Varieties of metal pipes for the heating system in the house

Self-assembly of a heating system made of metal pipes causes certain difficulties. They are produced in a certain footage, which is why it is difficult once when working with welding with your own hands. The most difficult thing is to work in narrow spaces, where you have to additionally use turn signals or bend a pipe. But the service life of metal pipes for heating is sufficient to not think about replacing it for one generation.

A large selection of metal pipes allows them to be used in various economic areas. These are water and gas pipelines, chimneys and heating systems, pipes for mounting frame structures and furniture. For heating in the private sector are used:

- solid-rolled metal pipes;

- welded straight-seam and spiral-seam;

- cold rolled and hot formed.

For arranging the heating system of a country house with your own hands, all these varieties, even welded pipes, are suitable, since they are less susceptible to water hammer during the seasonal start of the system.

Both welded and seamless steel pipes are suitable for heating systems

The welded pipe is checked by a flaw detector, which is able to detect the slightest deviations of both the inner and outer seams. Their cost is cheaper, but the guarantee of reliability and service life is similar to one-piece products.

Do-it-yourself installation of heating from metal pipes involves choosing the thickness of a product of different sections. As you know, the thicker the pipe, the more expensive they are, and the greater their weight (mass). But is the choice always justified in favor of thick iron pipes, which rust inside in the same way as thin ones? Seamless metal pipes of large thickness are recommended only for use in conditions of high internal pressure, as well as overloads from temperature differences.

In addition, heavy pipes give an additional load on the foundation, which is highly undesirable in a multi-storey building on floating soils.

Pipes for heating in a private house are offered in different types:

- standard (ordinary);

- thick (reinforced);

- thin-walled (lightweight).

Electric welding is used to connect steel pipes, and it is better to entrust such work during the installation of heating to a specialist

For heating from metal pipes, products of any shape can be used:

- round;

- rectangular;

- oval.

Installation of a heating system with metal pipes made of copper and steel is recommended to be entrusted to a specialist.

Service life of steel structures

WATER TREATMENT AND WATER-CHEMICAL REGIME OF THERMAL POWER INSTALLATIONS AND NETWORKS From the book Thermal Power Installations. Collection of normative documents of the author Team of authors 12. WATER TREATMENT AND WATER-CHEMICAL REGIME OF THERMAL POWER INSTALLATIONS AND NETWORKS 12.1.

Organize a water-chemical regime in order to ensure the reliable operation of thermal power plants, pipelines and other equipment without damage and loss of efficiency caused by SAFETY RULES FOR THE OPERATION OF HEAT-consuming INSTALLATIONS AND HEAT NETWORKS OF CONSUMERS From the book Thermal power plants. Collection of normative documents of the author Team of authors SAFETY RULES FOR OPERATION OF HEAT-USE INSTALLATIONS AND HEAT NETWORKS OF CONSUMERS AGREED BY THE Council of the Federation of Independent Trade Unions of Russia 06.05.1992

Info

Properties of steel pipes

The exact characteristics of steel water pipes depend on what type of steel it was made from. For example, non-galvanized water pipes are distinguished by their cheap construction and the wide distribution of this substance, but on the other hand, their service life is rather low.

Steel pipes coated with a galvanized layer do not have this disadvantage, however, they are much less suitable for repair and have several restrictions on the type of installation; they can only be assembled on a thread.

"Stainless steel" has almost no flaws. It is relatively inexpensive and easy to repair.

But here, too, there is a downside. It consists in the incredibly time-consuming process of installing stainless steel plumbing. This is due to a number of difficulties during welding of such pipes. Therefore, you will have to spend a lot of money on the services of a specialist welder.

The history of the emergence of metal-polymer pipes

One of the oldest materials for the manufacture of pipelines for various purposes is iron, and later its alloys (steels and cast irons), copper and other non-ferrous metals.

Copper plumbing began to gain particular popularity since the 1950s, first in the USA and Europe, then around the world.

Advantages of copper products:

- no risk of rust;

- better, in comparison with steel or cast iron, waterproofing of joints;

- less clogging of the internal volume.

Despite the obvious advantages, copper products have several significant disadvantages:

- for welding (soldering) pipes, special expensive equipment is required, which is not always available;

- high cost of copper: this material is more expensive than steel, aluminum, and all types of polymers.

Thus, although copper had excellent ductility and good workability, it was necessary to offer another, cheaper material.

They became aluminum. At first, immediately after the discovery, it is very expensive, but after a while, thanks to the development of mining, purification and processing technology, the price of the metal dropped significantly.

Among the disadvantages of aluminum, it should be noted:

- excessive softness: fine abrasive particles in any tap water inevitably spoiled the inner surface of the pipes, up to a breakthrough;

- a large difference in electrochemical potentials with copper and iron: upon contact with these metals or even with water, aluminum pipes begin to rapidly collapse, which ultimately reduces the benefits of using the metal to nothing.

However, a complete rejection of aluminum did not happen: with the discovery of a method for obtaining high-molecular compounds, that is, polymers, the idea arose to isolate the easily destructible metal with layers of plastic - both from the outside and from the inside. This is how multilayer metal-polymer pipes appeared.

The resulting products had a number of significant advantages compared to both steel and copper products:

- Much smoother inner surface. In this case, even small abrasive particles in water are not afraid: they only polish the plastic, giving it even greater smoothness.

- Due to the smooth surface, metal-polymer pipes for water supply have excellent throughput, exceeding similar parameters of metal products. In addition, the internal smoothness does not allow various kinds of contaminants to settle in the pipes, therefore, the internal clearance of such products practically does not decrease over time.

- Due to the dielectric properties, metal-plastic pipes do not collapse when in contact with metals and water and do not conduct current, that is, they do not require additional insulation.

- Minimal heat loss: plastic is worse than metals, it gives off thermal energy, therefore, heating circuits made of this material will save money.

- Ease of connecting pipes to each other. You can use various fittings (with split rings and union nuts) or solder (weld) polymer products.

Corrugated Stainless Pipe

How long will the corrugated stainless steel on the water supply?

According to one of the leading manufacturers, Lavita companies - indefinitely.Lavita expressly specifies an unlimited service life for its products.

What is the real service life of stainless steel in the water supply, it is not yet possible to say simply because of the limited time of its operation.

Destructive factors

The only thing that can cause damage to a stainless water pipe is a rough mechanical impact. Thin (only 0.3 mm) walls are easily crushed with a strong impact.

But you can not be afraid of the notorious water hammers and defrosting:

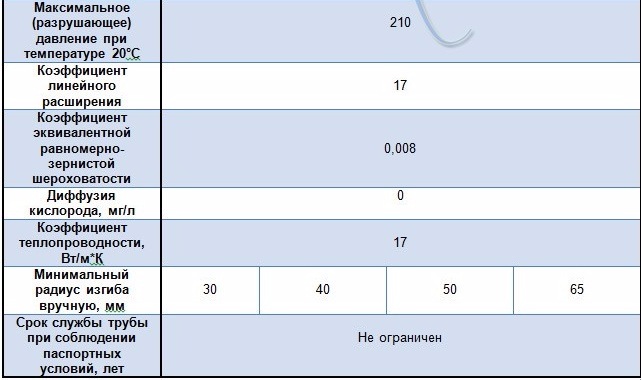

- The combination of tensile strength of 210 atmospheres (according to Lavita) in combination with the corrugation of the walls, which act as a damper, will allow the water supply to withstand any short-term pressure surge;

- When water freezes, corrugation will allow the pipe to lengthen and accommodate the volume of ice that has increased during crystallization without breaking.

Criteria for choosing metal pipes for heating

When building a house and laying a heating system with your own hands, the main question arises - which metal pipes are better? As you know, the metals used for communications are classified as:

- black;

- color;

- alloys.

The first category includes rolled steel, galvanized iron and cast iron. Non-ferrous metals do not rust, but oxidize, these are:

- bronze;

- copper;

- aluminum, etc.

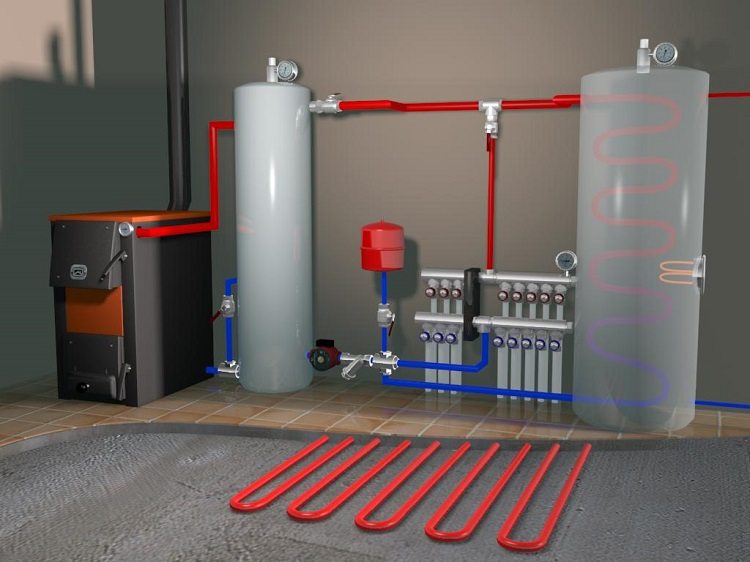

The type and layout of the heating system is one of the decisive factors when choosing pipes for the network

Main selection criteria:

- type of heating system (gravity or forced);

- maximum load (the conditions of the northern regions differ in the heating period of the southern latitudes);

- the possibility of replacing sections of the pipeline with the greatest load;

- installation method (hidden or closed, inside the walls);

- the general configuration of the system, including the number of storeys of a private house;

- design and maximum pressure inside;

- type of coolant;

- do-it-yourself transportation and installation possibilities;

- total length and budgetary framework for installation;

- maximum possible temperature in the system.

Performance requirements for a metal pipeline for heating

It is necessary to take into account the most important characteristics of steel pipes. This:

- weight of products;

- dimensions according to GOST and custom-made (TU);

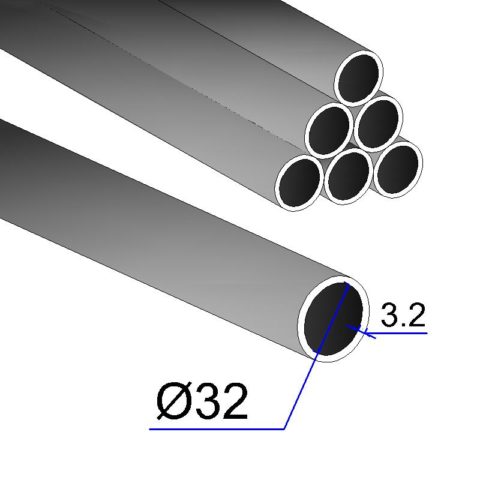

- outer and inner diameter (section of the conditional passage of the coolant and wall thickness);

- metal properties.

All parameters for this product are reflected in the legend. The length of the pipe is measured in meters, the diameter of the section and the walls of the pipe is in millimeters, the mass is in kilograms, the pressure is in Pascals, and the temperature is in Kelvin and Celsius. The parameters of pipe formation and welding type are indicated by a capital letter. The service life, measured in years, is rather arbitrary, depending on a number of factors indicated earlier.

One of the advantages of metal pipes is resistance to high pressure, which is present in any heating system.

Copper

The next metal on our list is copper.

Copper plumbing: stylish and durable

How long can these metal pipes for hot water supply last? There are no regulatory documents establishing specific service life. Manufacturers promise a vague "50+" years.

In practice though:

- The oldest copper plumbing has been in service for over a century and is still in perfect condition;

- Copper does not degrade over time, is not subject to corrosion and is only afraid of significant mechanical stress: the metal is very ductile, and the pipe walls are only about a millimeter thick.

Destructive factors

As they say in the hero city of Odessa, “there are still them”:

The service life of a copper water pipe may be reduced if, instead of soldering, press fittings with rubber o-rings are used during its installation. For 20-30 years, rubber loses its elasticity (primarily in hot water) and is capable of leaking;

Press fittings for copper pipes. The life of the plumbing is limited by the durability of the O-rings

Banal erosion can lead to the destruction of the walls of copper pipes. At a high flow rate, sand and other suspensions rapidly destroy soft metal;

The coarse filter at the entrance to the house is able to purify water from sand and suspensions

A water hammer and freezing of water in it can theoretically break a copper plumbing. However, the water hammer must be downright extreme (the breaking pressure for copper pipes is 200 - 240 atmospheres), and the defrosting must be repeated at least 5-6 times: the ductility of copper allows it to withstand a slight change in diameter or length without destruction.

Features of steel pipeline communications

Products for laying pipelines made of steel are able to withstand hydraulic loads without problems, so they do not affect their durability, which means that the service life of steel water supply pipes is not reduced.

This pipe product has good thermal conductivity, and a small value of the expansion coefficient due to temperature changes makes it possible to lay water pipes in the wall. Steel pipes, in addition, are great for arranging radiant types of water heating.

In addition to the advantages of metal communications made of steel, they also have disadvantages. So they have a significant weight, which causes inconvenience in the process of their operation. The laying of steel pipelines is impossible without the use of gas welding equipment, and this circumstance increases the cost of installation work.

In the event of water hammer, it reaches even 12 - 15 atmospheres. In such operating conditions, metal-plastic pipes are not able to withstand even a 15-minute operating regime. This is precisely the main advantage of engineering heating communications made of metal.

In multi-storey buildings in cities, steel pipes are laid either in the open, or placed in walls, which are then plastered. Provided that the pressure in the pipeline is about 6 - 7 atmospheres, and the temperature of the working medium reaches 90 degrees, only steel products can reliably serve.

Today, steel pipes have no competitors when creating water supply and heat supply systems in urban high-rise buildings, since they are characterized by mechanical strength and an insignificant coefficient of expansion.

But specialists are in no hurry to work with such pipe products, since the products are heavy, straight - the length can reach 12 meters and it is difficult to transport them. The most negative point is that gas welding is needed for the installation of steel pipelines.

Galvanized steel

Due to the anti-corrosion coating, galvanized steel should be more durable than black steel. How much?

We can find data about him in the same VSN 58-88:

Destructive factors

How and why can a galvanized metal pipe for water supply fail?

During his work as a plumber, the author observed the only scenario for the appearance of fistulas on a galvanized water pipe: they appeared on a welded joint. Strictly speaking, it is impossible to weld galvanized pipes from the word “absolutely”: in the area of \u200b\u200bthe seam, the zinc burns out completely. You see, it evaporates already at 900 degrees, and steel melts at 1400-1500.

As a result, the owner of a galvanized water pipe, mounted on welded joints, receives a line from a corrosion-resistant (albeit in some places) material, but at twice the price.

How to properly mount galvanizing with your own hands to ensure the maximum resource of the water supply?

Here is the instruction that plumbing equipment installers used in the 50-60s of the last century:

All connections are made only and exclusively on threads (cut by hand or on a screw-cutting lathe) using cast iron threaded fittings;

The joints are sealed with sanitary flax impregnated with minium lead winding.

Do galvanized pipes overgrow in water supply? Deposits and rust do not linger on their walls, however, the formation of a plug impervious to water is still possible under certain circumstances. It happens like this:

- Debris accumulates in the water supply (usually cold) - sand, scale from welding and rust flakes. A blockage is formed if the water supply taps always open only partially, and the speed of the water flow does not allow it to carry debris into the mixer and further into the sewer;

- Over time, the accumulation of debris is cemented with lime and iron oxides, gradually turning into a material with the strength of stone.

Real life

The author of the article must repent to the reader: he cannot name either the minimum or the maximum service life of galvanizing in water supply. The fact is that he has never met a galvanized pipe that needs to be replaced due to natural wear.

Liners and risers that were opened after 50-70 years of operation were invariably in perfect condition and did not differ from new ones in any way.

Some advantages of pipes that affect the service life

Steel pipes in the so-called "Stalinist" houses are operated in heating systems at a coolant temperature not exceeding 60 degrees. Heat supply structures that are equipped with cast-iron batteries can last more than 100 years, which is what happens in reality.

There is another advantage of steel - the lowest coefficient of thermal expansion compared to pipe products made from other materials. For example, for copper, this figure is 2 times higher, and for plastic - almost 20 times. Thus, plastic and other pipes, except steel, are not recommended to be hidden in the floor and walls due to the instability of their parameters, especially for heating structures.

Reducing or increasing products leads to the destruction of the integrity of the coating in which they are mounted. Therefore, when laying non-metallic communications, it is customary to use compensating materials - for example, soft thermal insulation. For the arrangement of radiant water heating systems, metal pipe products are best suited.

As for the shortcomings that affect the service life of metal heating pipes, experts consider the main ones to be:

- A high degree of susceptibility to corrosion processes and damage of a different nature.

- Rapid clogging of pipe products used in heating systems with deposits.

The best solution to eliminate the above problems is to use larger sections and use galvanizing technology. But the latter method has a significant drawback - antifreeze cannot be used in such a system.

A few more benefits

It is worth mentioning the life of steel pipes in Stalin-era houses, where they are used in the heating system at a temperature regime not exceeding 50-60 degrees. Heating systems that are equipped with cast iron radiators can easily last more than a century. Although they can’t even, they serve. There are cases when such heating systems were built at the end of the 19th century and functioned perfectly until the mid-80s of the 20th century.

It is worth noting another good property of steel. It is difficult to overestimate it - this is the lowest coefficient of thermal expansion among other pipes. So, for example, for copper it is 2 times more, and for plastic it is 15-20 times more. In simple terms, this is the stability of their sizes.

So, no other pipes can be hidden in walls or floors, as they increase or decrease in size when the temperature changes (this is especially important if heating is considered). And this already leads to a violation of the integrity of the coating in which they are embedded.

Therefore, when using non-metallic pipes, compensating structures are used, such as, for example, soft thermal insulation.

A steel pipe, like many metal pipes, is best suited for the construction of radiant (not to be confused with radiant) water heating systems.If we talk about the shortcomings, then the most important one can be recorded as a high level of corrosion, as well as damage of a different nature. All steel pipes used in heating rust very quickly and become clogged with various deposits. The best way to protect it is to use galvanizing technology and lay pipes of a larger diameter.

Perhaps the only and main drawback of using galvanizing is the impossibility of using antifreeze in this system, on which the operation depends, that is, the service time. If we consider it in more detail, then the zinc coating increases the resistance to corrosion, from which their service may deteriorate. This contributes to the fact that the term of "life" and service of metal structures is extended by about several years.

black steel

Steel rusts. Especially quickly it rusts with prolonged contact with water. That is why the resource of steel risers and liners laid down in the regulatory documents, frankly, is not striking in duration.

Standard service life

The main document establishing the normative service life of utilities in a residential building is VSN (departmental building codes) No. 58-88, adopted in 1988. They regulate the terms of maintenance, reconstruction and repair of buildings.

The document regulates the procedure for the repair and reconstruction of buildings

Annex No. 3 to the document contains the following figures:

| Engineering system element | Standard service life, years |

| Riser or cold water supply from gas pipes | 15 |

| A riser or hot water supply from gas pipes in a building with a closed heat supply system (without hot water extraction from the heating system) | 10 |

| The same, in a building with an open heating system (DHW is taken from the heating circuit) | 15 |

| Towel dryers in the DHW system | 15 |

Destructive factors

What factors limit the service life of VGP pipes without anti-corrosion coating:

| Image | Description |

|

Steel water risers. The first fistula that made the ceiling wet appeared in the ceiling |

Corrosion. Pipe rusting is accelerated by a broken outer layer of paint, frequent water supply shutdowns (in this case, the unpainted inner surface of the pipe is in contact with air with high humidity) and poor ventilation in the bathroom (read - consistently high humidity). The first fistulas appear on longitudinal welds (VGP pipes GOST 3262 - electric welded), on threads where the thickness of the pipe walls is minimal, and in ceilings where the surface of the pipes is not ventilated and (in the case of cold water risers) is continuously wetted by condensate falling on them. |

|

Lime deposits and rust have almost completely blocked the gap in the water pipe |

Overgrowing of pipes with deposits (primarily lime salts) and rust. The overgrowth rate is directly proportional to the hardness of the water in the region: where it erodes sedimentary rocks on the way to the consumer, the gap in the water supply decreases much faster. The narrowing of the clearance leads to a drop in water pressure on plumbing fixtures connected to the water supply. |

|

The diameter of the steel risers is selected, adjusted for a decrease in pipe throughput due to deposits |

Pipeline diameter. The larger the internal section of the pipe, the longer it maintains an acceptable throughput. |

|

The thicker the wall, the longer the pipe can resist corrosion. |

Wall thickness. According to GOST 3262, ordinary, reinforced and lightweight pipes are produced. It is clear that those reinforced before the appearance of the first through fistulas will last longer. |

Chemical flushing can transform old plumbing

Real life

In the memory of the author, the minimum period of trouble-free service of the steel cold water supply system in the new building was only 10 years.The house was built and rented shortly before the collapse of the Soviet Union, in conditions of austerity on building materials and the actual inoperability of Soviet norms and standards. Lightweight VGP pipes, purchased for reasons of economy, quickly and massively began to leak on welded joints and threads.

In the photo - a typical condition of the cold water riser after 20 years of service

The oldest engineering systems made of black steel have been serving for more than half a century.

In addition to the large thickness of the pipe walls, their longevity is facilitated by:

- Low humidity level;

- Lack of condensate on cold water pipes;

- Periodic painting of risers and eyeliners;

- Low content of mineral salts in water.