The best heaters

Next, we describe several popular wall and floor models of convector heaters.

We will pay special attention to their technical characteristics, advantages and disadvantages, which are taken from real consumer reviews.

wall

The Ballu BEC/EZER-1500 heater with two-level power control and a built-in display effectively heats a room up to 20m2. Such a device has an on timer, built-in overturn protection. If necessary, the manufacturer can include in the delivery set special wheels for operating the convector on the floor.

The main advantages of the Ballu BEC/EZER-1500 are silent operation, quick heating of the room, convenient operation, affordable price. Disadvantages: clicks of the regulator, tight buttons, the inability to warm the room above 20 degrees Celsius. There are defects: incorrect assembly of the heating element. The price of the model is 2500 rubles.

The wall convector heater Stiebel Eltron CNS 150 S was highly appreciated by consumers. This device is powered by a heating element with a power of 1.5 kW, its operation is controlled in manual mode. There is a thermostat on the moisture resistant case. The heater is equipped with protection against overheating and the influence of negative temperatures. Cost 6330 rubles

The main advantages of this convector include: silent operation, muffled clicks of the regulator relay, high speed of heating the room. No deficiencies found.

Another model of the wall-mounted convector Timberk TEC.E3 M 2000 is designed for heating rooms with an area of 24 m2. This device operates on a 220 volt power supply, there is a three-level power control by turning on several heating elements of 2, 1.15 and 0.85 watts. The convector has a moisture-proof housing, weighs 5.3 kilograms.

The advantages of the Timberk TEC.E3 M 2000 are an affordable price of 2912 rubles, low power consumption, the ability to quickly warm up the room, and silent operation. Disadvantages: short cable, poor build quality, the heater dries the air.

Heater Ballu BEP/EXT -1000 with three-level power regulation. This small-sized device has a weight of only 5.8 kilograms, there is protection against overheating and exposure to negative temperatures. The convector is designed for heating small rooms with an area of 15m2. The cost of the unit is 3300 rubles.

The main advantages of Ballu BEP / EXT -1000 are: remote control of the device, small dimensions, functionality, fast heating of the room. Some buyers point out one drawback of this model - the creation of low temperatures in the room.

pros

All models of the considered heaters, regardless of the type, can have different overall dimensions. Some of them are equipped with built-in sensors and many additional features. The main advantages of convectors are:

- Silent operation. This characteristic is associated with the absence of a fan in the device, which is buzzing;

- The ability to install the device on various surfaces (on the floor or wall, there are models that can even be installed on the windowsill);

- Beautiful design that will allow you to "fit" the installation into any interior;

- Low heating temperature of the case, on average 60 degrees, maximum parameters - 90 degrees;

- In overall models there are wheels for easy movement around the room, light appliances can be mounted on the wall;

- When heating the room with a convector, oxygen is not burned;

- Devices can be left unattended;

- Continuous operation. Many manufacturers give a 10-year product warranty.

Which is better oil or convector

We have already described the principle of operation, advantages and disadvantages of convectors, and now we will get acquainted with the main technical characteristics of an oil cooler. Such devices are most often used to heat air in a private house, in a country house or in a city apartment. To get started, you need to connect the device to a power source and set the desired temperature on the thermostat.

Such a heater consists of a metal housing made in the form of a radiator. Mineral oil is poured into the middle of the container, which heats up and transfers heat from the heating element. A rheostat is built into the device, which allows you to turn off the device when a certain temperature is reached.

The heater is equipped with protection against accidental overturning. In this case, the heating element is turned off.

The benefits of oil coolers include:

- Noiselessness;

- Low cost;

- The ability to move the device around the apartment, to warm up the desired room.

When choosing a radiator heater in a store, special attention is paid to the power of the device. In this case, 1 kW of electricity consumed is calculated for 10 m2 of usable space.

The range of power consumption is in the range from 1 to 2.5 kW. Some models have a turn-on timer, which allows you to warm up the premises at the right time.

And now let's get acquainted with the comparative characteristics of these two heaters:

- The first important nuance of choice is profitability. Here it is necessary to give preference to convectors, because they consume 25% less electricity;

- The second parameter is the warm-up time. When turned on, the convector immediately heats the air, its efficiency can exceed 95%. At the second device, the heating element is first heated, then the oil, the metal case and finally the air in the room;

- The next important characteristic is ease of operation (movement). Convectors have small overall dimensions, they can not only be placed on the floor, but also hung on the wall. Oil radiators are massive, their weight can reach up to 25 kilograms, they are unsuitable for wall mounting. The unit has wheels for more comfortable movement, and if you need to bring the unit to the 9th floor in a building with an inoperative elevator;

- Period of operation. According to the technical specifications, the convector can last at least 5 years, but in practice it turns out more. High-quality oil coolers also have a huge motor resource, but cheap Chinese models can crack in the metal, which leads to oil leaking from the body;

- And the last characteristic is the price of the device. Here the undisputed leader will be oil heaters.

Conclusion: When comparing these two heaters, it is recommended to give preference to convectors.

Device and principle of operation

To explain how this boiler works and how it works, you must first recall how conventional electric boilers work. In them, the coolant is heated by special tubular heating elements (heaters), which are in direct contact with the coolant. The temperature in the heating system also depends on the power of the heating element used.

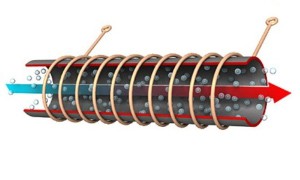

Inverter (induction) boilers work on a completely different principle, which is based on magnetic induction. Hence the completely different design of the apparatus. Let's look at it in more detail.

The main element of the device is a transformer (inverter, inductor), hence the very name of the heating boiler. The transformer has two coils (windings), each of which is responsible for its function.

- Primary, it is the boiler body itself, is short-circuited.

- The secondary is constantly energized. It is she who closes on the supply of electric current. This winding is called an inductor.

The boiler has two nozzles for the inlet and outlet of the coolant. When an energy carrier is supplied to the secondary coil, a magnetic field is formed, which exudes a sufficiently large amount of thermal energy. Water passing through a magnetic field heats up. This is a simple explanation of how an inverter heating boiler works.

Now about the device. Since the secondary winding can be located in different ways, then, accordingly, the design of the inverter boiler can be different. It all depends on which direction (horizontally or vertically) the turns of the coil will be located. For example, an ordinary metal pipe is taken as the basis of the heat exchanger, which is installed vertically with respect to the winding turns. That is, in order to heat this pipe, through which the coolant will move, it is only necessary to wrap it around the perimeter in the form of a coil from top to bottom or vice versa. In this case, the direction does not matter.

This design will be long in size, but narrow. In fact, you will get a pipe in a pipe, because the heat exchanger must be well insulated by enclosing it in a heater and an outer casing (usually metal). But it is possible to offer a completely different design, although in its purely constructive features it exactly repeats the previous one. A distinctive feature is the induction coil, which not only wraps around the heat exchange tube around the perimeter, but captures along its length. Each of its turns completely covers the length of the device. This is a more complex system, but we will not claim that it is more efficient. We just offer a few modifications for consideration.

Advantages and disadvantages

Let's start with the advantages, because by the very design of inverter boilers it becomes clear that they are, first of all, much more economical than traditional electric heating units. And this is probably their most important advantage. But there are other advantages:

- The complete absence of a heating element in the truest sense of the word. And, therefore, the service life of the device is significantly increased.

- Reducing the requirements for the quality characteristics of the coolant. Since the secondary induction coil does not come into direct contact with the coolant, it does not receive a negative impact from it.

- Low heating inertia. This allows you to increase the efficiency even in heating systems where a circulation pump is installed.

- It is possible to make a homemade inverter (induction) boiler. More on this below.

And a few negative points.

- Say what you like, but inverter-type electric boilers are more expensive than conventional heating elements.

- If you decide to install an inverter-type heating boiler for heating a country house with a large area, you will have to choose an induction boiler that is huge in size and weight. Because the number of turns in its secondary coil must be large. This is the only way to heat a large volume of coolant in the system.

- In addition, it is very difficult to regulate the power of the device and the temperature of the coolant in this model, so these boilers are equipped with a complex automation system.

A few words about homemade inverter (induction) heating boilers. There are a huge number of different designs that are publicly available on the Internet today. Craftsmen from different materials according to different drawings make them and advertise them as the cheapest and most reliable units.Let's just say that some of them are really noteworthy, with guaranteed quality and high safety rates. But the bulk of the structures are untested, without guarantees, devices that are scary to use in the heating system of a private house.

Do not forget that water is most often used as a heat carrier in heating systems. Illiterate assembly of the device can lead to a short circuit. It's good if the coil just burns out without harming people. Therefore, we recommend that if you are not specialists, then you should not create another headache for yourself. It is better to buy a ready-made factory version. This is both high quality and a guarantee of long-term operation and safety.

How does it work

Note! The principle of operation of the described device is based on the phenomenon of convection. From the course of physics, we know that cold air is heavier than warm air, it is located in the lower part of the room, heated air masses gradually rise up

Due to such movements, the entire air space in the room is heated.

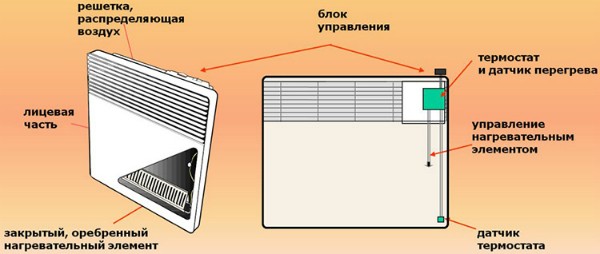

The convector works according to a simple algorithm. At the bottom of this device is a heating element (it is also called a heat exchanger). To increase the volume of air passing through, this part is made in the form of a radiator with several flat fins. The angle of their inclination regulates the direction of heated air flows. The heat exchanger closes a protective metal casing.

According to the energy carrier used, all convectors can be divided into the following types:

- Electrical appliances;

- Gas convectors;

- Water.

At the top, as well as at the bottom of the convector body, there are several holes for sucking in cold air and transporting heated air. Structurally, it is done in such a way that the body of our device does not have direct contact with the heat sink, so the casing does not heat up and does not transfer heat. A similar transfer of heat resources occurs in water and oil radiators.

In everyday life, the electric type of convectors is mainly used. Water devices have lower efficiency indicators, they differ from analogues in significant overall dimensions, therefore they are installed in the places of installation of traditional water radiators in niches under windows. Gas equipment, despite the possibility of saving energy resources, for some reason is not popular among consumers.