Adhesive selection

After counting the number of tiles, you need to choose an adhesive. To do this correctly, you can ask the manager. He will tell you which adhesive is recommended to glue the selected ceiling tiles. Ceiling wallpaper glue is not suitable for

It is not recommended to buy Moment glue. It gets very dark after a while, so the excess that accidentally stained the front surface appears.

The consumption rate of the selected adhesive is indicated on the package. In accordance with this value, per 1 m², you should buy the required amount of the substance, based on the area of \u200b\u200bthe ceiling, regardless of the size of the foam tile.

7. Best Styrofoam Board Manufacturers

The best guarantee of quality is the name of the manufacturer. In order to protect yourself, you should look towards the products of famous companies that value their reputation. Among the largest manufacturers it is worth noting:

- Armstrong is a company that produces both the most ordinary and rather non-standard tiles. Performance is in any case at altitude;

- Ormit - German-made tiles, characterized by high moisture-resistant qualities, a wide range of sizes and colors;

- Antares - admits all types of plates, the color scheme is diverse. Also produces skirting boards and corners;

- Matrix is a Chinese-made tile of small thickness. The main advantage is low price;

- Angara - another Chinese manufacturer with an attractive pricing policy, produces panels with a thickness of no more than 8 mm.

When buying a tile, in any case, it is better to make sure that there are quality certificates.

foam tiles

Before pasting the ceiling with tiles, you need to decide on the choice of material. For finishing the ceiling surface, the following types of material are on sale:

- extruded foam panels made by stamping. The material has a porous structure, which is clogged with dirt during operation. It is recommended that after installing the panels, paint them with acrylic paint. The material is inexpensive, brittle and wrinkled, inconvenient to use. When choosing this type of coating, you should take the material with a margin of about 10%. The thickness of a single panel is from 6 to 12 mm;

- extruded. Panels of small thickness, only 2-3 mm, but quite dense and expensive. Profiles imitating wood or natural stone are produced. Expanded polystyrene material is easy to care for, but cannot be painted. Paint literally rolls off a smooth surface;

- injection. The difference from other types of tiles in a clearly visible pattern, which is obtained during production. Materials can be painted, not difficult to mount. The cost is average.

It is easiest to glue the ceiling with extruded tiles. This coating is easier to care for.

The usual shape of the panels is square. But, non-standard, rectangular panels are produced. You can paste over the ceiling with seamless tiles, the edges of which can be wavy or even.

Foam ceiling tiles are considered the most popular material for gluing ceilings. But there are other types of tiles made from the following materials:

- acrylic. Such profiles visually increase the height and area of the room;

- tree. Environmentally friendly profiles;

- ceramics. This type is used in rooms with high humidity;

- metal. Spectacular, durable and non-combustible material, but very expensive.

When choosing profiles for the ceiling, pay attention to how the material is combined with the interior and furnishings.

Specifications

Most often, for finishing the ceiling, people give preference to foam boards. The reason for such popularity is due to the fact that they are considered to be of very high quality, and their cost is not so high, so everyone can afford them. The price is from 10 rubles.

There are several options for the production of the presented finishing materials.

Let's consider them in more detail:

- Pressing is a process during which compaction takes place using an industrial press. The product thus obtained has a thickness of 7-8 mm.

- Injection is a tile production method based on its olives. The molten material is sent to the desired mold and compacted under the influence of high temperature conditions. If you buy a plate made in this way, then its thickness can reach 14 mm.

- Extrusion is considered the most associated method for the production of polystyrene tiles. But I can also get extruded foam tiles in a side way. Most often, such material is covered with a decorative film.

On the video - foam ceiling tiles:

When buying a material, it is very important to make the right choice and choose tiles from high-quality construction foam. Opt for non-flammable and non-flammable foam

It will be possible to verify the presence of the presented properties if you carefully read the information provided on the product.

The most popular form of tiles for finishing the ceiling remains a square. Their size is 50x50 cm. You can also buy a rectangular tile, but it is not so common and is used when the ceiling is being finished in public buildings.

Of course, foam tiles are not a luxury. She finds her buyer when it comes to decorating a room in which a presentable appearance is not the main goal of repair work. Most often they are used in a country house. Also, foam tiles can be used to temporarily change the situation. Such a product costs about 30-40 rubles per 1 m2.

If you want to keep the beautiful view of your ceiling for a long time, then you should not wash the foam tiles, you need to vacuum it. This process is much simpler and easier. In addition, during wet cleaning, various stains may remain on the surface. This is what proves the effectiveness of dry cleaning. To clean foam ceiling tiles, use a fluffy brush. It allows you to perfectly remove dust from the relief elements.

In the photo - foam ceiling tiles:

But there are situations when the tiles need to be washed. But for these purposes, you should definitely use special detergent compositions. But when choosing them, it is necessary to take into account that each tool has its own characteristics. In addition, the room in which the tile is installed remains very important. If this is a kitchen, then care should be carried out more intensively and more often.

The video shows how to paint foam ceiling tiles:

You can wash the foam tiles on the ceiling using liquid products. Powders are not recommended, as abrasive wear of the surface will be observed, as a result of which traces will appear on the treated surface.

If a stamped plate is used, then it should not be washed. Wet cleaning is possible only in an emergency and do all the work very carefully. If you have an injection or extruded tile on your ceiling, then you can wash it as soon as it gets dirty. They are not afraid of any mechanical loads.

Measurement of harmful emissions

It should be remembered that styrene is able to accumulate in the body, gradually reaching dangerous concentrations, leading to intoxication. Being indoors for a long time, it is easy to exceed the allowable rate.If you notice a deterioration in your health or your family members, you complain about poor sleep, we recommend that you conduct air sampling tests in the apartment. But keep in mind that laboratory analyzers may not show increased doses of styrene.

The matter is that in Russia the threshold concept of measurement of harmful substances is applied. Multiple tests are carried out, which show an acceptable level. This does not take into account the ability of the substance to accumulate in the body. In Western countries, the USA, Japan, a linear concept operates. The total effect of the absorbed substance is taken into account. Based on this, the maximum allowable norms of styrene are reduced many times. The environmentalists of our country are sounding the alarm, demanding a revision of the MPC for polystyrene and changing the hazard class of this building material.

How to glue tiles on the ceiling two technologies

Styrofoam or polystyrene tiles on the ceiling are attractive because they allow you to quickly and cost-effectively put in order a far from ideal ceiling. If the ceiling is relatively even, the tiles are glued to a special glue. It is applied in a thin layer, but provides a secure fixation.

With uneven ceilings, this method will not work: the tile simply will not stick with large differences or the view will be deplorable. leveling is not always the time, desire or opportunity. Moreover, often this finishing option is considered as temporary, then planning to make a suspended or stretch ceiling. Therefore, it makes no sense to waste time and money. In this case, another technology is used - on the adhesive composition for drywall or putty. They work no worse than glue, at the same time leveling the base.

Before starting work, unpack all the material, make sure that it is the same color, size. If there are bumps, sagging, they are cut off with a blade or a sharp knife. Now you can proceed to the installation of ceiling tiles on the ceiling.

How to stick on a flat ceiling

If the ceiling is even, ordinary glue for polystyrene or foam tiles is used, the technology is as follows:

- We spread a thin strip of glue around the perimeter of the square and diagonally. The edges of the tiles do not need to be coated.

- We put the tile in place, smooth it with our hands.

- We hold for some time - until the glue "grabs".

- Do the same with the next tile. We apply it to the edge already glued, if necessary, we combine the pattern, after which we press the rest of it. Docking should be carried out as accurately and accurately as possible so that steps do not subsequently form. Align the edges to the nearest millimeter.

- Repeat with the rest of the fragments.

- If necessary, tiles on the ceiling can be cut. Do it conveniently

As you can see, everything is very simple and these are all the rules for how to glue tiles on the ceiling. Only one caveat: you need to press one square to another tightly. If you have already glued it, but there is a gap, you can move it by pressing a wooden plank to the free edge. When you try to do it with your hands, you can break the foam or polystyrene, and it’s easier to achieve what you want with a flat bar.

If the ceiling is uneven

If the ceiling has significant irregularities, gluing tiles to ordinary glue will not work. To remove significant differences, use drywall glue or putty. The mixture is diluted to a pasty state, applied to the ceiling, grooves are formed using a notched trowel. The amount of glue depends on the overall curvature, but it is advisable to start with a minimum layer. The area on which glue is applied at a time is approximately 4 fragments. During this time, the composition will not have time to grab, and it is not difficult to align such a fragment.

A tile is laid on a layer of glue. It sticks well, moves without problems. Aligning the edges of the stacked fragments, take the rule or the building level (preferably one and a half meters) and set the tiles in the same plane. Just press the fragments harder in the right place.

Then the composition is again applied to the ceiling, and, again, about 4 tiles. All of them are set in the same plane, or at least so that there are no sharp drops. Only in this case it is necessary to ensure that the necessary layer of glue does not grow too quickly - it is better not to apply more than 3-5 mm, otherwise everything will fall.

https://youtube.com/watch?v=eZPYhhpCoyI

Cleaning and Sealing

You know how to glue tiles on the ceiling, but there are some nuances left, without knowing which a worthy result is unattainable. When working on the front side of the tile, the adhesive composition often gets. It must be removed immediately and completely. You can use a sponge or a soft non-shedding cloth. Wipe the surface immediately after putting the fragment in place. After a few minutes, this will no longer be possible and traces will remain. Therefore, while working, keep a bucket of water and a sponge / rag at hand.

If there are small voids between the plates, you can fill them with the same mastic or putty (if it is white), just remove the excess immediately. Another option is white acrylic sealant. It perfectly masks all the cracks, adheres well to polystyrene foam and polystyrene. Thin cracks can be filled with a rubber spatula, and the excess can also be wiped immediately with a damp cloth.

The harm of polystyrene

To understand whether ceiling tiles are harmful, it is worth considering in more detail what it is made of. Expanded polystyrene was invented for the needs of the military industry, thanks to polymerization. It was used as a heat and sound insulator. Little was thought about the dangers of what was invented. Subsequently, the economical material has been widely used in the construction industry and the packaging industry.

This monomer causes irritation of the mucous membranes of the nasopharynx, severe headaches, disruption of the nervous system. It has a negative effect on blood formation and leads to leukemia. Destroys the liver, leading to toxic hepatitis. Possessing an embryogenic effect, with systematic contact it causes disturbances in the intrauterine development of the fetus.

Another dangerous property of styrene is the ability to accumulate in the body, so even small doses pose a threat. In addition to the above, when oxidized by oxygen, which is part of the air, formaldehyde is released, which is listed as a carcinogen. With daily inhalation of microscopic portions, pallor of the skin appears, an inexplicable loss of strength, depression occurs. International cancer organizations have linked formaldehyde emitted by polymer coatings to the risk of developing nasopharyngeal cancer. These processes accelerate with increasing temperature.

During fires, even those samples that are recognized as low-combustible begin to melt, emitting poisonous smoke. Deadly intoxication can occur in a few seconds, so the chances of salvation in a room trimmed with foam elements are minimal. Thus, the harm from pasting with ceiling tiles is beyond doubt.

markup

In order to glue the foam panels with high quality and beautifully, it is first necessary to apply markings.

You need to decide where to start finishing the ceiling:

- from the corner of the room;

- from the center of the room.

In the first case, you should measure 50 cm from the wall, draw a line to the opposite wall. Further perpendicular to it, after 50 cm, mark the lines and finish the markup in the form of a chessboard. It is better to start from a noticeable corner, and finish at the door. Smooth lines are conveniently applied using a paint cord.

In the second case, you need to find and mark the center of the ceiling. To do this, it is enough to apply diagonals. At their intersection is the center of the ceiling. You can use another method.

From the middle of opposite walls, beat off perpendicular lines with a masking cord. They intersect at the center of the ceiling.

Pasting technique

Consider how to glue foam ceiling tiles.Professional tips to help you get the job done:

- The option of applying the adhesive composition depends on the type of mixture. If it is acrylic putty or cement mortar, it is better to use spot application so as not to create weight on the base base. Using liquid nails, non-aggressive adhesive compositions, you can apply a track around the entire perimeter, to a central point, and then level the mixture over the entire surface of the decorative part with a spatula.

- Pasting is carried out with closed doors and windows. There should be no drafts so as not to disturb the drying process of the mixture - this can affect the bonding strength.

- Read on the composition how to apply it. There are adhesives that need to be smeared, then attach the tile to the ceiling, peel it off and let the composition dry a little. Manufacturers also produce glue with a mandatory application on the reverse side of the decor and the base surface.

- Apply glue to the tile, wait 1-2 minutes for setting and glue the element to the ceiling at a pre-marked point.

- Take the next part, attach it to the previous one without glue, visually assess the evenness and you can apply glue. Evenness must be checked in the first row for each element, selectively in subsequent rows. Thus, the owner gets the opportunity to quickly correct the layout if a small shift has occurred somewhere.

After the entire plane is decorated, trimmed elements are laid along the edges, you can seal the seams with a sealant, applying the composition in a thin layer to prevent thickening. The final touch is the decor of the joint between the ceiling and the wall with skirting boards, baguettes or decorative slats.

Tiles can be painted, painted or varnished, the main thing is that the parts are firmly and securely fastened, the finishing technology is selected according to the requirements and taste of the owner. For example, in rooms with a high level of humidity, the decor is painted to protect it from water, and in open areas with the aggressive effects of wind and sun, the finish can be varnished with a waterproof varnish without aggressive components and solvents in the composition.

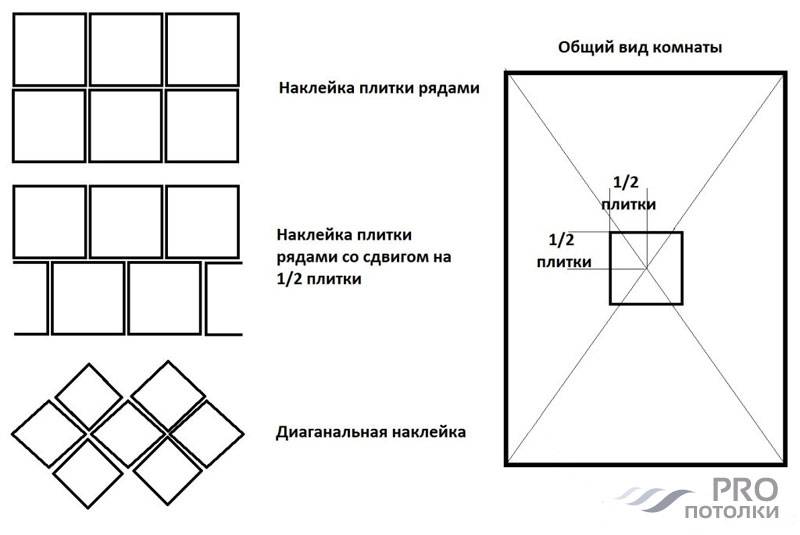

Placement and layout methods

Squares on the ceiling made of foam or polystyrene are placed with edges along the walls or diagonally. When gluing diagonally, the consumption of material is greater - more trimmings and not all of them can be used, but visually it looks better - it is more difficult to notice the seams.

Gluing most often starts from the chandelier. In this case, it is easier to "fit" it, since the edges of the plates can be cut a little, and the resulting gap will then close the cartridge from the chandelier. But not all rooms have a chandelier - often there are several lamps and they can be located on the walls. Then they start gluing from one of the walls, most often from the opposite entrance. With this approach, most likely the outer row will be cut off, and near the entrance it will not be so noticeable.

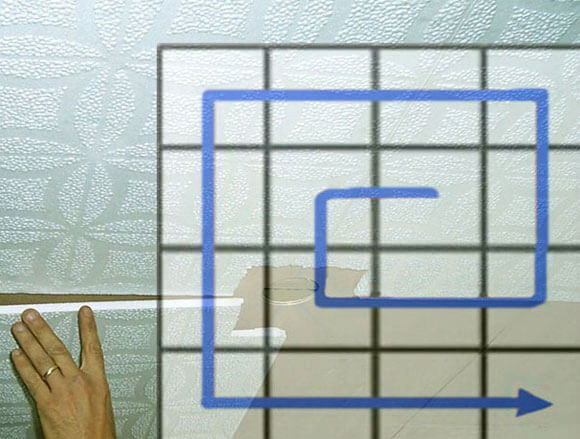

If you need to glue tiles on the ceiling from the chandelier, markup is required. In a square room, everything is simple - we find the center, we start from it. To do this, we take a paint cord, one end to one corner, the other to the opposite, pulling the cord and releasing, we get a line on the ceiling. We repeat the operation with another pair of corners. The center was found, it is easy to glue tiles from it. For diagonal gluing, there are already guides, and for parallel gluing, you will have to make two more strips - through the center to opposite walls (in the figure above).

But this is a very rare case. More often the rooms are rectangular, and the chandelier is not located in the middle of the ceiling. Therefore, more complex markup will have to be done.

To begin with, we also find the center of the room (painting cord diagonally). If it coincides with the place where the chandelier is attached, great, we “dance” from it. If not, we shift the starting point to the chandelier. Further markup is the same. We measure the distance from the starting point of installation to the nearest wall.Using this value, draw the squares as shown in the picture above (use the masking cord). After drawing the diagonals, we get guides for laying flow tiles. On them we level the edge of the first row. The more precisely we set this row, the easier it will be to glue the tiles on the ceiling further.

Criterias of choice

When choosing a ceiling tile, you should carefully examine the product, in particular:

- the edges on them should not have dents;

- the corners must be straight (exactly 90 degrees), otherwise uneven seams will form during installation;

- the drawing must be clear, without flaws.

You can check the product for strength in the following way. It is necessary to take it by one of the corners and hold it horizontally. High-quality tile will withstand the test and will not break under its own weight.

It is important to take into account the specifics of the room when choosing a specific type of panels:

- Extruded is suitable for any room, but often has profile defects and an uneven surface on the wrong side.

- Injection is suitable for rooms where it is necessary to achieve the appearance of a seamless ceiling. It is durable and fireproof, easy to paint and easy to clean.

- Pressed is suitable for rooms with minimal requirements for heat and sound insulation. The material is inexpensive, but fragile and sensitive to moisture.

After evaluating the features of all types of tiles, you can choose it for your own needs in accordance with the specified parameters. After that, you can proceed directly to the installation itself.

What is better stretch ceiling or ceiling tiles

The undoubted advantage of ceiling tiles is the ability to cope with the work without professionals. It is enough to buy the appropriate brand of glue and calculate the amount of material, and the gluing process will not be difficult. It also has the advantage of low cost. Perhaps this is all that can be said about the benefits of this material, now let's talk about the cons:

- The use in the kitchen is excluded: the surface is difficult to clean from the inevitable layer of soot and dirt.

- Products are flammable and do not comply with fire regulations. Expanded polystyrene is "famous" for a record short combustion period - less than 4 seconds.

- Cannot be mounted in the bathroom, as the material has a low moisture protection threshold. When leaking from above, the glue may collapse, peeling will occur.

- Installation requires a flat surface, only minor cracks are allowed.

- It should not be used in new buildings where the building is settling, leading to peeling of the ceiling elements.

- The glue does not disappear for a long time, an unpleasant odor is felt, and air toxicity increases.

- It will not be possible to reliably hide communications, for example, electrical wiring.

- Even a slight increase in temperature is undesirable. Lighting devices are heated, so they must be mounted as far from the ceiling as possible (minimum distance - 30 cm).

- The aesthetic appearance of the room suffers. The seams between the elements are noticeable, yellowness appears. Tiled finishes do not fit into most interior solutions due to their excessive decorativeness.

Stretch ceilings, on the contrary, are distinguished by aesthetics, the ability to harmoniously fit into the interior. Provides a smooth, flawless surface. Attracts the widest choice of colors and the possibility of photo printing.

Installed within a few hours. Easy to clean: wipe with a soft cloth dampened with a small amount of detergent. It is environmentally friendly, not harmful to humans and animals.

Starting repairs, everyone determines for themselves which is better - a stretch ceiling or a democratic ceiling tile. At the same time, it should be taken into account that, according to most indicators, an eco-friendly stretch ceiling is superior to the coating of foam elements, creating a beautiful modern interior and maintaining health.

Placement of tiles on the ceiling

There are two rules that builders use when sticking ceiling tiles:

in a small room, it is placed on the ceiling surface parallel to the walls. In this case, work begins to be performed from the corner located opposite the entrance to the room.

The fact is that the eye first of all falls precisely at this place in the room, so it is important to ensure parallelism between the walls and tile joints there;

in large and spacious halls and in those rooms where the walls and piers are not parallel to each other, the tile installed from the center visually wins. It is not glued parallel to one of the walls, but diagonally

Conventionally, the center of the room choose the place of installation of the ceiling chandelier. Of course, with this option for finishing the ceiling surface, the consumption of tiles is much greater than in the first case, but since the price of the material is small, there will be no particular overspending of the family budget. An example of such installation of finishing material can be seen in the photo.

In practice, these two methods are often combined. For example, tiles are glued starting from the center, but at the same time they are placed parallel to one of the walls. You can also find a diagonal sticker that starts from the wall. Using at the same time two types of tiles of different colors (preferably in contrasting colors), the ceiling is made chess, a spiral or a snake is launched over its surface. Thus, finishing costs will be minimal, and the appearance of the room will benefit greatly.

When carrying out work on gluing tiles, the elements have to be cut in place, for which they use an ordinary knife, only sharply honed. It is convenient to cut the polystyrene boards in a straight line, placing them on one side of the countertop, which in this case will be the guide.

Based on the above, we can conclude that polystyrene tiles are an ambiguous finishing material, but if necessary, make an inexpensive ceiling repair and not spend a lot of time - this option is quite acceptable.

Characteristics of polystyrene tiles

Of the advantages of expanded polystyrene tiles for the ceiling, it should be noted:

- inexpensive cost, which starts in retail from 30 rubles, only lime whitewashing will cost less;

- the ability to hide significant defects in the ceiling surface without puttying and other preparatory measures;

- the material can make unevenness on the base base invisible, but with large differences it is better to opt for a suspended structure;

- tiles are easy to care for, they can be washed with any, most importantly, non-abrasive detergent;

- finishing work using ceiling tiles does not require professional building skills; every owner of a house or apartment is able to stick it without much effort;

- quick completion of the repair, it will take no more than one day to finish the ceiling of a room of average size along with pasting with a decorative baguette;

- decorating the ceiling surface with tiles does not reduce the height of the room. For comparison: any suspended structure will fall below the floor slabs by at least 5-10 centimeters. With a ceiling height of no more than 2.5 meters, tiling is the most reasonable solution. Sometimes it is combined with suspension systems;

- in the event that there is a desire to change the polyurethane tile to another finish, there will be no problems with its dismantling. The material is easily attached to the surface with just a few drops of adhesive, and the weight is negligible, so it is possible to remove the plates with minimal damage to the floor.

Polystyrene ceiling slabs have the following disadvantages:

- the material of their manufacture is combustible and the fire safety of the apartment will be a big question;

- soot, dirt, grease - pollution is inevitable in the kitchen, wiping them off the surface of the tiles is an almost impossible task.This is especially true for the grainy surface of tiles produced by stamping or injection;

- seams are clearly distinguished between adjacent plates, they, of course, can be made inconspicuous, but invisible - no. A clearly visible presence of joints affects the appearance of the ceiling, while seamless surfaces (plasterboard or stretch) look much better;

- the material turns yellow from soot and absorbs odors, so it is better for consumers who smoke indoors to abandon this option for finishing the ceiling with polystyrene foam tiles. Similarly, paper wallpaper should not be glued.

How to glue foam tiles on various surfaces

Any draft ceiling must be prepared for gluing. If we are talking about a surface bleached with chalk, it must be cleaned by washing the chalk to the ground. It is useless to glue the tile on chalk - it will peel off very soon and fall off. If the ceiling is covered with lime, you need to run your hand over it and check the condition of the lime. Exfoliating areas should be removed with a spatula. If this procedure is neglected, the tile will peel off in the same way as from the chalk base. Only after cleaning the ceiling can you start priming it.

As for the ceilings made of concrete, drywall and wood, everything is much simpler here. These bases do not need to be cleaned, they should be immediately covered with soil.

The primer for this procedure should be deep penetration. Shake the container well, pour the soil into the paint tray, and then apply a thin layer to the ceiling with a roller. After the first layer dries, the procedure should be repeated. Careful priming will improve the adhesion of the surfaces, which means it will contribute to a more durable bonding of the ceiling tiles.

The next step is marking the ceiling. If gluing the tiles will take place in a straight line, it is enough to mark the center of the room - it will be located at the intersection of lines extending from the middle of the sides of the ceiling. If you plan to glue the tiles with a diamond, the center is marked by the intersection of diagonal lines originating in the corners of the room. For marking, it is most convenient to use a paint cord - it will allow you to immediately beat off the gluing lines.

When choosing an adhesive for foam tiles, you should avoid aggressive solvents in its composition, as they will simply corrode the product. It is also better to refuse water-based glue if gluing is done on a lime or chalk surface.

The best option would be the so-called polymer-based liquid nails. Pasting is most reasonable to start from the middle of the room. Glue must be applied in a strip along the perimeter of the tile and drip in the center. Having glued a square of the first four tiles, they should be aligned relative to each other and the marking lines. Since liquid nails are quite thick in consistency, this action will not be difficult. Thus, the entire ceiling is pasted over. The final tiles along the walls are trimmed if necessary before gluing.

At the end of the work, the seams between the tiles must be puttied. A narrow spatula works well for this purpose. It will create the appearance of a uniform surface without seams. In conclusion, the tile is primed and painted in two layers with water-based paint.

Glue application

Depending on the adhesive used, its application may be different, but the general principles remain the same. For example, glue is applied either in a dotted line or in a solid line on small protrusions on the inside of the product. If there are none, then it is applied in the corners and in the center.

Putty or glue is best applied directly to the tile so as not to block the markings on the ceiling. This is best done with a comb used for tiling. If there are irregularities up to a centimeter on the surface, use a comb with a large tooth from 11 millimeters.In the event that you see that the applied glue will not be enough, you can gently smear the ceiling. This must be done in such a way that the drawn axes are not erased, and the direction of spreading the glue on the ceiling and on the tile is opposite. For example, if you spread glue on the tile towards the door, then on the ceiling you need to spread it in the direction away from the door.

Special glue, such as ELTITAN, needs to be glued differently. Since you need to wait 15-20 minutes before laying, you can save your own time if you apply glue to a whole batch of tiles at once - 3-5 at a time.

Whitewashed ceiling sticker

You can tile the ceiling surface with tiles on almost any base coat. But, it is not always possible to glue ceiling tiles on a whitewashed ceiling. In this matter, it all depends on the following points:

- type of whitewash;

- features of applying the old coating.

If chalk whitewash was applied, then it is better to refuse tiles as a ceiling finish. The material will definitely start to come off.

Next, we will tell you how to stick tiles on the ceiling after lime-based whitewashing. Old whitewash will have to be removed if:

- the old finish easily lags behind the surface;

- on the ceiling there are several lime whitewash layers that are already stratifying;

- as a whitewash, frozen lime was used, reminiscent of the chalk coating method.

The tile used in the case of an old whitewash coating can only be light. These can be profiles made of foam or extruded polystyrene foam.

Installation of tiles consists of several stages:

- preparatory work;

- primer of the cleaned surface;

- markup;

- installation of foam plastic profiles with finishing.

Consider how to properly glue the tiles on the ceiling for whitewashing in more detail.

Preparatory work

Preparatory activities consist of the following:

- run your hand over the old whitewash, and make sure that the whitewash does not smear;

- then the surface is brushed, then wiped with a damp sponge;

- after the previous steps, you need to check again how well the old layer holds. Use a spatula to remove areas of whitewash that are suspicious. If the lime begins to fall off, then you need to remove these parts, capturing a few extra centimeters.

The preparatory activities are completed, and you can start priming work.

Primer application

Thanks to the primer, the adhesion between the base ceiling surface and the adhesive is improved.

The primer is applied as follows:

- before using a deep penetration primer, the composition is shaken and poured into a special container, from which it can be taken with a roller;

- the roller is impregnated with a primer and slightly squeezed. Then you need to walk with a roller along the cleaned whitewashed surface of the ceiling. The layer is applied thinly. To get to hard-to-reach areas, use a brush;

- you need to wait for the complete drying of the soil layer, then apply a second layer.

If large defects are found on the surface, then they need to be puttied.

markup

The quality of the future finish of the foam lining depends on the correctly applied markings.

The markup is done like this:

- mark a point at the intersection of the diagonals of the ceiling. This will be the center mark;

- further lines are marked along which you need to align the foam tiles. The location of these lines depends on the laying method.

You can not mark the entire ceiling surface. You can mark up only two center lines, then align the rest of the profiles with them.

Sticking

Before installing the panels, you need to cut off the burrs from them. As an adhesive, it is better to take liquid nails or glue from polymers.

Installation is done like this:

- installation starts from the center of the ceiling;

- glue is applied around the perimeter and center of the profile;

- the profile with the applied glue is aligned according to the markup and pressed against the ceiling;

- this is how a square of panels is laid out, and subsequent foam profiles;

- gluing in the corner, at the joints, is carried out after cutting the profiles;

- after the glue has hardened, the gaps between the profiles are puttied.

To finish and close the puttied joints, you can paint the foam tiles. If the profile has a rough rather than glossy structure, then the surface is pre-primed. The paint is applied in two or three layers with a roller. The first layer goes along the direction of the light, the next - across the natural light.