Tap hole in stainless steel sink

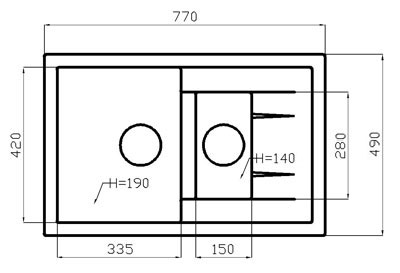

Diagram of the approximate dimensions of the kitchen sink.

There are several proven ways to drill a smooth hole in stainless steel.

It should be noted right away that it is impossible to make an exit under the mixer in an already installed plumbing, since due to the support on the countertop there is a possibility that the plumbing will crack. Before carrying out work, the sink must be turned upside down so that all its edges rest on the surface of the table, and only then proceed to work.

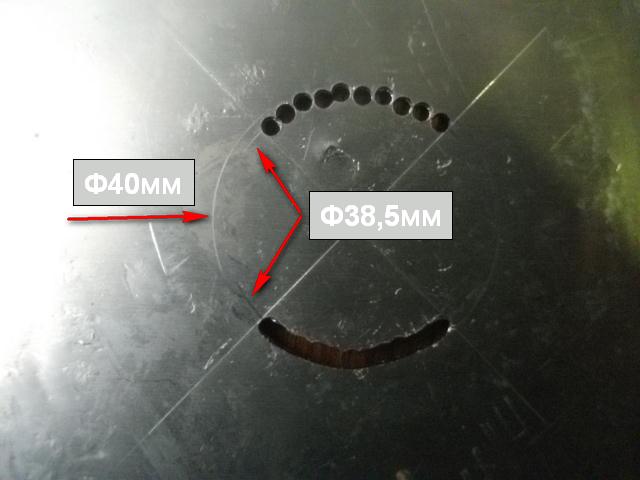

If it is possible to purchase or rent a special cutter for making holes, it will not be difficult to carry out the work. First of all, you need to make an initial hole with a drill and a 10 mm drill. Next, the cutter screw is inserted and tightened with the help of 2 keys, so it turns out that the metal is squeezed from 2 sides and pressed through by the press method. The diameter may vary depending on the type of cutter used. If it is not possible to purchase a special device, you can resort to other methods.

So, in order to make an outlet for communications of the desired diameter in a stainless steel sink without the use of special tools, you will need the following tools and materials:

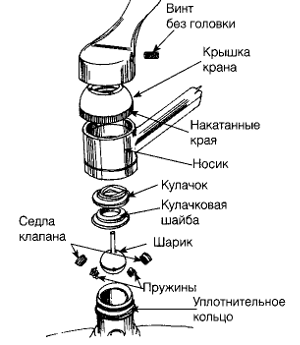

Scheme of the device mixer for the kitchen.

- marker;

- mounting tape;

- hammer;

- round file;

- center punch

In order for the diameter to correspond to the norm, first of all it is necessary to make a circle of the desired size and shape from mounting tape. The cut circle must be attached to the selected place under the mixer and circled with a marker in order to cut an even hole in the future. In addition, you need to mark the center in order to make the initial hole with a center punch. The tip of the punch should be directed to the center of the circle from the mounting tape and punch the initial hole with light taps. If you have a drill, you can drill with it. Next, the initial hole must be expanded with a round file to the boundaries noted earlier.

Just drilling an outlet for a faucet in a stainless steel sink is not enough, as the edges can turn out to be crooked, and it will be very problematic to align them later. After you get the exit under the mixer of the desired diameter, you need to carefully sand the edges of the cut, then you can proceed with the installation. To prevent further oxidation of the metal, the edges of a fresh saw cut must be treated with a sealant. After it hardens, you can proceed to install the sink.

Sinks made of artificial stone do not always have a special cutout, so there is a need to make a hole in the sink yourself. A common obstacle is the fear of damaging or crushing the sink. Although close in properties to natural, in fact, it is more like plastic: or, better, a polymer mass mixed with stone chips.

The ratio of the amount of resin to stone chips can be very different. Regardless of the proportions, this material lends itself better to a drill than stone. However, you still need to be careful and careful. A sink made of artificial stone requires careful handling: it is not recommended to carry out any work until its temperature has become equal to room temperature.

Expert answers

Valery.:

It is necessary to mark the circle of the hole of the required size with a marker and drill it with a drill along the marker with a dm 5mm drill,

daria kalashnikova:

drilled

NOT YET OLD:

Do not spoil the beauty, mount a wall-mounted faucet. Drill and you will have trouble - a place of constant leakage.

Andrey Kozmin:

stainless steel is easy to drill. there are special stepped drills, you can simply drill out according to the marking - then, anyway, the overlay closes. the main thing is what would happen according to the mixer.

yuri!!!:

I don’t know the thickness of the metal, but the principle is such a small drill in a circle, then a needle file, etc. if the metal is thin, then drill into the center and increase the metal with scissors.

Rogue of the Seas:

mark the circle under the mixer with a marker, carefully drill with a thin drill (3-4mm) along the inside of the marker, pick out with a stalemate

And I'm Fsia Taka Mysterious:

Cutter 32 mm for metal, it is placed in a drill! Pin a point with a dowel or nail in the place where the hole will be (there will be a crane). To do this, remove the sink. You can embed the faucet directly into the countertop, the hole in the countertop should be treated with silicone.

Winds:

and these sinks are not provided for the hole)))

cons of stainless steel with holes - they bend and after a short time the fixing nut under the sink loosens and the mixer loosens - accordingly, there may be problems with rapid wear of the ge. gaskets and leaks..

a hole is drilled in the countertop, a cut is treated with silicone, a metal washer must be placed (glued) under the nut - the mixer will remain motionless - acc. more durable.

Sergey Romanov:

there are crowns for metal, we have a price for them in the range of 1500-1800, the hole turns out to be neat, but do not forget to pour plenty of water, otherwise the edge of the saw will darken, good advice was given to drill with a small drill, but not 5mm, take it thinner (it is cheaper than crowns)

REM2009:

Drill in the center 6mm and then with such a drill to the desired size. (slang for "carrot") This drill in thin sheet metal allows you to get round, even holes, drilling in other ways is laborious and requires additional effort to obtain a quality hole. (often used in car service)

the best of the best:

in the market where sinks are sold, there is a special device, such as a clamp. Immediately squeeze out a pretty hole for the mixer. The fact that the metal is thin, yes. It is better to put a mixer with two valves on such a sink, and if it is “one-armed”, then it is completely easy to move. Fastening is thin, the crane bends.

mikhalych:

and it’s not fate to put it on the countertop? there are no problems at all with drilling and installation .... at what from any party it is possible to establish.

Ilyadru:

Stainless steel sinks are left and right according to the location of the bowl. But many manufacturers produce universal sinks (without a hole for a mixer), for which, in the process of manufacturing a kitchen, it is necessary to additionally make a hole with a diameter of 35 mm for a mixer. For these purposes, there are special devices: punches or, in other words, punches:

Their principle of operation is based on a pair: punch - matrix. Having punched or pre-drilled a hole, a rod is inserted, along which, with the help of a key or collar, the punch pushes the hole, entering the matrix. It should be said that it is necessary to purchase a fixture made of high-quality (well-hardened) materials. The approximate cost of such a kit (top photo) ranges from $10-80 depending on the manufacturer. Hole making services usually cost between $1-$3.

A friend of mine bought a die cut at a hardware store, made a hole in the sink with it, and returned the die to the store.

Good luck!

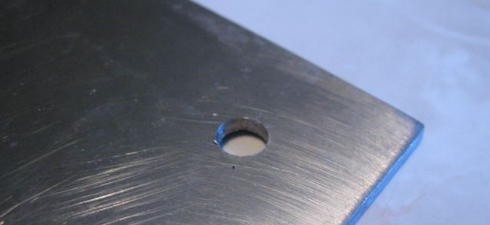

This is what the cutout looks like

Sergey Ponomarev:

at home with a drill and a file, the file is better round or semi-circular

Exiled to planet Earth:

Drill and crown for metal with the appropriate diameter ... .5 minutes of business ....))))))

Expert answers

psychologist:

crown of the appropriate size.

SNV:

draw a circle under the mixer. We drill with a small drill in a circle.

Vladislav:

The cutter is special, the cost is about 180 rubles, first with a drill, then with a cutter inserted into the drill we expand it to the required diameter, be careful, it cuts metal very quickly, so do not get carried away.

Yegorych:

Previously, holes were made in a circle by increasing the diameter of the drill and then with a file. Now there are many ways: 1. There are special drills in the form of a crown, for centering the drill in the middle, they are made of a special alloy. The base is common, the crowns vary depending on the diameter. Ask at the store where they sell the instrument. 2. There is a special press consisting of two halves, one with sharp uneven teeth and enters the second with a bolt. We drill a 10mm hole, insert the bolt and tighten the two halves with a key. It turns out a smooth, precise hole. Such pieces are included in the IKEA kitchen furniture set. My daughter gave me and I only work for her.

Andryha:

With a narrow chisel (I make 10-12 from a drill) just put a piece of wood under the bottom, for example. Breaks through easily.

Alexander Adamov:

I did this with a sharp drill bit. An ordinary drill for metal does not take a stainless steel.

Cornelius Schnapps:

Usually such holes are made right at the point of sale with a special press, but in practice it was necessary to cut a hole with a knife, such as a shoe from Rapid.

Vadim Mortin:

Drills are sold specifically for drilling stainless steel (by the way, there are also cutting wheels specially for stainless steel), Draw a circle on the sink with a felt-tip pen, drill holes along the line (putting a board under the bottom), then cut it out with a narrow chisel along the drilled holes and finally clean it with sandpaper wound on a round stick (a piece of a mop handle).

Crab:

If there is already a hole, then drill it in the sink with a cutter of the desired diameter. In this case, the drilling site must be wet, they must be watered

Mr Freeman:

buy another mixer - it will be cheaper every hundred times. Otherwise, you will clog the sink. Then you will have joy

vve-67@mail :

A diamond crown can help.

SERGEY VINOGRADOV:

There are all sorts of devices with DIAMOND coating, spraying

125aaa:

You can try an abrasive cutter with water. Just think you're some kind of nonsense. Mixer hoses are removable. You're doing something wrong, kmk.

Alex Mishin:

“New faucet of a different design and does not fit with flexible hoses”? It should not be passed along with flexible hoses! One of the hoses, and sometimes both, must be unscrewed from the faucet, passed through the hole in the washbasin and screwed back into the faucet base. To do this, you usually need a 10 ... 12 mm wrench with a small thickness of the jaws - an adjustable wrench is not good, sometimes you have to grind an open-ended wrench on emery. Only hoses with reduced diameter union nuts can pass through the washbasin opening - 3/8″ instead of 1/2″. True, I once expanded the hole in the washbasin - it was without a hole for the mixer at all, only with a hole less than a centimeter in diameter for screwing the chain. I succeeded - I still can’t understand how the washbasin didn’t crack! It was in 1979 - then to buy any kind of washbasin was an almost insoluble problem.

Truculentus:

You don't need to drill anything. Unscrew the hoses, put the mixer, and screw the hoses from below.

Design of faucets and sinks which option will be optimal

- With retractable hose. This option is suitable for small rooms or small sinks. Subject to the choice of a deep bowl, the “mobile” hose will significantly expand the list of possibilities for using the mixer in the kitchen;

- From one collection. It is considered one of the simplest and also fastest options, in which the selection of elements is already done for you. In this case, you not only get a kit made in the same style, but devices with similar technical parameters. Large manufacturers, at the same time, include optimal installation schemes in the data sheet of models and also indicate the recommended distance from the mixer to the sides of the bowl;

- Items from various collections. The option is suitable when buying, for example, a round sink, or a model with a non-standard shape.In this case, visual alignment becomes the best way, which can be done right in the store.

Some services also provide ready-made solutions by pre-selecting faucets and sinks for the buyer according to parameters such as: style, characteristics, dimensions, shape, operating options, etc. This allows not only to quickly find the perfect solution.

If you want to buy all the structural elements in a specialized store and do not have the skills to make the right decision, the best way to solve the problem is the service of a consultant. The seller will not only offer things

optimal for your kitchen, but will also give the necessary recommendations for the selection, installation, operation, etc.

Where to cut a hole

Another significant question that will arise no matter what materials the sink was purchased from is to cut a hole in it from the front side after the installation has taken place? Or do it before installation and from the back side?

Each method has a number of advantages and disadvantages.

In the first version, the edges on the front side will be much smoother, but there is a chance to spoil the front side of the sink with a drill, and if it has a narrow rim, then split the edge.

In another option, the risk of spoiling the bowl is much less, but there is a chance of getting a sloppy edge of the hole on the front side. In many cases, this is not a problem, since the edges of the hole are closed with a tap. When turning over, there is an option to casually make a hole on the wrong side, thanks to this it is best to highlight the side on which you want to install the faucet.

In any of the ways, it is best to place the hole further from the edge of the product, but at the same time, without hitting the bowl. To do this, at the beginning of work, you need to attach the lower nut of the water tap to the sink and highlight its center.

Differences of stone algomerate shells

If, for example, you purchased a sink made of stone agglomerate, it will be a little easier to work with it.

Artificial stone sink from agglomerate Well-known manufacturers in most cases attach a cutter or core, which knocks out a piece of stone that has already been drilled, but not completely. If they are not present, then a great option is to use a diamond-coated cutter or crown and proceed as you would when working with porcelain stoneware.

A fostner cutter will also handle a hole in a stone agglomerate product. But get ready for the fact that then it will need to be sharpened, or even completely thrown away.

Be sure to read the instructions and operating rules before taking any action so as not to inadvertently lose the product warranty.

Fake diamond

If the sink is implemented as a single piece with the countertop and the same color as it, then this is an acrylic decorative stone. Of the materials listed above, this one has the lowest density, which makes it the easiest to work with. If the purchased sink is actually made of artificial stone, then the answer to the question of how to drill a sink from acrylic stone is very simple - with traditional drills for working on metal or wood.

The hole for a typical faucet, in many cases, has a diameter of 35 mm. In a product made of artificial stone, it is easily drilled with a blade drill for woodworking or a forstner cutter of a similar diameter. You need to work at low or average speeds. When drilling into this material, the vast majority of chips will appear, and the plastic that is part of the artificial stone emits a bad smell, somewhat reminiscent of epoxy-based glue.

Acrylic stone sinkAcrylic stone is the softest of all acrylic stone options, due to which a significant part of the countertops is made from it.If there is a need to make a hole in it for a sink or hob, it is better to practice in advance in the middle of the cut-out part so as not to harm the entire countertop. Ignoring the fact that artificial stone is sawn with a jigsaw without big problems, it is undesirable to cut it with it. While working with a jigsaw, in other words, stress concentrators (sharp transitions, sharp corners, small cracks) often appear, which affect the life of the product.

Best Answers

//:

Just like drilling glass: A ring of plasticine is made around the drilling site and acetone is poured into it, then it is drilled with a simple drill at low speeds, gradually adding acetone to the desired level. The difficulty is that the hole is larger than 10 mm. hard to do.

Sergey Polovny:

Drill bit for tiles or glass

~ CAT ~:

No, a dead number, it will burst.

Ukraine 2000:

Why drill it? But a drill on concrete or glass is possible. Just be more careful with a diamond circle

And yes, you have to be very careful when drilling. Not forgetting that the washbasin is two-layer and the leg is one

grandfather fir:

with a drill with a drill, only glue the place of drilling with adhesive tape

Anatoly Bondar:

With a copper tube of the desired diameter, pouring emery powder with liquid.

Vitalban1:

A crown (diamond - of the required diameter) is taken into a drill, at low speeds, with watering, though first you need to grind the JIG from the tile, at the same time you will practice - then you put the jig on the sink, preferably a flat surface, fasten the jig with tape and drill with water

PopuAs:

Yes, drill, don’t listen to anyone, only “without a beat” of course ....

torn heart:

Here I say:

Poke a hole with a self-tapping screw. Drilled with a simple 6mm drill without impact.

How to drill stainless steel correctly

Drilling stainless steel is always a laborious process that requires a certain amount of experience, it requires increased sensitivity and care. Stainless steel is a material that is quite difficult to drill, in this case it is necessary to use a special lubricant, this will greatly facilitate the whole process. Many do not really know how to drill stainless steel or the Russian analogue of AISI 201, but everything is quite simple, you just need a little experience and care.

The main component in stainless steel drilling is lubricating fluid, because without it, nothing good will come of drilling, you will only spoil the drill and the material itself. The lubricating fluid has a viscous state, it is quite oily and contains machine oil and sulfur. Sulfur in a lubricant can be of a very different nature, it can be colloidal sulfur, sulfur for fumigation, and so on.

Drilling stainless steel, which is better to choose?

As mentioned earlier, the lubricating fluid can have a very different character, there are two types of sulfur, one is a lighter composition, and the other has complex components such as fatty acids and sulfur.

In order to make a lubricant with a more complex solution, it will take a lot of patience and perseverance, in this case you need soap (it is best to choose household soap), it must be broken into even pieces and dissolved in hot water.

If you add a little cold water to the solution, you can see how the fatty acids solidify, as a result of which they can be easily separated from each other.

After that, fatty, hardened acids should be thoroughly rinsed, for this case it is best to take a small container, fill it with warm water and stir actively for 5 minutes, while do not forget to gradually add cold water there.

Everything ingenious is simple

Drilling is a process in which two components are loaded at once, this is a drill and the material itself, during the situation some moments may arise, such as overheating of the drill, overheating of the material at the point of drilling, and much more.In this case, many people have questions about how to drill stainless steel, how to avoid overheating, and much more, in fact, everything is quite simple, you just need to slow down and drill gradually, this will avoid overheating.

Note: if you need a manipulator for construction work, you can rent it on the website of manipulators.ru at a bargain price.

Hole for sink faucet

The rule is the same for all sinks, the higher, the deeper the bowl should be. When choosing an arc-shaped mixer, flat models are not recommended. Such designs are more suitable for mixers of small height and become a good option, if necessary, to equip a small corner.

When choosing a design for the kitchen, it is also important to consider the following:

- The sink should be of such a shape that the jet of water would fall exactly on the bottom of the bowl, even with full pressure (a narrow sink is not the best option);

- When installing the sink on the countertop, a high-rack faucet model will be a quality choice;

- The angle of incidence of the jet is quite rarely equal to 90 degrees, so the distance from the counter to the side of the sink should be taken into account;

- The number of holes required in the design determines whether a wall-mounted sink can be purchased. Or a product that is installed on a countertop (the model can be presented both with one hole and with three).

Another criterion for choosing a product is the design of the faucet. How to choose a model, read on.

Benefits of choosing a sink

H

the most famous among the inhabitants are sinks made and stainless steel. At the same time, both left and right designs are known, differing in the location of the bowl. In many ways, such models are good due to their durability, but most often sinks of this type are produced without a hole for the mixer. Isn't it hard to do it yourself? Wrong!

Regardless of the brand of the manufacturer, a sink that is completely ready for installation is the right option to buy. That's why:

- A hole in the sink for the faucet can be made with the condition of having certain skills. Otherwise, you can not only significantly worsen the appearance of the structure, but completely make it unsuitable for further use;

- The diameter of the faucet hole must exactly fit the faucet model. In the absence of the necessary tools, this can be difficult to achieve;

- The operation requires a punch (cutting), the price of which ranges from 50 to 100 dollars. A person who decides to buy a budget sink and mixer will not spend money on a rare task;

- Choosing a product that matches the design of the room and the stylistic decision of the kitchen set requires knowledge of the characteristics, classification, or even care features. Most of the listed parameters are simply not needed when choosing a model that does not require a hole for a washbasin faucet.

Of course, it is impossible to state categorically that sinks with a hole for a mixer are better than analogues. For example, people who want to save money on buying a bowl are given the opportunity to use the services of plumbing

.

The price of the work, at the same time, is no more than $ 3 per operation and includes the creation of as many holes as you need. A neat hole for the stem and die can be obtained in just a few minutes.