The presence of a balcony in the apartment is a great opportunity to equip this extra space with benefit. Agree that turning your balcony into a smoking room or storage of unnecessary trash in a small apartment is wasteful. Therefore, in recent years there has been a growing trend to use this space as a recreation area, a winter garden or an addition to the kitchen. But in order to carry out a quality repair of the balcony, first of all, you need to take care of its insulation and resistance to various weather conditions. The most time-consuming and expensive stage in this matter is the thermal insulation of the floor. Is it possible to carry out these works independently, saving on the services of a construction team? The answer is yes! Below you will find a complete guide on how to insulate the floor on the balcony with your own hands.

Choosing the Right Material

Because the balcony is a portable structure, according to SNiP, it has certain restrictions on the weight load. This applies not only to the furniture located on it, but also to the materials used in the decoration. Therefore, the main criteria when choosing a heater are light weight and ease of use.

If you have a loggia in your apartment, then for its repair you can choose materials with any weight, but do not forget about their waterproofing and fire-fighting properties.

What materials are suitable for floor insulation on the balcony?

Mineral wool

This is a material made of fiberglass or basalt threads. Its advantages:

- low thermal conductivity;

- small mass and density;

- ability to fill gaps;

- low combustibility.

Among the minuses of mineral wool, one can note poor moisture resistance and the content of components hazardous to human health in its composition.

In total there are three types of mineral wool:

- slag;

- glass wool;

- stone wool.

The last of them is the most optimal and safe for use in residential premises, including for insulating the balcony floor. But in any case, when working with this material, it is necessary to observe safety precautions and use protective gloves and a mask. The principle of floor insulation with mineral wool can be seen in the following photo.

Styrofoam

The method of insulating the balcony with foam plastic is very popular. This option is the cheapest, fairly light and easy to use. The disadvantage of polystyrene is its high fire hazard.

Penoplex

Penoplex has similar properties to polystyrene, but its qualities are somewhat better: a denser structure, increased thermal insulation properties and the absence of chemical reactions with other materials. A significant advantage of insulating the balcony with penoplex is also the fact that this material does not support combustion due to the presence of flame retardants in its composition (this applies only to the variety, the marking of which contains the letter C).

Penofol

Penofol is a foil insulation, the basis of which is polyethylene foam. Pros of penofol:

- excellent moisture resistance;

- little weight;

- flexibility;

- soundproofing property.

The downside is the low thermal insulation, as a result of which it is necessary to insulate the balcony with penofol together with another heater, for example, with foam.

Expanded clay

Recently, expanded clay is rarely used to insulate balconies, but this material has significant advantages over the latest heaters. Among them, it is worth noting the absolute incombustibility and environmental friendliness. But you need to use it on the balcony floor carefully because of its high density.

The next photo was taken after the expanded clay screed was completed on the balcony.

Additional materials

In addition to a heat insulator for insulating a balcony with your own hands, you may need:

- waterproofing material;

- mounting foam;

- a mixture for leveling the screed if the concrete floor on the balcony is uneven;

- plywood or OSB boards;

- bars.

Preparatory work

Before insulating a balcony, you need to make sure that all structures are in good condition, are not destroyed and are not separated from the wall of the house. This is important, since a large load during construction work and further use of the balcony can lead to its collapse.

The permissible load on the balcony ceiling is 200 kilograms per square meter.

Do-it-yourself floor insulation on the balcony is a simple process if the right materials are selected and all the preparatory work is done.

Then you need to assess the condition of the floor. Mold, large gaps and unevenness in the concrete base can significantly reduce the quality of the work being done. To bring the balcony into proper condition, you must:

- Dismantle the floor covering - linoleum, tiles, boards. If the concrete floor screed is significantly damaged, it must be completely removed.

- After assessing the condition of structures and floors, they are strengthened if necessary. Joints, cracks are sealed with building mixtures, and gaps and cracks are foamed. Also, the gaps can be sealed with sealed tape.

Strengthening the balcony slab can be done along the channels.

- After carrying out these works, the floor is cleaned of the remaining debris, dust and dirt.

The photo shows the strengthening of the balcony structure with the help of a channel.

Waterproofing

The next step before warming will be to protect the room from moisture. This is necessary so that fungi and mold do not multiply under the insulation, and the thermal insulation does not deteriorate under the influence of weather conditions.

Step-by-step instructions for waterproofing the floor on the balcony:

- Dry and clean floor is processed primerand then dried again.

- A waterproofing membrane or a polyethylene film is laid on the treated surface with an overlap on the walls, approximately 10 centimeters, and fixed with a stapler.

- Separate pieces of the film are overlapped, and the joints are connected with adhesive tape.

When using waterproofing mastic, the floor is also cleaned, treated with bituminous mastic in two layers, and after it dries, with a special polymer mixture. In the photo you can see the process of waterproofing the floor on the balcony.

Floor insulation on the balcony

When the floor is cleaned and protected from moisture, you can proceed directly to its insulation. Our step by step guide will help you with this.

Stage number 1. Laying the first layer of insulation

A heater is laid on the previously laid waterproofing. It must be adjusted in size and ensure that there are no gaps between the sheets.

If you have a balcony with a hatch, you must remember that it must also be insulated, otherwise all the work carried out will be meaningless.

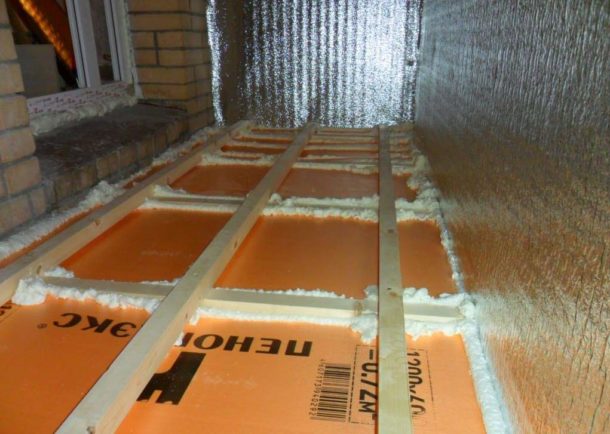

Stage number 2. Installing the lag system

The bars are pre-treated with an antiseptic. Then they must be cut to the width of the floor and installed on the insulation, the extreme ones - at the walls, the next ones - at a distance of about 50 centimeters.

[smartcontrol_youtube_shortcode key="mounting log on the balcony" cnt="2" col="2" shls="true"]All beams are set to the same height, which is controlled by the building level, and then fixed with self-tapping screws in several places.

Stage number 3. Laying the second layer of insulation

Between the lags, another layer of insulation previously cut to size is laid closely. In this case, the material should not rise above the level of the bars. Cracks and gaps are foamed.

Stage number 4. We carry out cleaning

When using mineral wool, it is necessary to put another layer of waterproofing material on it. After insulation with foam or foam, additional waterproofing is not needed. Then, a layer of plywood (or OSB), pre-treated with an antiseptic and a primer, is laid on top of the insulation on the logs. Flooring can be laid on top of the plywood.

To understand this technology more clearly, watch the video with its practical application.