Despite the abundance of modern flooring options, polyvinyl chloride (linoleum) roll sheets do not give up their positions and remain very popular among the townsfolk. True, the area of \u200b\u200bthe room does not always allow using only one strip for finishing the floor, then an aesthetically unattractive seam is formed at the joints. Special technology will help to eliminate this defect. We offer you to figure out how to glue linoleum by cold welding without the help of a qualified specialist.

Methods for gluing linoleum

Joints are the most vulnerable and weak point of the described coating. Sooner or later, the material at the seam begins to bulge, twist, thereby spoiling the appearance of the room and turning into a potential source of injury.

Initially, craftsmen welded strips using an ordinary soldering iron, which did not allow to obtain a perfectly even connection, and the seam itself did not always come out uniform.

Modern technologies allow welding linoleum at home without damaging the quality of the coating in two ways.

- Hot seam welding involves the use of a special building hair dryer, which acts on the coating at a high temperature (up to 650–700 ⁰С). Therefore, its use is only valid for commercial PVC roll material.

- Cold welding of linoleum is ideal for domestic use.

The essence of the cold welding method

Do-it-yourself linoleum welding is performed using special adhesives. This method got its name because during the processing of the joints of the coating, the material melts, but heating mechanisms are not used.

Due to the ease of execution, even a non-specialist can master the technique.

Simply put, the joints of the fabric to be welded are filled with glue, which is a PVC solvent. The coating strips melt under its influence, and when the active substance evaporates, the surface becomes monolithic.

Before you weld the stacked linoleum using this method, you should evaluate its advantages and disadvantages.

Advantages of the method

The popularity of the described method in comparison with processing with a building dryer is due to a large number of advantages:

- With such gluing, the seam becomes almost invisible, does not spoil the appearance of the room.

- To process felt-based linoleum, there is no need to purchase or rent welding equipment or tools. The only thing to do is to cut the edge.

- The implementation of the entire complex of cold welding work, even for an inexperienced craftsman, will take no more than a few hours.

- The described method allows you to neatly join the relief seams.

However, the technique is not suitable when laying a layer of insulation under the linoleum: the joint will be clearly visible.

What glue to use?

There are several types of special compositions suitable for welding linoleum.

- Type "C" is used if the linoleum sheets are cut unevenly, a large gap is formed between them, or if they remain in a free state for a long time. The consistency of this substance is thicker, it fills the seam, melts the edges. Used as a repair compound for old coatings.

- A more liquid type "A" glue is used to connect the new linoleum in the presence of minimal gaps. This consistency allows the substance to fuse the material, penetrating into the seam. Suitable for single-layer coating or linoleum on a foam substrate.

- Type "T" glue is used for felt or polyester based material.Has a pasty consistency, more difficult to use.

Main stages of work

To glue linoleum end-to-end using the cold welding method, you must clearly follow the instructions.

- We roll out the coating sheets, combining the surface pattern. We lay adjacent canvases with a slight overlap (no more than 5 cm).

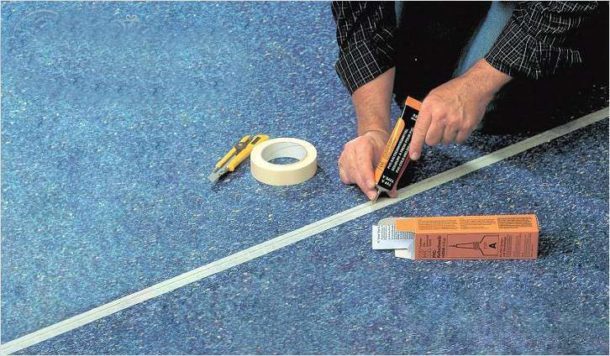

- Using a flat metal rail as a ruler, we draw a line over the joint so that it passes through both strips.

- According to the markings made in the previous paragraph, we cut both canvases with a sharp knife. Thus, it is possible to obtain the most even joint.

- We connect the parts of the linoleum with double-sided tape, fixing it initially on the floor. Each of the sheets is fixed separately, at the junction we pass with a roller.

- We glue masking tape on top of the seam, which will play the role of protection for the front side.

Important! If the solvent adhesive gets on the surface of the linoleum, the composition will be impossible to remove.

- We cut the masking tape at the junction, freeing ourselves the field for action.

- Despite the fact that the technique is called "cold", experienced craftsmen still recommend warming up the junction. For this, a household iron and a flat metal plate applied to the linoleum are used. An electrical appliance is placed on it for a short period of time.

- After the described heating, the adhesive composition is introduced into the gap between the sheets. To do this, use a special needle that comes with the tube. It is necessary to squeeze out the glue evenly, controlling that it completely fills the seam. Excess is removed with a knife.

The strips of a floor covering welded thus have a plain surface, are practically imperceptible. You can see how a specialist glues the seams in the video below.

The work should be done carefully and extremely carefully, trying not to overdo it and not melt the front surface of the linoleum. Mastering this simple technique will help save on the services of professionals and give housing a well-groomed appearance.