How to disassemble a water heater

Before proceeding with the disassembly of the water heater, it is necessary:

- shut off the water supply, then drain the remaining water from the heat exchanger by opening a hot tap;

- shut off the gas supply;

- disconnect the pipe from the chimney;

- disconnect the device from the power supply.

Now you can carefully disconnect the column from the communications. For disassembly, the device can be completely removed from the wall, or you can remove only the body and the problem node.

If disassembling the gas column is only needed to flush the circuit, then the procedure is carried out in three stages:

- Removing the handles located on the front of the device. They are easily removed by simply pulling them towards you or prying them with a screwdriver.

- Removing the case - the panel is fixed with screws. Their position differs depending on the model. The screws can be on the top, bottom, or back. They are found and removed. After that, the panel is removed. In some cases, the body is additionally secured with hooks. Then you have to pull the panel a little so that it comes out of the hinges.

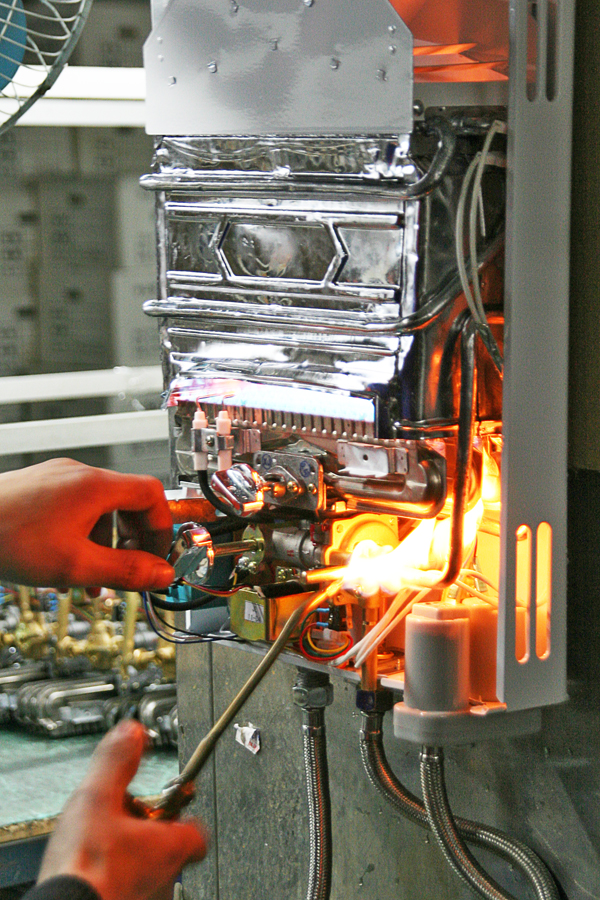

- Dismantling the heat exchanger - usually it is attached to the pipes, gas burner and hood with screws. They should be unscrewed and the element carefully removed without touching the wires and contacts.

To carry out all the manipulations, you only need a screwdriver. When taking out the screws, you need to collect them in one small jar or box so as not to lose. After dismantling, you can start flushing the heat exchanger.

…

Necessary documentation for accounting of a geyser

Before installing the geyser, you should prepare a package of documents:

- an act on the technical condition of the existing chimney (a special service is involved in drawing up such acts);

- a technical passport for a new gas water heater or the name of the model you are going to buy (it is required to submit it to GorGaz to draw up a project);

- project for the installation of new equipment;

- application of the owner of the apartment for the installation of new gas equipment;

- job application.

The replacement itself can be carried out both by professional craftsmen and by oneself with the necessary experience and skills.

What should be remembered when replacing a column?

When installing gas equipment, remember that there are special rules governing the work. Installation of a geyser is possible in such cases:

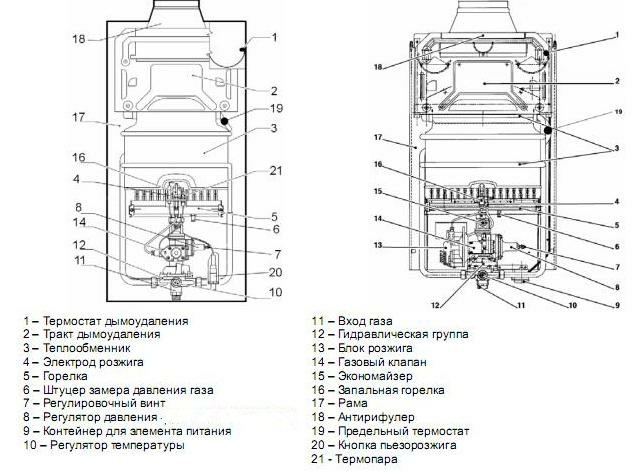

Scheme of the internal structure of the gas column.

- the volume of the room where the equipment will stand should be from 7.5 cubic meters;

- ventilation must be available (window with opening sashes, window leaf, etc.);

- ceiling height should be at least 2 meters;

- a chimney is required, the diameter of which should be from 120 mm. It is provided for by the general project in those houses where the installation of such equipment is allowed;

- the pressure in the connected water supply should not be less than one tenth of an atmosphere;

- speakers for apartments can only be placed in the kitchen, their placement in the bathrooms is prohibited;

- gas equipment must not be placed above the stove and at a distance closer than 10 cm. The wall on which the column is hung must be made of non-combustible materials.

How to remove scale without removing the radiator

To perform this procedure, it is enough to remove the front panel of the water heater and disconnect the heat exchanger pipes from the water unit. Do not ignore the second step and do not flush the coil with the "frog"! You do not know how the detergent will affect the membrane and other parts of the water valve, so it is better not to take risks so as not to repair the unit later.

There are 3 ways to flush the heat exchanger internally:

- Connect the hoses to the pipes of the heat exchanger and pour the cleaner manually through the funnel.

- Remove the geyser from the wall, turn it upside down and put it on the floor. Periodically pour a solution of citric acid into the coil and wash out the scale with water through the hoses.

- Make a booster from a circulation pump for heating - a device for pumping liquid through a heat exchanger. The scheme is simple: a pump, connecting hoses and an open container with detergent.

The burner and the gas column chamber will have to be cleaned with a brush with a long soft pile. Use a household vacuum cleaner to remove dust.

The structure of the stove gas valve

Gas valve (fig. 1) Let's start with the valve body 6, which is rigidly screwed to the gas pipeline of the stove with a clamping bracket. At the bottom of the tap there is a hole 4 that brings gas to the stove burner. There is a small nipple in the faucet opening that connects the pipe and the faucet. For gas combustion, air and gas are mixed (injection) in certain proportions in the Venturi tube. Also in the gas valve, equipped with an idle speed adjusting screw.

Inside the tap there is a bronze plug 5 of a conical shape, which, when turned, regulates the gas supply to the stove thermostat, and then to the burner. In order for our plug to be reliable, fixed in the valve body, a clamping spring is installed, which abuts against the plug, preventing it from popping out from the gas pressure. The housing cover has a groove that guides the cork during rotation.

Faucet not working? We diagnose by phone, so the cost of this service for you is

We will take money for the call in the amount of 500 rubles in case of refusal to repair, and this service costs

The cost of the repair work performed without the cost of the required spare parts in our company varies

Before leaving, our employees will issue a guarantee from our company for the work done for a period of

Sources of danger

There are actually only two of them.

The fact is that independent work related to the opening of the gas pipeline will inevitably lead to a gas leak.

- At a certain concentration of natural gas or propane-butane mixture in the air, it will become unbreathable.

- Long before this, the gas-air mixture will become explosive. The slightest spark when turning on an electrical appliance, triggering any relay (for example, a convector thermostat) or clicking a light switch will lead to exactly the consequences that we tried to warn the reader from in the first section of the article.

The rules to avoid negative consequences are pretty obvious.

- All work is carried out with the windows wide open in the entire apartment or house. Yes, regardless of the season. Do not be afraid that your favorite cactus will freeze: if everything goes well, forced ventilation will last no more than 10 minutes.

- The room must be completely de-energized. What the instruction is connected with is, I think, clear from the previous explanation. Take it seriously: as already mentioned, the cost of a mistake can be the highest.

Getting Started

Tools

What should be prepared before opening the gas pipeline?

- We have already mentioned a pair of gas keys. It is a couple - because in most apartments of the old stock, the connection to the stove is made with rigid pipes; to unscrew the locknut and coupling, you need to hold the squeegee in a stationary position, preventing it from turning the valve.

- To seal threads on gas, FUM tape or a synthetic thread with Tangit Unilok sealant can be used. Linen with paint is also suitable, but the paint is applied to the thread and winding for a relatively long time, and in our case the count will go for seconds.

- When repairing a faucet, a special graphite lubricant for gas valves or ordinary grease can be used. The graphite base is more practical: it retains its properties longer.

- In addition, when repairing the valve, you will need a 1/2-inch female plug and a flathead screwdriver.

revision

So, what to do if the gas tap smells of gas and its replacement is not included in your plans?

- We close the valve by turning its handle perpendicular to the pipe.

- We fix the drive after the valve with one of the gas keys and further hold it in a fixed position.

- With the second key, we drive the locknut and coupling onto the long thread of the drive.

- We partially turn off the valve with a key - until the moment when it starts to rotate by hand.

- We completely unscrew the valve and immediately put a plug on the thread. Do not be afraid that excess pressure will interfere with you: it is only 3 - 5% higher than atmospheric pressure.

- We wind the thread under the plug and twist it by hand to the end.

- We unscrew the valve from the drive.

- We unscrew the plug with a slot for a screwdriver on the back of the valve and take out the spring hidden under it; then we push the conical plug out of the body.

- We clean the body and plug from the remnants of the old grease and apply a new one in a thick layer.

- We assemble the valve in the reverse order.

- We put it instead of the plug, not forgetting to replace the thread winding.

- We screw in the drive and, having rewound the threads, we drive the coupling and locknut into the working position.

Replacement

What to do if the gas tap in the kitchen is leaking and you want to replace it with a new one?

If the new valve is the same length as the old one, the steps are completely the same as those described above - with the difference that, for obvious reasons, manipulations with the plug are made unnecessary.

How to change the gas valve in the apartment if its length does not match the length of the old one?

- The drive with the coupling and the lock nut is thrown out.

- The short thread after the drive is supplied with a short extension with internal and external threads. It will allow the flare nut to press the gasket against the flat and wide edge of the extension, and not against the serrated end of the pipe.

A special case

How to change the tap on a gas cylinder if it cannot be turned off with an ordinary key? Heat the valve with a building hair dryer - and its expansion will make the effort required to unscrew it quite feasible.

Areas of responsibility

The first and main thing that the reader should pay attention to is that the inlet valve in the apartment falls under the responsibility of GorGaz or a similar organization operating in your area of residence. Both the repair and replacement of valves, and their periodic revision, and the connection of gas equipment (stoves, boilers, convectors, hobs) should be handled by a locksmith of this organization

- Do you have a lot of experience in plumbing? in particular, you happened to change valves and valve boxes under pressure;

- you know where your apartment is de-energized, and you have access to the switchboard and the machines in it;

- the gas pipe in front of your valve has no visible signs of corrosion;

- you have locksmith tools at your disposal (at least two gas wrenches No. 1 and / or No. 2), sealing material for threads and grease or graphite grease -

The following text will help you replace or repair the gas stove tap yourself.

Why the gas column does not work

There are several common reasons why the geyser does not work. You can find and fix them yourself.

Lack of traction

Any geyser has a function that controls the presence of traction. If there is a shortage of it, then the gas automatically shuts off and the ignition on the gas column does not work.

It is very easy to check the presence of traction yourself. You need to bring a match to the vent or chimney. If the flame burns evenly, then there is no thrust. If the fire is drawn into the hole, then the chimney is working correctly. It happens that there is a reverse draft, and then the air flow blows out the fire in the burner.

If there is no thrust, then it is necessary to determine the reason for this. Most likely, there is a blockage in the ventilation or pipe that needs to be eliminated.

…

Batteries are dead

In an automatic geyser, dead batteries are often the cause of the problem. They give off a spark when ignited.Basically, batteries last for 7-15 months of operation.

In this case, the problem is very simple to solve - replacing the old batteries with new ones.

Insufficient water pressure

Each geyser works only at a certain indicator of water pressure in the line. There are models that are able to heat water only at 0.2 or 0.3 bar. If the pressure is lower, the device will not work.

…

After detecting low pressure in the line, it is necessary to find out the cause and eliminate it:

- If the pressure has decreased throughout the water supply network, then you need to call the utility company and report the problem.

- Sometimes the cause of the pressure drop is a clogged pipe or filter. It is recommended to check the filter and clean it if necessary.

Note! If a drop in water pressure in your line is not uncommon, then you can correct the situation by installing a pump that will increase the water pressure or replace the device with another one that can operate at 0.1-0.15 bar

Clogged gas burner

Most often, the piezoelectric element in the gas column does not work due to a clogged burner. If it is clogged with soot and soot, it is necessary to disassemble the structure and thoroughly clean each of its elements. Then you should collect all the details and try to light the column again.

No gas supply

Usually, when the column is turned on, the sound of incoming gas is heard and its slight smell is felt. If neither one nor the other is present, then the fuel is not supplied. This is one of the reasons why the ignition of the gas column does not work.

If there is no gas flow, it is recommended to first check if the gas filter is clogged. If so, the filter is cleared of blockage. In other cases, you need to call the gas service and find out what is the reason for the lack of fuel.

Note! If there is a gas leak, and you smell it in the room, then you can not turn on the gas water heater. Call a Gas Specialist Immediately

Problems in the water node

After 3-4 years of intensive use, the column water assembly membrane gradually loses its elasticity and may even break. If this happens, the device will not work.

To check the membrane, it is necessary to remove the device case and unscrew the bolts that hold the assembly. Then remove the cover of the water block and inspect the membrane. If it is damaged, then replace it with a new one. It is better to purchase an element made on the basis of silicone. Such a membrane will last longer.

Replacing the elements of the water unit should be carried out only if you are confident in your abilities and have the skills to repair such devices.

If you cannot identify the reason why the geyser does not work when turned on, call a specialist. He quickly figured out what was wrong and fixed the problem.

Conclusion

Fearing to seem intrusive, the author will remind you once again: if you have even the slightest doubt in your abilities, for any problems with gas, contact a specialized service. Additional information about gas equipment, as always, will be offered by the video in this article. Good luck!

There are special lubricants for gas taps, they belong to the Greases group. Applications: It has been successfully used in natural gas shut-off valves in main and secondary lines in household appliances, instantaneous water heaters and similar equipment. Lubrication of smaller faucets made of metal, glass or plastic.

Features: high water resistance, no drop point, thus no melting or leakage from lubrication points.

You understand correctly, Viktor Yurievich! The lubricant must meet certain requirements. According to GOST R 50696-2006, the lubricant must be inert to hydrocarbon gases, moisture, low and high temperatures. Until now, GOST has not standardized the formulation of such lubricants. Repair services of regional gas companies use lubricants SK-1, 1-13S, NK-50, LZ GAZ-41.For example, the composition of the lubricant SK-1, parts by weight: cylinder oil No. 2-68, technical stearin - 13, aluminum stearin oil - 2, highly dispersed graphite (C-1) - 16, caustic lithium - 1.

You will not find in the trade these domestic lubricants approved and approved for use in natural gas and liquefied petroleum gas environments, because they are intended for industry.

From imported lubricants in Moscow, products of the American manufacturer of specialty lubricants Huskey are available. For shutoff valves of gas pipelines (cone valves), sealing reinforcing grease HUSKEY No. 3 GENERAL PURPOSE VALVE LUBRICANT & SEALANT. HUSKEY HVS-100 SILICONE GREASE is used for plug valves of household gas stoves and other gas equipment.

I want to warn you against the thoughtless use of any silicone grease from the nearest auto shop on cork taps of household gas stoves. It absolutely cannot be done! The main properties of greases do not depend on the oil, in this case it is silicone, but on the thickener.

To prevent rust and plaque from appearing, you need to choose a good gas lubricant.

Gas equipment can be affected by negative environments - water, chemical compounds, so I can advise Dow Corning Molykote 111 Compound, it lubricates well, seals the nodes and also acts as an electrical insulator.

The compound ensures the tightness of gas valves, protects them from jamming, salt deposits and corrosion, thereby extending their service life.

«>