve the shape of the section from the inside (use of an internal limiter).

- Using an external stop to prevent expansion of the side walls.

Rigid materials as a filler retain their shape better, so they are more often used. But due to the use of elastic fillers, there is less stretching of the outer surface of the bend.

The need for profile accounting

The category of profile pipe-rolling includes products that have a different cross-sectional shape - round, square, oval or flat-oval. Despite this diversity, for the construction of a greenhouse or a canopy, rectangular or are mainly used. This is due to the fact that it is much easier to mount the outer coating on their flat walls.

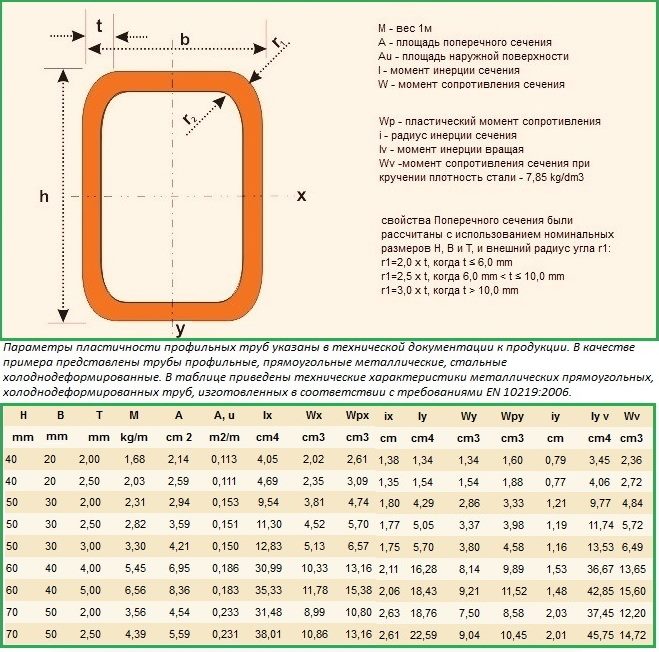

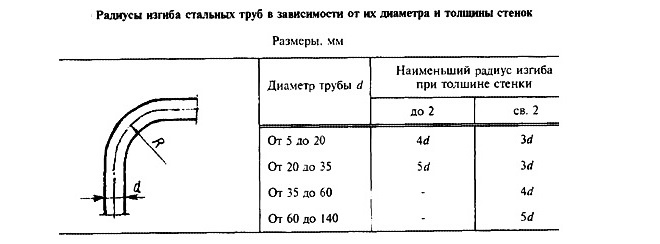

The range of modern profile pipes is very diverse. Their geometric parameters, the main of which are the cross-sectional area and wall thickness, determine the plastic capabilities of the product. The latter characterizes such an indicator as the minimum allowable radius of curvature. It is this parameter that allows you to determine to what minimum radius the pipe can be bent so that it is not damaged.

Avoid common mistakes that lead to damage to workpieces

To determine such a parameter of a pipe with or a rectangular profile as the minimum bending radius, it is enough to know the height of its profile. If you are going to bend a profile pipe with a cross section in the form of a rectangle or square, the following recommendations should be followed.

- Pipes whose profile height does not exceed 20 mm can be bent in sections whose length exceeds a value equal to 2.5xh (h is the profile height).

- Products whose profile height exceeds 20 mm can be successfully bent in sections whose length corresponds to 3.5xh or more.

Minimum bending radii for steel pipes

Such recommendations will be useful to those who are going to bend profile pipes with their own hands in order to make racks, canopies and various frame structures from them. In this case, however, it should be borne in mind that the possibility of high-quality bending of pipes is also affected by the thickness of their wall. Products with a wall thickness of less than 2 mm should not be bent at all, and if it is necessary to create structures from them, use welded joints.

At home, it is possible to bend professional pipes, which are made of carbon or low-alloy steels, only taking into account certain nuances. Such pipes, after bending, can spring back and return to their original state, so the finished structures must be re-fitted according to the template. The springback value is characterized by such a parameter of profile pipes as the plastic moment of resistance - Wp. This parameter is indicated in the accompanying documentation (the lower it is, the less the professional pipes will spring during their bending).

Pipe benders for profile and round products

Pipe benders for steel and copper pipes are:

- manual,

- mechanical.

Moreover, belonging to a manual or mechanical type determines both the design features of the pipe bender and its performance.

Manual devices

Manual pipe bender consists of:

- bed,

- conveyor,

- clamping element.

The pipe is loaded into a conveyor, consisting of rollers connected by a chain transmission, and is pressed by the upper (or lower) roller, which presses on the corresponding face of the product. By rotating the handle of the feed rollers, it is possible to advance the measured segment through the pressure zone, and as a result, to bend the profile pipe or a similar round product.

However, the manual process has its own nuances. Firstly, you can still bend the profile pipe with your own hands, but to achieve the result, you need to make a significant effort. Secondly, manual pipe benders are suitable for processing only small batches of products.

Mechanical apparatus

The mechanical apparatus saves us from the need to spend our strength on bending the profile pipe to the desired radius. Indeed, in a mechanical pipe bender, both the conveyor and the clamping element work not from the muscular strength of the operator, but from an electric motor and a hydraulic drive.

In this case, the scheme of operation of the device remains unchanged. That is, as in the first case, we fill the conveyor with a pipe, create a clamping force on the plane of the product to be bent (where it is necessary to bend the profile pipe even before the measuring section begins to move along the conveyor) and turn on the device in the network. As a result, the pipe passes through the pressure roller zone and changes its curvature. The process of manual and mechanical bending will be discussed in more detail below.

How to bend a pipe without preheating

It is possible to bend the profile pipe yourself, without preheating it, both with and without filler. Do not require filling with sand or rosin pipes, the profile height of which does not exceed 10 mm.

The nuances of bending thin-walled pipes of small size

There is another technique that involves the use of a spring with a dense coil of coils instead of a filler, which is inserted into the internal cavity of the professional pipe and protects the product walls from deformation, as well as from excessive changes in their thickness during the bending process.

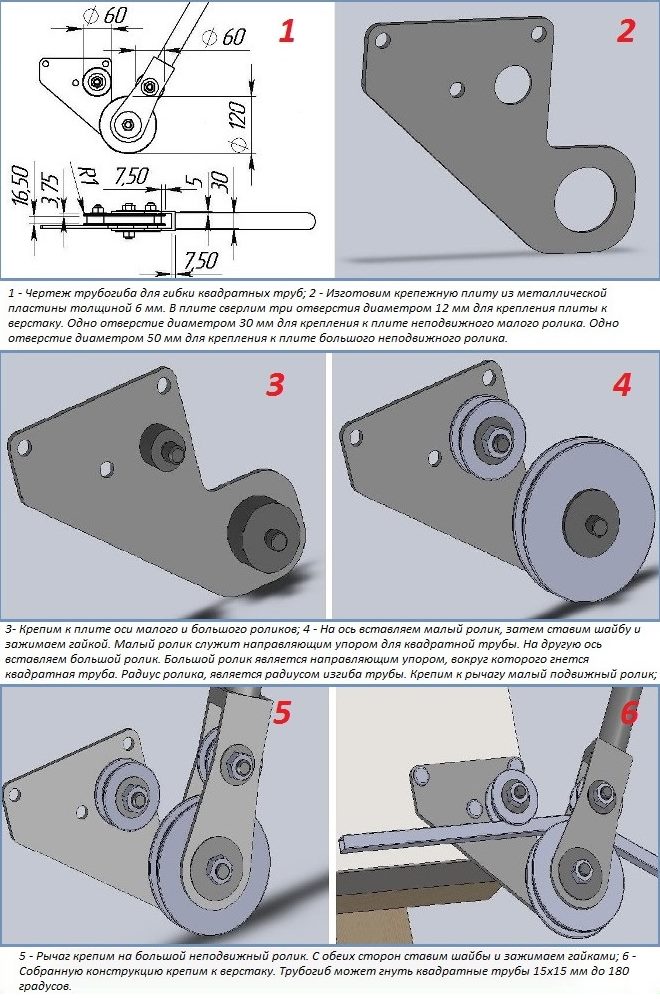

Drawing and details of a mechanical pipe bender for profile pipes

The design of an elementary pipe bender is simple and affordable for self-production.

For those who need to bend profile pipes with their own hands, without first heating them, you can use the training video and the following simple recommendations.

- It is possible to obtain the required bend on profile pipes using the simplest devices - a vice, mandrels, bending plates.

- Can be used for products with a round profile.In this device, it is necessary to redo the working rollers, the shape of the recess in which must correspond to the pipe profile.

- You can bend pipes most efficiently and accurately with the help of which you can purchase or make yourself.

How to bend a sheet of metal straight

If the workpiece is relatively small, then you can use a vice, in which, with the help of two wrapping bars, you can firmly fix the sheet of metal, and only then bend it with a hammer. If necessary, the bending point can be heated with a gas burner, but this method is not applicable to galvanized products!

bending a sheet of metal

If we are talking about a thin metal sheet, then the bending procedure can be significantly simplified.

To do this, at the place of the bend, the metal is “scratched” (we use a rule or a metal ruler, as a cutter - a pointed piece of a hacksaw blade for metal). The metal cut to half the thickness subsequently easily bends along the outlined line. We can say that we almost figured out how to bend a sheet of metal.

We bend galvanized

How to bend galvanized?

It can be either a galvanized metal sheet or a finished product, for example, a profile. The sheet is bent in the same way as when bending any other metal sheet. How to bend a profile? You will have to deal with him. To obtain a large radius of curvature of a square or rectangular profile, you can use the following method: we tightly fill the profile with fine sand, clog both holes with wooden stakes, and only after that, gently tapping with a mallet, bend it.

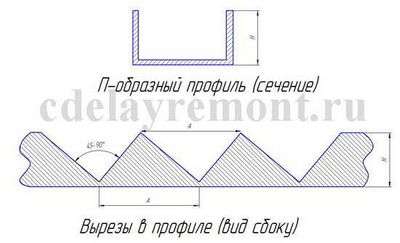

To bend a U-shaped profile (this, in principle, also applies to obtaining sheets of a curved shape), it is necessary to additionally use an object-shape, the curvature of which corresponds to the finished part. To facilitate the bending process, triangular elements can be cut out in the profile.

Then the product to be bent is “wrapped” around the object by uniform tapping with a hammer.

Important! In order for the fold to be as even and correct as possible, the hammer blows should be light and lie as close to each other as possible. How to bend galvanized easier? Using a grinder, we make one or two cuts in the bend area (thus the structure is temporarily weakened), bend the product, and then weld the bend

This approach is important to use when bending profiled pipes and products of complex metal shape. Remember that it is impossible to heat galvanized steel to simplify the curvature!

Perhaps one of the most difficult tasks facing people who are thinking about how to bend the corner. To get a solid product, you will have to sweat, evenly and slowly tapping the surface of the corner, gradually arching it.

It is recommended to use a gas burner, which can heat up the bend. You can do it easier - use a grinder as in the case described above with a galvanized product. It’s even easier to buy an already curved product, then the question “how to bend a corner” will disappear by itself.

How to bend rebar

At home, it is quite possible to bend the reinforcement, however, a lot depends on your physical data and the diameter of the metal rod.

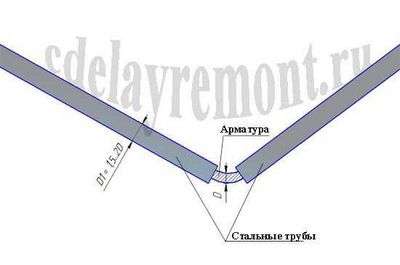

How to bend rebar? To do this, we need two pieces of steel pipes, the diameter of which is greater than the diameter of the bent rod. The longer the length of such pipes, the easier it will be to bend the reinforcement (gain in strength due to the leverage). All that needs to be done in order to bend the reinforcement is to insert it into two pipes and, fixing one of the pipes (pressing it with your foot or resting it between the posts), wielding the second one as a lever, give the reinforcement the desired curvature.

That's all!

Metal bending with flexible tools

By pressing the line, with the help of a whisper, it moves along the drawn line, so that the cutouts reach approximately half the thickness of the sheet. The folded sheet should be placed on an anvil or any other heavy and flat piece of metal.

You need a metal corner to make the curve of the cut metal.

Fold the sheet at an angle, secure it in a bag, or place it on the edge of a surface at a right angle so that the groove is flat on the edge and continues to curve and aid the hammer.

The deeper the gutter, the easier it is to turn the sheet. To facilitate this process, we recommend that you seek help from someone.

Includes:

- friend

- relatively

- someone you know

- colleague.

How to get a metal ring?

When the metal sheet is coated, it is not at an angle but in a ring, you can do this by tapping the surface of the sheet with a hammer. Use lines on clear lines parallel to the lines.

From impacts, the sheet will change its shape more and more, focusing more closely at the edges of the sheet metal, since the radius of the circle must be the same in all directions.

When the bend is finished, the edges of the leaves are finished to the end, you can connect them with a rivet or beer. When you have finished this operation, wipe the shape of the resulting ring.