Insulated Swedish stove device technology in stages

Let's look at the stages of the construction of an insulated Swedish stove.

Foundation layout

The marking of the UWB foundation is done according to the project with preliminary clearing of the site from trees, shrubs, grass. The site for UWB should be open with an equipped entrance for construction equipment.

The marking of the site should include not only the marking of the slab itself, but also the marking of the drainage system around the house (around the slab) for drainage from the house and draining storm water. Along with the marking of the sewer, marking is made for the installation of a septic tank and sewer routes from the house to the septic tank.

Excavation

The UWB foundation technology involves a large amount of excavation work. The insulated Swedish slab requires leveling, cleaning and digging for the entire area of the slab. Therefore, take care of renting construction equipment in advance, for example, here.

The foundation for the UWB foundation must be flat and level. A layer of geotextile is laid at the bottom of the pit. A layer of high-quality sand is laid on the geotextile material.

Important! Insulated Swedish slab requires tamping the sand cushion using a tamping machine. When tamping sand, it must be constantly moistened with water, for which a hose is attached to the machine and the water supply

A layer of sand cushion should be from 15 cm.

Engineering work

The insulated Swedish stove involves the laying of all utilities at home before the stove is installed. Therefore, sewerage pipes, water supply pipes to the house, drainage system pipes must be laid after the sand cushion.

Second base layer

On top of the laid communications, a second underlying layer of gravel or crushed stone is made, with compaction up to a thickness of 100 mm.

Swedish board formwork

For the formwork of the Swedish slab, special L-shaped or rectangular slabs of solid extruded polystyrene foam are used. These slabs will not be dismantled, but will be included in the foundation structure.

Warming and insulation of UWB by area

On all surfaces of the UWB, 10 cm of expanded polystyrene boards are laid. The result should be a kind of "trough," into which concrete mortar will need to be poured.

UWB reinforcement

According to the made layer of polystyrene foam, standard reinforcement of the foundation is carried out with a mesh with cells of 150 by 150 mm. The mesh is laid with an overlap of 25 cm, and attached to the expanded polystyrene with special fastening clips.

Floor heating system device

On the laid grid, the underfloor heating system is installed with the installation of a collector cabinet (cabinets). Installation is carried out according to the foundation project, which should include the underfloor heating project. Water heated floor pipes are attached to the reinforcement mesh.

Pouring a concrete slab

To pour a concrete slab, ready-made concrete of the M250 brand is purchased with the delivery of concrete by special machines. The slab is poured in one day without interruption. The surface of the filled slab is leveled and covered with polyethylene from precipitation and debris.

The warmed Swedish plate dries (gaining strength) within 28 days. This time is used to complete the laying of communications and the installation of a septic tank. Also, work is underway on concreting the blind area around the house with the installation of storm drains.

After drying, the UWB is polished and fully prepared for the subsequent installation of floors in the house.

Popular site articles

-

Cons of a semi-dry floor screed

-

Preparation of a semi-dry floor screed: components, proportions

-

Subfloor device in a wooden house

-

Preparation of the base for self-leveling floors

-

What is the difference between leveler, self-leveling floor and self-leveling mixture

-

Fiberglass: proportions of fiberglass in the screed

-

Resistive heating cable: what is it, why is it needed

What is the cheapest foundation for a house?

Considering how to properly build a foundation for a private house and not spend more than necessary, you should take into account the type of soil, the weight of the building and a lot of other characteristics, then you will be able to choose the ideal option.

The lowest cost and time spent are inherent in the columnar foundation. But it has two significant limitations: installation only on inactive or immovable soils and a small weight of the structure. As a result, it is categorically unsuitable for a residential building or heavy construction.

In second place are piles, but here it all depends on their variety. Screw the most inexpensive of all but suitable for light buildings, bored - for brick and concrete, and driven provide a high level of stability, but are very expensive.

Strip foundation. A non-buried and shallow-buried view will not cost much more than a columnar one, and a deep-laid tape has the highest price due to the increase in work and the use of a large amount of materials.

A monolithic slab is the most expensive type of foundation, but provides maximum reliability on heaving soils. In some cases, such a foundation is the only option suitable for the soil.

What are the types of foundation? How is the construction of the foundation and how much does it cost? See all this and more in this issue:

As a result, it is far from a fact that a seemingly inexpensive foundation will remain so. Sometimes it happens, for example, that it is more profitable to make a monolithic foundation than to bury a tape foundation to the freezing depth. The choice of foundation should be based on a combination of factors, because the price may change depending on the situation.

Slab foundation with bituminous coating under a brick house

Foundation for wooden log houses

Structures made of logs and timber are lighter than brick or concrete, but exceed frame houses, so the best option for them would be a shallow tape or pile-grillage foundation.

The first option allows you to equip the basement, has sufficient resistance to loads and relatively low cost. To ensure its durability, it is necessary to equip high-quality waterproofing and pour a thick sand cushion.

For a pile-grillage foundation, it is necessary to dig holes to the level of soil freezing and connect them with isthmuses. Then concrete is poured into the pits and ditches and a concrete band is obtained, from which pillars emerge, resting on the soil below the freezing level.

The device of the pile-grillage foundation

These types of foundations provide an opportunity to equip a reliable and durable foundation that can easily withstand the weight of a wooden house of one or two floors and avoid unnecessary overpayment by equipping an unnecessarily expensive support designed for an impressive mass.

Differences from the insulated Swedish stove

The main difference between the Finnish and Swedish designs is that the Finns proposed using a strip foundation as an additional support around the entire perimeter.

UWP is just a concrete slab cast in a kind of expanded polystyrene pallet, which is how it differs from UFF. As a result, the installation of an insulated Finnish plate does not require the preparation of a strictly verified surface horizon, which means that construction can be carried out on sites with a slight slope. We have already written about this type of foundation here.

The absence of a rigid connection between the strip foundation and the floor platform makes the structure more resistant to fracture and increases the resistance to loads on problematic unstable soils. In addition, the UFF foundation technology makes it possible to perform the installation and pouring of the slab after the walls have been erected and the roof has been installed.This means that these works can be carried out in the cold season without stopping construction for the winter.

Pros and cons of UVF

Like most building structures, the insulated Finnish foundation has advantages and disadvantages. Among the main advantages, experts call:

- the possibility of mounting the base on any type of soil, except for weak peatlands with a high level of groundwater;

- economical consumption of materials in comparison with other types of bases, except for the Swedish slab, where the cost is approximately the same;

- the floor screed is not load-bearing and the entire weight load from the enclosing structures is transferred to the tape part of the foundation;

- the presence of a built-in underfloor heating reduces the cost of installing heating;

- pouring the insulated floor is possible at any time of the year;

- the possibility of constructing a load-bearing base on small slopes and with elevation changes in the relief.

The disadvantages of the Finnish slab foundation technology include:

- the need for earthworks with the digging of a trench and a pit, which may require the involvement of special equipment;

- backfilling with non-metallic materials after installation of the tape part, followed by mechanical tamping;

- low bearing capacity of a shallow tape, limiting the number of storeys of buildings.

As you can see, for a light one-story individual construction, an insulated Finnish foundation is a technically and economically sound option.

Installation

The depth of the trench depends on the distance to groundwater and the type of soil.

In connection with all of the above, it is necessary to conclude that a warm foundation can be built at the very beginning, and if the geological analysis of the soil does not allow this, then it will be necessary to insulate after the house is fully erected. In the case of the first situation, you must first dig a trench around the entire perimeter of the future home.

Depending on the climatic conditions and the composition of the soil, its depth should be from 50 to 100 cm. After that, it will be possible to start mixing the solution itself. Most commonly used, consisting of:

- cement;

- sand;

- crushed stone;

- water.

First you need to take one part of water and cement, mix everything and add 3 parts of sand and the same amount of rubble to them. The mixed solution must be poured into the dug trenches. In advance, you can resort to reinforcement. This will allow you to strengthen the structure, and, accordingly, the whole house. For these purposes, materials such as old frames from any vehicle, old wire, pipes and any other scrap metal, which, most likely, was lying around somewhere in the country or in the garage, are perfect. Thus, if the depth meets all the above requirements, then this bookmark will allow you to insulate the foundation of the house to the maximum.

What is a UWB foundation

When choosing this type of foundation for a frame house, it is possible to achieve the most cozy and comfortable living conditions. This type of foundation involves the presence of a cushion of sand and gravel, with drainage. A heater is placed on top of this pillow, and then the slab itself with underfloor heating pipes and communications, reinforced with fittings, is already installed.

The unique technology of the presented material involves the use of a special heat-insulating layer under the slab and near the foundation. This layer is characterized by a large thickness, so that heat loss can be reduced by up to 65%.

Video instruction for the construction of an insulated Swedish plate:

Thermal insulation methods

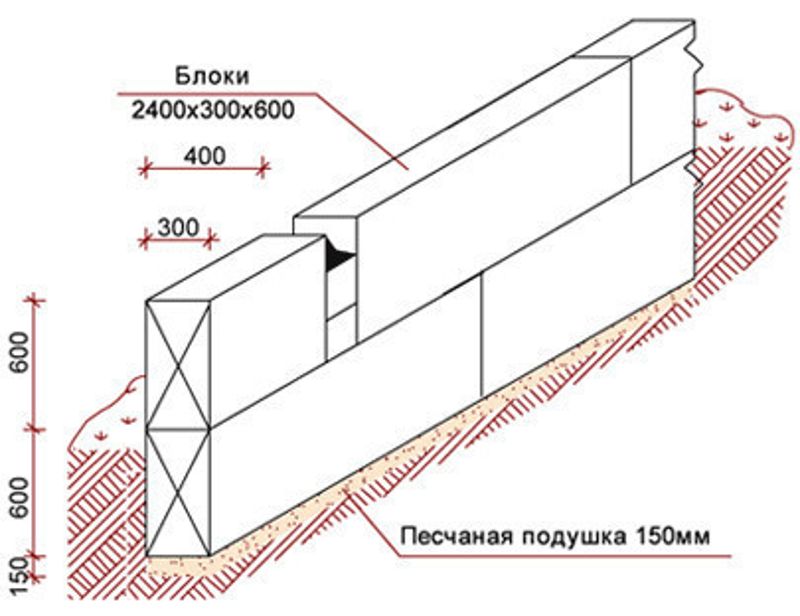

Concrete block foundation: sand cushion, blocks.

In addition to the option that involves the construction of a liquid foundation pit with concrete mortar, there is another way to insulate a home. It is due to the fact that instead of mortar, individual concrete blocks are placed in the pit.They are ready-made material for the foundation, which are already reinforced and pressed into rectangular slabs. They can be columnar (they have a regular rectangle in cross section) and tape. They are concrete blocks in the form of trapezoids. The wide base of such plates allows you to withstand enormous loads on the foundation and on the soil.