Selection and installation of radiators

For the bottom connection, bimetallic heating radiators are recommended, they are easy to assemble, install and repair. Radiator sections can be removed, added or replaced if damaged.

When buying, it is better to give preference to domestic manufacturers, it is important to check the integrity of the battery and packaging. Documentation must be understandable and written in Russian

Before installation, you need to make markup. it is done with a pencil on the wall. In this case, the points where the brackets will be installed are marked. The bottom of the radiator must be at least 7 cm from the floor and 10 cm from the window (if located under the window). Distances are maintained so that the air in the room circulates freely. The distance to the wall should be about 5 cm.

For more efficient circulation of the coolant, heating radiators are installed with a slight slope. this eliminates the accumulation of air in the heating system.

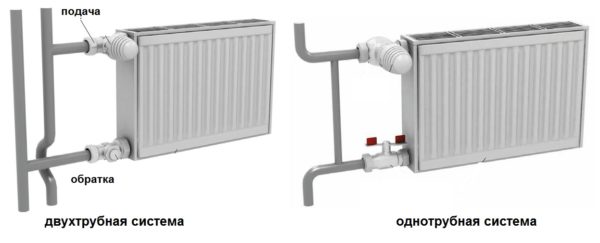

When connecting, it is important to follow the markings and not confuse the return and supply. If connected incorrectly, the heating radiator can be damaged, and its efficiency will decrease by more than 60 percent

There are the following types of bottom connection:

- one-way connection - the pipes come out from the corner below and are located side by side, heat loss can be about 20 percent;

- versatile piping - pipes are connected from different sides. such a system has more advantages, since the length of the supply and return lines is less, and circulation can occur from different sides, heat losses are up to 12 percent;

A top-down connection is also used. but in this case it will not be possible to hide all the heating pipes, since the coolant will be supplied in the upper corner, and the output will be from the opposite lower corner. If the heating radiator is closing, then the return line will be brought out from the same side, but from the lower corner. In this case, heat loss is reduced to 2 percent.

If you plan to connect heating radiators with your own hands, it is important to follow the installation and safety techniques. The coolant must be drained during installation or repair, the batteries are cold

If in doubt, it is better to call the wizard or use the training video tutorial, since with a lower connection it will be difficult to repair the sections. It is better to plan a heating system with bottom heating together with the layout of the house.

Heating radiators with bottom connection Aluminum radiators for home Steel panel radiators Heating radiators or underfloor heating

Is it worth it to use a single-pipe heating system

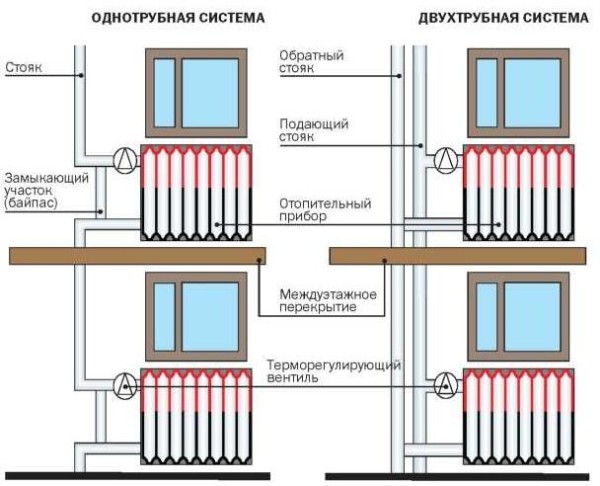

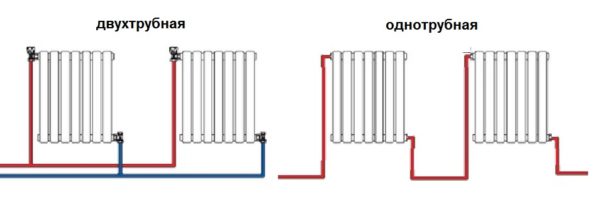

When laying pipes, a 2-pipe heating system is often used. Schematically, it can be represented in the form of 2 circuits, one is responsible for supplying hot water to the radiators, and the second for removing the cooled coolant and supplying it to the boiler. This approach allows you to organize the circulation of water of the same temperature in all batteries.

A significant disadvantage of this method of organizing heating is the financial cost of pipes (the price of such a heating device will be about 1.5-2 times more than a single-pipe one), and the labor intensity increases. In addition, pipes will be more difficult to disguise.

The single-pipe scheme does not imply the presence of a separate riser for the removal of the cooled coolant, that is, the pipes will need about half as much. Schematically, it can be represented as a closed circuit, and the connection of radiators with a single-pipe heating system is made in series.

Comparison of one- and two-pipe heating systems

Such a system began to be massively applied during the construction boom back in the USSR, at the same time its significant shortcomings were discovered:

the main thing can be considered that the last batteries in the circuit receive a coolant with a temperature of about 30-50% lower than those closest to the boiler, this leads to the fact that the rooms are heated extremely unevenly;

Note! This shortcoming can be easily solved by increasing the number of sections of the last radiators. But when building a large number of objects, this will lead to an increase in calculations, which is not very convenient.

- you will need a fairly powerful pump, it will not work to organize the movement of the coolant by gravity;

- it is characterized by large heat losses;

- the start-up of the system takes longer than in the case of a two-pipe system;

- when doing work with your own hands, the risk of air pockets during operation is especially high. It's just that quite often it is not possible to maintain the necessary slopes along the entire length of the pipes.

The listed list of disadvantages is typical for a conventional single-pipe heating system. Today, most of these shortcomings are successfully eliminated by installing simple devices. For example, it is already possible to regulate the temperature in individual batteries, and the installation of balancing valves will make it possible to achieve almost the same operating conditions for all batteries in the circuit.

Given the significant savings on materials, such a scheme of the heating system definitely deserves attention.

One-pipe and two-pipe heating systems

Depending on the number of pipelines, the systems are single-pipe, two-pipe and radial. In a single-pipe system, the coolant is supplied through one pipe, passes through the channels of the battery, gives off part of the heat, and flows back into the same pipe. The only advantage of such a system is the ease of installation and the minimum amount of consumables. Due to these features, this installation scheme is used in the construction of multi-storey standard houses. The radiators are connected in series, respectively, in devices remote from the boiler, the temperature of the coolant decreases. If the supply and return in the heating system is made with one pipe (side connection of the heating radiator from the vertical riser), it is impossible to regulate the temperature of an individual device, since narrowing or blocking the flow will affect the operation of all subsequent batteries. To ensure this possibility, a jumper between the supply and return pipes is required.

In two-pipe systems, two pipes, supply and return, are separately connected to each battery. At the same time, the consumption of pipes increases, but the system works much more efficiently. Connecting a radiator to a two-pipe heating system is recommended to be done diagonally, but other connection methods can be used depending on the location of the pipelines. The two-pipe system has several advantages:

- Natural and forced circulation of the coolant can be used.

- A heating connection scheme of any complexity can be used, taking into account the architectural features of the building.

- The temperature control of each device is carried out separately and does not affect the operation of the system as a whole, which allows maintaining different temperatures in individual rooms.

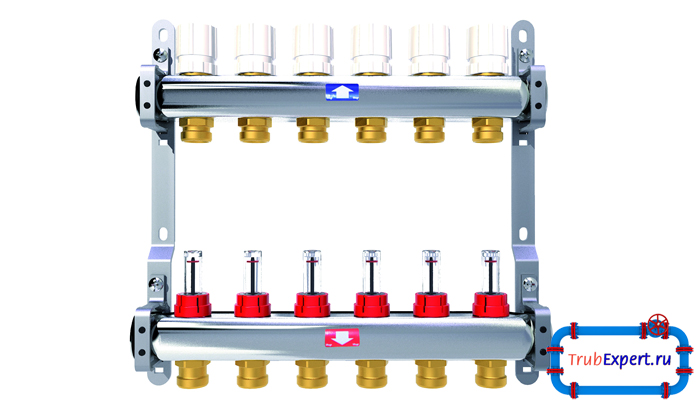

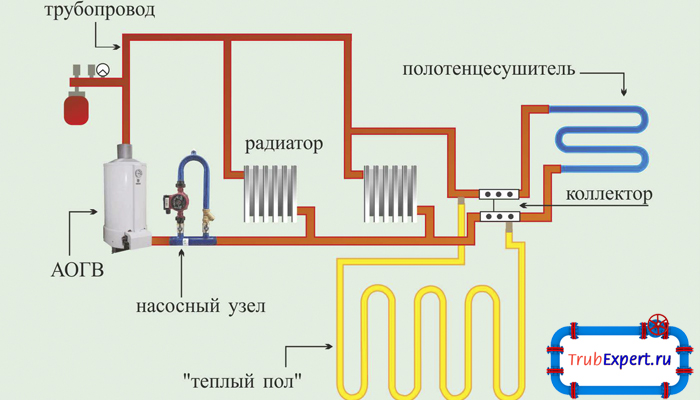

Collector wiring (beam system) involves the supply of coolant to each battery (or room) directly from the boiler. The temperature control of the devices is carried out using the manifold control valves. This wiring method allows you to connect a heated towel rail or floor heating system to the heating system, regardless of the batteries.

Collector for distributing pipes of the heating system

Collector wiring allows you to balance and adjust the system with a high degree of accuracy, but in addition to the advantages, it also has many disadvantages:

- High cost. The consumption of the pipe increases several times and the installation of additional equipment (collector, hydraulic separator) is required.

- The pipe is laid into the screed in one piece, joints in the screed are not allowed.

- Natural circulation is not enough; a circulation pump is required for each circuit. The use of electrical equipment makes the system dependent on the power supply.

- Restrictions when choosing the type of pipe. Usually, a metal-plastic pipe or a cross-linked polyethylene is used. Connecting a radiator to polypropylene pipes, which are distinguished by an affordable price, is impossible in this case.

As a conclusion. How to choose the right connection method

If you do not know which option to choose, then, first of all, pay attention to the battery installation diagram, because

it is on it that the performance and functionality of the devices mainly depend. And if you violate the installation rules, then this can lead to a sharp jump in pressure in the system (read: to unpredictable consequences). And if you plan to install it yourself, and without the required skills or knowledge, you can even spoil the interior of the room.

You can read more about the operating pressure in the heating system here.

When choosing a connection method, get ready for the fact that the efficiency of the system as a whole may drop, moreover, significantly. But this is nothing compared to how convenient the bottom connection is and how effectively it “hides” the pipes. But if you connect the batteries correctly, then in the future you can save a lot!

To learn more about the issue that was covered in this article, we recommend watching the thematic video.

Aluminum heating radiators Rifar with bottom connection

Rifar Alum 350 Ventil 1400 rub.

Today, when designing a heating system in a country house, much attention is paid to the rationality and compactness of systems. Therefore, the bottom connection of radiators is the most versatile and aesthetic option, due to the fact that all return and supply pipelines are laid under the floor, and the connection to the radiator is carried out at the bottom, which is very convenient

It was believed that the lower connection can reduce the efficiency of heating systems by 5%, but today, thanks to modern developments, this opinion has changed. For such heaters, underground piping is optimal. Distribution tubes are used in such devices for better distribution of the coolant.

The best choice is the Rifair radiator, which, in case of bottom connection, is equipped with a special thermostatic device located in the body of the heater. Rifair radiators use seamless technology without the use of welding, which allows the use of oil as a heat carrier, as well as various antifreeze antifreeze liquids. Thanks to a special light aluminum alloy, a high heat transfer rate is ensured, and the special design of the internal channels and body allows it to withstand high pressure.

In terms of overall dimensions and the best heat transfer indicators, domestic radiators with a lower connection Rifar stand out, where, having a special compactness, they can heat quite decent areas of premises. All models are able to withstand pressure up to 20 bar and coolant temperature up to 110 C.

In private houses and high-rise buildings, it is recommended to use Rifar steel panel radiators, consisting of several panels. A distinctive feature is a two-layer environmentally friendly lacquer coating that does not emit harmful substances into the environment, and special methods for performing the painting process and applying protective layers reliably protect the heater. In the case of a bottom connection, a ¾ inch male thread is provided. Among the options offered, there is a large selection of sizes, where you can choose the right model for any ceilings and window sills.

Universal Russian radiators Rifar with a bottom connection can be installed in heating systems with copper, steel, metal-plastic and polypropylene pipes. All models are made using injection molding.

We work for glory.

All Rifar heating radiators are technologically advanced radiators made under the strict supervision of professionals.

Polypropylene pipe piping

Before connecting aluminum radiators with polypropylene pipes, a piping diagram should be drawn up

When compiling it, it is important to avoid unnecessary knots and “rings” in the pipes, which will make the work more reliable.

Piping can be carried out both in a single-pipe and two-pipe heating system, but taking into account the following nuances:

- In the first option, a bypass must be installed.

- With a two-pipe system, additional connecting elements are needed.

Polypropylene pipes can be connected in two ways:

- The most reliable is soldering. since the ends of the pipes and the tee are fastened together so firmly that they become a single system that is not afraid of either high temperatures or pressure increases. Soldering is carried out with a special tool.

- If you use fittings. for fixing which do not require special devices, you should be prepared that they will have to be tightened and checked regularly. This is due to the fact that when heated, the pipes expand, gradually weakening their “grip”. As soon as the fasteners loosen, leakage will follow.

In order for everything to be done correctly, the sequence of actions should be followed:

- Check that the cuts of the part of the harness that fits directly to the battery are even. Cut the pipe again if necessary.

- The next step is to solder the parts of the harness that fit the fitting located at the top of the radiator. With a special soldering iron, even a beginner can carry out this procedure. It is enough to insert one part of the tee into the pipe, heat the junction with a soldering iron and hold them until the seam cools down. As a rule, it takes no more than 3 minutes. The same process is carried out with the second side of the tee.

- Assembly of the lower part of the harness. which is connected to the lower fitting, is carried out in a similar way, only more adapters are required.

- The locking device is connected to both parts of the harness. what is the pipe for.

After the shut-off valves are connected, all nuts are tightened, having previously screwed tow impregnated with sealant onto the thread of the fitting.

If you decide to install aluminum heating radiators, it is important to know the following:

As practice shows, the conversion of aluminum radiators for bottom connection is in great demand, especially in houses with autonomous heating. They look more aesthetically pleasing, heat the room evenly and quickly, but require some knowledge during installation, so it is recommended to trust their installation to professionals.

Choosing a place and method of installing a radiator

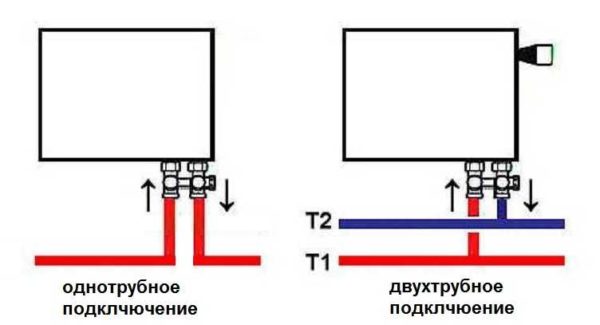

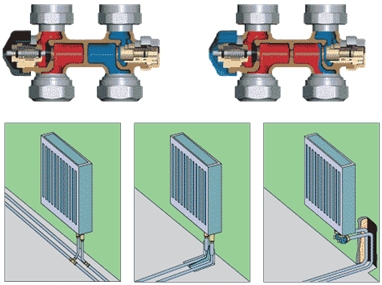

The options for connecting heating radiators depend on the general heating scheme in the house, the design features of the heaters and the method of laying pipes. The following methods of connecting heating radiators are common:

- Lateral (unilateral). The inlet and outlet pipes are connected on the same side, while the supply is located at the top. The standard method for multi-storey buildings, when the supply is from the riser pipe. In terms of efficiency, this method is not inferior to the diagonal one.

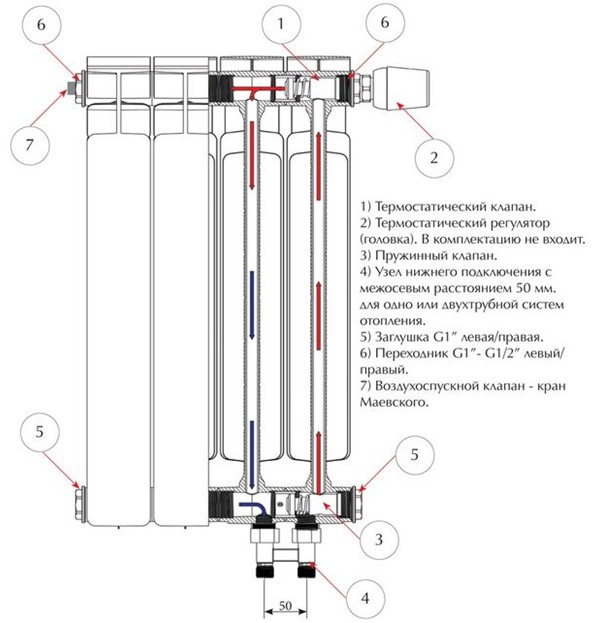

- Lower. In this way, bimetallic radiators with a bottom connection or a steel radiator with a bottom connection are connected. The supply and return pipes are connected from below on the left or right side of the device and connected through the lower radiator connection unit with union nuts and shut-off valves.The union nut is screwed onto the lower radiator pipe. The advantage of this method is the location of the main pipes hidden in the floor, and heating radiators with a bottom connection harmoniously fit into the interior and can be installed in narrow niches.

The advantage of most bottom-connected steel radiators is that the thermostatic valve is already built-in for mounting a thermostatic head, so it's not surprising that they cost a little more than similar-sized side-connected radiators.

- Diagonal. The coolant enters through the upper inlet, and the return is connected from the opposite side to the lower outlet. The optimal type of connection that provides uniform heating of the entire battery area. In this way, correctly connect the heating battery, the length of which exceeds 1 meter. Heat loss does not exceed 2%.

- Saddle. The supply and return are connected to the bottom holes located on opposite sides. It is used mainly in single-pipe systems when no other method is possible. Heat losses as a result of poor circulation of the coolant in the upper part of the device reach 15%.

When choosing a place for installation, several factors are taken into account to ensure the correct operation of heating devices. Installation is carried out in the places least protected from the penetration of cold air, under window openings. It is recommended to install a battery under each window. The minimum distance from the wall is 3-5 cm, from the floor and window sill - 10-15 cm. With smaller gaps, convection worsens and battery power drops.

Typical mistakes when choosing an installation location:

- Space for installation of control valves is not taken into account.

- A small distance to the floor and window sill prevents proper air circulation, as a result of which heat transfer decreases and the room does not warm up to the set temperature.

- Instead of several batteries located under each window and creating a thermal curtain, one long radiator is chosen.

- Installation of decorative grilles, panels that prevent the normal spread of heat.

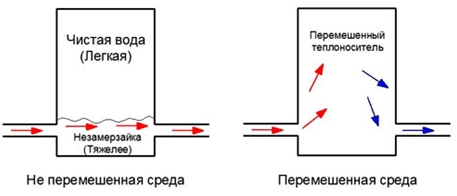

Coolant circulation methods

The circulation of the coolant through pipelines occurs in a natural or forced way. The natural (gravitational) method does not involve the use of additional equipment. The coolant moves due to a change in the characteristics of the liquid as a result of heating. The hot coolant entering the battery, cooling down, acquires a greater density and mass, after which it falls down, and a hotter coolant enters in its place. Cold water from the return flows by gravity into the boiler and displaces the already heated liquid. For normal operation, the pipeline is installed at a slope of at least 0.5 cm per linear meter.

Scheme of coolant circulation in the system using pumping equipment

For forced supply of coolant, the installation of one or more circulation pumps is mandatory. The pump is installed on the return pipe in front of the boiler. The operation of heating in this case depends on the electrical supply, however, it has significant advantages:

- The use of pipes of small diameter is allowed.

- The main is installed in any position, vertically or horizontally.

- Less coolant required.

The main advantages of the bottom eyeliner

As noted earlier, this method provides for the supply of hot liquid to the radiator on one side, and the output of the cooled liquid on the other. Thanks to this, the pipes can be easily hidden without losing much of their effectiveness. And the batteries themselves warm up faster from below than from above due to the high speed of water circulation.

Sometimes the efficiency of the equipment in operation is reduced due to airing of the line or its clogging.But even after that, this method of piping ensures uniform heating of the devices (the efficiency is not lower than in the case of the upper piping).

Important! Regardless of which connection method has been chosen, a number of special requirements must be observed during installation. And this applies primarily to the ratio between the width of the radiator and that of the window

Advantages and disadvantages

The advantages of the bottom connection of a bimetallic radiator include:

- Aesthetic look. With this connection scheme, the pipes are easier to hide. For example, this can be done by hiding them under the floor, into the wall, or under the baseboard.

- Ease of installation. The pipes are connected directly, with this option there are few bends, turns, etc. Thus, the coolant flows without significant obstacles.

- The price of the lower connection scheme is less than the others;

- The bottom connection system is more stable, that is, it is difficult to unbalance it.

Disadvantages of the bottom connection:

- If pipes are run under the floor to achieve an aesthetic appearance, it will be very difficult to eliminate the leak. The floor will need to be removed. In an apartment building, such a system is not connected, since there is a central heating system.

- The level of heat transfer from radiators with a lower connection scheme is somewhat less than with other connections.

As for the low heat transfer, this can be explained by the design of the channels in bimetallic radiators. Hot coolant is fed into the battery and very quickly heats up its lower part. The top of the battery warms up due to the convection process. Thus, the top of the battery may not be fully warmed up, and air will constantly collect there.

This also applies to the situation when the coolant consists of water and antifreeze (Fig. 4). Antifreeze is heavier than water and is always at the bottom, while water will rise up. Thus, with the lower connection scheme, the circulation of the coolant inside the device is disturbed. This leads to little heat dissipation and inefficiency of the bottom wiring diagram.

How to connect a bimetallic radiator? Of course, for this you need to have certain knowledge and skills. The correct connection of a bimetallic heating device is to follow certain rules. It should be noted that it is better to connect the lower pipe scheme at the beginning of the repair work. Since this eyeliner is actually carried out because of the aesthetic appearance, the pipes go either under the floor or in the wall.

All distances must be strictly observed, for example, from the floor to the radiator, the correct distance must be at least 15 cm, between the wall and the appliance at least 2 cm.

Next, using the level, you need to accurately draw the places for the brackets. It is better to install the radiator on a stand and put a level on top, then you can be sure that all measurements are taken correctly. Brackets, as a rule, come with a bimetallic heating device. The number of these fasteners must correspond to the size of the device.

In order to properly connect the pipes, it is important not to confuse the supply and return lines. To prevent this from happening, you need to carefully study all the inscriptions, since there is a corresponding marking on the radiator

If the bimetallic heating radiator is connected incorrectly, the heat transfer decreases several times, namely by 60%. Of course, the model of the heating device also depends on this.

The lower tubes, which are L-shaped, must be strengthened, but only after checking the entire system. This is usually done with foam.

Installation and connection of bimetallic radiators must be carried out in protective packaging

This is very important, because if you damage the paint on the radiator, then an irreversible process can begin.From damage, the paint will continue to swell

If this happens, but you need to purchase a special enamel-based paint and treat the scratch. The packaging must be on the radiator before connection.

All component plugs and taps must be included with the radiator, but this must be checked with a consultant in the store. Namely, this is Mayevsky's crane and plugs for another collector. The Mayevsky crane should be correctly installed with a torque wrench in order not to overtighten the connection and damage the crane. In no case should the connections be cleaned with anything, since a leak may occur when the system is started.

What is a radiator connection node

The connection point for a radiator with a bottom connection is an H-shaped piece of plumbing fittings with two parallel fittings at a distance from the seats of a steel panel radiator, and a rigid jumper between them. A typical part has, on one side, a fitting in a pressed union nut with a gasket (American connector) with an inner diameter of 3/4 inch, on the other side, a 3/4 inch external thread is applied to the fitting.

Inside each of the inputs there is a shut-off ball valve or a screw valve that allows you to regulate or shut off the incoming coolant; when the battery is removed during its repair or replacement, a shut-off function is used.

Radiator connection diagrams

How well the radiators will heat up depends on how the coolant is supplied to them. There are more and less effective options.

Radiators with bottom connection

All heating radiators have two types of connection - side and bottom. There can be no discrepancies with the lower connection. There are only two pipes - inlet and outlet. Accordingly, on the one hand, a coolant is supplied to the radiator, on the other hand it is discharged.

Lower connection of heating radiators with one-pipe and two-pipe heating systems

Specifically, where to connect the supply, and where the return is written in the installation instructions, which must be available.

Radiators with side connection

With a lateral connection, there are much more options: here the supply and return pipelines can be connected to two pipes, respectively, there are four options.

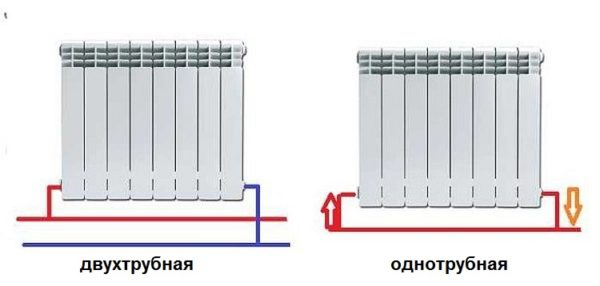

Option number 1. Diagonal connection

Such a connection of heating radiators is considered the most effective, it is taken as a standard, and this is how manufacturers test their heaters and the data in the passport for thermal power - for such an eyeliner. All other connection types are less efficient at dissipating heat.

Diagonal connection diagram for heating radiators with a two-pipe and one-pipe system

This is because when the batteries are connected diagonally, the hot coolant is supplied to the upper inlet on one side, passes through the entire radiator and exits from the opposite, lower side.

Option number 2. Unilateral

As the name implies, pipelines are connected on one side - supply from above, return - from below. This option is convenient when the riser passes to the side of the heater, which is often the case in apartments, because this type of connection usually prevails. When the coolant is supplied from below, such a scheme is used infrequently - it is not very convenient to arrange pipes.

Lateral connection for two-pipe and one-pipe systems

With this connection of radiators, the heating efficiency is only slightly lower - by 2%. But this is only if there are few sections in the radiators - no more than 10. With a longer battery, its farthest edge will not heat up well or even remain cold. In panel radiators, to solve the problem, flow extensions are installed - tubes that bring the coolant a little further than the middle.The same devices can be installed in aluminum or bimetallic radiators, while improving heat transfer.

Option number 3. Bottom or saddle connection

Of all the options, the saddle connection of heating radiators is the most inefficient. Losses are approximately 12-14%. But this option is the most inconspicuous - the pipes are usually laid on the floor or under it, and this method is the most optimal in terms of aesthetics. And so that the losses do not affect the temperature in the room, you can take a radiator a little more powerful than required.

Saddle connection of heating radiators

In systems with natural circulation, this type of connection should not be done, but if there is a pump, it works well. In some cases, even worse than the side. Just at some speed of movement of the coolant, vortex flows arise, the entire surface heats up, and heat transfer increases. These phenomena have not yet been fully studied, therefore it is still impossible to predict the behavior of the coolant.

We connect heating radiators correctly

Regardless of the type of radiators chosen and the connection scheme suitable for them, it is important to calculate and install everything correctly. In each case, the optimal system will be

For expensive houses of a large area, it is advisable to contact specialists who can offer the best project. It's not the kind of thing to skimp on

In each specific case, its own system will be optimal. For expensive houses of a large area, it is advisable to contact specialists who can offer the best project. This is not an issue to skimp on.

In order to properly install and connect heating devices in a complex design scheme, it is better to use the services of professionals

For small residential houses, you can independently choose the appropriate scheme and install heating devices. Be sure to take into account the features of your home, the rules for installing batteries and the feasibility of using a particular scheme.

When installing radiators, one should not forget that the type of material for the battery itself and pipes must be the same. Plastic pipes connected to cast iron heaters will bring many problems, ruining the heating system.

Being engaged in self-assembly of heating batteries, one should not forget to install ball valves to bleed air and an inlet regulator