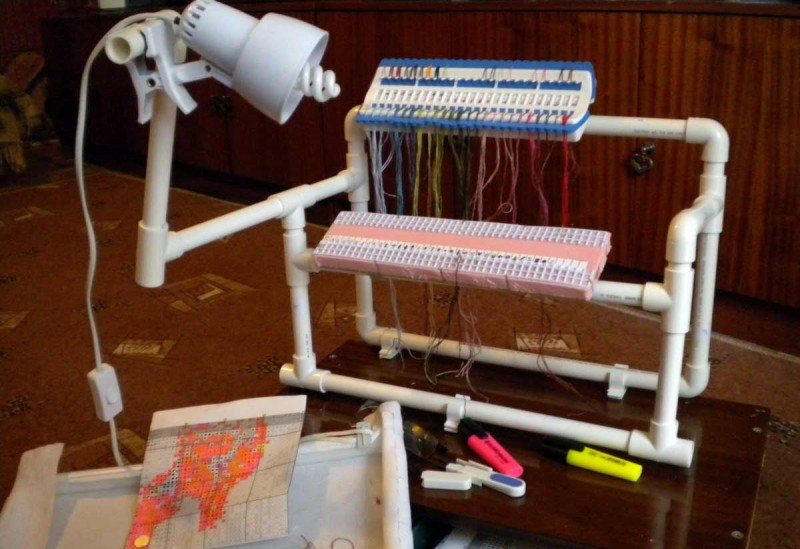

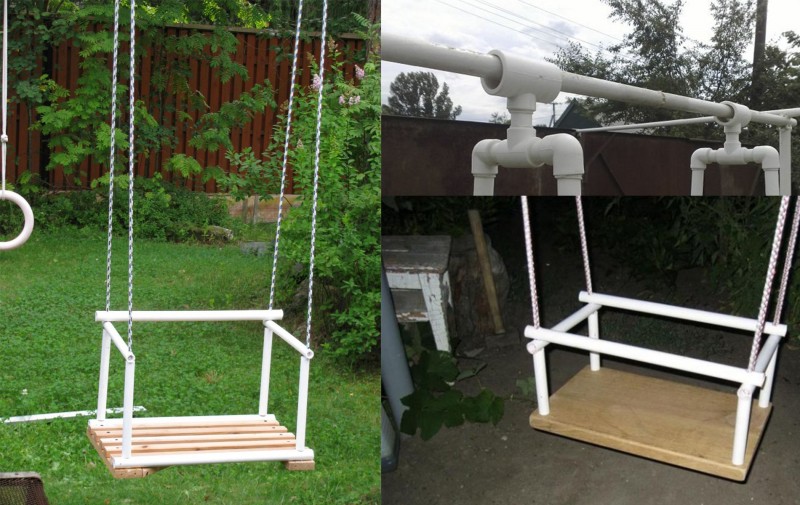

What is good plastic pipe

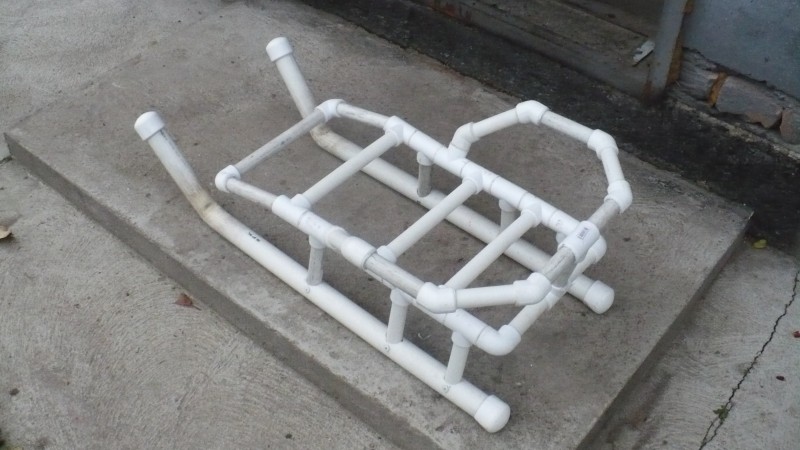

We will not talk about the direct purpose of the product, but about the convenience of using varieties of plastic pipes precisely as a material for crafts. Plastic pipes are light weight, strong and durable enough. They are resistant to dirt, do not collect dust and are easy to clean. Products made of plastic pipes are safe to use even by small children (they do not break, do not have a heavy weight, do not emit toxins).

For creative work, PVC pipes are more often used, which are quite rigid and easily connected with special nozzles and "adapters", allowing you to get collapsible structures. Polypropylene pipes can also be used, but their connection will require a special welding machine or compression fittings, and finished products can no longer be disassembled.

Preparation of pipes, valves, fittings

The first step is to study the instructions for the soldering iron. It contains all the recommendations, as well as restrictions on the use of the machine. The instructions also contain a table by which you can determine the heating time of the pipeline elements.

Next, the preparation of the workplace is carried out, as already mentioned above. It is necessary to fix the welding machine with a clamp, connect it to the network. Set the operating mode to 260 o C. The temperature is set on a special regulator.

Now you need to strip the Teflon inserts and put them on the machine. It remains to wait for the heating of welding. During the entire work, you can not turn off the soldering iron. The set temperature regime will not allow overheating of the Teflon inserts. But under no circumstances should the temperature be lowered. The resulting connection will be unreliable, wear out over time and leak.

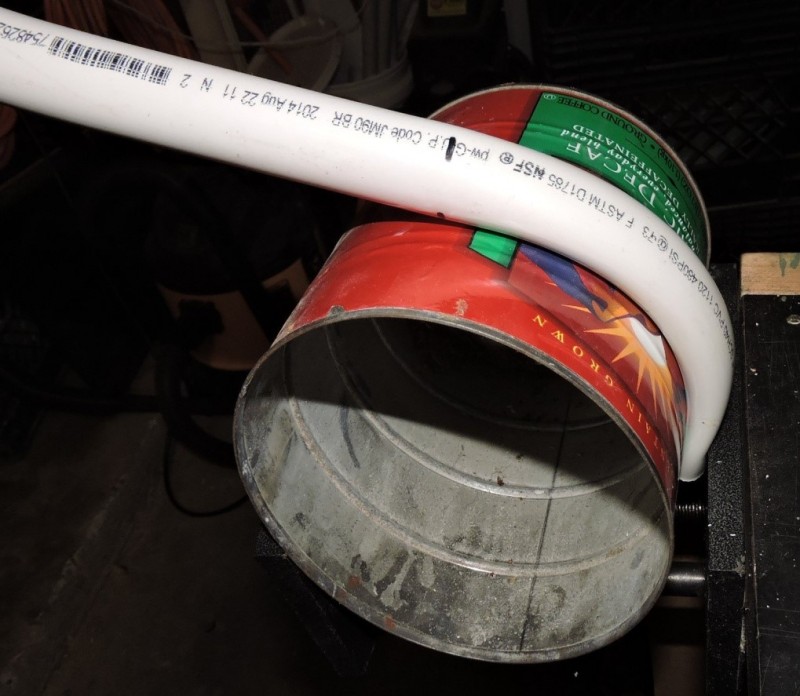

Now you can proceed to the preparation of pipes. First you need to make segments of suitable sizes. All sections should be carefully processed. The reinforcing layer is removed. With the help of scissors-cutter, the edge of the pipe is cut off, now you need to chamfer with a cone-shaped cutter. The surfaces to be soldered should be degreased, cleaned of dirt, dust and unevenness should be eliminated.

Soldering tools for polypropylene pipes and taps

When the problem is solved with the choice of ball valves, you can proceed to the preparation of tools for soldering polypropylene pipes and locking mechanisms. Soldering equipment can be purchased or rented.

In general, this device is useful on the farm, it is often used when repairing breakdowns or installing a plumbing system. It includes a heating element in the form of a xiphoid plate, in which there are holes for various nozzles, and a thermostat. With the help of the latter, you can set a specific soldering temperature. For polypropylene, it is 260 degrees Celsius.

Most often, the power of such devices is 2500 W, and they are connected to a household outlet with a voltage of 220 V. The soldering machine is capable of operating in a temperature range from 50 to 320 degrees Celsius.

The device is equipped with Teflon nozzles of different diameters, suitable for all polypropylene pipes used in plumbing systems. If the pipe is a non-standard size, then the nozzle can be purchased separately.

When a one-time soldering of pipes and taps is planned, the easiest way is to rent a soldering machine. This will save you money while completing the task. But this is not all that is required.

List of required tools:

- A welding machine for polypropylene pipes (it is also sometimes called a soldering iron, because the connection of PP products is carried out by soldering).

- Devices for cutting and stripping pipes. The end cut is performed with a conical knife, precision scissors and a cutter with a roller are also needed.However, it will also be possible to cut a polypropylene pipe with a hacksaw. But then the edges of the cut will turn out to be uneven. For a complete installation of the water supply, you will need a special tool. Sometimes it is included in the set of the welding machine.

- If you plan to solder reinforced pipes, then you will additionally need a hand knife. It will be used to remove the reinforcing layer. Otherwise, welding will be unreliable, such a connection will quickly fail.

- Markup tools. Usually, a construction pencil or marker is used to apply it. With their help, it will be possible to highlight the connection line of the pipe with the tap, along which the soldering will go.

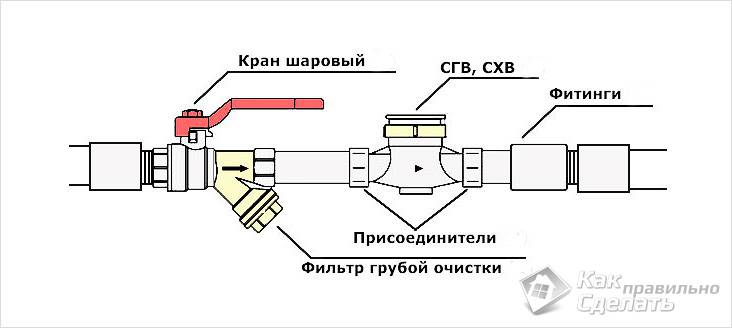

Fitting

When installing any type of pipes in the process of performing plumbing work, you can not do without fittings, which also include all kinds of taps and valves. These can be solder ball valves, straight or angle valves (with an American). Brass ball valves (crimp, with a butterfly handle) are used, which are distinguished by good anti-corrosion resistance. When connecting such a tap to a pipe, a split brass ring is used to crimp the pipe; rubber (ethylene-propylene) is used as a sealing material. Such ball valves are three-way, with external thread, with internal thread, for connecting pipes at a right angle.

No special tools are required to install these faucets.

Metal-plastic or polypropylene

Modern plumbing equipment is, first of all, five-layer pipes made of metal-plastic, which have gained particular popularity due to their many advantages over other types of pipes:

- compacted inner layer of polyethylene;

- elastic aluminum layer of the pipe, which retains the shape and configuration specified during installation;

- connecting the inner and outer layers of the polyethylene of the pipe with its aluminum layer using glue;

- durable layer of anti-corrosion polymer;

- not obligatory observance of the exact calculated dimensions when installing pipes made of metal-plastic.

When installing plumbing equipment, another type of pipe is also used - polypropylene pipes. Their advantages over metal-plastic ones are economic benefits (polypropylene pipes are at least three times cheaper), as well as ease of installation. They can be connected without much difficulty even with metal pipes.

HOMEMADE MIXERS

In showers of rest houses, baths, hotels, you can see mixers similar to those shown in fig. 1-2-39.5-2-40. In these mixers, all connections are threaded.

A faucet is constructed from shutoff valves, pipe cuts, spurs (Fig. 1-2-39), similar to a bath faucet with a stationary shower tube and a mesh. The role of the bath-shower switch is performed by two valves located directly on the highways leading to the bath and shower. Depending on the need, they are alternately blocked. In addition, these valves prevent the so-called transfer (penetration) of hot water into cold water, and vice versa.

Unlike a tap, which has only one external thread for connecting through a coupling to the supply pipe, the valve has two internal threads for this purpose. Choose the one at which the water will go through the valve in the direction of the arrow on its body. If the arrow is not marked, you should look into the ends of the valve with internal threads. A jet of water from the pipe should enter the end of the valve where there is no valve. To make the valve more noticeable, unscrew the stem by the flywheel a little.

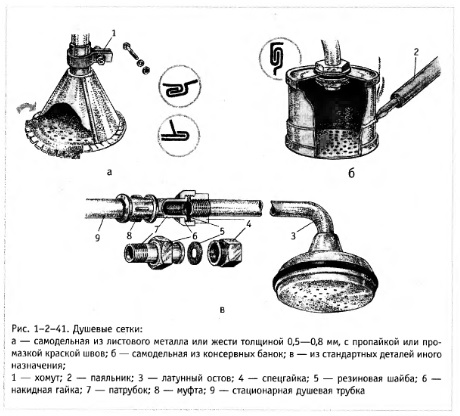

A suitable funnel from a garden watering can can be used as a shower screen. When self-manufacturing, the parts of the funnel are connected with a recumbent fold (Fig. 1-2-41a) and soldering. Before folding, cuts are made on the funnel tube in 2-3 places on the side where they will not be soldered.The end of the shower tube is wrapped with a strip of thin rubber. A funnel tube is put on it with incisions and everything is grabbed from above with a clamp so that the water pressure does not tear off the funnel.

When making a shower net from two or one tin cans (Fig. 1-2-416), a hole is made in the center of the cut out bottom of the can, sufficient to push the end of the shower tube. The bottom is fixed on it with gaskets, washers and locknuts. The main part of the can is soldered to this bottom, in the bottom of which mesh holes should already be punched. When soldering, it is necessary to disconnect the shower tube from the faucet. Do not solder on weight and at height. It is not necessary to invent a shower net if there are parts from an old-made flexible hose (Fig. 1-2-40), a branch pipe and a union nut from a standard mixer

It is important that the threads of the pipe and the coupling match, and the union nut is screwed onto a special nut with a similar thread. If this does not happen, you can turn parts with the desired thread on a lathe

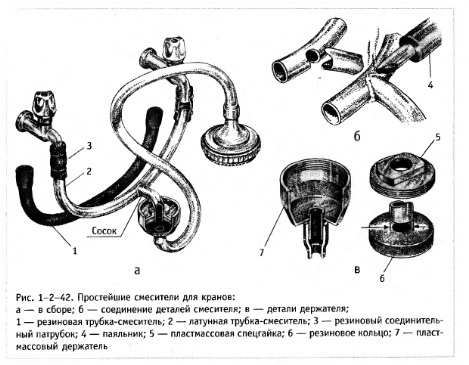

On fig. 1-2-42 shows the simplest mixer, which was produced by our domestic industry some time ago. The mixing of cold and hot water here takes place in a brass, chrome-plated tube, the outflow is through a soldered spout. It is easy to connect the ends of the mixer through rubber tubes to taps, spouts of various shapes, etc.

This faucet, located above the washbasin with taps, does not require any additions. The faucet comes with a hose with a shower screen. The hose with the mixer is joined with the help of the holder. A hose with a shower screen successfully complements the faucet above the bathtub, tray, etc. The design of the faucet has a number of disadvantages. So, a thin-walled hose can break, so it is better to replace it with a rubber pressure hose with thread reinforcement or a rubber hose for gas welding and metal cutting. So that the connecting rubber pipes do not come off the ends of the mixer under water pressure, they are tied with thin copper wire, strong linen threads or clamps are placed.

Currently, such a tubular mixer is not available, but it is useful to borrow some elements of its design. Thus, the equivalent of a brass tube is a rubber tube with a hole in the middle. True, in this case, the shower tube or hose will be more difficult to “cement”. In the plastic case of the factory-made holder with an internal thread, a rubber ring is inserted, which is locked with a special plastic nut, which has edges for screwing in and out in the center. With a hole in the rubber ring 5-8 mm thick, the holder is fixed on the nipple of the mixer. The diameter of the hole is 2 mm smaller than the outer diameter of the nipple. The main advantage of the holder is that you can quickly remove, put on and connect the hose with a shower net.

The holder can be machined independently on a lathe. On a special nut, a hexagon is not needed. It is replaced by a protrusion with two flats for a regular wrench (Fig. 1-2-42c). You can do without a holder at all. In this case, pull the hose directly on the nipple. At the point of contact, the hose is covered with a clamp or thread.

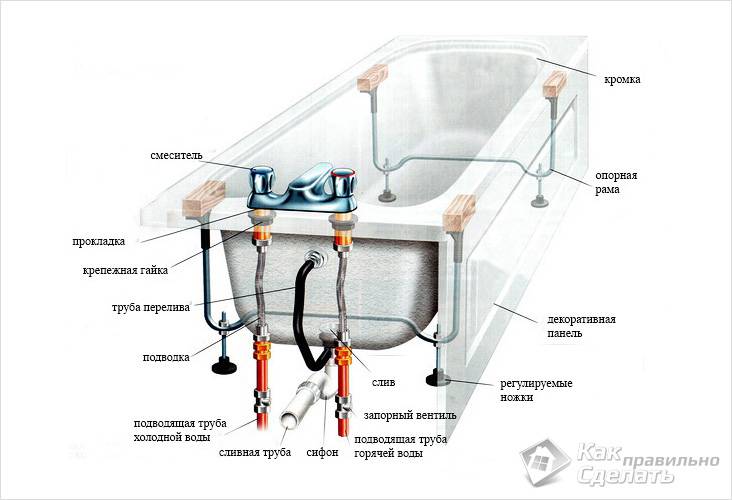

Installation of faucets in the kitchen and bathroom

If it becomes necessary to replace the faucet in the kitchen, this task is also not difficult to handle on your own.

When choosing a faucet, pay attention to the presence of the necessary gaskets, without which it is impossible to prevent the flow of water

To install the crane you will need:

- wrench;

- fum-tape for winding the pipe;

- gaskets included;

- couplings (if necessary).

Before starting to replace the faucet, turn off the water supply using the existing taps on the riser pipes, then open the water supply on the old faucet to make sure that the water supply is turned off.Next, the old mixer is dismantled with careful movements using a wrench or adjustable wrench. In the exposed areas of the faucet, old gaskets, rust on the threads are removed using a regular piece of cloth.

The bathroom faucet can be connected directly to the pipe. Insert the kitchen faucet into the hole in the sink, after putting on it the sealing ring separating the faucet and the sink. The bottom of the sink should be protected by a large rubber gasket and locking ring, which are secured with a wrench.

Two connecting hoses with nuts on the mixer are connected to the corresponding pipes for supplying cold and hot water. Preliminarily, the threads on the pipes should be wrapped with a special fum tape to create tightness and prevent leakage, and then tighten the nut.

The water faucet in the bathroom is keyed to the pipe using an adjustable sleeve on a rubber gasket.

Following the instructions, it is not so difficult to connect the faucet to the pipe.

Of course, you can replace taps or faucets yourself, without the help of plumbers. Sometimes it can be replaced in just 1 hour, and you have to pay a tidy sum of money, calling a plumber is far from free. For this reason, it is worth making a personal effort.

This article says that in most cases, cranes fail due to their frequent use, I do not completely agree with this. As practice shows, in most cases, faucets or faucets with hot water supply fail. This is due to the fact that hot water constantly exposes the sealing gum to sudden changes in temperature. Accordingly, the gasket becomes unusable. The first sign that a faucet needs repair is constant water dripping and leaking. In some cases, the faucet begins to emit an unpleasant buzz.

In some cases, the dismantling of the old faucet entails the need to change the plumbing system. This is especially true when you have a metal pipeline. As for me, I would give my preference to pipes made of polypropylene. You can read more about the advantages of these pipes and how to solder them in the corresponding article - soldering polypropylene pipes.

I also want to note that the type of key, namely adjustable, is correctly indicated in the article. Why exactly him? This is especially true for mixers that are mounted on the wall. The fact is that most faucets are made of brass or chrome. There are also combined models. So, a brass faucet is veneered with nickel or enamel. This coating may be damaged if not handled correctly during installation. If you use a simple open-end wrench, which has a weak grip when tightening the nut, it may break. Most often this leads to surface damage. But if you use a wrench, then there will be no such problems. It fits snugly to the surface of the nut, which allows you to install the mixer without damage. But you can’t do without an open-end wrench in cases where you need to install an eccentric or other connection that is not at risk of losing its “presentation”.

Separately, I will express my opinion regarding the winding of the thread. I am not a supporter of the fact that for a connection that has a rubber gasket, it is necessary to additionally use a winder. Although in some cases it is required. For example, if the rubber gasket does not fulfill its main role. Moreover, it should be understood that the use of tow should also be limited.

What is necessary

For the installation of polypropylene pipes, you will need special tools for cutting and connecting elements.

The list of tools includes such devices as:

- pipe cutter;

- welding machine;

- sweep;

- glue gun;

- marker for marking;

- connecting part and tape measure.

It is better to use a professional pipe cutter for polypropylene pipes - such a tool guarantees reliability and a perfectly even cut, it will not allow burrs to form on the cut surface. When choosing a pipe cutter, it is worth considering such an important parameter as the minimum and maximum pipe diameter. The tool should be chosen with a blade made of alloy steel only.

A manual type welding machine must have a thermostat and a heating plate with holes for installing nozzles. The welding machine requires a pair of Teflon-coated nozzles. It should be chosen from well-known brands that have proven themselves in the market, since the tool of dubious manufacturers may fail during operation, which will stop all work.

Stripping are manual and in the form of a nozzle on a drill.

- Couplings with internal knives (shavers) are used for stripping the outer layer. Under the diameter of the pipe, which is cleaned, select the desired coupling. They also use double-sided couplings that allow you to work with different diameters. To clean the inner layer of the pipe, they take a stripper-facer, in which the knives are inside. The pipe is inserted into the tool and rotated several times.

- Strippers in the form of attachments for a drill differ from manual options only in the presence of a rod that is inserted into the tool chuck.

The glue gun can be used as an alternative to other types of connections. This tool has two advantages: glued seams are almost as reliable as welded and other joints, and the glue sets quickly. Such connectors perfectly fasten shaped parts and other elements.

Polypropylene pipes are often used when installing sewers in city apartments and country houses. This is due to the reliability and ease of use of the material. Connecting ball valves to the water supply is an important stage in the installation of the system. The article is devoted to the nuances of this task.

Photo crafts from PVC pipes

We also recommend viewing:

- Making a diaper cake with your own hands

- Crafts from egg trays with your own hands

- DIY crafts from birch bark

- What can be done from the constructor

- Crafts from baby food jars

- DIY matryoshka for kindergarten

- Beautiful colored paper applications

- Crafts from pumpkin and sunflower seeds

- What can be done with PVA glue

- DIY mushroom crafts

- Walnut Shell Crafts

- DIY paper angels

- The best DIY foam crafts

- Balloon figurines

- How to make a paper frog

- Simple DIY straw crafts

- Do-it-yourself volumetric paper application

- Interesting DIY wood crafts

- DIY crafts from old things

- Interesting ideas for applications from circles

- Interesting plasticine crafts for children

- The best DIY wine cork crafts

- Beautiful fabric appliqué

- Application from colored paper Cockerel

- Toilet paper roll crafts

- Application of geometric shapes for children

- Overview of hot glue craft ideas

- Do-it-yourself original crafts from wood cuts

- Funny felt toys

- Educational soft books made of felt

- Beautiful DIY crafts from socks

- Original crafts for the cement garden

- Crafts from light bulbs with your own hands

- DIY crafts from coffee beans

- We sew a phone case from felt

- What can be done from dried roses

- What can be done from old tires

- DIY original valentines

- Amazing towel figurines

- DIY felt crafts

- How to make DIY rattle toys

- DIY felt animals

- DIY felt letters

- Craft paper bunny do it yourself

- DIY crafts from scraps of fabric

- Original crafts from tin cans

- Ideas for using old fur

- Epoxy resin jewelry

- Original do-it-yourself pumpkin crafts

- DIY wallet for paper money and coins

- Charming flowers from felt do it yourself

Please repost

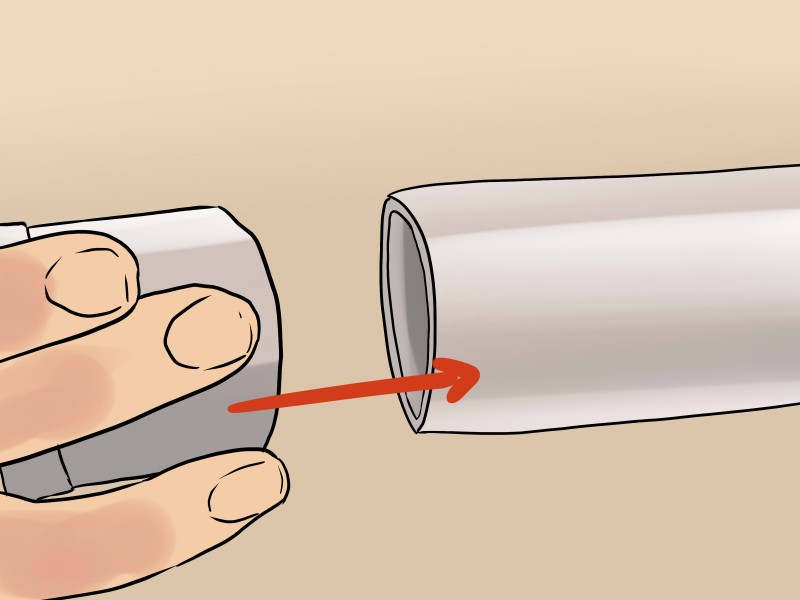

Connection stage

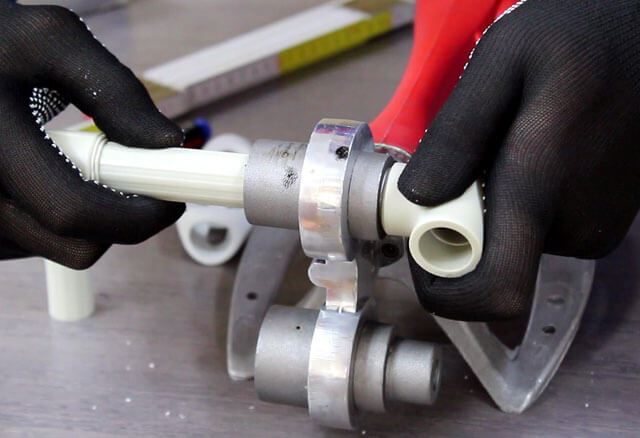

When all the preparation is over, you can proceed to the main stage of soldering. The prepared pipe is inserted into the first Teflon nozzle, and the faucet sleeve into the second. The instructions say the heating time for polypropylene, follow the recommendations.

When the specified period has elapsed, the pipe with the sleeve must be sufficiently melted. Now comes the soldering of products. One of them is inserted into the other in full accordance with the markup. When performing a task, accuracy and speed are paramount. In no case should the pipe be twisted in the coupling when they are combined, this will lead to a design defect.

This completes the welding of polypropylene pipes. It remains to wipe the metal elements of the apparatus from the remnants of the molten material. In this case, the soldering iron will not require cleaning for further use.

You can determine the quality of the soldering visually; at the junction of the pipe with the locking element, a small edge of molten polypropylene should form. The connection itself, in case of successful welding, will be completely even, without any deformation.

It is possible to finally determine the reliability of the connection of the water supply elements after the water has been supplied. If the task is completed in full accordance with the requirements put forward, recommendations and instructions for the soldering machine, then the joint between the polypropylene pipe and the shut-off ball valve will be reliable and tight. Such a connection will last the maximum period, most likely, without any problems or leaks.

But you need to check not only the tightness of the soldering. It is also worth making sure that the locking mechanism works correctly. Ball valves for polypropylene pipes should completely close and open without much effort even when the water supply is functioning.

- 1 Metal-plastic or polypropylene

- 2 fittings

- 3 Installation of ball valves

- 4 Installation of faucets in the kitchen and bathroom

The breakdown of plumbing equipment for most owners most often causes serious concern and the conviction that coping with it on their own is an impossible task. But if you think logically, then many malfunctions can be eliminated on their own, without having special specialized knowledge. In fact, following clear instructions, even from a store clerk, is enough to make your own contribution to creating comfort in your home.

Due to regular use, taps connected to the pipeline most often fail. These can be kitchen faucets, taps on various pipes that supply water to a washing machine, to a gas water heater, taps on risers or on pipes in front of water meters.

Selection and installation of a PP crane

When selecting and installing a polypropylene faucet, it is important to follow all the rules

Features of the selection of a crane

How to choose a PP faucet for a heating system, water supply or other communications? When choosing, consider the following parameters:

- crane type. Manufacturers produce cranes of two types:

detachable devices are used when it is necessary to quickly dismantle the system and / or remove stop valves. In this case, the connector can be installed on one or both sides;

PP faucet with two-way detachable connection

collapsible devices are mainly used for attaching additional elements (collectors, tanks, sensors, and so on).

Fitting for connecting elements of the communication system

Collapsible valves can be of two subspecies: straight, designed to connect individual sections of the pipeline without changing the direction of movement of the working medium, and angular, changing the direction of movement by 90 °.

Demountable corner PP crane

- overall dimensions of the crane (diameter, length). All parameters must clearly correspond to PPRC pipes. Otherwise, it will not be possible to achieve tightness;

- appointment. For installation on pipelines with different temperatures, valves with different technical parameters are manufactured. You can visually distinguish one device from another by the color of the marking edge. For cold water, products with blue markings are used, and for hot water and heating systems, taps with red markings are used.

Fittings for cold and hot water supply

Installation rules

The installation of a PP crane is carried out in accordance with the following rules:

welding equipment is preheated to a predetermined temperature

To make the connection as strong and tight as possible, it is recommended to weld the fitting with the pipe at the temperature specified in the technical documentation for the device;

if a detachable connection is provided, then the joint is additionally sealed with FUM tape or other similar insulating materials;

when soldering, it is important to ensure that there is no displacement between the parts, as this can lead to depressurization of the connection;

after welding, all parts must cool. Only after that you can proceed to the further assembly of the pipeline.

Scheme of installing a crane on a pipeline

The process of installing a PP crane by welding is shown in the video.

Equipment for welding PP pipes can be rented at any specialized store. Before performing work on the installation of the crane, it is recommended to practice on pipe cuts.

Peculiarities

As with any other type of plumbing communications, the installation of polypropylene pipes has a number of features.

- In butt welding, the walls should not be thicker than 4 mm. The mating surfaces must be trimmed, while strict parallelism of the connected elements must be observed. When docking, it is recommended to use special guides.

- Since threading on a polypropylene pipe cannot be done, threaded fittings are used for threaded joints, and a sealant and Teflon tape are used to seal the connection.

- When welding polypropylene pipes, it is imperative to ventilate the room. At a negative temperature in the room, this type of work cannot be carried out, since docking with insufficient heating of the elements does not guarantee the tightness of the connection.

When welding with polypropylene pipes, it is necessary to heat the soldering iron to the desired temperature and install it on the stand. When working, safety precautions should be observed, since we are talking about a high temperature of 260 C.

For high-quality connection of elements, it is necessary to withstand the melting time required for a certain pipe diameter.

Below are the diameters and time intervals.

- 16 mm - 5 sec;

- 20 mm - 6 sec;

- 25 mm - 7 sec;

- 32 mm - 8 sec;

- 40 mm - 12 sec;

- 50 mm - 24 sec;

- 63 mm - 40 sec.

What to look out for

The nuances of choosing ball valves:

Of paramount importance is the fact that the diameter of the polypropylene pipes at the attachment point must match the diameter of the ball valves. On sale you can find different types of valves, including products with couplings from 20 to 63 millimeters. This range of diameters includes all possible sizes of plumbing systems, so there will be no problems with the choice.

Ball valves have several forms of handles: valves, heads, levers, and so on. For each section of the water supply, you need to choose the right product

For example, in some situations, the valve valve will be impossible to turn due to limited access to it, so it is better to take a lever and so on.

We must not forget about the aesthetic component of ball valves if they are installed in an open section of the pipeline

The shape of the product should fit into the interior of the room, which is also important.

In addition, it is worth taking into account what material the product is made of. Plastic faucets are cheaper than metal faucets

But significant savings will not work if it is planned to install a small number of locking and ball mechanisms.

In this case, it makes sense to buy faucets made of metal.

Crane made of polypropylene. Advantages and disadvantages

Ball valve polypropylene (PP) consists of the following elements:

- polypropylene body;

- ball valve made of brass. To give strength, the locking mechanism can have a protective anti-corrosion chrome coating;

- the stem, which, like the ball, is made of brass;

- sealing and gland rings;

- handle that drives the locking element.

PP ball valve in section

PP ball valves are distinguished by:

- a high level of tightness due to the one-piece body and the presence of seals;

- resistance to corrosion;

- possibility of use in a wide range of temperatures (from -10°С to +95°С);

- the possibility of selecting the appropriate size. The diameter of the product may vary depending on the customer. The most popular sizes are 20 mm - 50 mm;

- environmental friendliness of the material of manufacture.

The term of use of the polypropylene crane makes about 50 years.

Among the negative characteristics of accessories can be identified:

- the impossibility of regulating the flow level, since this type of valve belongs to the type of locking mechanisms, that is, the valve can have two positions: “open” (allows the flow of the working medium) and “closed” (complete blocking of movement in the pipeline);

- flammability, which does not allow installation of fittings near a fire, for example, a stove;

- the impossibility of repair, since the one-piece body cannot be disassembled. In the event of a breakdown, a complete replacement is required.

The pros and cons of PP cranes determine the scope of their use. Where is a polypropylene stopcock applicable? Devices are used:

- in systems of cold and hot water supply in apartments, country houses, industrial premises;

- during the construction of sewer networks;

- in the construction of heating systems;

- in the food and agricultural industry;

- when arranging technical pipelines for various purposes.

The procedure for soldering polypropylene elements

When all the necessary tools and materials are prepared, you can proceed to the task. It is divided into two stages: preparatory and directly soldering fittings for polypropylene pipelines. First of all, you need to prepare a place to work.

In the set of the apparatus for welding there is a special clamp. It is used to fix the machine, for example, to the table. This mount is very reliable, the device will not stagger. Therefore, it will be convenient to work with him. But in some situations, soldering is performed not at the desktop, but directly next to the water supply. In such a case, the machine has a handle to hold on weight.