Features of the operation of heating systems equipped with a pump

Country houses equipped with a separate heating system can be unevenly heated due to the distributed thermal energy in all rooms. The smallest amount of heat will reach those rooms that are farthest from the boiler. To solve this problem, it is possible not only to stop at the creation of new heating systems with a pipeline with a large diameter, but also to tie the pump into the heating system. currently present.

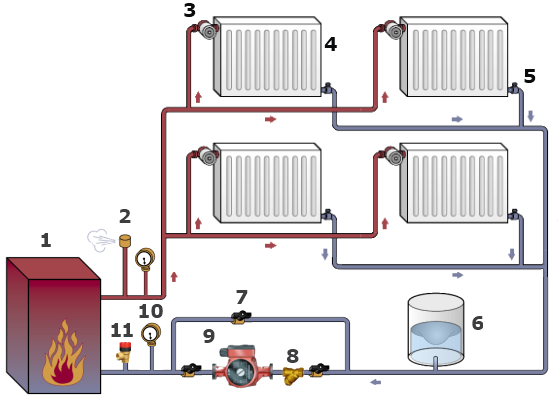

Typical scheme for installing a circulation pump: 1 - boiler, 2 - air vent, 3 - thermostatic valve, 4 - radiator, 5 - balancing valve; 6 - membrane tank, 7 - ball valve, 8 - filter, 9 - circulation pump, 10 - thermomanometer, 11 - safety valve.

Connecting a pump to a heating system is not as expensive as connecting a new pipeline.

At the same time, the dismantling procedure is applied to the old heating systems in this case, which cannot be an easy task. Installing a pump is much cheaper, especially since its installation can always be done by hand. The pump avoids the formation of air locks inside the pipes, ensuring its normal circulation through the pipeline. With the help of the pump, stabilization of temperature indicators in each room of the house is achieved. The device as a whole serves to optimize the operation of the heating system of any dwelling.

Scheme of the piping of the circulation pump.

The type of sealed throttleless pump for heating system is the most common because of their simple operation and convenient design. The body of this type of pump is made of cast iron. In this case, plastic or steel can be used as a material for such a part as a rotor. The process of operation of such devices is silent. In this case, it will not be necessary to replace the gaskets in the heating system, which will be filled not with a cooling element and lubricant, but with water. During the entire period of operation, the unit will be distinguished by high reliability. The main condition for this is the correct connection of the pump to the heating system.

What is a circulation pump and why is it needed

A circulation pump is a device that changes the speed of movement of a liquid medium without changing the pressure. In heating systems, it is placed for more efficient heating. In systems with forced circulation, it is an indispensable element, in gravitational systems it can be set if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the temperature outside, thus maintaining a stable temperature in the room.

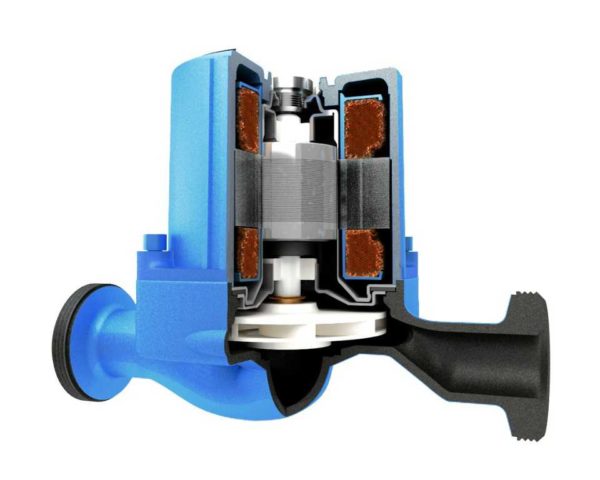

Sectional view of a wet rotor circulation pump

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but they are very noisy and require regular maintenance. Wet rotor units operate almost silently, with normal coolant quality, they can pump water without failures for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than enough to heat any private house.

Recommendations for the correct installation of the pump

In order for access for servicing the pump to be convenient, the unit must be properly connected. In practice, when installing the pump, the basic installation rules should be taken into account:

After installing the circulation pump, it must always be accessible so that in the event of a breakdown, it can be easily repaired or replaced.

- Both sides of the pump unit must be equipped with special ball valves, which are necessary when carrying out maintenance of the entire heating system or during the dismantling of the unit.

- It is necessary to equip the entire system with a filter in order to protect the device from the effects of small particles that lead to damage to the unit and its components.

- Since the water passing through the heating system is far from ideal, additional protection will be required for the normal operation of the pumps. Therefore, the heating bypass must be provided with a valve from above, which must be installed. You can choose any valve: automatic or manual. Its purpose is to release air pockets that form in pipes; its terminals must be directed clearly upwards.

- The wet type pump must be installed in a horizontal position so that it is completely submerged in water, and not just a separate part. Incorrect installation may cause damage to the working surface of the unit, and the installation will be meaningless.

- To increase the working potential of the structure, it is necessary to perform a special treatment of all fasteners and connections in the system with a sealing agent.

- It is necessary to follow the sequence in the process of connecting the pump and fasteners.

How the unit works

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant due to the capture of liquid from one side and forcing it into the pipeline from the other side

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant by capturing the liquid from one side and forcing it into the pipeline from the other side. All this happens due to the centrifugal force, which is formed during the rotation of the wheel with the blades. During the operation of the device, the pressure in the expansion tank does not change. If you want to increase the level of coolant in the heating system, install a booster pump. The circulation unit only helps to overcome the resistance force with water.

The installation scheme of the device looks like this:

- A circulation pump is installed on the pipeline with hot water coming from the heater.

- A check valve is mounted on the section of the pipeline between the pumping equipment and the heater.

- The pipeline between the bypass valve and the circulation pump is connected by a bypass to the return pipeline.

Such an installation scheme implies the release of the coolant from the device only if the unit is filled with water. In order to keep the liquid in the wheel for a long time, a receiver equipped with a check valve is built at the end of the pipeline.

Circulation pumps used for domestic purposes can develop a coolant speed of up to 2 m / s, and units used in the industrial field accelerate the coolant up to 8 m / s.

Worth knowing: any kind of circulation pump is powered by the mains. This is a fairly economical equipment, since the engine power for large industrial pumps is 0.3 kW, while for household appliances it is only 85 watts.

Principles of installation and connection of the pump

To prepare the heating system for pump installation, the heating fluid is first drained and the entire system is cleaned if it is contaminated. The system is filled with water only after the pipes are fixed, after which they are carefully checked for faults for their further elimination. Using the central screw, excess air is removed from the system.

In order for the installed pump to interact with the cooled coolant, and to extend its service life, the unit is mounted in the return line pipeline. When installing in a forced circulation system, the connection of the expansion tank should not be made to the main riser, but to the return pipeline.

Having placed the pump strictly horizontally, it is attached to the pipes. As an additional device, the circulation pump can be mounted in a natural circulation system. In this case, the pump must be equipped with a filter and a detachable thread. The filter diameter must match the pump diameter. The operation of the pressurized system must be supported by a conventional valve that matches the thread diameter of the unit. When using an open system, it is not required.

After the pump is mounted, a valve should be installed on the main and return pipelines. To allow air to be bled from the system, a special device is installed on the bypass.

Where it is planned to install the pump, a pipe is cut off and a special connection for shutoff valves is welded to it, it is installed before and after the pump unit. This must be done for ease of removal, cleaning and repair of the device. Having blocked the water with taps on the outlet and inlet pipes of the pump, the heating boiler is turned off, then the nuts are unscrewed, on which the pump is attached to the pipes.

It is necessary to connect the pump after starting the entire system and filling the pipes with water. Air should not remain in the pipes, so it is released every time before starting the pumping unit. To release air manually, use special valves installed on both sides of the pumping unit.

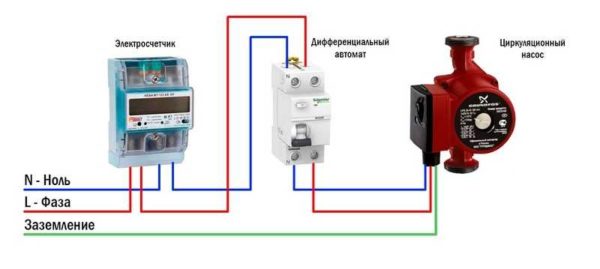

Power connection

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable. Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

The connection to the network itself can be arranged using a three-pin socket and plug. This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

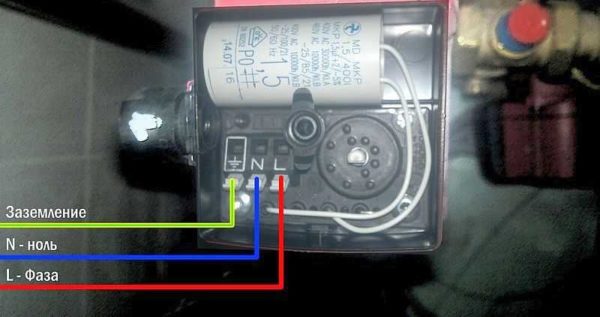

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors. They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

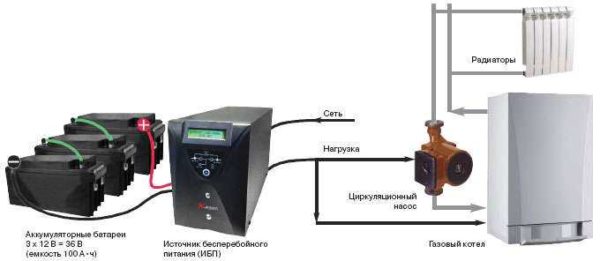

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

Hello. My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

What indicators to consider when choosing a pump

The correct choice of the pump is based on the hydraulic resistance index overcome by the device itself, in the process of creating the required pressure and force of the water flow. For an optimally selected pump, the recommended power should be lower than the calculated one by 10-15% of the calculated power indicator. If the required power level is exceeded, the device may have a shorter service life, which will lead to its rapid wear. It is possible to increase the noise level in the heating system. If the power of the unit is less, then under these conditions the required amount of coolant will not be provided.

Scheme of the device of the circulation pump.

The calculation of the pump power indicator is based on the diameter and length of the pipeline, the level of water temperature and the pressure of the coolant. Ten meters of the heating system must be provided with half a meter of pressure due to the pump. The flow rate of the coolant in the course of calculations is compared with the level of water flow used in the boiler, the power of which is known. You should have data for calculating how much water is needed for the normal operation of each of the rings of the heating system. Calculation of heat losses of a building can be made on the basis of tables of thermal conductivity of materials. The length of the heat pipeline, the number of heating radiators are also taken into account. The power of the battery is determined by the amount of water required per minute to ensure optimal heating of the room.

The circulation pump can be equipped with either electronic or manual speed control. If the speed of the pump shaft is set to the highest mark, then the maximum coefficient of operation of the device should be obtained.

Pump device

Since the motor stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material.

The main elements that make up the circulation pump are:

- housing made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- a wheel with blades or an impeller;

- engine.

As a rule, the impeller is a construction of two parallel disks, which are connected to each other by means of radially curved blades. One of the discs has a hole for fluid to flow through. The second disk fixes the impeller on the motor shaft. The coolant passing through the engine performs the functions of lubrication and coolant for the rotor shaft at the place where the impeller is fixed.

Since the motor stator is energized, it is separated from the rotor by a cup made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite sliding bearings.

Why do you need a pump in the heating system

Circulation pumps for heating private houses are designed to create a forced movement of the coolant in the water circuit. After the installation of the equipment, the natural circulation of the liquid in the system becomes impossible, the pumps will work continuously. For this reason, high demands are placed on circulation equipment regarding:

- performance.

- Noise isolation.

- Reliability.

- Long service life.

A circulation pump is needed for "water floors", as well as two- and one-pipe heating systems. In large buildings it is used for hot water systems.

As practice shows, if you install the station in any system with natural circulation of the coolant, the heating efficiency and uniform heating along the entire length of the water circuit increase.

The only disadvantage of such a solution is the dependence of the operation of pumping equipment on electricity, but the problem is usually solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private house is justified both when creating a new one and when modifying an existing heating system.

The principle of operation of the circulation pump

The operation of circulation pumps may differ slightly, depending on the type of construction, but the principle of operation remains the same. Manufacturers offer more than a hundred models of equipment, with various performance and control options. According to the characteristics of pumps, stations can be divided into several groups:

- According to the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used. The designs differ in the location of the impeller and moving mechanisms in the housing. So, in models with a dry rotor, only the flywheel, which creates pressure, comes into contact with the coolant fluid. "Dry" models have high performance, but have several drawbacks: a high level of noise is generated from the operation of the pump, regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely encased in a coolant medium that serves as a lubricant for the parts that bear the greatest load. The service life of the "wet" type water pump in the heating system is at least 7 years. There is no need for maintenance.

- By type of control - the traditional model of pumping equipment, most often installed in domestic premises of a small area, has a mechanical regulator with three fixed speeds. It is quite inconvenient to regulate the temperature in the house using a mechanical circulation pump. The modules are distinguished by high power consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. Automation independently analyzes the temperature indicators in the room, automatically changing the selected mode. At the same time, electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose a suitable model, it will be enough to know about the above nuances.

Which pumps are suitable for residential installations

Installation of a circulation pump.

The optimal temperature of the heating system of a country house is achieved using built-in thermal valves. If the set temperature parameters of the heating system are exceeded, this may lead to the fact that the valve will be closed, and the hydraulic resistance and pressure will increase.

Using pumps with an electronic control system helps to prevent noise, as the devices will automatically follow all changes in water volumes. The pumps will provide smooth adjustment of pressure drops.

To automate the operation of the pump, a model of an automatic type unit is used. This helps protect it from misuse.

The pumps used may differ according to the type of application. For example, dry ones do not come into contact with the coolant during operation. Wet pumps pump water when they are submerged. Dry types of pumps are noisy, and the installation scheme of the pump in the heating system is more suitable for enterprises rather than residential premises.

For country houses and cottages, pumps designed to work in water, having special bronze or brass cases, are suitable. The parts used in the housings are stainless, so the system will not be damaged by water. Thus, these structures are protected from moisture, high and low temperatures. Installation of such a design is possible on the return and supply pipelines. The whole system will require a certain approach in its maintenance.

In order to increase the degree of pressure attributable to the suction section, you can install the pump so that the expansion tank is nearby. The heating piping must be descending at the point where the unit is to be connected. It will be necessary to make sure that the pump can withstand strong pressures of hot water.

The need for a circulation pump

As mentioned above, there are two types of heating systems: convection, that is, with natural circulation of the coolant, usually this type is used in houses with an area not exceeding one hundred square meters, and a pressure pump, where a circulation pump is installed. The convection method of heating with a large area of \u200b\u200bthe house will not be able to ensure an even distribution of the coolant over all branches of the system, so it is likely that some radiators will not work efficiently. It's just that the coolant will reach them poorly or already with large heat losses, but simply cooled.

The pump creates the necessary pressure inside the system, which helps to distribute the coolant evenly throughout the circuit and drive it at a certain speed, which does not interfere with heat transfer through the radiators. Therefore, approaching the choice of a circulation pump, it is necessary to know exactly the parameters of the entire system, especially its hydraulic components.

What materials are needed to connect the restrictions when choosing a pump

The device of a heating system with water heating, operating on the basis of natural or forced circulation, will allow you to create the necessary level of heat in the room. This process will not depend on central heating. So that the circulation pump correctly moves the water in the forced heating system. it must be installed correctly. The installation of the pump structure does not require much space. According to the connection diagram, among the components of the heating system, along with the pump, there must be such parts and tools as:

Correct installation of the circulation pump.

- membrane tank.

- Mesh filter.

- Clutch connection.

- Control block.

- Signal system.

- Valves.

- System make-up line.

- Grounding.

- Circulation pump.

- Alarm and temperature sensors.

- Wrenches (19-36 mm).

- Check valve.

- Bypass.

- Stop valve.

- Plug.

- Electrical cord.

- Welding machine.

The forced circulation system allows you to hide the main pipeline deep into the wall.

In order to optimize the heating system, it is necessary to carefully consider how it will function using the installed pump. The correct selection of the device, that is, equipped with a detachable thread, will speed up the installation of the pump. This will allow you not to purchase connections separately. After carrying out the preparatory work, you should read the instructions for the purchased pump and the diagram of its device in order to confidently proceed with the installation yourself.

Connecting the circulation pump to the heating is a popular procedure necessary to create the required pressure during the operation of the entire system. In this case, it becomes possible to create structures, the principles of connection and operation of which are different.

The natural circulation system, unlike the forced one, will not make the return and main pipeline invisible, that is, hide it in the lower part of the wall. With a small height of the rooms, part of the window will be blocked by the injection pipe, so the appearance of the room will be disturbed.