When finishing work, a gypsum-fiber sheet, or GVL, is often used. This material was created much later than drywall, so it did not win such wide popularity as GKL. However, due to the special composition of these boards, they have outstanding strength and fire resistance characteristics, which are much higher than those of drywall. Therefore, GVL is indispensable for the construction of bulk floors, rough finishing of walls and ceilings, as well as for the construction of all kinds of boxes. The only question that arises when working with this building material is how to cut the GVL from Knauf.

Advantages of GVL

To answer our question, we need to understand what this material is. Gypsum fiber sheets, like drywall, are made from building gypsum. But that's where the similarity ends. The main features of GVL are:

- Reinforcement with loose cellulose.

- Complete homogeneity of the material.

- No top cover.

- Fire resistance.

- High density.

Many manufacturers are engaged in the release of this building material, but the GVL manufactured by Knauf under the name Superlist is the most popular. If we continue to compare gypsum fiber with drywall of the same company, we can see that they complement each other perfectly. And the use of these materials for finishing work at the same time will only benefit the repair.

Despite the fact that any box can be made from GVL, and the walls will be strong and non-flammable, however, this material cannot be bent like drywall. So, for the installation of complex structures with rounded shapes, it is not suitable.

But on the floor, in dry screeds with expanded clay (Knauf-superpol technology), gypsum-fiber sheets are unmatched. Using them in the construction of a subfloor will give guaranteed positive results. Floor elements glued from two sheets GVLV with a total thickness of 20 mm, have the following useful properties:

- They don't break.

- They don't let the cold through.

- Creates a perfectly flat surface.

- Moisture-resistant gypsum boards can withstand humidity up to 70%.

Tools required for work with GVL

Many who independently prepared for installation and installed drywall mistakenly believe that they work in the same way with GVL. But here they are in for a nasty surprise. Gypsum-fiber sheets, with all their strength qualities, when you take them for a break, turn out to be brittle and break easily. By the way, that's why they cannot be bent like drywall.

Tools for cutting gypsum fiber sheets at home:

- Sharp construction knife with a thickness of 12 mm. The blades will need to be changed frequently as they dull quickly.

- A special hacksaw for plasterboard, which can cut this material almost without dust.

Some craftsmen claim that it is convenient to cut GVL with a special cutter used by shoemakers.

- A grinder or a circular saw is used only in a well-ventilated area and provided that the end justifies the means. This is the fastest way and at the same time very dusty. If you decide to choose this tool, you will have to stock up on respiratory and eye protection.

- Perfect fit jigsaw with a built-in vacuum cleaner, if you install a wood file with a tooth pitch of 4 mm in it. But there will still be a lot of dust, so you should work with goggles and a respirator.

Gypsum fiber cutting process

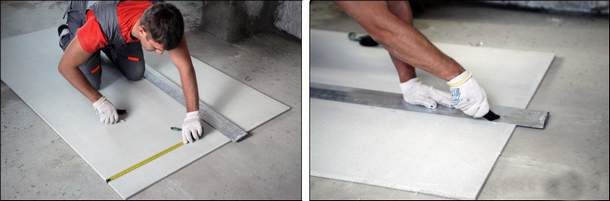

With any method of cutting, remember to be careful and careful when handling gypsum fiber boards.If it is decided to use cutters or a special hacksaw for the work, then you need to proceed as follows:

- On the GVL sheet, we make the necessary markup.

- We apply a flat rail to the marking line. You can also use a rule.

- We draw with a knife as many times as necessary so that the depth of the cut is at least 2/3 of the thickness of the sheet.

- We put the rail under the notch line.

- With a sharp upward movement, gently break.

Before cutting, it is better to additionally watch a video on how to cut the sheet correctly.

GVL has even edge edges and there are usually no problems with docking. But if for a number of reasons there is a need for a slight adjustment, then a peeling planer is suitable for this purpose.

But it is most convenient to make a fold with a shoe cutter or a chisel. With a large volume, you can use a milling cutter. A groove cutter of 3–4 mm will allow you to complete the necessary work in 2–3 passes.