What are handheld milling collets

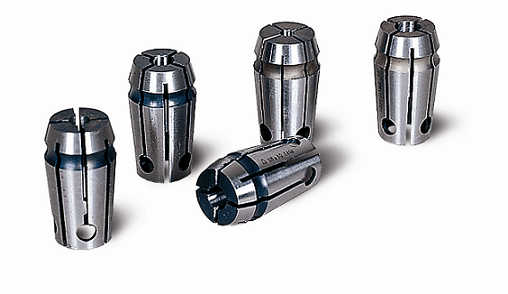

Collets are often mistakenly confused with chucks used for similar applications. Their main difference is that the chuck is a more versatile clamping device and, unlike collets, can be successfully used to hold tools with different shank diameters. In collets designed for a shank of a certain diameter, it is impossible to fix a tool with a shank of a different size. That is why, from a set of collets, you should choose exactly those that exactly match the diameter of the shank of the tool used.

Collet chuck

Collet nuts designed for tools with shanks of different diameters do not differ from each other, the differences between such devices lie in the different sizes of their clamping elements. In this regard, one nut, from which the collet is removed quite easily, can be used in a set with clamping elements for shanks of various diameters, but it is much more convenient and practical when each of the collets for the router is included in the set with its own nut.

Device manufacturing algorithm

The collection takes place in 3 stages. Let's take a closer look at each of them.

Making a mini cartridge

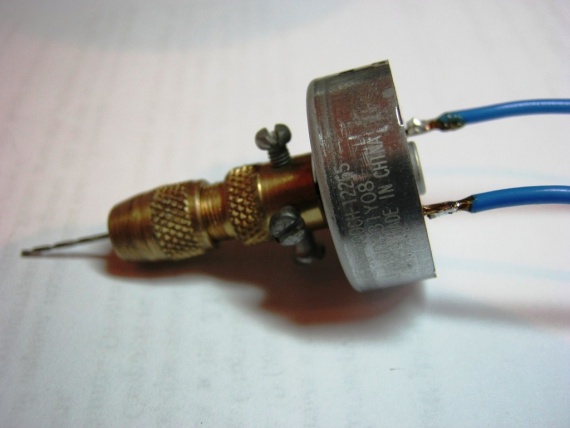

In order to assemble a mini drill chuck, you need to purchase a collet - a special mechanism designed to clamp cylindrical objects.

Next, you need to connect the motor to the contacts of the future battery, which will power the device during operation.

If your drill spins in the wrong direction, swap the location of the wire contacts.

Finding a drill of the right size is not difficult. Insert the drill bit into the collet body and clamp firmly. Next, the finished nozzle must be installed on the motor housing. The collet must fit snugly on the motor shaft. Otherwise, you cannot avoid vibration. The cartridge for a homemade mini drill is ready.

Nozzles for a homemade mini drill

can be purchased at any hardware store. Before buying, make sure that they fit the diameter of the collet.

Hull preparation

As a housing for the future device, you can use both an antiperspirant container and an ordinary hollow tube of a suitable size. If you are using a simple hollow tube

. it is necessary to cut off the bottom and insert a rubber or other plug in its place. If you are making a device from antiperspirant housings

. a hole must be drilled in the cover for the drill to exit.

Connecting elements

On the reverse side, you need to install the engine. If your motor does not fit in size - pick up another tube. The fit must be very tight to avoid vibration during shaft rotation. After that, it is enough to tighten the bolts on the collet and connect the resulting device to the mains.

One of the main disadvantages of collecting a drill with your own hands from a motor is less power compared to a standard device, and low drill strength.

If your job requires a cutter, you can easily make your own from an old lighter.

To do this, remove the twisting drum from the lighter and put it on a bolt of a suitable size. Secure this with a nut and insert into the collet hole. The surface cutter is ready!

If for any reason cartridge does not fit

to the cylindrical shaft of the motor or coil, it is necessary to degrease it well and then put it on hot glue. This will help to obtain a stable and durable structure.

Such a mini drill with purchased nozzles can perform minor repairs of technical equipment, drilling plastic, thin metal and making crafts.

The problem of consumption or lack of collet chucks is especially familiar to jewelers. Specialists involved in the manufacture of printed circuit boards also face the indicated problem.

Collet chucks can be created independently from improvised means. However, there are some nuances that will be covered in detail in the article below.

It should be noted right away that a hastily made collet will not be collapsible. That is, removing one drill from it and inserting another, strictly speaking, will not work. For this reason, the manufacturing technique is more suitable for those who need to create a large number of identical holes.

So, to create a homemade collet chuck, we need:

- drill;

- blank;

- steel wire;

- flux for soldering;

- sander.

Initially, steel wire should be wound on a blank in the form of a rigid spring (half-rings fit as close as possible to each other). Further, the resulting design should be properly soldered.

Today, anyone can easily purchase a special cam for any type of drill. This can be done both in building boutiques that provide equipment for sale, and on the Internet (at auctions such as Ebay or Amazon).

The price of such a device does not exceed sixty rubles. Purchasing a cam will save you forever from searching for suitable collets to use different drills.

Of course, it is better to purchase a high-carbon durable steel cam. To tighten it, it is recommended to use a special key, which must be included in the kit.

Engine power and control system

There are three gradations of milling cutters: low, medium and high power. High drive performance is required for longer cutter lengths. So, for artistic milling and making grooves up to 10 mm deep, low-power milling machines with a power of up to 800 watts are quite enough. In turn, the processing of edges of worktops, the manufacture of quarters and joinery processing of massive parts require the use of tools with a power of over 2 kW.

The power of the router should be chosen carefully: due to the work at high speeds, the gyroscopic effect is clearly manifested, which makes it difficult to hold the tool in your hands. On the other hand, an increase in power is associated with an increase in the dimensions and weight of the tool, which greatly complicates the processing of small parts that require a delicate approach.

Any router should be equipped with a speed controller, preferably an electronic type. The diameter of the cutters can vary widely, therefore, to achieve the correct cutting speed, it is required to set the rotation speed from 10 thousand rpm to 35 thousand rpm. The speed setting range for different milling cutters can vary greatly, this parameter is determined by the type of materials being processed and the size of the cutters that will be used during work. It must be remembered that the scale of the speed controller is marked conditionally, and therefore the user manual must necessarily contain a speed correspondence table.

To work with precious woods or artificial stone, the router must be equipped with so-called constant electronics. This is a small spindle speed control unit that maintains the set speed regardless of the load on the engine and the current mains voltage. Without this option, it is almost guaranteed that there will be inhomogeneity of the milled surfaces.

How to make a mini drill chuck Video

For a homemade cartridge, you will need a piece of metal or textolite pipe, the diameter of which is suitable for the motor shaft.The length of the homemade sleeve should be at least 2 times the length of the shaft and allow the drill to be securely fastened.

You can fix the sleeve with screws or hot glue. As a rule, the motor shaft has a diameter of 2-5 mm, and drills for making boards have a smaller diameter. This means that it is necessary to fill the resulting space with filler and achieve alignment of the drill and shaft.

Take rosin as a filler and pour it into the hole of the sleeve. Melt the rosin with a soldering iron and insert the drill. The rosin will harden and hold it securely.

In order to achieve perfect alignment, melt the rosin again and turn on the power. While the rosin is not frozen, try using tweezers to correct the position of the drill. If necessary, repeat the operation again.

(1

ratings, average: 5,00

out of 5)

Assembling a mini drill with your own hands

The main purpose of a mini drill is to drill printed circuit boards, plastic, wood and some other non-hard materials.

Compactness and efficiency have allowed this tool to become one of the main assistants for the home master. Moreover, it is not at all necessary to buy a ready-made tool - a home-made mini drill does its job just as well as its factory counterpart.

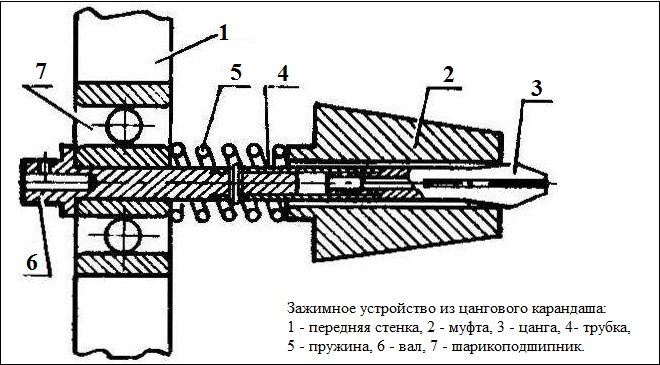

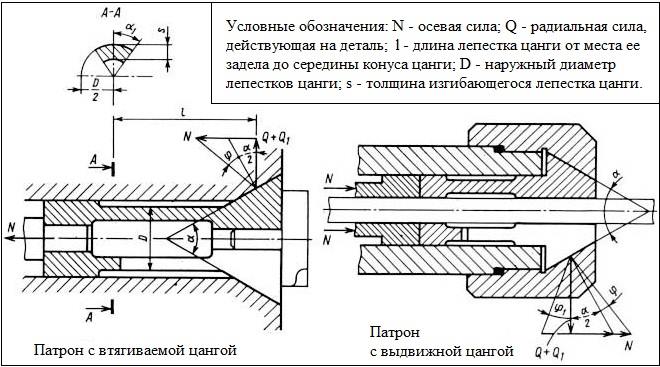

Collet chuck design

The chuck consists of a clamping nut and a set of collets. Available with retractable, retractable or fixed collets. By appointment, the collet can be clamping or feeding.

The feed collet is a hardened steel sleeve with 3 notches that form a kind of petals with ends directed to the center and springy. The opening of the feed collet should be such that the workpiece is tightly clamped. The feed collet is wound onto a rotating feed rod that feeds the workpiece using a hydromechanical or cam mechanism. During the installation of the workpiece in the cartridge, its Morse end slides between the petals, spreading them apart. Under the influence of elasticity, the petals are tightly pressed against the workpiece. The grip increases during processing due to frictional forces.

The one-piece collet is a sleeve with tabs that spring back when impacted. To work parts with a diameter of less than 3 mm, three-blade collets are used, from 3 to 80 mm - four-blade, more than 80 mm - six-blade. Grip is increased by reducing the clearance of the slots while the collet is being retracted into the chuck.

Split collet - used for clamping parts of the smallest diameter. The cams of such a cartridge are moved apart with the help of springs. Split collets can be equipped with replacement inserts, their type and dimensions depend on the characteristics of the workpiece.

In collet chucks, metalworking tools (drills, taps, milling cutters) with a small Morse shank diameter are also fastened. The cutter is fixed with a replaceable collet, additionally reinforced with a nut. While screwing the nut, the collet sinks inward, and being elastic, firmly clamps the Morse shank. The disadvantage of this type of cartridge is that each cutter diameter requires its own collet.

In longitudinal turning machines, a self-tightening chuck is used to hold a mini workpiece being machined. The device of such collets is somewhat different from the usual ones. Together with them, conventional Morse taper clamping tools can also be used to clamp the workpiece.

Homemade collet-coupling of the simplest design

The simplest collet, working on the principle of a coupling, can be made of steel wire with a diameter of 1 mm. It should be borne in mind that the collet of the proposed design is not a universal clamping device and can only be used for drills of the same diameter.

At the same time, it is important that the transverse dimension of the drills used correspond as closely as possible to the diameter of the output shaft of the drive motor.In addition, it is important to consider that such a collet can only be used when drilling materials with low viscosity.

For the manufacture of a collet coupling of the proposed design, the following consumables, fixtures and tools will be required:

- a cylindrical blank made of metal, the diameter of which corresponds to the diameters of the output shaft of the electric motor and the drill;

- steel wire;

- electric soldering iron;

- flux for soldering.

The very process of manufacturing a collet chuck for a microdrill is performed according to the following algorithm:

The wire is wound around the blank in such a way that a rigid spring is formed.

It is important that the coils of the spring are as close to each other as possible.

The finished spring, without removing it from the blank, is carefully soldered .. The simplest collet can be made by hand and in a different design

The design of such a cartridge, the cost of manufacturing which will be very low, consists of two halves fastened with a screw. Cylindrical grooves are machined on the inner surface of each of these halves, which, when the screw is tightened, provide fixation of both the clamp on the drive motor shaft and the tool used. Having decided to make such a collet clamp with your own hands, keep in mind: in order for it to work correctly, you must always balance it before using it.

The simplest collet can be made by hand and in a different design. The design of such a cartridge, the cost of manufacturing which will be very low, consists of two halves fastened with a screw. Cylindrical grooves are machined on the inner surface of each of these halves, which, when the screw is tightened, provide fixation of both the clamp on the drive motor shaft and the tool used. Having decided to make such a collet clamp with your own hands, keep in mind: in order for it to work correctly, you must always balance it before using it.

Mini drill from electric chuck

. which can be purchased separately, or taken from the light bulb. If you buy it, then it is very inexpensive, but this cost will be justified.

Also, to assemble a mini-drill with your own hands from a cartridge, you will need the following things:

- motor;

- a jar of soap bubbles;

- construction knife;

- insulating tape;

- hot glue;

- soldering lamp;

- household switch.

Body and core of mini drill

Work must begin with the preparation of the body of the mini-drill, which will serve soap bubble jar

. This is done like this:

- Get the lid off the jar. For this purpose, we heat the soldering iron and use it to make a small hole in the lid of the jar.

- The diameter of this hole should be slightly larger than the diameter of the drill base.

- The bottom of the jar must be completely cut out.

Let's start working with the core:

- We connect the cartridge with the motor. Most often, motors are taken from already used different tools.

- Before the bonding process, the motor must be completely degreased with acetone.

- The cartridge can also be degreased, but it is not necessary to water it like a motor with acetone. A normal wipe will suffice.

The bonding method is by cold welding

. If this method does not suit you, you can also use hot glue. Remember that the more complex your future mini-drill is, the more seriously you will need materials to assemble it yourself.

During landing for welding or glue, you need to work very carefully so that everything turns out as smooth as possible. Redoing the work later will not work, keep this in mind.

You also need to consider the following:

- at the attachment point on the cartridge there is a hole that must be covered before connecting the parts;

- putty is carried out using simple plasticine;

- only holes need to be filled with plasticine; it should not remain on top of the cartridge.

How to choose the right collet set

When purchasing a set of collet clamps for a hand router, you may encounter the fact that the collets will not be of very high quality. In addition, they may not match the diameters of the tool shanks for which they are intended. Such situations, unfortunately, are not uncommon and are especially typical for those cases when a cheap set or products from little-known manufacturers are purchased. Most often, the only way out of such situations is to purchase a new set of collets for the router.

The collet chuck must match the router spindle, and the collet must match that chuck. Collets often have different taper angles and only fit "their" clamping nut

In order not to face the problem of acquiring collets of inadequate quality and the wrong size for the router, it is better to opt for products from trusted manufacturers. If this is not possible, it is necessary to carefully check the collets included in the set for their compliance with the required quality and standard dimensions of the tool for the router.

Collet chuck design

The chuck consists of a clamping nut and a set of collets. Available with retractable, retractable or fixed collets. By appointment, the collet can be clamping or feeding.

The feed collet is a hardened steel sleeve with 3 notches that form a kind of petals with ends directed to the center and springy. The opening of the feed collet should be such that the workpiece is tightly clamped. The feed collet is wound onto a rotating feed rod that feeds the workpiece using a hydromechanical or cam mechanism. During the installation of the workpiece in the cartridge, its Morse end slides between the petals, spreading them apart. Under the influence of elasticity, the petals are tightly pressed against the workpiece. The grip increases during processing due to frictional forces.

The one-piece collet is a sleeve with tabs that spring back when impacted. To work parts with a diameter of less than 3 mm, three-blade collets are used, from 3 to 80 mm - four-blade, more than 80 mm - six-blade. Grip is increased by reducing the clearance of the slots while the collet is being retracted into the chuck.

Split collet - used for clamping parts of the smallest diameter. The cams of such a cartridge are moved apart with the help of springs. Split collets can be equipped with replacement inserts, their type and dimensions depend on the characteristics of the workpiece.

In collet chucks, metalworking tools (drills, taps, milling cutters) with a small Morse shank diameter are also fastened. The cutter is fixed with a replaceable collet, additionally reinforced with a nut. While screwing the nut, the collet sinks inward, and being elastic, firmly clamps the Morse shank. The disadvantage of this type of cartridge is that each cutter diameter requires its own collet.

In longitudinal turning machines, a self-tightening chuck is used to hold a mini workpiece being machined. The device of such collets is somewhat different from the usual ones. Together with them, conventional Morse taper clamping tools can also be used to clamp the workpiece.

Classification

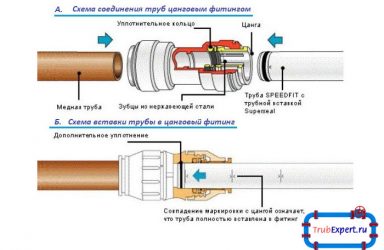

When starting the installation of household communications, it should be understood that the parts for pipelines differ from each other and each of them has its own intended purpose. Classification according to general characteristics helps not to get confused in the variety of market offers.

Push-in fittings can be divided by purpose into:

- gas pipeline (pneumatic);

- plumbing (hydraulic).

Parts for the gas pipeline have only one sealing ring on the fitting or do not have one. Pneumatic fittings according to the type of thread can be divided into parts with straight pipe threads and parts with conical threads.

By use, fittings are divided into three categories:

- intended for a rigid pipe (metal);

- for semi-solid pipelines (metal-plastic);

- for soft pipes (polymers).

Collet fittings made of plastic do not have a union nut. They are fixed by means of a latch of the body of the part directly onto the collet. The collet has metal teeth with which the soft polymer of the pipe is pressed.

By type of connection:

- intended for a straight section - simple couplings, transitional couplings for different diameters, transitional couplings from a pipe to a hose (with a fitting), plug couplings;

- intended for a drawbridge - tees, crosses;

- designed for turning or bypassing - corners.

In order to select fittings of the required configuration in sufficient quantities, you should have a project for the future pipeline.

How to make a cartridge yourself

To perform work on wood, soft metals and plastics, home-made printed circuit boards, a mini-drill of small power, made by yourself, is suitable. The easiest way is to equip it with a ready-made mini self-clamping mount from a pen or pencil. But if there are none at hand, it’s not difficult to make a mini-collet with your own hands. Required: soldering iron, steel wire 1 mm thick, solder.

- a spiral is rolled from the wire with a diameter equal to the diameter of the motor shaft and the drill with which to work;

- the spiral is soldered, high quality connections are provided by soldering flux or KFET;

- the spiral is put on the shaft and the mini collet is ready.

A video about how a qualified metal turner made a self-tightening chuck with his own hands:

Purpose and types of collet chucks

Collets, acting as clamping elements, provide fixation not only for the tools for the router, but also for the workpieces that are being processed. In chucks equipped with collets, in particular, workpieces subjected to both roughing and finishing can be fixed equally successfully.

According to their design, collet chucks are divided into several main types:

- retractable;

- retractable;

- equipped with fixed grips.

The design of chucks with retractable and retractable collets

By appointment, collet chucks can be classified as supply and clamping. The first ones are a hardened steel sleeve, on the side surface of which three incomplete cuts are made, forming springy clamping petals. The dimensions of the inner hole of such a device, in order for it to be able to provide a reliable fixation, must strictly correspond to the geometric parameters of the workpiece being processed. The cartridge of this type is used complete with a supply pipe (it is screwed onto its threaded end). In order for the workpiece, which is located in such a pipe, to receive axial movement, a cam mechanism or a hydromechanical drive is used. Such a device works on the principle of a well-known collet pencil, through the expanding and contracting petals of which the slate rod moves.

Collet clamps, their types, application features tips for making a do-it-yourself clamping collet

A collet chuck is a type of chuck commonly used in lathes.it is a self-clamping type of such devices, since it does not require additional parts. This is a simple and reliable device that is perfect for turning. About what are the features of the collet clamp and how to choose it correctly, and will be discussed in the article.

Depending on the upcoming work and the purpose of the machines, all clamping products can be classified into the following types:

- Lever;

- collet;

- Drilling, they are quick-clamping;

- Wedge and hydraulic cartridges;

- Three- and four-jaw;

- Thermochucks and membrane.

Drilling self-locking chucks are used on universal or special lathes. Their use allows you to transfer the clamping force with less torque compared to drill chucks.

Self-manufacturing

A small drill is best for woodworking, metalworking and plastics, and for making a variety of printed circuit boards. It should be equipped with a ready-made mini clamp-type mount.

But if this was not at hand, then you can easily make it yourself. Here you will need a soldering iron, millimeter-thick steel wire and solder.

Further, the manufacturing process goes as follows:

- We turn the spiral from the wire. Its diameter should be equal to the diameter of the motor shaft and the drill with which it will be necessary to work;

- We solder the spiral. High quality is ensured by soldering flux or similar;

- Then we put the spiral on the shaft - and the mini-chuck for our drill is completely ready.

Homemade collet chucks are great in the absence of ready-made clamps for drills and if you have the appropriate skills to make such mechanisms yourself. They will also become indispensable in the household, when work with specific details is required, and ready-made clamps may not be suitable for any characteristics.

The clamping collet is an important element in lathes of various modifications. With its help, you can perform work on the processing and milling of metal and plastic parts. In addition, it can be easily made independently using improvised materials.

The variety of such mechanisms available today allows you to choose the optimal clamping model for personal needs.

It is also very important to take into account the method of its attachment to the spindle and the dimensions of the flange, since without them it will be impossible to select a collet

Good luck with different types of clamps!

Push-in connection Pipes and plumbing

Plastic pipes are becoming more and more popular every year, they are actively used for organizing networks of both cold and hot water supply, as well as for installing heating systems.

To combine such pipes into systems and to connect them to plumbing devices, various connecting elements are used, which include a collet clamp.

Collet-type fittings, which do not require special tools and complex equipment, are able to provide a reliable and durable connection of pipeline elements for various purposes. Such clamps can be used both for the installation of pipelines, and for connecting to the latest plumbing devices.

Straight and elbow push-in fittings

How to make a cartridge yourself

To perform work on wood, soft metals and plastics, home-made printed circuit boards, a mini-drill of small power, made by yourself, is suitable. The easiest way is to equip it with a ready-made mini self-clamping mount from a pen or pencil. But if there are none at hand, it’s not difficult to make a mini-collet with your own hands. Required: soldering iron, steel wire 1 mm thick, solder.

Work progress:

- a spiral is rolled from the wire with a diameter equal to the diameter of the motor shaft and the drill with which to work;

- the spiral is soldered, high quality connections are provided by soldering flux or KFET;

- the spiral is put on the shaft and the mini collet is ready.

A video about how a qualified metal turner made a self-tightening chuck with his own hands.

The question of how to make a do-it-yourself collet is relevant for those who are engaged in jewelry, engraving or printed circuit board manufacturing and use such equipment. It is the specialists of these categories who most often encounter a breakdown of the collet clamp, which can be replaced with a new serial model or made by hand.

There are several options for making a do-it-yourself collet chuck, each of which has certain nuances. However, no matter what method a home-made clip is made, its price will compare favorably with the cost of a serial model.

The principle of operation of the collet chuck

Chucks with a set of interchangeable collets are used for fastening axial workpieces and cutters on milling, turning, drilling machines, equipment with numerical control (CNC). There are many sizes and types of collet chucks that work on the same principle. The self-tightening nut applies pressure to the end of the collet, which moves into the cone opening, its diameter is reduced by squeezing, firmly holding the tail end of the Morse cutter. To remove the cutter or part, the nut is screwed on, the pressure is reduced and the collet is unclenched.

Typically, such fasteners are used to process bushings, cylindrical parts with a Morse shank, and bars. They are very convenient for secondary fastening of an already processed part. If the profile of the part does not match the shape of the cartridge inlet, replaceable cartridges from the set are used.

Conclusion

The quality of processing a particular material depends on the cutter you choose, so weigh all the advantages and disadvantages before purchasing a tool. A wide range is distributed according to the purpose of products, material and design. We have reviewed some of the most popular types so that you can navigate how to choose a cutter when making a purchase. Get creative and create masterpieces with the help of decorated products.

https://youtube.com/watch?v=-2b40bKYjfE

Of all the types of manual milling cutters, vertical plunge cutters are most widely used. This is a very versatile, but at the same time quite specific tool, in matters of choice and acquisition of which knowledge of the features of the device of the main nodes will help.