Important features of soil drainage

For proper drainage of water from the soil, it is necessary to properly carry out drainage work. Here are a few rules that you must follow:

- There should be a slight slope towards the water outlet.

- The drainage layer is laid with an overlap, the value of which can be from 10 to 50 centimeters, depending on the stability of the soil.

- The edges of the geotextile around the drainage layer must be secured by welding or stitching.

- Geofabric should be sprinkled with a small layer of sand.

Having correctly selected the density of geotextiles and correctly carried out work on its laying, you will provide your site with the removal of excess groundwater for a long time.

How much does geotextiles cost from leading manufacturers price overview per m2

The production of geosynthetics is actively developing not only abroad, but also in Russia. This is driven by the high demand for such products. The most notable manufacturers of geotextiles:

- Kanvalan - price from 18.5 rubles / m2;

- Snapbond - from 19 rubles / m2;

- Geotex - from 17 rubles / m2.

Please note that the present value is relevant for the Moscow region as of September 2018. It is taken taking into account the lowest density of the material of the non-woven production method.

With the help of the geotextile, the efficiency of construction, horticulture, and road construction is increased. At the same time, the cost of such material is relatively low - one might say, insignificant, taking into account how much other materials and services in these areas cost. Therefore, do not hesitate and purchase geotextiles for a variety of purposes. After all, it is very simple to use it - lay the canvas and arrange anything on it.

Variety of structures

The operational properties of geotextiles directly depend on its structure. Depending on the task, a certain option is selected. Functions such as water drainage, moisture resistance and much more are provided by the structure itself.

Lattice

Non-woven fabric. Polymer strips are securely connected to each other in a checkerboard pattern, resulting in the formation of cells.

Net

By volume, it is a flat fabric. Strips of material can be connected in various ways:

- at an angle;

- closely intertwined;

- perpendicular

Cells are larger and more voluminous.

Geomat

The material characterizes the chaotic connection of fibers or threads. Elements are fastened in three ways:

- thermal;

- mechanical;

- chemical.

Geomat has excellent flexibility and lightness. It freely passes water and air currents.

Geocell

Large non-woven fabric with volumetric cells. The second name of the product is volumetric geogrid. The cloth is made in the form of honeycombs from polyethylene tapes. The material is fastened by welding, providing a reliable and durable connection. Due to the transformation of the form, it is convenient to store and transport it.

Membrane

The section includes three types.

- Geomembrane is a dense material. The geotextile is liquid impermeable.

- Bitumen-geosynthetic - geofabric with a bituminous layer.

- Clay geosynthetic fabric. Material with a clay layer.

The main sphere of use of membranes is the equipment of the bottom of artificial reservoirs: ponds, streams, lakes.

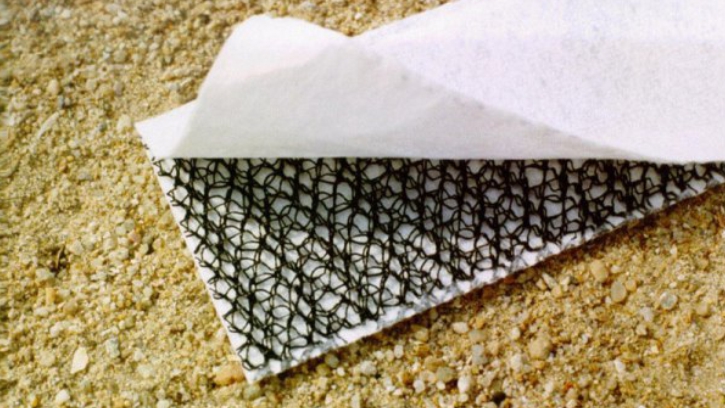

Clay mat

The material consists of three layers. The two outer layers are geotextiles connected by a needle-punched technique. Clay is laid between them. After that, they are securely connected by stitching.

geostrip

Narrow canvases, the width of which does not exceed 90 centimeters. The fabric features technically designed edges. For the production of material, the method of cutting strips from a wide geosynthetic material is often used.

Bentomat

Rolled material made by needle punching. Manufacturers combine woven polypropylene geomaterial with non-woven fabric. A special insulating layer is placed in the middle. It consists of special granulated sodium bentonite.

Geocomposite

Multilayer geofabric. The minimum number of layers is two. There are two types: reinforcing and draining material. But companies also use the terms: armogeocomposite and geodrain.

Main technical characteristics:

- a quality product, manufactured in accordance with all standards, has excellent strength;

- tensile strength reaches several hundred kN/m, while the elongation is not more than 18%;

- increased density of geofabric, this indicator varies from 80 to 1200 g/m2;

- factors such as water and air permeability, service life, soil compaction and much more are individual and must be specified when purchasing a material.

Types of geotextile materials

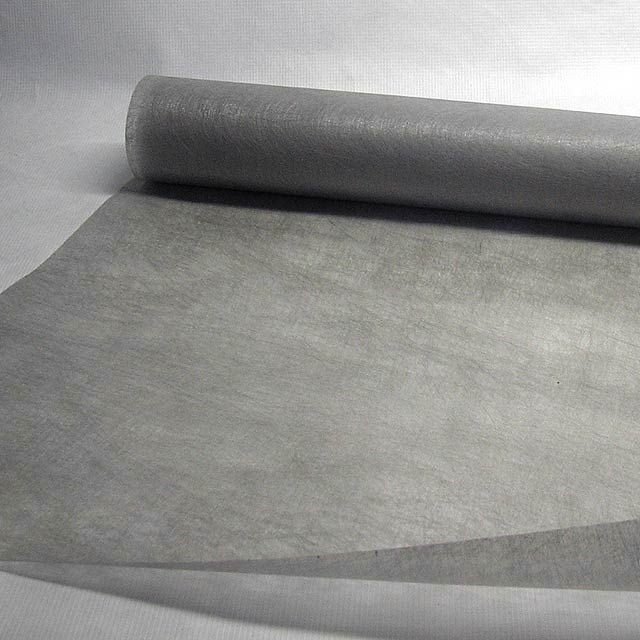

Geotextile is a synthetic material consisting of a combination of polymer fibers, the arrangement of which provides free moisture filtration, but retains fine solid particles. The material has high strength and does not absorb water, which makes it possible to use it in adverse construction conditions on open areas in contact with the ground, under the influence of precipitation and ultraviolet radiation.

Initially, the purpose of the geosynthetic material was to fix the various layers of soil to prevent them from mixing and washing out.

Later, geotextiles found wide application in many areas of construction. The material is resistant to chemically aggressive environments, biologically inert, not subject to corrosion and fungal attack. Geotextiles are made on the basis of modern polymers that meet all the requirements of environmental and sanitary standards.

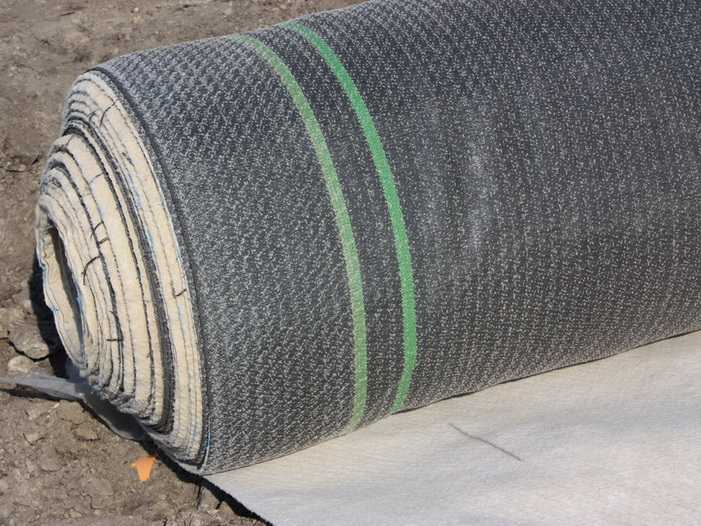

In accordance with the features of the production technology, geotextile materials are divided into:

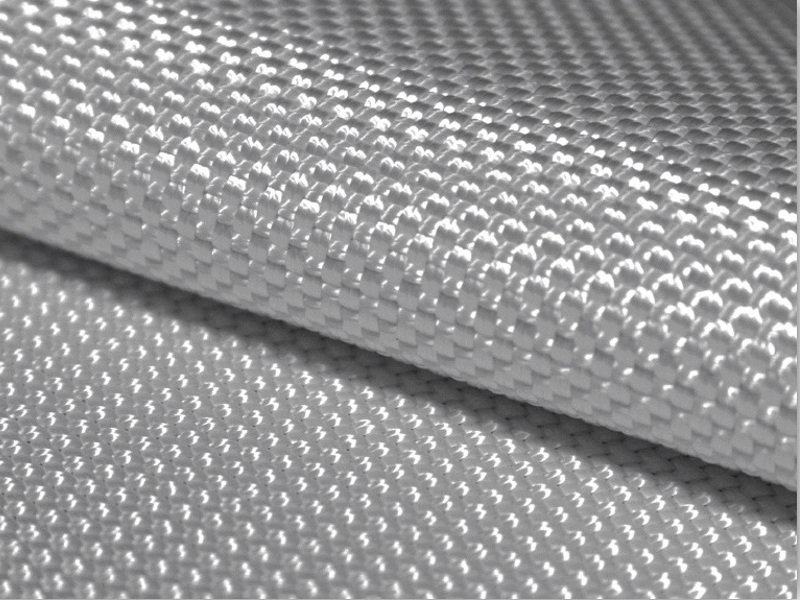

- woven (also called geofabric);

- non-woven (geo-textile, non-woven geosynthetics).

Woven geotextiles are made by mechanized weaving of fibrous elements of varying degrees of strength with each other. The pairing of threads is made at a right angle. The geofabric has the ability to deform, exactly repeating the shape of complex surfaces. It is used as a reinforcing protective layer of hydraulic and soil structures. The material reliably strengthens the slopes of artificial embankments and prevents the occurrence of landslides, while not interfering with the formation of natural grass cover.

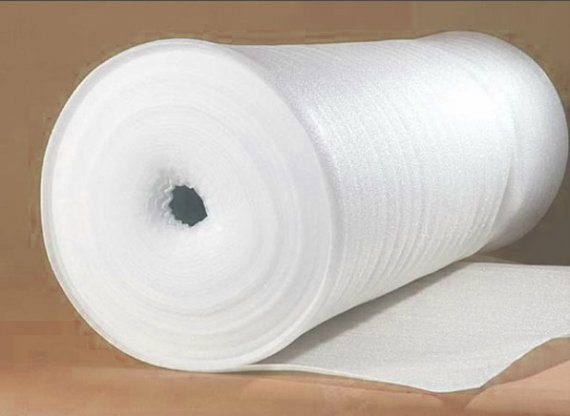

Non-woven type geotextile is a permeable fabric produced in one of three ways:

- thermal bonding of fibrous elements;

- method of fastening threads on a calender;

- needle-punched technology for creating canvases.

Depending on how the geotextile is produced, the characteristics and cost of the material may vary to some extent. The most widely used geosynthetics are made by thermal adhesive conjugation of polymeric fibrous structures. The geotextile produced by the needle-punched method is considered a more expensive material and is used to create structures of increased responsibility.

The main distinguishing parameters of non-woven geotextile materials are relatively low strength indicators and the ability to significantly stretch (values of relative elongation of the material reach 70%).

Due to these features, non-woven geotextiles are widely used for filtering drainage and soil-fixing structures, as well as for protecting waterproofing membranes and waterproof elements of sedimentation tanks and landfills from mechanical damage.

Geotextiles on personal plots

By analogy with the industrial application of the novelty, it is used in the garden in the following cases:

- in the construction of foundations and basements of garden houses, the construction of baths and greenhouses;

- for decoration of elements of garden design - platforms and paths, reservoirs and elevated areas of relief;

- when creating surface and in-depth drainage systems for the removal of storm and groundwater.

Geotextiles are also used directly in horticulture and horticulture when growing trees and shrubs, vegetables and berries on a personal plot.

The degree of complexity and responsibility of garden buildings and other structures is lower than industrial construction objects, however, geotextiles will provide the necessary quality of structural elements for a long time:

- supporting structures of load-bearing walls will ensure their stability if the soil includes a layer of new material;

- drainage systems will be protected from clogging with small soil particles, which will prevent deterioration and cessation of the functioning of the drainage system;

- paths and patios made of paving slabs will not form bumps and dips if geotextiles are used in their device to preserve the structure of the supporting layers.

A layer of special fabric will also allow you to maintain the shape of an alpine slide or other relief element. Artificial ponds, streams and waterfalls can be decorated with any materials without the risk of damaging the reservoir bed.

Drainage of areas with elevated groundwater levels is necessary for the growth of many plants that cannot tolerate too moist soil. The system for removing excess moisture consists of dug trenches and perforated pipes laid in them. Water enters the holes and is discharged through pipes into a reservoir or channel. From the need to remove the components of the system for cleaning from blockages, wrapping pipes with geotextiles will relieve:

- access to moisture inside will be provided;

- soil particles cannot get into the pipes, retained by a layer of fabric.

Flowerbeds and flower beds, beds and lawns are equipped using the same material. Laying geotextiles between the drainage and fertile layers will protect against the loss of the shape of the embankments, their subsidence or swelling. The fabric will prevent capillary entry of moisture from the underlying soil layers, interrupting the microscopic channels. The number of weeds, whose root system cannot ensure the germination of unwanted garden inhabitants, will decrease.

The fabric will prevent water from washing out the applied fertilizers, as well as the soil enriched with useful substances. The roots of agricultural plants will develop in favorable conditions, access to lean soils will not be available to them.

The surface use of this material is also practiced to radically reduce the number of weeds. The beds are lined with geotextiles, useful plants are planted in cut holes or slots. Shading will not allow weed stalks to germinate, while water will flow into the fertile soil unhindered.

You can use geotextile as a covering material, and more than once - it will protect heat-loving plants from the winter cold. In the dry season, shelter landings will save them from the scorching sunlight.

Material laying features

Small areas or narrow paths can be made with a single layer of geotextile. If larger areas are to be paved or the ground is too mobile, two layers of material are recommended. The first is laid on the ground, and the second on the drainage. This technology ensures that the coating retains its geometric and operational qualities in all weather conditions. What else you need to know when preparing the soil in order to cope with the task by doing the work with your own hands:

- Leveling the area. The territory is pre-marked using a level or theodolite.

- Pegs are driven in along the perimeter, and a cord is pulled, relative to which the plane is inspected.

- The mounds are cut off, the potholes and the pit are covered with soil.

- Getting rid of vegetation.Roots of trees are uprooted, a layer of grass is cut off.

- Exclusion of the possibility of formation of voids due to the decomposition of organic substances.

- Reducing the risk of weeds growing in tile gaps after laying.

- Soil compaction. After performing the above operations, it is necessary to compact the soil.

It is recommended to make a powder on the ground with sand, 2-3 cm thick. We lay geotextiles on this base. To prevent damage from sharp edges of rubble, a second sandy layer is made over the fabric. It is leveled with a building rule or a flat rail. Lay out according to the marks gravel and sand.

A curb stone is installed and concrete is poured over the formwork. Then lay out the second layer of geotextile, checking the horizontalness of the marks. The blanks are cut taking into account the overlap (at least 20 cm) and a small approach to the vertical along the curb.

What is geotextile

- 1 What is geotextile?

- 2 Varieties of geotextiles

- 2.1 Geotextile material

- 2.2 Method of making canvases

- 3 Applications and functionality of geotextiles

- 3.1 General capabilities of geotextiles

- 3.2 Application in road construction

- 3.3 Application of geotextiles in the drainage system

- 3.4 The use of geotextiles in the garden

- 3.4.1 Garden paths and playgrounds

- 3.4.2 Artificial reservoirs

- 3.4.3 Arrangement of garden beds

- 4 Geotextiles on the Russian market

It is customary to call geotextile a material made from synthetic polyester or polypropylene fibers, woven or non-woven method. High-quality geotextiles are characterized by high performance and a fairly long service life. The material goes on sale in rolls of different widths, which can vary from 2000 to 5500 mm, from 10 to 150 meters long, and can have different thicknesses and densities.

Geotextiles are produced in different versions, which differ from each other in their operational and physical and technical characteristics. But some qualities are characteristic of all varieties of such products:

- The materials have a sufficiently high elasticity.

- Geotextiles contribute to the uniform distribution of the load from bulk materials.

- Cloths are resistant to chemical oxidative processes.

- The material perfectly prevents the germination of weeds through the main cover.

- Properly laid geotextiles contribute to timely drainage, cope well with the filter function.

- The materials have excellent reinforcing properties.

- Such products are not susceptible to destruction under the influence of insects or rodents.

- Geotextiles are affordable and easy to use.

Types and scope of geotextiles

The quality and scope of geotextiles directly depend on the material from which it is made. The most popular options are:

- geotextiles made of polypropylene or polyester are of high quality;

- in most construction works, a product made of monofilament and spatula raw materials is used, which is also characterized by high strength;

- the thinnest possible option, which is valued for its high water resistance, is thermally bonded geotextile;

- a rarely used option is a product made of mixed threads, since the cotton or wool raw materials included in it are subject to decay.

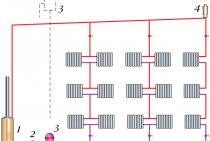

This method is applicable to the equipment of sewage. Here, pipes are wrapped with a layer of geotextile fabric. If the site is located in an area with a close location of groundwater to the surface, a drainage layer is specially equipped to protect the crop to drain excess fluid from the garden.

Common ways to use geotextile for drainage are shown in the following diagram:

Varieties of geotextiles

There is a well-defined classification of the material depending on the polymers used and the method of manufacture:

- Polyester geotextiles are not used for drainage systems. The fact is that when it is saturated with moisture, it is in no hurry to part with it. Such material is used in other areas.

- Material based on polypropylene sheets, for example, Dornit geotextile for drainage, considered the most suitable material for these systems. Polypropylene is highly durable, resistant to aggressive substances.

- According to the manufacturing methods, thermo-riveted and needle-punched material are distinguished. The first is characterized by increased strength, but as a result of heat treatment it has lost its ability to pass moisture, therefore it is not suitable for drainage systems. For the installation of drainage systems, it is necessary to give preference to needle-punched geotextile. Its surface is perforated on special machines. At the same time, the chaotic arrangement of punched holes and their diameter gives the material excellent filtration qualities, thanks to which the system is reliably protected from silting.

For drainage lines, it is necessary to use only monofilament geotextiles, mixed materials contain cotton components that can disrupt the groundwater filtration system.

Geotextile Dornit for drainage

Before choosing a geotextile for drainage, be sure to consult a specialist or find out all the information about the proposed type of material from the manufacturer. Any mistake in selection can lead to a decrease in the efficiency of the drainage system.

The choice of geotextiles by density

It is from this indicator that many operational characteristics of the material depend. Quite often it is difficult to determine what density of geotextiles is needed for drainage under certain geological conditions at the site of the system.

The fact is that a certain contradiction begins to operate:

- The thinner the material, and therefore its specific gravity per square meter, the better it will pass groundwater. Materials with a low density usually have excellent water carrying capacity, but the mechanical strength is lower.

- When laying drainage under a roadway or in difficult mining and geological conditions, increased requirements are placed on the strength of the material, so the culvert capacity has to be sacrificed to a certain extent.

Types of geotextiles

The industry offers a wide range of products in this category, but not all of them are suitable for paving preparation. The main criterion for the purchase of products should be an indication on the packaging or in the accompanying documents about the admissibility of the material for earthworks and roadworks.

If for some reason it is impossible to find a recommendation, then attention should be paid to the density of the fabric. It should not be less than 150 gr/m2

In this case, the geotextile, when laying paving slabs, will withstand the layers of crushed stone, sand and base material on it.

According to the production method used by the raw materials, and technological qualities, it is customary to divide geotextiles into the following types.

Knitting and stitching

Inexpensive, but with proper installation, reliable material. It is optimal for paths and playgrounds on the site, where significant physical activity is not expected.

needle-punched

The fabric is made of polypropylene or polyester fibers. Excellent performance for most paving jobs. During production, holes are punched in one direction, which gives the material the ability to pass moisture in only one direction.

heat-fixed

The most expensive and durable material in this category, which does not automatically make it the best.Many craftsmen prefer simpler fabrics due to the low filter coefficient. The costs are justified with a large expected load, where the thickness of this type of geotextile and its strength are needed, for example, in the construction of a parking space.

When arranging the local area, a fabric density of 150–250 g/m2 is considered sufficient. There are products on the market related to geotextiles for other purposes, for example, to cover plantings.

The density of such a material is 30–120 g/m2, which is clearly insufficient for the formation of a reliable and durable substrate. Knowing what the technological characteristics declared by the manufacturer mean, it is easy to determine which geotextile is needed for laying paving slabs in a particular case, if it is decided to do the work yourself.

Varieties

Composition and methods of manufacture

The material is divided into types depending on the method of production and composition. As a rule, modern geotextiles are made of polyester or polypropylene. Raw materials are abbreviated as PES and PP.

For the production of non-woven geotextiles, fiberglass or polyamide is used.

And also on sale you can find options that contain components of natural origin (woolen or cotton threads). Such material is called mixed.

Production Methods

In accordance with the method of manufacture, geotextiles are divided into two groups:

geofabric (knitted or woven material);

non-woven geotextile.

The first option is distinguished by increased strength and stability characteristics. They are also resistant to deformation processes. Such a material is ideal for separating the reinforcing layer (construction area).

The product, which comes second on the list, has excellent water-permeable properties. It is chosen for the arrangement of drainage systems, regardless of the complexity of the soil (landscape design). We will evaluate each of the types in more detail in order to choose the appropriate option for a specific situation.

Geofabric

Woven material, in turn, is divided into two varieties. Production material - polyester or glass fibers. In some cases, the canvas is produced in the form of a simple weave of threads, the thickness of which varies from 1 to 3 millimeters.

On sale there are options when the weave consists of different threads. The combination of material gives excellent stretch and elasticity. And also instead of threads, thin artificial material (stripes) is used.

Cloths of this type perfectly retain their shape, have increased strength and boast excellent water permeability. If the drainage system is located at a great depth, woven geotextiles will fit perfectly and cope with all the tasks. It is often used to drain foundations.

Warp-knitted geotextile (knitted) also belongs to this material group.

Non Woven Geotextile

This version of the fabric is made from synthetic material (thread or fiber). They are placed in two ways: randomly or oriented. Threads are made of polyester or polypropylene.

Most often, manufacturers use the monofilament method - one continuous thread for the entire fabric. And also a technique is popular in which the material is created from pieces of 5-10 centimeters (spatula geofabric). Product for drainage systems is not used.

Geotextiles are connected by various methods:

- needle-punched method;

- hydraulic bonding method;

- pressing;

- welding (thermo);

- combination;

- extrusion.

How to choose the right foundation material

When choosing which geotextile to use, 3 main qualities of the material are usually taken into account: stiffness, elasticity and porosity

The first property is important when the installation of a drainage profiled membrane is necessary to prevent subsidence of the soil.Elasticity helps protect the material from destruction during soil deformation and the resulting stretching of the geotextile

And the number and size of the pores allows you to divert water. Preventing the filler from washing out.

The density of geotextiles is most often considered when choosing a material for the construction of roads and runways. To prevent the coating from deforming under the weight of trucks or aircraft, this figure can be up to 800 g / m³.

When arranging a drainage system at home or sewerage, the material used should not be less than 200 g / m³ in density, but if pipes are supposed to be wrapped with this material, then the density no longer plays a role here, giving way to the ability of the layer to protect against water and other qualities.

How to choose the right density of geotextile for drainage is discussed in detail in the following video:

Areas of use

Geotextiles have been widely used in various industries and have actually become a universal multifunctional tool.

Road construction

This avoids filling the bulk material with soil particles and keeps it stable.

The use of this canvas makes it possible to build roads even in areas with soft, weakly bearing soils.

The material forms a reinforcing layer and prevents the destruction of slopes.

housing construction

Polymeric canvas is recommended for use in construction on heaving soils, as well as in swampy areas. Foundation geotextiles are known for their drainage properties and prevent the sand cushion from washing out and silting up the excavation.

landscape design

Often, non-woven needle-punched textiles are taken for these purposes.

But this is not the most suitable option in view of the fact that it is too thin and not particularly durable.

Geotextiles for a pond are better to take one that consists of fibers glued together by thermal adhesion.

When creating a pond, the polymer sheet prevents the walls of the pit from shedding, water blooming, and protects the waterproofing film from damage.

New material and its role in industry

The road industry, in order to increase the durability of highways, needed a way to prevent mixing of pavement layers. For this purpose, a special canvas has been developed that has the necessary properties:

- strength, resistance to chemical attack and temperature fluctuations, ensuring long-term presence in the composition of the road structure;

- elasticity to maintain integrity under the action of mechanical loads;

- permeability for unhindered drainage of embankments.

The successful introduction of new items in this industry has made it possible to expand the scope of its use in areas of activity that require similar qualities.

The widespread use of innovation, provided by its operational properties, began in a number of areas:

- in the construction industry during the construction of building foundations, to ensure the stability of the foundation soil and to protect drainage systems from silting;

- during excavation and agricultural work to exclude erosive effects on the soil and ensure the removal of excess moisture.

The most diverse application was found for the new fabric in the construction of individual housing and the arrangement of household and garden plots.

How to choose the density of geotextile

The density of geotextiles is an extremely important indicator

. Indeed, in the case of an erroneous choice, the fragility of the entire system is ensured.

Depending on the type of soil and purpose, the density of the polymer may vary.For example, in the construction of runways, dornite is used with a density of 800 grams per cubic meter. When it comes to construction in areas with unstable ground and frequent landslides, it is necessary

canvas

not thinner than 300 grams per square meter

.

For the construction of a drainage system in areas with normal soil, a fabric with a weight of 200 grams per square meter is quite suitable.

The same material is recommended for use in landscape design and gardening.

Density of geotextile depending on the application

|

Density g/m 2 |

Application |

|

Used in the agricultural industry. Designed to protect seeds from birds and pests. The canvas is laid on the ground. Does not prevent penetration of water and sunlight. |

|

|

Geotextiles of this density are used for arranging greenhouses, greenhouses, greenhouses. The material serves as a reliable protection and at the same time transmits light and water. |

|

|

Designed to protect against weeds. The sun's rays do not pass through it, but the moisture necessary for the root system of cultivated plants freely passes. For them, special holes are made in the fabric. Material of this density is also used as filters; they are wrapped around the pipes of the drainage system. |

|

|

Most often used in landscape design for arranging ponds and flower beds. In addition, artificial embankments are strengthened with dornite of this density. |

|

|

Suitable for arranging decorative ponds in summer cottages, protecting foundations, building sidewalks and arranging drainage systems. |

|

|

They are used in the construction of roads and parking lots for cars. |

|

|

For parking large trucks. |

|

|

Used for the construction of federal highways, busy highways and freeways. |

|

|

Designed mainly for the construction of runways |

When deciding which geotextile to choose, first of all, be guided by what function it will perform. Depending on the purpose, the density of the material may vary. The service life of the entire system will directly depend on the correct choice of polymer web.

When designing and building a house, it is worth considering the location of surface and groundwater and, depending on this, make adjustments to the work plan.

This is important, since moisture that has entered the foundation begins to gradually destroy it, which can adversely affect the entire system. And to prevent this, during construction, a drainage system is used to drain water, in which geotextile acts as a filter.

With a closed drainage system, it separates the filler from the soil, protects the entire layer from destruction by tree roots and water. The main thing is to choose the right material. This article will look at how to choose and install drainage geotextiles correctly.

Types of geotextiles and their characteristics

Depending on the manufacturing technology, there are:

- Needle-punched geotextile - created by dragging fastening threads through the base using a serrated needle. It has excellent strength and excellent water permeability, due to which it is widely used in the arrangement of drainage systems.

- Thermally bonded geotextiles are made by heat treatment of the fabric, in which synthetic fibers are melted and more rigidly bonded to each other. It is characterized by a dense structure, high tensile strength, but lower filtration qualities.

Thanks to a special manufacturing technology, geotextiles have a number of undeniable advantages, the main ones being:

- Environmental friendliness. Geotextiles are not subject to decomposition into chemical components, thereby not harming human health and the environment.

- Strength. Non-woven material is resistant to mechanical damage, piercing and tearing loads.The significant elongation of the material to break, which occurs due to the infinite length of the threads, virtually eliminates its damage during installation.

- Environmental resistance. It does not fade, does not silt and does not rot, it is resistant to ultraviolet radiation, the effects of acids, alkalis and organic substances.

- Ease of installation. The material is produced in the form of small and light rolls, which are convenient to transport and, if necessary, cut in half with a conventional hand saw. The material itself in the process of application is convenient to cut with a knife or scissors.

- Economy in price. With excellent quality characteristics, the cost of geotextiles is quite low, due to which they are widely used both in industrial construction and for domestic needs in the arrangement of suburban areas.

The possibilities of using the material amaze with the versatility of agrofibre. At the same time, with the release of new brands of geotextiles, the range of use of the material is constantly growing.

Brief description and scope

At the heart of drainage systems, geotextiles play the role of a reliable filter that prevents flooding of the drainage material or drainage pipe. This is a special type of building material. For its manufacture, mineral, basalt, synthetic and fiberglass are used. The product can be in the form of a web, tape or three-dimensional structure.

The product is used in various industries (construction, light industry, medicine) and for various purposes:

- protection;

- reinforcement;

- waterproofing;

- ground insulation;

- filtration;

- drainage;

- pavement design;

- delimitation of layers of materials of different fractions (formation of dense and durable interlayers).