Turning on the boiler

- The gas boiler is plugged into an outlet.

- The switch must be set to zero.

- The gas supply is turned on (the tap on the gas pipe opens).

Further actions may differ for different models of gas boilers.

For example, the Aton or Danko boiler switch must be set to the “asterisk” icon, press the entire switch and hold it for 5-10 seconds.

Then, without releasing the switch, press the button located next to it.

The unit will respond with a characteristic click and hum. After that, the regulator is released and the required power is set.

To turn on the Baksi boiler, you also need to turn on the gas, plug in the plug and press the "Start" button. The operating sound will appear. The device needs to be given a little time, and it will automatically ignite the flame.

After that, you need to press the power button again and by this connect the heating circuit (the corresponding icon will appear on the display). In conclusion, the desired temperature is set using the buttons.

Buderus brand heating appliances are characterized by high reliability. - a brief overview of popular models and their cost.

Consider the types of generators for gas boilers.

To organize a full-fledged heating system in a private house, it is necessary to install a boiler. The article considers the main criteria for choosing heating equipment.

Symptoms

If the gas boiler goes out, what to do, you must certainly decide, but you should first familiarize yourself with how the malfunctions manifest themselves. They can be expressed in the fact that the main burner does not turn on or burns very weakly. The reason may be the clogging of the nozzles, they should be cleaned with a wire of small diameter. And if air has entered the system, an error code is displayed on the equipment display, while the boiler must first be turned off and then restarted.

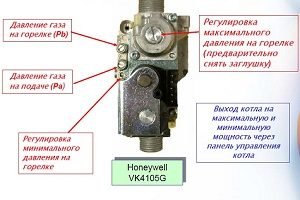

If the gas chimney is not properly selected, this can lead to flame separation. The nozzle starts to make a whistle or a loud noise, and you can deal with the defect by adjusting the gas pressure on the igniter. You may encounter such a problem if there is excessive draft or if the supply ventilation is very intense.

10 Mysterious Photos That Will Shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures got really unbelievable.

Never do this in a church! If you're not sure if you're doing the right thing in church or not, then you're probably not doing the right thing. Here is a list of the terrible ones.

10 Adorable Celebrity Kids Who Look Very Different Today Time flies and one day little celebrities become unrecognizable adults Pretty boys and girls turn into s.

13 Signs You Have the Best Husband Husbands are truly great people. What a pity that good spouses do not grow on trees. If your significant other does these 13 things, then you can.

9 Famous Women Who Have Fallen In Love With Women Showing interest in someone other than the opposite sex is not unusual. You can hardly surprise or shock someone if you admit it.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she broke into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Causes of boiler attenuation and troubleshooting

If you are interested in the question of why the gas boiler goes out, then, quite possibly, the reason may be the ice growths that cover the head of the device. It is impossible to get rid of them quickly, otherwise there is a possibility of damage to a component of the system.If ice is frozen on the inner walls, then air access will be blocked, as a result of which the gas boiler will go out. Defrosting should be done gradually, the head for this will have to be removed. After it should be brought into the room and thawed. While defrosting is in progress, the boiler can operate without this part.

The gas supply to the burner must be shut off, and as soon as the igniter is ignited, the valve can be opened. After the main burner lights up, the equipment should be warmed up. It should work on a slight gas pressure. Warming up must be completed, only after that it is allowed to increase the intensity of the gas supply. When the unit is operating, it is necessary to control the state of the contacts of the piezo ignition elements. They must be hot. If the contacts cool down, the gas pressure should be reduced. This will prevent the thermocouple from cooling. Otherwise, a signal will go off, causing the automation to work.

Removing air pockets before lighting a gas boiler

Air vents must be installed in the upper fitting of each radiator. These can be Mayevsky taps, or automatic valves.

Automation will cope with everything itself, you just need to give it a little time (the pressure drop will tell you that the air has come out).

To release air with a Mayevsky crane, you need to prepare a bucket, a rag, a special key from the installation kit (or a screwdriver and pliers).

A container is alternately substituted for each radiator, the tap is unscrewed, and the air comes out with a hiss. Then the battery will begin to "spit" air mixed with water. You can close the air vent when a trickle of water flows out of it.

Approximately 5-7 minutes at each radiator - and the first air plugs are removed. The readings of the pressure gauge are checked (they should go down), and the water supply tap is turned on again. It would be good to repeat the procedure for lowering the air again.

Ultimately, the pressure should be above average, but not the maximum, because when the water heats up, the pressure will rise even more.

By the way, in order not to splatter furniture and walls when the air is released, you can hang a rag on the faucet, through which water will drain into a bucket.

Instructions for preparing for the launch

To gas, you must follow a simple instruction. The first start is made when the installation of equipment and piping is completed, the correct installation is checked. All fastenings, the location of the boiler must be made in accordance with fire safety regulations. A certain distance must be observed from the boiler to the wall. Which one, you need to look in the instructions for the boiler. For some models of gas boilers, this condition is not necessary. You need to make sure that there are no flammable objects and materials nearby. Do not place the boiler near windows, as its operation will be disrupted

Much attention should be paid to ensuring that the body is fastened evenly, there are no distortions.

After that, the equipment is connected to a cold water supply, while all plugs are removed from the nozzles, and a special filter with a ball valve is mounted at the inlet. This keeps the system free of contaminants that could cause damage. Ball valves must be installed on each branch pipe that is used for piping.

When solving the problem of how to start the boiler, great attention must be paid to the supply of gas pipes. In this case, it is not recommended to perform the work on your own, for this an employee of the relevant service is invited, who performs such a connection, sealing, and, if necessary, mounts a gas meter

What else needs to be connected before launch? It is necessary to conduct a separate power line for the boiler.The equipment is supplied with an electrical cable with a plug; during installation, it is necessary to ensure that there is an outlet near the boiler, it is better to separate it from others. Next, a connection is made to the chimney, checking its draft, performance. The pipe itself must go outside, the conditions for its installation depend on what type of chimney is chosen. The last part of the start-up preparation is that the boiler is disconnected from electricity so that it can be filled with cold water. Next, it checks for leaks, turning on the thermostat to the maximum value so that the mode switch automatically lights up.

How to remove air pockets

Simply connecting the system by filling it with water is not enough. It will not work or its efficiency will become extremely low. To carry out a full-fledged first start-up of the equipment, it is necessary to drain all the air that has accumulated in it from the system. A modern gas boiler may have a special system for automatically venting air when filling, but the efficiency of such systems is low. This means that manual venting of the main and other systems is required during connection. Only then can you start.

Removal of air locks during connection is carried out not only at the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with radiators. Especially for this, they are equipped with the so-called Mayevsky cranes, which you just need to open by substituting a basin under them. At first, a slight whistle will be heard - this is air gradually leaving the system. If the plugs are removed, then water begins to flow. If the batteries are freed from air masses, then the valves must be closed. Such a simple procedure is carried out with each radiator, it must be checked and cleaned of plugs. When air is removed from all radiators, the pressure gauge needle will be set to the desired value. Before turning on the gas boiler, it is necessary to add a coolant to the system, that is, feed it with liquid.

Next, you need to completely remove all air plugs from the circulation pump, which requires disassembly of some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, and then find a cylindrical part that has a cover in the middle of the body, it has a slot for a screwdriver. The boiler must be started, that is, turn on the power, set the heating regulator to the required operating position. After that, a weak hum will be heard - this will earn the circulation pump. You can hear gurgling, other sounds. Using a screwdriver, the cover in the found part must be slightly unscrewed, this should be done until water flows. As soon as the liquid begins to seep, the cap must be screwed back. This procedure needs to be carried out 2-3 times, after which the air pockets will completely leave the system, and the sounds and gurgling will disappear, the pump will start to work quietly. Immediately after this, the electric ignition of the equipment will work, the gas boiler will start its work on its own.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up, begins to enter normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. From properly performed preparation, start-up, adjustment of the system depends on how efficient the heating will be.

The first start-up of the heating system is a crucial moment, on which the serviceability of its elements, coherence and uninterrupted operation depend.

How to turn on a gas boiler, fill the radiators with coolant, bleed air, check everything and not forget anything.

Consider the procedure and rules for commissioning the heating system.

If the boiler is new and you do not want to lose the possibility of warranty service, you will have to invite service employees. They will make an appropriate note in the passport that the first launch was carried out in accordance with all the rules.

Before the boiler is turned on, it must become part of a single heating system.

All its elements, such as:

- pipes;

- radiators;

- pumps;

- filters;

- expansion tank;

- thermostats;

- security group;

Must be installed in accordance with the diagram. Once again, everything should be visually inspected and proceed to filling the system with coolant.

Where do we start

A household gas boiler is a powerful and productive device designed to heat the coolant and run the heated liquid through the heating system of the house. Modern boilers heat not only batteries, but also tap water in large volumes, have electronic control and various security mechanisms.

When buying a boiler, you should pay attention to the heating area, so that it is slightly larger than your living space.

Naturally, you have already installed the unit itself and completed all the necessary connections and piping of the heating system. We checked the chimney and draft, as well as the device itself for proper operation and the absence of leaks. This stage of work, as a rule, takes place in the presence of employees of the gas industry, who carefully record all the results and "give the go-ahead" to the use of this device.

Before starting the boiler itself, it is necessary to fill the heating system - pipes and batteries, with a coolant, that is, with water. To do this, unscrew the valve at the bottom of the boiler. For different models of boilers, the “appearance” of this supply valve may be different, but it cannot be confused with anything. In extreme cases, check the instructions for your device.

Having opened the valve, we will begin to supply water to pipes and batteries. Be sure to control the pressure level, we are waiting for a mark of 2 - 2.5 atm. This indicator can be measured using the pressure gauge built into the boiler.

When the desired pressure inside the system is reached, it is necessary to bleed the air that may remain inside the batteries and pipes. Air locks significantly worsen the heat dissipation of your battery, is this the result you achieve?

In order to quickly and efficiently bleed air, it is necessary to unscrew the Mayevsky taps on each battery. At first, you will hear a whistle or hiss - this is normal. If water starts to run from the radiator, it means that there is no air lock here.

When you check all the heating appliances - see what the boiler pressure gauge now shows. It is likely that the pressure will drop a little and you will need to feed the heating system with water.

But in addition to plugs in the pipes, the air inside the circulation pump can interfere with the normal operation of the boiler. This is easy to fix. Some models are equipped with an automatic air release system, but as a rule, this is not effective enough, so it is better to get rid of the air manually for the first time.

To do this, remove the front cover from the boiler body, then look for the pump itself - a cylindrical part with a plug for a flat screwdriver. Sometimes, the pump is located behind the dashboard, which is easily moved or removed from the gates. To release air from the pump, plug the boiler into the socket and start heating the water. The boiler will start up. The pump will also begin to turn on in the working process - this will be confirmed by incomprehensible gurgling sounds inside the unit - do not be alarmed, this is air. We take a flat screwdriver and slowly unscrew the plug. When water flows, we twist the plug back. This procedure should be carried out several times. When you stop hearing the gurgling of water inside the device, and your gas boiler starts working, it means that you managed to get rid of the air inside the pump completely. At this stage, you should again check the pressure gauge readings with the instructions for the device.In principle, you can stop there - now your boiler will heat water inside the radiators, and if it is a double-circuit unit, then in the water supply.

But it will not be superfluous to carry out pressure testing and flushing of the heating system. After these procedures, you will be 100% sure that the inside of the radiators is clean and your heating system has no leaks.

Varieties of gas boilers

These units are divided according to the type of installation:

The first type of gas boilers is more powerful, thus it can heat a large area of \u200b\u200bthe room. They also have a long service life, which was achieved due to the manufacture of heating elements from metals such as steel and cast iron. However, for installation and better operation, these gas boilers require a separate room.

As for wall-mounted units, they have smaller dimensions, respectively, and the weight is also less, which allows them to be mounted on walls. This type of boilers has less power, they also have a significantly reduced service life, and they are more demanding on cleaning the coolant element and the type of liquid being heated. The advantages of these devices include small size, which greatly simplifies installation without requiring a separate room, like floor-standing units.

Reasons for stopping work

1. Long idle time of the boiler. As a result, defrosting of the boiler may occur and it will become unusable. As a result - a sharp attenuation, the sounds of the wind blowing out the flame are heard from the combustion chamber.

Due to these factors, an alarm appears on the dashboard, indicating the need for urgent diagnostics of the device. Modern boilers are a rather complex and fully automated system. Therefore, if one of the sensors signals a problem, the unit stops working.

It is not necessary to immediately change the boiler or install a new chimney, it is very important to understand the problem and find a way to solve it

2. Chimney malfunction

If there are problems in the form of attenuation of the boiler, it is also important to check the serviceability and functioning of the chimney. The first reason may be the formation of ice on the walls of the chimney, which occurs through the deposition of hot steam, followed by the formation of condensate

After a certain period of time, the condensate freezes and becomes a thick layer of ice. After that, the draft decreases and the boiler dies out. The solution to this problem will be cleaning the chimney and its insulation in order to minimize the freezing of condensate.

Please note: backdraft is quite dangerous, as some old-style boilers have outdated automatics that do not turn off the boiler, and it continues to accumulate combustion products inside the room. 4

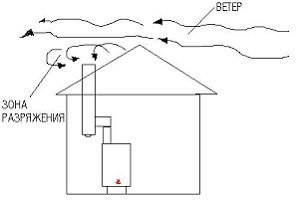

Insufficient chimney lift. If the height of the chimney is not enough to prevent air from entering the boiler with subsequent attenuation, a good solution for quick ignition would be to increase its length, at which the top of the chimney should extend beyond the roof ridge by about 50-60 cm

4. Insufficient chimney lift. If the height of the chimney is not enough to prevent air from entering the boiler with subsequent attenuation, a good solution for quick ignition is to increase its length, at which the top of the chimney should extend beyond the roof ridge by about 50-60 cm.

5. Burnout of the pipe. Insufficient draft is the result of a hole in the pipe into which wind enters, and therefore the chimney begins to function poorly. In this case, a complete replacement of the chimney is required.

6. Power surges.This reason does not depend on external factors in any way and arises as a result of a drop in the voltage level. When the proper voltage level is restored in many boilers, the flame ignites again, in this regard, many owners do not even notice this problem.

7.1 Gas meter malfunction. There are times when the boiler mechanism sticks, and it blocks the gas admission. To identify the source of a breakdown, it is necessary to check the operation of the counter mechanism, the readings of which should change.

7.2 The sealing of the fasteners is broken. A gas leak provokes a pressure drop, at which the system automatically operates and the gas apparatus goes out. You can identify this problem by the presence of a specific smell in the room.

Please note: you can self-diagnose and identify the problem using a regular sponge with soap suds - bubbles will appear at the leak points.

Features of filling the system with water

To turn on the heating system, you must first fill it with a coolant, i.e. water, which, after heating, will begin to circulate. A feature of modern equipment is that special manual make-up is not needed. During the first launch, you need to carefully check everything so that further work goes on smoothly and clearly. Not only a pump is built into the boiler body, but a special tap near the pipe for supplying cold water to the system. During the supply of cold water, noise is heard, this is quite normal, you should not panic here.

During filling, it is necessary to monitor the pressure in the system; for this, special sensors and pressure gauges are provided. Modern equipment necessarily has such additional elements, so you don’t need to buy them separately. As the gas boiler fills up, the mark on the sensor rises. When it reaches 1.5-2 atmospheres, it is necessary to stop the supply of cold water, i.e. filling is completed. The pressure parameter may be different, since it all depends on the equipment manufacturer, its requirements for the operating pressure in the system. But this is not the final filling yet, replenishment is necessary as the heating system is freed from air locks.

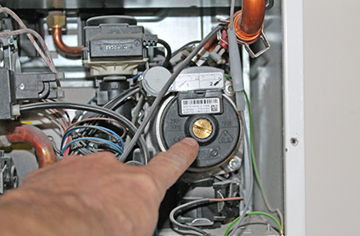

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will give a corresponding error).

To do this, remove the front panel of the housing, unscrew the central bolt on the pump and turn the shaft in the direction indicated by the arrow with a slotted screwdriver.

An air vent is installed above the pump. The bright cover must be pulled up and let the air escape.

Floor boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. — review of design options and models.

Conclusion

At first, the system may make gurgling sounds, all because it is impossible to bleed air to the last atom during start-up. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the normal range.

Temperature adjustment and other boiler settings are described in the instructions for each model.

Gas boiler design

The principle of their work is the same, they are divided only by design, there are several types:

- single-circuit - mainly used for heating small rooms and residential buildings;

- double-circuit - they are also capable of heating rooms, however, in addition to this, they can heat water for domestic or technical purposes.

As for the removal of waste products, gas boilers are equipped with special systems with:

- natural cleaning - in this case, gas boilers are directly connected to the chimneys, which are led to the top of the roof. Thus, by natural draft, combustion products are taken. Combustion air is taken from the room, but the chimney must be high, at least 500 mm from the ridge of the gas boiler. Otherwise, your boiler will blow out and go out.

- forced cleaning - gas heating units are connected to a coaxial chimney, this design is a "pipe in a pipe", both lead to a closed combustion chamber. Combustion products exit through one pipe, and air enters through the second, which supports combustion.

Let's move on to the circulation method. There are dependent and independent gas boilers. In the first case, there is an electric circulation pump in the system, which creates pressure. Also in such boilers there are many complex machines and sensors, thanks to which the process is regulated. The latter do not require an electrical connection, thus they get an advantage, and when you do not have light, you can still use a gas boiler.

How to set up the heating system after starting the boiler

To adjust the heating system, we need to carry out small manipulations with the control valves. The fact is that almost all schemes have one small drawback - the last batteries from the boiler, as a rule, do not have enough thermal energy. It simply does not reach there in the required volume, and we will need to eliminate this drawback by distributing the hot water supply evenly between all heating appliances.

This is not difficult - the control valves of the first two or three batteries need to be screwed a little. If you go from the boiler, then the tap of the first battery is twisted halfway, the second is a little less, and the third is even less. Here you have to experiment - to achieve uniform heating of all batteries, it may take several days. But it doesn’t matter anymore, because in general the heating system works fine, and the house is warm.

This is how, without making any effort, the first start-up of the boiler and the adjustment of the heating system are performed. As you can see, there is nothing complicated about this, and it is not worth the money that representatives of service centers charge for it. It is better to spend them on the purchase of an electronic temperature control system in the room - this programmer will reduce the energy consumption of a wall-mounted heating boiler!

You bought and installed a new heating appliance in your home and are now racking your brains how to turn on the gas boiler?

If you do not have the opportunity or desire to entrust this process to specialists, we will tell you in detail about all the stages and necessary actions so that this boiler heats your home productively and stably. Proper installation, care when connecting the boiler, as well as strict compliance with safety standards for using the device guarantee you a warm and comfortable home during the heating period.

What to do if the gas boiler does not start and how to fix it

If several attempts to start the boiler did not turn out to be successful, then there was not a banal failure. This indicates a malfunction of some node or sensor. Accordingly, in order for the system to start normally again, you must first eliminate the source of the problems.

Often a hint can be seen on an electronic scoreboard, if, of course, there is one. Here, a conditional code should be displayed indicating the cause of the failure. One point should be noted. Currently, a fairly wide selection of boilers is on the market, including well-known manufacturers such as Ariston, Beretta, Navien, Proterm. Bosch and so on. Moreover, each of them has its own error codes. The decryption can be found by studying the instruction manual.

The gas boiler does not start - the main reasons

Let's take a closer look at what might be causing the problem. All malfunctions that occur in a gas boiler can be conditionally divided into 4 groups. These are, in particular:

Each of these faults, in turn, can be caused by a number of reasons. For example, when the burner goes out, the draft should be checked first. If it is excessive or, conversely, insufficient, the burner will constantly fade. This problem is typical for boilers with an open combustion chamber and a natural exhaust system.

This design includes sensors that are triggered if the decay products are not drawn out well. The sensor sends a signal to the control unit, which, in turn, automatically shuts off the burner. With excessive draft, the flame is drawn out faster, which is why it goes out by itself. In this case, too, the burner shuts off automatically based on the signal received from the sensor. In some cases, the flame goes out if there are strong gusts of wind outside.

Another reason may be a malfunction of the corresponding sensor. Checking this is easy enough. Close the sensor terminals and try to light the boiler. If successful, then you need to change the faulty node. The burner will also go out as a result of depressurization of the gas system. In addition, instability in the operation of the power system or poor contact of the thermocouple can provoke a malfunction. After you fix these problems, the boiler will start up again.

If the boiler has been operating for a long time, but at the same time it does not heat the water to the required temperature, then the cause may well be air pockets formed in the system or a drop in pressure. Also, problems with the chimney can provoke this problem. Among the possible causes here is an insufficient amount of oxygen supplied. In addition, the water may not heat up because the pump or some of the automation elements have failed. Another possible reason is the insufficient power of the double-circuit boiler. It simply does not cope with its task if the heating is started and the hot water tap is open at the same time.