Long burning versions

The specifics of these modifications are as follows:

- Positions of convective channels. They allow optimal accumulation of heat from the furnace section. Cold air is inside the case, passing through special outlets at the bottom of the device. Air masses are rapidly warming up. And warm air fills the room after 2-5 minutes from the start of kindling.

- Heating adjacent rooms. Air-heating wood-burning modifications of long burning can be used as a heating base for the whole house. With prolonged combustion, heating of a building with an area of \u200b\u200bnot more than 350 - 400 sq.m. is enough. Connection of air ducts is possible due to the design of the housing. Pipes are bred throughout the building. Each pipe ends up in every room that needs heating.

A compartment has been introduced into the body of some modifications, where you can keep the required amount of firewood. With it, the stove can work for several days.

Heat resistant sealants

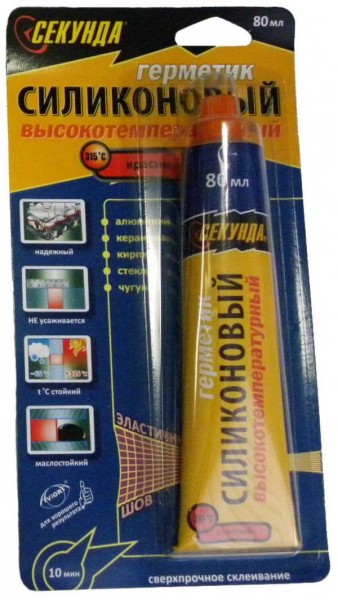

This group is made on the basis of silicones. The temperature regime may vary depending on the specific composition. For example, iron oxide is added to silicone to increase heat resistance. These sealants tolerate temperatures well up to 250 o C, with short-term increases to 315 o C. Iron oxide colors the paste reddish brown. Using such a sealant for a brick stove or fireplace, you will not spoil the appearance - it is practically invisible. You can use it to seal the joints of heating pipes. But here the view is not the best.

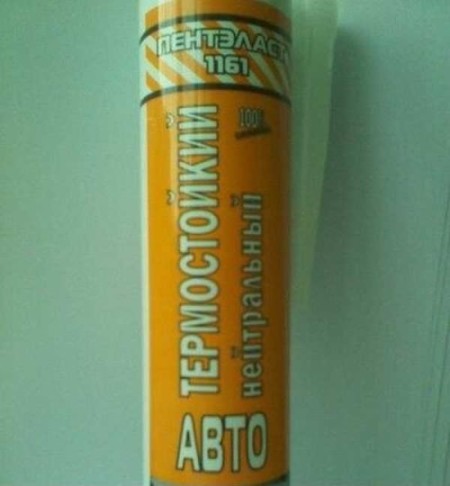

The exact temperature data is indicated on the packaging. Check it before use.

Heat-resistant sealant in a tube for a gun

Depending on the composition, silicone sealants are acidic or neutral. Acidic, when hardened, release acetic acid. Therefore, such compositions cannot be used with metals, concretes, and cements that are not resistant to corrosion. Due to the reaction between the sealant and the material, a layer of salt or oxides is formed, which violate the tightness. Such a seam does not fulfill its functions: it passes both water and air. Neutral silicone sealants are compatible with concretes, metals and cements, which release water and alcohols when dry. After their evaporation, the seam becomes airtight.

- Resistance to ultraviolet radiation. Therefore, they can also be used outdoors, for example, for sealing a roof passage.

- Waterproof. This property allows them to be used as a sealant for a chimney - to seal cracks and seams in places where the roof passes and where roofing materials fit, to seal threaded connections during heating installation.

- Good adhesion with materials of different structure. Can be used for brick, concrete, metal, ceramics, glass, wood, plastic.

- After drying, the composition retains a certain degree of plasticity: it does not crack with minor deformations and vibrations. Therefore, silicone sealants are used not only (or not so much) for sealing cracks in furnaces, but for repairing systems in cars. But plasticity also has a negative side: paint does not adhere to silicone. It just cracks and peels off.

Heat resistant sealants are red or reddish brown.

Polymerization goes from the surface inward and requires the presence of air (or rather, moisture from it). Therefore, it is impossible to make seams of greater depth than recommended: inside the silicone may simply not harden. Such a seam will be unreliable and may pass smoke / moisture.

In order for adhesion to materials to be good, it is necessary to prepare the surface before applying the sealant. To do this, remove all salts, oxides, dust. Clean surfaces to clean material.Then washed with water and degreased. Silicone sealants should not be applied to wet surfaces. After cleaning, wait for the surface to dry completely and only then apply a layer of paste.

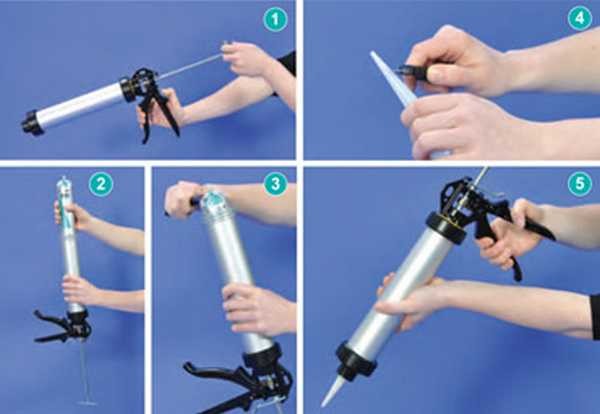

This is how sealant is applied from a tube with a gun

Silicone adheres well to smooth surfaces, but to improve adhesion, it is advisable to treat them with sandpaper or sandblasting or other abrasive materials. The surface is then re-rinsed, degreased, dried, and then applied sealant.

Silicone high temperature sealants are either red or red-brown in color. There are no transparent silicone sealants for stoves and fireplaces.

Technology and methods of using sealant for heating systems

The use of sealant for interior or exterior applications requires prior preparation. The composition corresponding to the type of system is selected. The consumption of liquid sealant for a home heating system is calculated based on the volume of water. For every 60-80 liters, 1 liter of sealant is needed.

It is also necessary to prepare the system itself. All air is removed from it, filters are dismantled, all taps are opened. A pump is installed on the first radiator, with the help of which the remaining air is removed and the pipe warms up to 50-60 degrees.

Outdoor treatment

Measures for sealing joints and threaded connections are carried out in a certain order.

- There is a damaged area.

- All liquid is drained from the system.

- The damaged area is cleaned of dust, old sealant (if any at the joint), degreased.

- Sealant is applied, in accordance with the instructions.

Internal processing

For internal work, a liquid sealant is used for the heating system. After preparation with air release and dismantling of filters, hot water is drained from all radiators in the volume required by the recipe. To do this, stock up on a container of the appropriate size.

Liquid sealant to eliminate leaks in the heating system is diluted with water. At the same time, a couple of liters of coolant is left in its pure form for subsequent flushing. The Mayevsky crane is removed from the radiator, and a pump is connected instead. With its help, the system is filled with liquid with a sealant diluted in it. The pressure increases to 1.5 atmospheres. In this position, the system should work for about 6-8 hours until the entire composition hardens.

After that, the coolant is drained again, but first you need to make sure that all the problems are fixed. Water without sealant is poured into the heating system, drained and poured again. Thus, the radiator is flushed from the remnants of the material.

After 3-4 days, the presence of cracks and leakage is checked again. If necessary, the sealing process is carried out again.

It should be remembered that a similar option for eliminating holes in the heating system of a private house only works if the water leakage does not exceed 30 liters per day. In the event of an increase in this indicator, a major overhaul is required with a complete replacement of the pipeline section. If you are not a master, then for these purposes it is better to contact a specialist, otherwise the problem can only get worse.

Working with sealant will not cause difficulties if you perform all the manipulations in accordance with the instructions.

During the operation of heating equipment, it periodically becomes necessary to repair a crack or gap that has appeared. Especially often, owners of brick stoves and fireplaces face such a problem: these devices have such specifics. They crack due to different thermal expansion of the constituent parts. In this case, the slots can be through and go into the furnace or into the smoke channel. In this case, soot on the wall and increased fuel consumption are far from all the harm: combustion products enter the room, and they can cause poisoning.

Chimney problems are less common (if you put in a quality sandwich or ceramics), but no less dangerous. For normal draft, the chimney must be airtight. The degree of fire safety depends on this. And that's why. Soot often accumulates on the walls of the chimney. If it is not removed in time, it will flare up if there is air access. The temperature will be very high - 1500 o C and above. If there is insufficient thermal insulation around the hot pipe, the ceiling or roof may catch fire. What will happen next - you understand.

A leaky chimney is one of the reasons that causes the flame of a gas burner to go out. This is a fairly common problem with gas boilers. Agree that in winter, when the winds are unpredictable, checking the boiler several times a day and lighting it is not at all a joy. All such cracks are easier to seal with sealants. This is usually a ready-to-use substance that resembles a paste in consistency.

High temperature sealants are available in a wide range

Heat resistant silicone pastes

The maximum temperature limit of 250-300°C allows the use of such compositions in exterior decoration, restoration of the outer layer of the portal, in joining sandwich pipes and when processing them at the points of passage through the ceiling. Silicone acts as the main substance here. Depending on the impurities, the maximum temperature for which the paste is designed may have different indicators.

In their diversity, heat-resistant sealants are divided into acid-containing and neutral. In the furnace business, neutral pastes are used, since the acid released during the solidification of the substance has a sharp unpleasant odor. Crystallization of neutral sealants is accompanied only by the release of water or alcohol. In addition, acid has a detrimental effect on sealed seams.

In order to resolve the issue of the applicability of silicone sealant, its main properties should be highlighted.

- The composition in finished form is not subjected to destruction by the UVI. This allows you to use this type not only indoors, but also on the streets.

- It adheres well to various types of surfaces. The only condition is their preliminary preparation (dust removal, wetting).

- Waterproof properties make this type of sealant an indispensable option when sealing the place where the chimney pipe exits through the roof.

- The plasticity of the finished substance will not allow destruction during thermodynamic changes. Sealant is excellent as an adhesive element when facing fireplaces.

- Possibility of application in mechanized devices.

In order for the heat-resistant sealant to perform its functions with high quality, it is necessary to wait until the paste has completely solidified before kindling the fireplace. This may take up to several days. The manufacturer provides detailed information.

Design features

Multi-fuel units have several fireboxes for different types of fuel. Usually coal or firewood is loaded into one, the other is designed for liquid or gaseous fuels: gas or diesel fuel. Several furnaces for different fuels are good because several separate independent circuits can be connected to them and the temperature in them can be different. For example, one serves batteries, the second - a warm floor. It is possible to separate by floor or according to some other principle

If you like this idea - when buying, pay attention to the fact that each firebox has a separate heat exchanger, which is not available in all boilers

If we talk about the developments of recent years, then almost all modern models have built-in heating elements. It turns out that such equipment makes it possible to work on any currently available energy source.

Another interesting novelty: burners have been developed that can use gas or diesel fuel with equal success (in any case, so the manufacturers say). With such a spray unit, there is no need even for two burners or chambers. The type of fuel used is changed by moving the switch to one of the positions.

For more economical and efficient heating of large areas and reducing the cost of heating, it is desirable to use heat accumulators. This is especially advisable with the regular use of firewood and coal as one of the fuels. This is due to the peculiarity of multi-fuel boilers: when using solid fuel, the boiler power is not regulated and sometimes it becomes too hot in the room. In the presence of a heat accumulator, the excess heat is removed there and “conserved” there, and if there is a lack of thermal energy, hot water from the heat accumulator is supplied to the system or goes to the hot water supply. Such a system allows you to heat the boiler much less often (how often depends on many factors, the boiler power, heat loss at home, weather, fuel calorific value, etc.).

Types of sealants and materials

The main component of sealants is polymers. In this case, different polymers are used and give different characteristics to the main composition. They are packaged in tubes of different sizes and configurations. Some resemble tubes of toothpaste and squeeze out the same way. There are tubes for mounting gun. In this case, the spout is cut off on the cone of the lid, the tube is installed in the device, squeezing out the required amount using the trigger lever.

Heat resistant sealant in a tube

There are two-component compositions that need to be mixed before work. They are more often used by professionals because of the stringent requirements: when mixing, it is required to measure parts with high accuracy (the permissible error is only 0.5-1 gram). In addition, if even a small part of one component accidentally gets into another, a reaction occurs, and the suitability of the mixture is only a few hours. In general, ready-made paste sealants are easier to use.

For chimneys and stoves, special high-temperature compounds are used. High temperature sealants come in two categories:

- Heat resistant. They are used for places that heat up to 350 ° C. Their area of \u200b\u200buse is the outer surfaces of stoves and fireplaces - gaps between masonry bricks (but not between stove casting and masonry), sealing joints of brick chimneys, sandwiches and roofs (but not simple metal chimneys ), parts of the heating and hot water system, etc.

- Heat resistant or heat resistant. Withstand very high temperatures - up to 1500 o C. Scope: if we talk about stoves and fireplaces - junctions of casting and masonry, in boilers - in combustion chambers or furnaces, in chimneys - joints and seams, including immediately after the weekend chimney pipe. These compounds can be used in places of direct contact with the flame, but then there must be one more characteristic: fire-resistant or fire-resistant.

Depending on the temperature and the required characteristics, one of these sealants is used. So the oven sealant, depending on the area of application, can be either heat-resistant silicone or heat-resistant silicate. To understand what is the difference between them, what they are, how to use them, consider the properties and characteristics.

Sealant grades

For the most part, manufacturers in the names of the compositions reflect their main purpose. For example, they write "Sealant for furnaces" and then the name. In the group of furnace sealants, the following brands performed well:

- Penosil. This company produces Penosil +1500 heat-resistant oven sealant in black. It withstands temperatures up to 1500 o C. A film forms on the surface in 15 minutes. There is an assortment of heat-resistant motor sealant. The composition has a red color, suitable for temperatures up to 300 o C.It is an acidic silicone sealant and should not be used on metals, concrete or cement.

Penosil - sealant for furnaces

Soudal Calofer High Temperature Sealant

Heat resistant sealant in tube Tytan

Versions with water circuit

They have a water heat exchanger. These versions allow you to heat the entire house. They successfully combine decorative qualities and thermal efficiency. The structure is equipped with panoramic glass. Through it, you can monitor the working flame. The liquid heat carrier circulating in the heat exchanger is heated. This action is the basis of heating. These versions can be connected to radiators. For this, they have special taps on their body. Through them, the supply and return of the pipeline is arranged.

Such models can be mounted in any heating technology: isolated, open, with normal and at least with forced draft of the heat carrier.

Prism or cylinder

Depending on the required heat output, the hot oil boiler can have either a cylindrical or a prismatic combustion chamber. In both cases, the tube sheets are made of seamless hot-worked standard steel tubes. In the first case, the recommended range of used capacities is 100–5000 kW of thermal power, divided (depending on the manufacturer) into 10–15 standard sizes.

- built-in blast air heater (up to a power of 12 MW);

- completely oil-cooled surface of the combustion chamber with a reduced (on average less than 400 kW/m3) heat load with highly efficient combustion;

- hatches and manholes of large sizes, providing full access for inspection and maintenance (cleaning) of all heating surfaces, both from the inside and outside;

- tube sheet forming a screen with a large heat exchange area and a heat density of less than 26 kW/m2, which, if necessary, is completely emptied. Its manifolds provide hydraulic balancing of the system. The pipes are shielded from radiant heat;

- gas-tight stainless steel inner lining, which gives corrosion resistance against the temporary presence of condensate (during the first start-up or after a long idle time of the boiler);

Prismatic design boilers can operate both on traditional fuel (gas, diesel fuel) with the installation of appropriate burners, and on fuel oil. When using a special furnace, non-traditional, low-calorie fuels such as wood waste, agricultural waste and other biomass can also be used.

Boilers of electrode type

The principle of operation, which is incorporated in electric heating boilers, is different than in heating elements. Here, electrodes serve as actuating elements. Immersed in water, they ionize it, splitting the molecules into charged particles with opposite signs. Molecules acquire energy as they move towards the electrodes. The water heats up with a simultaneous increase in pressure.

Electric boilers of the electrode type are remarkable for the following qualities:

- their heating has a high speed;

- they do not need a circulation pump;

- no scale;

- very compact.

The negative point of the installation is the overheating of water as a result of a possible decrease in the level of its circulation, as well as the expense of funds for the replacement of electrodes that are subject to severe wear from ionization.

Heating elements boilers

The main working element here can be a straight or U-shaped metal tube with a quartz insulator. A nichrome wire runs through the center of the tube, heated by electricity. She transfers heat through the sand and the tube to the water.

Electric boilers are controlled by microprocessor automation. Adjustment is carried out in a smooth or step mode. The unit provides circulation of the coolant with the help of a pump. All this has a positive effect on consumer demand. But there are also disadvantages. These include the following:

- short service life of heating elements prone to burn out;

- scale formation on the surface of the heating element tube, as a result of which heat transfer is difficult;

- additional costs for installing filters that reduce water hardness.

Types of sealants for heating systems

Different manufacturers offer a large selection of sealants that differ in their chemical composition and purpose. They are conditionally divided into the following groups:

- silicone;

- polyurethane;

- liquid polymers.

Each of them has its own purpose and properties.

Silicone sealants

Silicone is the most popular. With it, you can close any joints and eliminate leakage. Withstands temperature fluctuations ranging from 30 to 60 degrees. The composition has all the necessary qualities to perform quality work:

- strength;

- penetrates into the most inaccessible places;

- elastic.

When buying, pay attention to the composition of silicone sealant. Acid found in some types can cause metal corrosion

General purpose silicone sealant

General purpose silicone sealant

Polyurethane

They belong to the group of oligomers. In addition to polyurethane compounds, there are also polysulfide ones. Both types are widely used in construction. To seal heating systems, carefully study the composition, since not all materials are suitable for these purposes.

A distinctive feature of polyurethane sealants is durability, resistance to aggressive environments and mechanical stress. In addition, material consumption is very economical.

Polyurethane sealants are one- and two-component. The former are cheaper, but freeze longer. They have good elasticity, adhesion to metal, resistance to high temperatures and corrosion. However, despite the many positive qualities, polyurethane sealants are not as popular for domestic purposes as silicone sealants because of their high price.

Single component polyurethane sealant

Liquid sealant for heating system

Liquid type sealants are used where there is no free access to the leak or it is simply not visible. The principle of operation of the polymeric liquid material is based on the fact that it is poured into the system together with the coolant. In the section of the pipeline where there is a leak, the composition, interacting with air, begins to polymerize. Thus, thickening, it seals the cracks.

There are the following types of liquid sealants:

- for systems installed in water;

- for heating systems running on antifreeze;

- to troubleshoot metal surfaces;

- for plastic pipes.

Such a variety allows you to choose a sealant for individual needs, so carefully study the instructions before buying.

How to choose a sealant to fix leaks in the heating system

Heating systems differ from other communications by changing the operating temperature and possible deformations. To eliminate leaks in CO, certain compositions are needed that can withstand such operating conditions. The most popular are silicone paste sealants of such types as:

- drying - after complete drying, the material shrinks, therefore, if the drying technology is not followed, cracks and smudges may appear;

- non-drying - serves to eliminate small leaks and seal threaded connections. Their disadvantage is that under excessive pressure, the sealant can be squeezed out of the joints.

Silicone and thiokol sealants are suitable for sealing threaded connections, since after hardening they do not deform and do not clog the thread.

Acrylic compositions are suitable for household radiators. They are resistant to temperature changes, mechanical stress and aggressive environments. Getting into a crack or joint where there is no air, the sealant quickly thickens, forming a plastic mass. This facilitates the installation process, but dismantling in the future will be difficult.

In addition to the above-described sealants, there are special compounds that work at ultra-high temperatures. For example, in fireplaces, chimneys or stoves.

The manufacturer must necessarily indicate for which particular case this or that type of sealing material is used.

Finnish combined heating boilers

A fairly large market share is occupied by Finnish boilers. This is due to several reasons. Firstly, their climate is close to ours, so we should expect that their power will be sufficient in our conditions. Secondly, most campaigns have been working for a long time, and, therefore, they have gained experience and have a certain potential. Well, and thirdly, their quality is at the level.

Jäspi Group is one of the Finnish companies operating in this sector of heating equipment. Their boilers have a good reputation and all are equipped with heating elements. In the basic configuration of the boilers, there is one heating element for - 6 kW. Under the order can supply 2 or 3 pieces.

In the Jäspi VPK line, you can use wood, pellets, diesel fuel, gas. Jäspi Tupla has a high efficiency, copper coil, runs on diesel/gas and solid fuels. In this line, the fireboxes are autonomous, only the combustion products exit into one pipe, therefore the smoke channels are combined in front of the chimney fitting. Work on gas or diesel fuel is characterized by high efficiency. With the correct setting of the burner, the fuel is burned almost completely, so cleaning this combustion chamber is only required once a year. When using firewood, their size depends on the modification: in Tupla 1 S - 35cm, in Tupla 2 S - 50cm.

Jäspi Triplex boilers are a model with reduced emissions of harmful substances into the atmosphere, equipped with new ceramic grates. It is also possible to use firewood 35 and 50cm. For modifications with a length of 50 cm firewood, top combustion can be realized.

The Jäspi Biotriplex line uses the latest developments: the transition from pellets to firewood and vice versa does not require changing equipment. The two furnaces are independent of each other.

Versions of fireplaces

All Finnish stoves - brick fireplaces have similar characteristics and design features:

- The Finnish-style heat exchanger is made of either stainless steel or high-strength cast iron. Fireplace cast iron versions have excellent thermal performance, strong reliability and long working life. Steel versions are slightly inferior to them, but they have a modest weight and reasonable prices.

- Fuel. Mostly firewood, some versions work on fuel briquettes. It is forbidden to use as a fuel: coal, peat, waste from woodworking enterprises.

- Operating principle. The classic versions use the traditional method to burn wood. Recently, Finnish companies have begun to receive versions - fireplaces for the home with long burning. And after spending one load of firewood, you can ensure the work is not within 6 hours (the previous figure), but up to several days. Therefore, often such models become the main sources of heat in the building.

- How to install a Finnish stove. Manufacturers supply such devices with a casing that develops their heat dissipation. Finnish cladding: stone, steel, ceramic panels. Particular demand is noted for the corner version.

Main types

Methods for dividing adhesive pastes into groups are quite diverse. Some types of classifications may not be useful in selecting a substance for a particular job. Let us dwell in detail only on the fundamental types, and initially consider a few more divisions.

- Classification by type of packaging. Sealants are sold in soft tubes, which are convenient to apply in case of small surface areas. For the application of the substance does not require additional devices. We have long been familiar with the method of application, since toothpaste is produced in such tubes. An alternative is a rigid tube, which is adapted for a special pistol.With the help of such a device it is convenient to apply sealant, filling the gaps with it.

- Classification by the number of components. The basic principle of action of sealants is the intermolecular interaction of a substance and a surface. In order for the connection to be stable, it is necessary to wait for the solidification of the substance. Some manufacturers use auxiliary polymers to speed up this process. When they are mixed, a paste is formed, which has adhesion properties. But the technology for preparing such a mixture requires very precise proportions. The high rate of hardening forces repair work to be carried out at an accelerated pace. Therefore, such two-component sealants are more often used by craftsmen with sufficient experience. The one-component type of glue dries longer, but it is completely ready for use and allows, if necessary, to dismantle the glued surfaces in order to correct the mistakes made.

- Separation by maximum exposure temperature. Allocate heat-resistant sealant for fireplaces and stoves and heat-resistant. But, in addition to these parameters, both types of sealants have distinctive properties that allow them to be used in different types of work.

Models on pellets

Independent heating of houses is possible with the help of modifications that work on pellets. Moreover, the heating process is like full automation. Pellets are compressed fuel from woodworking industry waste. The specifics of this technique:

- Fuel is supplied automatically.

- When burning pellets, more heat is generated than when burning wood.

- There are versions focused on heating air and liquid heat carrier.

Pellet versions work on a stand-alone method. Automatic devices with microprocessors regulate their work.

Carefully selected proportion of air supply and laying pellets in the furnace section. When burning pellets, a tiny fraction of underburning remains in a wood-burning stove.

Options for heat dissipation by room:

- Through air ducts. They are connected to special channels of such models.

- through heating radiators.

Work on the autonomous principle of heating installations lasts 6-8 hours. When the technology of fuel supply and storage is updated, this period develops dozens of times.

Results

As with all building materials, sealants also need to be understood. High-temperature sealants are a very narrow and specific segment, but even here there are many nuances, ignorance of which can lead to errors and insufficient tightness of products.

The choice of building materials for installation and repair work with brick fireplaces is severely limited by such parameters as heat resistance, adhesion, and environmental safety. The need for the use of such substances arises even at the stage of construction of fireplaces or stoves. The difficulty lies not only in the high temperature of the working unit, but also in the difference in thermal expansion coefficients for different elements.

For example, the exterior of a fireplace portal is often tiled. Due to the fact that it has a rigid bond with brick and the difference in the ability to expand with increasing temperature, soon after the start of operation of the fireplace, damage appears in the exterior. For normal operation, an elastic adhesive is required, which would not only hold the elements of the tile, but would not collapse itself when the fireplace insert was heated.

Today, using fireplace sealant, such problems can be dealt with without professional knowledge. This material is diverse in some parameters, and, consequently, in the scope

Therefore, it is important to understand what types of sealant are divided into, which are commercially available from different manufacturers.

Results

All these advantages justify the high demand for Finnish products. Although it has a serious disadvantage - huge prices for the Russian consumer.But they completely justify the cost of them in a few years. The user receives powerful, high-quality and safe equipment that even a child can heat.

The climatic company "Termomir" offers a wide range of heating boilers of various types and countries of production - Russia, Germany, Italy, the Czech Republic, etc. Read the information or call our consultants to select the right boiler model.

A heating boiler is a device that, by means of the combustion of fuel (or electricity), heats the coolant for water heating of premises through a system of batteries and radiators. Boilers are designed for space heating from 30 sq. m and up to several thousand. Household low-power heating boilers are used for heating and hot water supply of private and country houses, cottages, cottages, garages, workshops, cafes and restaurants, schools and other educational and children's institutions, as well as swimming pools, baths and saunas. In addition, they are used for individual apartment heating. Production and industrial boilers are designed for heating workshops, warehouses, hangars, enterprises, and other large buildings and premises. For objects of a very large area in the heating system, it is allowed to combine boilers into a cascade of two or more devices. Small and simple heating boilers can be placed in the basement, in the attic, in the garage, even in the kitchen and bathroom. The installation of high capacity floor standing boilers is recommended in a separate boiler room. Some models of boilers have an outdoor (street) installation.

Modern boilers of a new generation are equipped with programmable control units with various automatic settings and functions (for example, a weather-compensated control system), as well as devices for remote control of the boiler - a GSM module (controlling the operation of the device via SMS messages).

The selection of heating boilers is carried out according to the main parameters: the required heating area and boiler power, type of energy carrier, number of heating circuits, type of combustion chamber, type of burner, type of installation, steel or cast iron heat exchanger, etc.

To determine the power of a heating boiler for heating a house or apartment, a simple formula is used - 1 kW of boiler power for heating 10 m 2 of a well-insulated room with a ceiling height of up to 3 m. Accordingly, if heating of a basement, a glazed winter garden, rooms with non-standard ceilings and etc. boiler power must be increased. It is also recommended to increase the power (about 20-50%) when providing a boiler and hot water supply (especially if heating of water in the pool is necessary). Our consultants will help you calculate the exact power of the boiler according to the heating area.

Comparison of heating boilers by type of fuel:

"Economy class"

- inexpensive and simple boilers, the service life is shorter than that of boilers of a higher category. Some manufacturers have budget models of boilers, for example,