Why gasify housing

Today, natural gas is the most convenient and, importantly, profitable type of fuel. Sooner or later, every owner of a private house will want to gasify his possessions

Of course, there is an alternative - electricity. However, its cost is too high and it is very expensive to heat large areas in winter in this way. Plus, you will always depend on weather conditions - any hurricane can provoke a rupture of cables and then you will have to stay for a while without food, hot water and heating. But to spoil the gas line is much more difficult.

Photo of natural gas

There is, of course, another "grandmother's" way to heat a home - a stove or a fireplace. But ash, coal, firewood, all this will lead to excess dirt. It will take a lot of time and labor to fire up the stove, so this option is best left as an alternative in case of an apocalypse. So, whatever one may say, but blue fuel today occupies a leading position.

Control devices

And what equipment do you think is more effective for use in gas fire extinguishing installations?

Storing electronic information in a credit institution requires responsibility, therefore, it is necessary to select reliable fault-tolerant equipment for AUGPT.

One of the options for automatic fire extinguishing is given below.

- Security and fire control panel S2000M. This is the control center. Here, information is collected, the outputs of different devices are combined, cross-links are created between several sections of alarm loops, and access rights to control functions are differentiated for different users. RS-485 interface, information transfer according to a given protocol.

- Display unit S2000-PT. Manages fire automatics, displays the status of various AUGPT equipment, notifications from other devices. The following states are possible:

fire;

ASPT blocking;

launch of ASPT;

Attention;

malfunction;

automatic on/off.

- Reception and control device S2000-ASPT. Manages sirens, as well as fire extinguishers. Monitoring the health of triggers for a short circuit or open circuit, setting the delay in the release of OB separately for each of the start modes, monitoring the state of the serviceability circuit, the output control circuit, the door status sensor circuit and manual start, fire alarm loops.

- Block signal-starting S2000-SP1. Relay expander - controls sirens, lamps, electromagnetic locks, other elements, interacts with other devices, sends alarm signals to the monitoring console.

- Smoke optical-electronic detector IP212-58. Ultra-sensitive smoke detector - reacts to the appearance of smoke in the room. The developed design allows to reduce the dustiness of the chamber.

- Electrocontact element of remote control EDU 513-3M. It is used for manual start of fire automatic equipment. In stationary mode, displays a blinking LED with a frequency of 4 seconds. Works in conjunction with the control panel.

For the electrical supply of devices, we use an uninterruptible power supply "RIP-24" version 02P with batteries with a capacity of 7 Ah.

Powered devices operate 23 hours in standby mode and 3 hours in "Fire" mode.

We will give data on the energy consumption of the equipment used.

| Source of power | electrical equipment | Consumption in stationary mode (mA) | Consumption in "Fire" mode (mA) |

| RIP | S2000M | 35 | 35 |

| S2000-PT | 20 | 130 | |

| S2000-SP1 | 15 | 150 |

Designing a gas fire extinguishing installation

Now is the time to find out what is needed to prepare for the design, what stages the project consists of.We draw up the project, guided by the document SP 5.13130.2009.

Before the first stage of the project, we need to collect and study the following information:

- purpose of the premises: warehouse, public, industrial or residential;

- location of utilities: water, electricity, ventilation, internet and telephone cables;

- architectural and planning, design features of the object;

- climatic conditions, maintained air temperature;

- class of fire and explosion hazard of the structure.

Having studied and analyzed this information in detail, we will be able to identify the successive stages of our planning.

Development of project documentation is carried out in accordance with this plan.

- Definition and approval of TOR for the project.

- Setting the efficiency indicator of AUGPT, taking into account the indicator of leakage of the protected object.

- Determining the type of fire extinguishing agent.

- Hydraulic calculation of AUGPT. We produce it according to the methodology from the document SNiP RK 2.02-15-2003. It includes calculation:

- estimated mass of OM for fire suppression;

- the duration of the substance delivery;

- irrigation intensity;

- maximum extinguishing area with one sprinkler;

- the diameter of the pipelines of the system, outlets, the number and type of nozzles (filters) for uniform distribution of gas throughout the facility;

- the maximum value of overpressure when the working solution is injected;

- the number of system modules, as well as the stock of RH.

- Estimation of costs for equipment, installation of AUGPT.

- Calculation of the size of openings for throwing a substance into the room at excess pressure.

- Calculation of the delay time for the release of gas to the outside, which will be required to turn off the ventilation system, etc., as well as the safe evacuation of people (at least 10 seconds).

- Selecting the type of device: centralized or modular.

- Determining the number of RH cylinders to be installed.

- Decision on the need to keep a stock of fire extinguishing agent.

- Create a piping layout.

- Deciding on the need for a local start device for a centralized AUGPT.

- Establishment of the correct design of pipelines.

- The choice of control devices for a gas fire extinguishing installation.

After the completion of the project, i.e. a complete calculation of the installation, as well as the purchase of the necessary equipment, we can begin the process of installation and commissioning, which are regulated by regulatory documents SNiP 3.05.06-85, RD 78.145-93 and other engineering, technical, legal documentation.

Dear readers, we have reviewed the process and stages of designing a gas fire extinguishing installation.

This typical AUGPT project for the server room of a credit institution is, rather, an academic guide for everyone who wants to implement this equipment at their facility.

If this material was useful to you, recommend it to your friends.

See you soon on our blog pages.

Fire extinguishing gas

These installations use gas or gaseous reagents, which, when entering into a chemical reaction with heated air, prevent the further combustion process.

They are divided into the following ways of influencing the source of ignition.

- Inhibitory - gaseous reagents block the way for a further chemical reaction of combustion. It can be sulfur hexafluoride or one of these types of freons: 318C (C4F8), 227EA (C3F7H), 23, 125 (C2F5H), FK-5-1-12 (CF3CF2C(O)CF(CF3)2), carbon dioxide (CO2).

- Deoxidizing - non-flammable inert gas displaces oxygen from the room. These are, for example, carbon dioxide, a mixture of inergen, nitrogen, argon. Devices of this type fill the entire area of \u200b\u200bthe burning room with a substance to extinguish the flame. To increase their efficiency, an access control management system (ACMS) is required that shuts off ventilation, closes doors, windows to limit air access to the fire source as much as possible.

The composition of an average fire extinguishing installation installed in rooms of different fire hazard categories includes these components:

One or more gas cylinders, which are equipped with an electric valve or a squib.

Piping from cylinders with spray tips.

- A control device, start-up control, which activates the installation on a fire alarm signal.

- Communication channels for information transfer (cables).

- Devices for collecting / processing information (for example, a personal computer).

- Fire alarms - sound sirens, speech devices, light detectors (plates).

- Smoke removal system.

Gas extinguishing devices are significantly more expensive than their brothers - foam, water and powder fire extinguishing devices.

They are also more efficient. Therefore, this equipment is widely used in many industries, everyday life and is used to eliminate fire in:

- production;

- storehouses of material assets;

- museums;

- archives;

- construction sites;

- rooms with expensive electronics;

- other socially significant objects.

They are successfully used in large buildings, rooms with a complex layout due to the high speed of distribution of the fire extinguishing agent (S).

AUGPT can operate in three launch modes:

- remote - start from a manual call point, usually located at the guard post or at the front door;

- local - activated from the start button on the cylinder with OM or from the launch device on the isothermal tank with liquid carbon dioxide;

- automatic - is activated by a signal from automatic fire detectors.

The main advantages of gas fire extinguishing are the following qualities.

- Do not emit pesticides in the process of work, do not pollute the environment.

- They quickly detect fires, fill the room with gas in 10-30 seconds.

- No damage to material assets when extinguishing a fire.

- Large application temperature range: from -40 ºС to +50 ºС.

- The room can be returned to a stationary state a few hours after natural ventilation.

The disadvantages of AUGPT can be called these factors.

- Relatively costly to install and operate.

- Do not extinguish substances that burn without oxygen.

- Cannot be used outdoors.

- A complete evacuation of the personnel building is required prior to commencement of work.

What should be the gas pipeline to a private house

We all know about the explosive properties of gas, so there can be no talk of any initiative in this matter. However, you will have to collect all the necessary documents, make a project, submit applications to the appropriate authorities, etc. So, get ready to visit various services and queues. Consider all the requirements that cannot be violated.

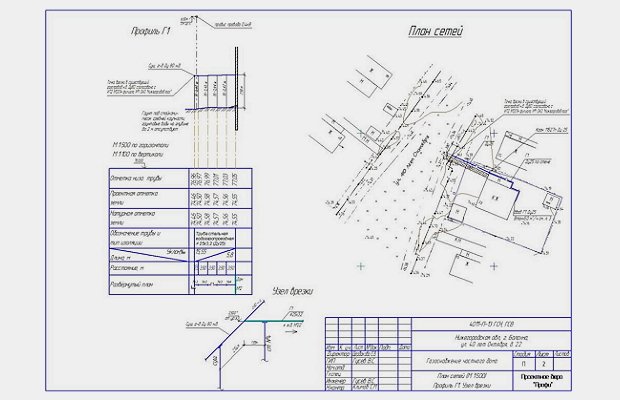

In the photo - a gas supply project for a private house

All materials, from pipes to welding electrodes, must be of high quality and have certificates

The location of all elements of the pipeline is also very important. Collapsible connections should be located only in open places

Be sure to provide free access to them. This will allow at any time to assess their condition and, if necessary, carry out repairs. It is forbidden to wall up pipes and other nodes of the gas network in the walls or foundation of the building. It is also unacceptable to run the gas pipeline through platbands, plywood walls, transoms, door and window frames and temporary partitions. True, sometimes they allow a gas pipeline to be laid through a specially made channel in the wall, but only in special cases and after the approval of the project.

Distortions are also not allowed, all pipes must run strictly vertically, horizontal sections have a slope of 0.002–0.005 m towards the instruments. If we are talking about a riser, then in this case a skew of a maximum of 2 mm per meter is allowed.They are located mainly in the stairwells or in the kitchen, but in bathrooms and living rooms it is forbidden to do this. Cranes also require special attention, they must be installed so that the cork axis is parallel to the wall. The stop nut must not be placed on the side of the wall.

Photo of gas supply pipes of a private house

It is very important to maintain distance. There must be at least 2.2 meters from the bottom of the pipe to the floor, and 10 cm of free space must be left between the upper side of the gas pipe and the ceiling

Also, pipes should not be placed close to the walls, as this will make visual control difficult. If this distance is not specified in the project, then a gap must be left, the minimum value of which will be equal to the radius of the pipe, but not exceeding 10 cm. The gas pipeline must be located on the supports rather tightly, gaps are not allowed.

Privileges

The state identifies a number of categories of citizens in need of social support measures. They are provided with various benefits for utility bills. At the federal level, there are no benefits for connecting a private house to gas. Financial incentives are provided only for payment for the consumed resource.

However, the local authorities of the regions have the right to determine the categories of citizens and the list of benefits provided within the framework of their regulatory documents. In almost every region, a subsidy is provided for the costs that were incurred during the gasification of the house, for the following categories:

- participants, disabled people and widows of participants in the Second World War;

- rear workers;

- residents of besieged Leningrad and underage prisoners of fascist camps;

- disabled people of groups 1 and 2;

- families with three or more children.

It should be noted that in the Leningrad region, for example, the authorities decided to allocate a regional benefit for the gasification of private houses in the amount of 110 thousand rubles for the categories listed above. The rest of the population - 70 thousand rubles.

A number of regions stipulate at the level of their regulatory documents the percentage of compensation or benefits from the expenses incurred, but limits it to the upper bar. To find out if a citizen is entitled to a benefit, you must contact the local administration for clarification.

If you have a legal question regarding the problem of connecting gas in a private house, you can use the form below.

Paperwork and equipment selection

But before you face the installation, you will need to run around different authorities and collect a package of documents. Prepare a passport, title documents for the land and the building located on it. You also need to write and submit to the gas service an application in which you express a desire to gasify the house. After that, you will receive a form of technical specifications, it is filled in by the developers. Only then can the project be started.

In the photo - gasification of a private house

You will need to conclude the following contracts:

- on the performance of work and the preparation of technical documentation;

- on gasification and installation of appropriate equipment;

- act of putting gas equipment into operation;

- for the supply and payment of natural gas.

In some cases, if you have not ventured into an autonomous gas supply, you have to pull pipes through the neighbors' plots, and then you will need written permission from them. It is necessary that specialists come to you and examine the chimney in the house, in the end they are required to issue an act. You will also have to visit the local architectural and planning department. The head of this organization is also required to issue a permit for gasification of the site.

It has already been said that absolutely all materials, especially pipes, taps, hoses, must have the appropriate certificates. Without the availability of such documentation, it is impossible to put into operation all these elements. Blue fuel flows through pipes with a diameter of 150 mm and a wall thickness of 5 mm.Basically, elements are selected from low-carbon or low-alloy steel. In principle, both seamless and welded structures can be used. Naturally, the gas pipeline is assembled from a sufficiently large number of pipes. They are connected by gas welding. Very serious requirements are also imposed on the quality of the electrodes and they cannot be neglected.

Photo of the gas pipeline of a private house

But the list of necessary materials does not end there, a number of small parts will also be needed - tees, crosses, couplings, adapters, elbows and plugs. They are usually made from cast iron or steel. To fix all threaded elements well, you should choose the right tool. For example, keys with notches and parallel jaws provide maximum grip with the part. Is it worth mentioning the boiler, column, stove and other equipment.

Primary gas start

For the initial start-up of gas, you need to obtain permission to commission the gas consumption network. To do this, a written application and the following documents are submitted to the GRO:

- act of acceptance of the gasification facility (for newly built houses);

- act of acceptance of the gas consumption network (it is drawn up after completion of construction and installation work under the contract);

- an act of commissioning a gas pipeline-commissioning a house (drawn up between the owner of the house and the GRO, or with another contractor);

- an act of checking the technical condition of chimneys and ventilation ducts (for a fee, it is compiled by a third-party organization, which can also be a voluntary fire society);

- agreement with the GDO for connection;

- maintenance and repair agreement;

- contract for the supply of natural gas.

A prerequisite is the execution of a gas supply agreement under Decree 549. The GDO and the gas supplier are not always the same organization. You can clarify with which company you need to conclude a supply contract with the GDO, or with the local administration.

An agreement on the maintenance and repair of the VDGO is concluded with the GDO, or another organization.

During the actual start-up of gas, the operability of the equipment, the absence of leaks, and pressure parameters are checked. If all checks were successful, sign:

- act of delimitation of property;

- act of delimitation of operational responsibility;

- connection act (confirms that gas supply has begun to the house).

Also, during the initial start-up, the owner is instructed on the rules for handling gas.

Obtaining technical conditions for gas supply

In the request for the issuance of technical conditions, you must specify:

- surname, name, patronymic, place of residence and postal address;

- the planned date for putting the house into operation (if you apply at the construction stage, or with an undeveloped plot);

- the planned value (calculation) of the maximum hourly gas consumption, including at various points of consumption (there may be several of them, if there are several gasified objects on the site).

GRO experts will help you calculate the gas flow rate, or you can do it yourself according to the characteristics of gas equipment.

To the request for the provision of technical specifications, you must attach:

- copies of title documents for the land plot house;

- situational plan (this is a diagram of the land plot and adjacent areas, which can be obtained from the local administration or made by yourself);

- calculation of the planned maximum hourly gas consumption (it is not necessary to submit it if the planned maximum gas consumption does not exceed 5 cubic meters);

- a copy of the passport;

- a power of attorney confirming the authority of the representative;

- consent to the connection and construction of a gas pipeline on the land plot of the main subscriber, if the connection is carried out on a neighboring plot owned by another person (this is necessary if the gas communications of your house will be connected to the neighbor's gas pipeline).

The technical conditions will be developed by the specialists of the GRO to which you submit the documents. The content of the TU must indicate:

- maximum load (hourly gas consumption);

- terms of connecting the house to the gas distribution network;

- validity period of technical conditions (no more than 70 days).

If you do not apply for a connection agreement within 70 days, the technical specifications will have to be ordered again. The term for registration and issuance of technical specifications will be no more than 10 days.

Conclusion of an agreement for gas connection

If the technical specifications confirm the possibility of gasification, you need to apply for connection. It needs to specify:

- surname, name, patronymic;

- series and number, date of issue of the passport, postal address and other means of information exchange (telephones, fax, e-mail address);

- name and location of the object to be connected to the gas;

- terms of design, construction and phased introduction of the house into operation;

- planned distribution of the maximum hourly gas consumption;

- number and date of issue of technical specifications.

An application for connection with documents must be submitted to the “Single Window” service, through the GRO website, or by mail. When sending by mail, you need to make an inventory of the attachment.

Connection terms:

- a draft contract is sent within 5 working days if a gas distribution network already passes through your site;

- within 30 working days, a draft agreement is sent if you belong to the second or third category of applicants and the GDO is required to coordinate with the owners of communications and land plots the laying of a gas pipeline to your house;

- within 15 working days a draft agreement is sent in all other cases, including for the first category of applicants.

The term for concluding an agreement and connecting to gas depends on the category of applicants. In total, Decree No. 1314 indicates 3 categories:

- the first category includes most private houses - the maximum gas consumption does not exceed 20 cubic meters. m. per hour, the distance from the equipment to the gas pipeline is not more than 200 meters, and the working pressure is not more than 0.3 MPa;

- the second category - hourly gas consumption up to 500 cubic meters, distance to the gas pipeline up to 500 meters (in the countryside) or 300 meters (in the city), working pressure is not higher than 0.6 MPa;

- the third category is the hourly gas consumption up to 500 cubic meters, the distance to the gas pipeline is up to 500 meters (in the countryside) or 300 meters (in the city), the operating pressure is not higher than 0.6 MPa, but the network passes through two or more municipalities.

GDO specialists will assign you to one of the categories based on the documents submitted. You are given no more than 10 days to review the draft agreement.