Due to its low cost, ease of installation, unpretentiousness in operation and maintenance, linoleum polymer coating has become widespread. Almost the only nuance that can cause some difficulties are the joints of linoleum. If the places where the two strips are combined are not processed in any way, sooner or later the material begins to move away and bully, which spoils its decorative appearance. The best option for household use is the use of glue for linoleum joints.

Why is gluing joints necessary?

There are several ways to get a monolithic floor covering: by purchasing a canvas from a 4-meter-wide roll or by fitting narrower strips of 1.5 m each and laying them end-to-end.

If the base of the linoleum is carefully glued, it is possible to achieve the most accurate alignment of the strips with each other, which makes the seam almost invisible. However, as practice shows, over time, dust, various contaminants, and moisture accumulate between untreated joints, affecting the appearance of the coating and gradually deforming it. This phenomenon can be prevented by additional processing of the joints.

- Hot welding. When it comes to dense material - commercial linoleum - or you need to make an artistic application, the best option would be to use a special device - a building hair dryer. But this technology requires from the master, in addition to the availability of specialized equipment, a certain experience and level of skill.

- Cold welding. In everyday life, the "hot" connection is rarely practiced; more often, docking is performed using a special colorless glue. It is applied to the seams of linoleum, causes a chemical reaction, as a result of which the sheets are soldered together. The junction becomes practically indistinguishable to the eye and protects the coating from wear.

Advantages of cold welding

Cold bonding has many advantages:

- The resulting seams are monolithic, reliable and look very neat. For gluing, there is no need to heat the material to a temperature of 350 ° C, as with hot welding, as a result of which the coating may burn, warp, and lose its external attractiveness.

- There is no need to purchase special expensive equipment and accessories.

- The use of glue does not require special skills; any home master can use it.

- To work, you need a minimum set of tools.

Used types of glue

Presented on the market reactive adhesive range can be divided into three main groups. The choice of the required type is carried out based on the size of the seam, the variety of linoleum.

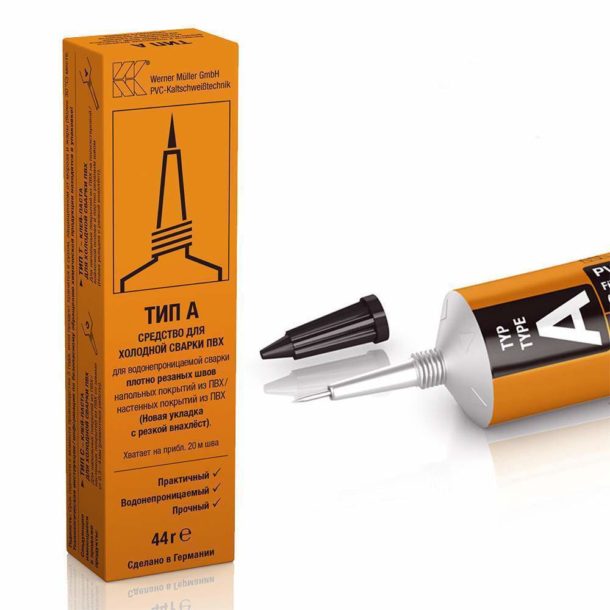

- Type "A". Such glue has a liquid consistency, it is used exclusively for processing new, freshly laid household linoleum or commercial flooring. With its help, a strong and transparent seam is obtained. Not suitable for working with wide gaps.

- Glue type "C" is used to fill large gaps. Its consistency is thicker than the previous version. It is permissible to use such a composition for gluing separated joints of long-laid linoleum, provided that the distance between the strips is not more than 3-4 mm.

- Type "T". Designed for gluing multicomponent linoleum having a polyester or felt base.

Glue brands

The following products are the most popular:

- "Econ" (50 ml), used for butt-gluing all types of linoleum and other coatings, PVC products. Price - 150 rubles, one tube is enough for 25 linear meters. m.

- Werner Muller (30 ml) - recommended by Tarkett linoleum manufacturer, suitable for residential, semi-commercial, commercial flooring. Cost - 470 rubles, consumption - 1 pack per 10 linear meters. m.

- Sintex H-44 (100 ml) - 230 rubles. One tube of Sintex glue, which is also used for welding ABS plastic, pipes and other PVC products, is enough to process 45–50 m of a seam.

- "Homakol S 401" (60 ml) - 260 rubles, designed for linoleum and PVC tiles, consumption - 1 tube for 24-30 linear meters. m.

- Glue "Econ"

- Welding "Werner Müller"

- "Syntex"

- "Homakol"

Advice! Do not be deceived by the ease of application of reaction compositions, their use requires the utmost attention and caution from the master. The slightest drop falling on the canvas will spoil its appearance. Therefore, we recommend that you always keep a cotton napkin over the tube, and if the composition gets on the material, wait for it to harden, and then carefully cut it off with a knife.

How to apply adhesive for linoleum?

We note right away that in the process of performing cold welding, it is extremely important to protect the respiratory organs and hands: the substance used is toxic, not recommended for inhalation, contact with the skin.

To understand the technology of cold welding, below is a step-by-step instruction that consistently describes the process:

- We carry out a thorough cleaning of the junction, which we plan to process.

- Masking tape is glued to the joint.

- Before opening the glue, carefully cut the tape along the entire length.

- In the resulting gap through a special nozzle, we squeeze the adhesive composition out of the tube.

- After about a quarter of an hour, remove the masking tape. After 60 minutes, you can safely walk on the floor.

Important! When the material is glued immediately along the entire length, in places of minimal surface differences, it begins to bulge and bulge ugly. The situation will be prevented by gluing joints in small segments no more than 50 cm.

Cold welding of linoleum seams with the use of special glue will extend the life of the coating. The price of this method will pleasantly surprise, its use is possible for any type of surface. The main thing is to follow the recommendations on the package.