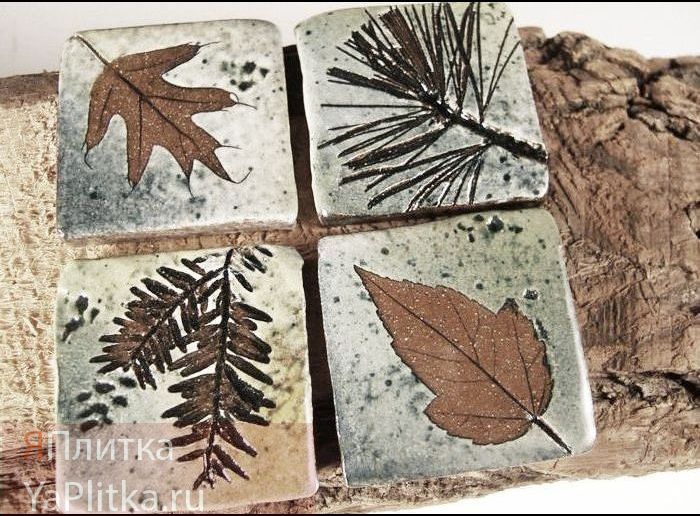

Printing with ceramic paints with firing

The most expensive method of printing on ceramic tiles. It involves a long and technically complex process of obtaining an image. First, a palette of the necessary ceramic paints is carefully selected and applied to the surface of the tile. Then a special powder is sprayed onto the resulting image and the ceramics are placed in an oven for sintering paints and glazes. The result is a tile with a wear-resistant surface and an attractive texture.

|

|

|

Hot Decal Printing

Decal ? special paper with an image printed on it. But unlike the previous method, it does not copy the picture onto the surface of the tile, but itself acts as a decor carrier.

During printing, the decal is applied to the tile and covered with a special varnish. Then the semi-finished product is loaded into a kiln for firing at high temperatures.

This method is characterized by high stability of the image, its excellent aesthetic properties. Among the shortcomings, it is worth noting that the production process is quite long, and the price of the resulting product is high.

Necessary equipment

To perform high-quality printing on ceramic tiles, the equipment must be selected correctly.

To transfer an image by sublimation, you will need the following equipment:

- an inkjet printer with a continuous ink supply system;

- sublimation ink;

- polymer composition for pre-treatment of tiles;

- matte photo paper;

- tablet thermopress;

- thermoscotch.

Printing a photo on a ceramic tile in a decal way requires the purchase of the following devices and items:

- jet printer;

- decal varnish;

- decal paper;

- kiln for roasting.

- To transfer an image with subsequent sintering, you need:

- inkjet printer for working with tiles;

- ceramic paints;

- powder glaze;

- bake.

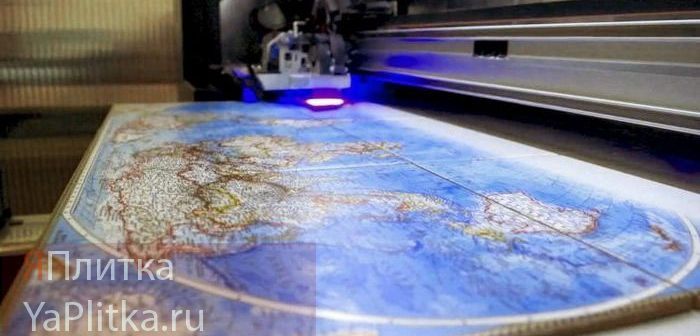

Printing on UV printers does not require additional equipment

But among such devices, it is important to choose the right one.

There are several types of ultraviolet-based devices:

- hybrid;

- roll;

- tablet;

- combined.

|

|

|

Ceramic 3d tiles are not created only on roll printers, as they are adapted for flexible thin materials.

Hybrid devices work by moving blanks into the ink supply area within a fixed table.

UV flatbed printer ? the most suitable device for tiles. It guarantees the accuracy of the result obtained due to the reliable fixation of the material to the working surface of the device.Printing is carried out due to the movement of the table or the ink supply elements.

The combo printer works with solid and roll stock, but is more at risk of breakage due to complex design and task overload.

Photo printing features

The times when the design was applied exclusively to tiles with Rotocolor are already gone thanks to the introduction of innovative digital printing technology. This method consists in transferring any photograph or drawing from an electronic file to the surface of the workpiece. The result is a 3D ceramic tile, you can choose absolutely any photo for transfer, which opens up almost limitless possibilities for designers.

An excellent appearance is provided not only by images of landscapes, elements, favorite characters or stylish interiors, but also by photographs of various textures in 3D format: ceramic tiles with the effect of leather, a rare mineral, textiles and much more. An original option would also be laying tiles on the floor with a photo of coastal pebbles, emerald grass, the seabed, or an extreme approach? the open mouth of a bloodthirsty shark, a gaping abyss, the mouth of a volcano.

UV printing

A ceramic tile UV printer produces an image using an inkjet method, during which a special nanoink is sprayed onto the surface of the tile. They allow you to create high-resolution prints due to the reduced droplet size supplied from the nozzle of the device. Such inks are adapted for a UV printer and contain substances that harden under the influence of the rays emitted by it. This feature prevents the ink from drying within the printer.

Printing on UV printers has the following advantages:

- high resistance to the influence of such negative environmental factors as fat, water, chemicals and mechanical stress;

- practicality in use (paints do not require dilution, quickly harden under ultraviolet rays);

- environmental friendliness;

- high quality and detail printing;

- saturation and realism of the color palette;

- the brightness of the resulting image due to the application of paints on top of the glaze;

- the possibility of large-format printing, which allows you to create photo panels on ceramic tiles.

The safe use of the device requires the observance of certain precautions:

- protection of the skin in direct contact with ink;

- installation of special filters that reduce ozone emission.

Production methods

The quality and durability of the image depends on the production technology.

To date, there are three methods for transferring an image to a base.

sublimation method

The essence of the method is as follows. A high-quality image is applied to a special film - the workpiece.

Then it is pressed with a press to the ceramic base.

Through sharp high temperatures (180-250⁰С), the ink from the film is fixed on its surface.

The durability of the image is determined by the quality of the production technology.

With all the rules, it can last for many years. Products obtained in this way are not recommended for use in conditions of high humidity (in swimming pools, bathrooms) and for outdoor decoration (not resistant to fading).

Decal method

A blank image in the form of gummed paper (decal) is printed on a ceramic printer. Lacquered and then dried. Then the decal is immersed in water and thus the pattern is transferred to the base. It is dried and then fired at a temperature of 750-900⁰С.

The glaze melts, and the paint penetrates deeply into it.After solidification, the image is securely fixed. Products obtained by this method can last more than 50 years. They do not fade, resistant to mechanical and chemical stress.

They can even be used as flooring.

This is the most expensive and time-consuming way to create photo tiles.

UV printing

This technology is fully automated. It allows you to use UV ink to apply an image to any solid surface.

To do this, you only need a special machine with UV lamps. As a result, the paint only covers the product with a thin crust. Therefore, it must be protected with specialized varnishes. You should not expect high technical characteristics from it.

The finished product is not recommended for use in wet areas and outdoors.

The choice of photo tiles today is very large. Carefully study the manufacturer, the manufacturing method, select the design.

Which one to choose is up to you!

sublimation method

Sublimated photo printing is carried out as follows:

- The desired image is applied to special paper using a printer filled with sublimation inks.

- The resulting photo is applied as an image to the tile and fixed.

- The tile with the picture is placed under the heat press for 1-3 minutes.

- The product is water cooled.

To obtain a clear and bright pattern, it is necessary to strictly observe the time the tile is under the hot press. Does this interval have a fixed value? it depends on the thickness of the workpiece. After its expiration, the product should be immediately immersed in cold water, thereby stopping the process of ink penetration. In any case, it is better to remove the tile a little earlier than the due time and, in case of an insufficiently bright image, continue the procedure. Overexposure of the tile in the apparatus threatens with the spreading of the contour and the manifestation of yellow spots.

You can find out the time indicator from special tables.

The image obtained by this method is characterized by excellent quality and brightness of colors. All the smallest details and halftones are transferred from the picture clearly and look very realistic. The durability of the print on the tile surface is very high and is only detrimental to harsh abrasive cleaners or harsh chemicals.

Where to use

The areas of application of tiles with photo printing cover almost all types of premises. Volumetric ceramic tiles are an excellent solution in a small room. It visually adds space and saves it at the same time. A tile with digital printing allows you to relieve the atmosphere from unnecessary decor items, since it is an independent and rather spectacular decoration.

In the kitchen of tiles, you can lay out a photo panel in the area of \u200b\u200bthe apron. In the bathroom ? water landscapes on the walls and floor of the room. An office or living room will be decorated with a realistic image of a fireplace. In the bedroom, on the wall opposite the head of the bed, an alluring and enchanting landscape will perform a relaxing function.

What is a photo tile

The peculiarity of this material lies in the uniqueness of the design. The pattern can be selected from the manufacturer's catalog, or created according to personal sketches. This makes it possible to receive designs that are not similar to anyone else.

A photographic tile is a classic ceramic tile, on the surface of which a pattern is applied in a special way. It is beautiful, strong, moisture resistant and durable. Therefore, it can be used for both interior and exterior decoration. It is able to advantageously highlight individual elements of the interior.

Large panels look especially expressive. Photo tiles are used to decorate bathrooms, kitchen aprons, living rooms, halls, swimming pools, as well as to decorate the walls of restaurants, sports complexes, hotels, etc.

In addition to all the positive qualities, there are also disadvantages:

- The cost per 1 square meter of such a product is more than 2 times the classic version.

- The size cannot exceed A3 format (45×30 cm).

- A low indicator of the technical characteristics of many models (it all depends on the method of production).

Installation of the finished product is no different from a standard tile. For convenience and ease of use, the manufacturer often applies special markings.

Mankind has come a long way since the advent of silkscreen printing in the tile production process.

Mankind has come a long way since the advent of silkscreen printing in the tile production process. but with the advent of the printing press, tile production has become limitless in its possibilities

but with the advent of the printing press, tile production has become limitless in its possibilities 3D ceramic tile can replace a primitive flat surface, but the complexity of printing on it limits offers, although it looks stunning in monochrome

3D ceramic tile can replace a primitive flat surface, but the complexity of printing on it limits offers, although it looks stunning in monochrome As soon as 3D ceramic tiles are 3D printed by manufacturers, it will be possible to create amazing colors and surface patterns that will win the hearts of consumers and architects.

As soon as 3D ceramic tiles are 3D printed by manufacturers, it will be possible to create amazing colors and surface patterns that will win the hearts of consumers and architects.