Scheme of the elevator heating unit

In any building, including a private house, there are several life support systems. One of them is the heating system. In private houses, different systems can be used, which are selected depending on the size of the building, the number of floors, climate characteristics and other factors. In this material, we will analyze in detail what a heating unit is, how it works and where it is used. If you already have an elevator assembly, then it will be useful for you to learn about defects and how to eliminate them.

In simple words, a thermal unit is a complex of elements that serve to connect a heating network and heat consumers. Surely readers have a question whether it is possible to install this node on their own. Yes, you can if you can read diagrams. We will consider them, and one scheme will be analyzed in detail.

How the elevator works

In simple words, the elevator in the heating system is a water pump that does not require external energy supply. Thanks to this, and even a simple design and low cost, the element found its place in almost all heating points that were built in the Soviet era. But for its reliable operation, certain conditions are needed, which will be discussed below.

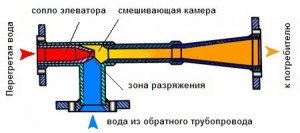

To understand the device of the heating system elevator, you should study the diagram shown above in the figure. The unit is somewhat reminiscent of an ordinary tee and is installed on the supply pipeline, with its side outlet it joins the return line. Only through a simple tee would water from the network pass immediately to the return pipeline and directly to the heating system without lowering the temperature, which is unacceptable.

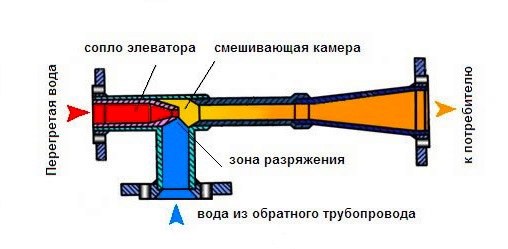

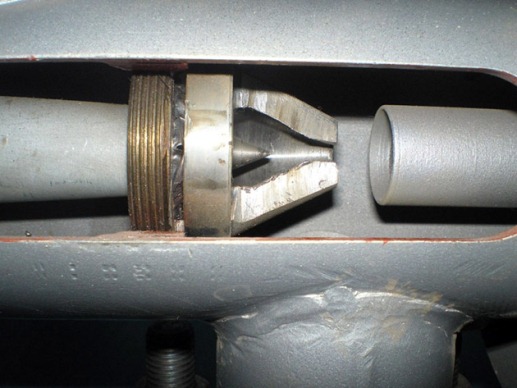

A standard elevator consists of a supply pipe (pre-chamber) with a built-in nozzle of the calculated diameter and a mixing chamber, where the cooled coolant is supplied from the return. At the outlet of the node, the branch pipe expands, forming a diffuser. The unit operates as follows:

- the coolant from the network with a high temperature is sent to the nozzle;

- when passing through a hole of small diameter, the flow velocity increases, due to which a rarefaction zone appears behind the nozzle;

- rarefaction causes suction of water from the return pipeline;

- the flows are mixed in the chamber and exit the heating system through a diffuser.

How the described process takes place is clearly shown by the diagram of the elevator node, where all flows are indicated in different colors:

An indispensable condition for the stable operation of the unit is that the pressure drop between the supply and return lines of the heat supply network is greater than the hydraulic resistance of the heating system.

Along with the obvious advantages, this mixing unit has one significant drawback. The fact is that the principle of operation of the heating elevator does not allow you to control the temperature of the mixture at the outlet. After all, what is needed for this? If necessary, change the amount of superheated coolant from the network and sucked water from the return. For example, in order to lower the temperature, it is necessary to reduce the flow rate at the supply and increase the flow of coolant through the jumper. This can only be achieved by reducing the nozzle diameter, which is impossible.

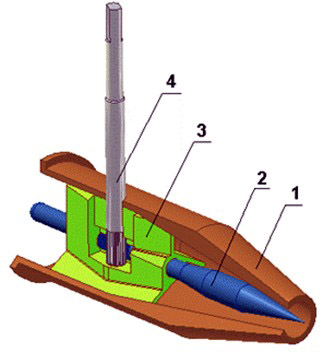

Electric elevators help to solve the problem of quality regulation. In them, by means of a mechanical drive rotated by an electric motor, the diameter of the nozzle increases or decreases. This is realized by means of a cone-shaped throttling needle that enters the nozzle from the inside for a certain distance. Below is a diagram of a heating elevator with the ability to control the temperature of the mixture:

1 - nozzle; 2 - throttle needle; 3 - housing of the actuator with guides; 4 - shaft with gear drive.

Note. The drive shaft can be equipped with both a handle for manual control and an electric motor switched on remotely.

A relatively recently appeared adjustable heating elevator allows the modernization of heating points without a radical replacement of equipment. Considering how many more such nodes operate in the CIS, such units are becoming increasingly important.

Distribution devices

The elevator assembly with all its piping can be represented as a pressure circulation pump, which, under a certain pressure, supplies the coolant to the heating system.

If the facility has several floors and consumers, then the most correct solution is to distribute the total heat carrier flow to each consumer.

Features of installation and verification

Installation of the elevator assembly

It should be noted right away that the installation and verification of the operation of the elevator unit and the heating system is the prerogative of representatives of the service company. It is strictly forbidden for residents of the house to do this. However, knowledge of the layout of the elevator units of the central heating system is recommended.

When designing and installing, the characteristics of the incoming coolant are taken into account

The branching of the network in the house, the number of heating devices and the temperature regime of operation are also taken into account. Any automatic elevator assembly for heating consists of two parts

- Adjusting the intensity of the flow of incoming hot water, as well as measuring its technical indicators - temperature and pressure;

- Directly the mixing unit itself.

The main characteristic is the mixing ratio. This is the ratio of the volumes of hot and cold water. This parameter is the result of precise calculations. It cannot be a constant, as it depends on external factors. Installation must be carried out strictly according to the scheme of the elevator unit of the heating system. After that, fine tuning is done. To reduce the error, the maximum load is recommended. Thus, the temperature of the water in the return pipe will be minimal. This is a prerequisite for accurate control of the automatic valve.

After a certain period of time, scheduled checks of the operation of the elevator unit and the heating system as a whole are necessary. The exact procedure depends on the specific scheme. However, you can draw up a general plan, which includes the following mandatory procedures:

- Checking the integrity of pipes, valves and devices, as well as the compliance of their parameters with passport data;

- Adjustment of temperature and pressure sensors;

- Determination of pressure losses during the passage of the coolant through the nozzle;

- Calculation of the offset factor. Even for the most accurate heating scheme of the elevator unit, equipment and pipelines wear out over time. This correction must be taken into account when setting up.

After carrying out these works, the central heating automatic elevator unit must be sealed to prevent outside interference.

You can not use home-made schemes of elevator units for central heating systems.They often do not take into account the most important characteristics, which can not only reduce work efficiency, but also cause an emergency.

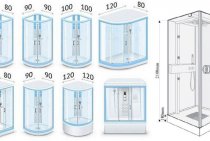

Three way valve

If it is necessary to divide the coolant flow between two consumers, a three-way valve is used for heating, which can operate in two modes:

- permanent mode;

- variable hydro.

The ball valve is mainly used for:

- adjusting the temperature of underfloor heating;

- battery temperature control;

- distribution of the coolant in two directions.

There are two types of three-way valves - shut-off and control. In principle, they are almost equivalent, but it is more difficult to smoothly regulate the temperature with shut-off three-way valves.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

Expansion tank for closed-type heating: device and principle of operation Shut-off valves for heating: types and characteristics Heating collector: equipment design and installation features

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement entails legal liability. Contacts

The device and principle of operation of the heating elevator

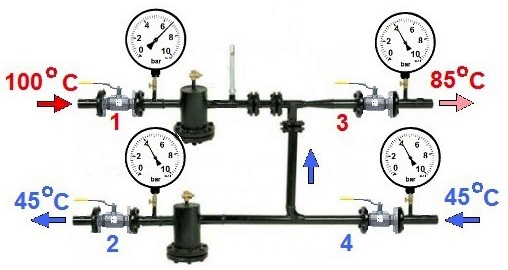

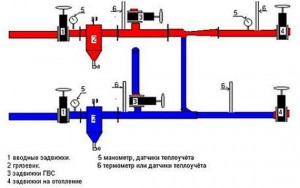

Thermal node scheme

The elevator harness includes:

- mud filters;

- pressure gauges (at the inlet and outlet);

- thermal sensors (thermometers at the elevator inlet, outlet and return line);

- valves (for preventive or emergency work).

The advantages of its use for heating large objects, houses and skyscrapers:

- reliability, due to the simplicity of the design;

- low price of installation and accessories;

- absolute energy independence;

- significant savings in heat carrier consumption up to 30%.

But in the presence of indisputable advantages of using an elevator for heating systems, the disadvantages of using this device should also be noted:

- calculation is done individually for each system;

- you need a mandatory pressure drop in the heating system of the facility;

- if the elevator is unregulated, it is not possible to change the parameters of the heating circuit.

Elevator with automatic adjustment

The elevator regulates the supply and pressure of the coolant, and its pressure drives the flow in the heating circuit.

How does a heating point with an elevator mixing unit work

Elevator mixing units are installed in the heating points of buildings that are connected to a heating network operating in a mode with high-quality regulation on "superheated" water.

Qualitative regulation involves changing the temperature of the water entering the heating system depending on the temperature of the outside air, with a constant flow of water circulating in it.

"Overheated" water is considered if it comes from a heating network with a temperature exceeding that required for supply to the heating system.

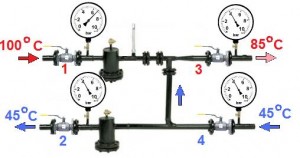

For example, a heating network can operate on a 150/70, 130/70, or 110/70 schedule, while a heating system is designed for a 95/70 schedule. The temperature graph 150/70 assumes that at the estimated outdoor temperature (for Kiev it is -22°С), the temperature at the input of heat networks to the house should be equal to 150°C, and it should go into the heat network with a temperature of 70°C, while in a house designed for a 95/70 schedule, this water should enter with a temperature of 95 ° C.

The elevator unit mixes the flow of water from the heating network supply with a temperature of 150°C and the flow of water leaving the heating system with a temperature of 70°C - as a result of mixing at the outlet of the elevator, a flow with a temperature of 95°C is obtained, which is fed into the heating system.

How mixing happens

In the mixing chamber of the elevator unit there is a “nozzle / cone” confuser that accelerates the flow of superheated water. With an increase in the flow rate, the pressure in it decreases (this property is described by Bernoulli's law) to such an extent that it becomes slightly lower than the pressure in the return pipeline. The pressure difference between the mixing chamber and the return pipeline leads to the flow of the coolant through the "elevator boot" jumper from the return to the supply.

In the mixing chamber, a mixture of two streams is formed with the already required temperature, but with a pressure lower than the pressure of the return pipeline. The mixture enters the elevator diffuser, where the flow rate is reduced and the pressure is increased above the pressure of the return pipeline. The pressure increase is no more than 1.5 m. of water, which imposes restrictions on the elevator units in the use for heating systems with high hydraulic resistance.

1 cheap and easy

2 Maintenance free

3 Does not depend on the electrical network

Disadvantages of elevator mixing units

1 Not compatible with automatic regulators, therefore, their joint installation is prohibited by law.

2 Creates an available head at the input to the heating system of not more than 1.5 m of water column, which excludes the installation of elevator heating points in buildings whose heating systems are equipped with thermostatic radiator valves.

3 The elevator unit has a constant mixing ratio, which does not allow supplying the heating medium of the required temperature to the heating system in case of underheating in the heating network.

4 Too high sensitivity to the available pressure at the input of the heating network. A decrease in the available pressure relative to the calculated value leads to a decrease in the volumetric flow of water circulating in the heating system, which in turn leads to an imbalance in the system and shutdown of distant risers/branches.

5 For the operation of the elevator, the pressure difference between the supply and return pipelines must exceed 15 m.a.c.

Where are heating points with elevator units installed?

Almost all heating systems put into operation before 2000 are equipped with heating points with elevator units.

Where can elevator ITPs be used?

At present, for all designed and reconstructed residential and administrative buildings, it is mandatory to use automatic control in the heating substation. The use of elevator units in conjunction with automatic regulators is prohibited by law.

Elevator units can only be installed at facilities where there is no need for automatic control of the heating system, the available pressure (pressure difference between the supply and return pipelines) at the inlet is stable and exceeds 15 m. of water, for the operation of the connected heating system, the pressure difference between the supply and return to 1.5 m.w.st., and the heating system operates at a constant flow rate and is not equipped with automatic regulators.

Elevator heating unit what is it and how does it work

Elevator heating unit

Today it is impossible to imagine your life without heating. Even in the last century, the most popular was the oven.

Not many people use it these days. The main disadvantage of stove heating is the cold floor. All the air rises and thus the floor is not heated.

Technological progress has come a long way. And now the most profitable and popular is the water heating system. Of course, to ensure comfort in the house, heat is of great importance.

Regardless of whether it is an apartment or a private house. However, it must be remembered that the type of heating depends on the type and category of housing. In private houses, individual heating is installed.

But most apartment residents still use the services of a centralized heating system, which requires no less attention.

The elevator assembly is one of the main components of the system. However, not many people know what functions it performs. Let's look at its functional purpose.

An example of the implementation of scheme 1 ACU

Schematic diagram of an automated control unit with a sufficient available pressure drop at the inlet

(P1 - P2 > 6 m water column) for temperatures up to ACU t = 95-70 °С

The modern world can not do without innovative technologies for a long time. There is not a single technology or system in which revolutionary solutions have not been applied. The heating system is no exception. This is due to the fact that this is a rather significant technology, which is designed to provide a comfortable existence.

For obvious reasons, when designing a house, special attention is paid. Since ancient times, houses were built from the stove, that is, the stove was first built, and then it was overgrown with walls and ceiling

This was done for a reason, for this we need to say “thank you” to our climate.

Starting from the middle zone of our spacious country and ending with distant Sakhalin, rather uncomfortable temperatures prevail for most of the year. The thermometer ranges from +30 to -50 degrees.

Due to the rather complex temperature resonance, the heating system is just as important as the electricity supply. Previously, a competent stove-maker who knew how to make the right stove was valued at the level of a blacksmith. After all, you need to correctly calculate the size of the furnace, the diameter of the chimney, besides, the furnace had to be multifunctional:

- food was cooked in it;

- she heated the room;

- warmed up the water

- served as a small bed.

That is why the construction of the furnace was a difficult and time-consuming task. She had to have enough thrust so that all the products of combustion did not enter the room. But with all this, it had to be economical.

Today, little has changed fundamentally. The main functions and requirements for the heating system remain the same:

- saving;

- maximum efficiency;

- multifunctionality;

- simplicity of design;

- quality and durability;

- minimal operating costs;

- safety.

Fire was the first source of heat for man. And even now its relevance has not lost its significance. The most primitive way of heating was to build a fire, which gave protection from predators, low temperatures, and served as a source of light.

Further, over time, humanity began to tame the gift of Hermes. Furnaces appeared, they were usually built of clay and stones. Later, with the progress of technology, ceramic bricks began to be used. And that's when the first ones appeared.

Steel furnaces appeared much later, they determined the formation of the steel age. The fuel for the stoves was coal, firewood, peat. With the gasification of cities, furnaces have become. And all this time, man sought to improve the heating system.

Basic rules for constructing a warm water floor circuit

A water heated floor heats the surface of the finish coat indirectly through a concrete screed, the thickness of which is 5 cm. With the right device, under this screed there are the following elements:

- water and steam protection from a polyethylene film;

- rough concrete screed with a thickness of 15 cm;

- heat-insulating layer of foil insulation.

In addition, another layer of steam and water protection is laid on top of the heating screed.

The register of a water heated floor is laid out at a distance of 50 cm between the knees and no closer than 20 cm to the walls. One end of the pipe is removed from the boiler through the mixing unit, the second is the return line, it is connected to it in front of the boiler.

The device in the screed involves the use of pipes without joints, which is possible only when using plastic or metal-plastic pipes. The joint is the weak point of the pipeline, and if repairs are necessary, the screed will have to be dismantled.

Knots

The boiler is the heart of the system. It converts either electrical energy or hydrocarbon fuel into thermal energy. It is in his competence to heat up the coolant in order to transfer heat through it to its destination.

There are boilers according to the fuel consumed:

Gas heating in the house

- gas boilers;

- boilers for liquid fuel (diesel fuel or kerosene).

Boilers must be installed in a well-ventilated area. In the case of gas fuel, there must be a connection project, and it must be under the control of the sponsored gas service.

Boilers do not require a certain supply of flammable liquid for full operation. The most economical boiler is a gas boiler.

Boiler - performs the tasks of heating water, which gets into the taps and faucets through the plumbing. Since the main coolant circulates in a closed system and is of poor quality, and recently antifreeze has been used as a coolant instead of water, therefore warm water does not go directly through the boiler. It is heated in a special tank, which is connected to the boiler.

Thus, pure water does not mix with process water in any way. Heating occurs through the walls of pipelines that encircle the internal contour of the tank. In the collection, this tank is the boiler.

Circulation pumps are designed to create a directed movement of the coolant through pipelines. The advent of pumps led to the emergence of an increasingly sophisticated heating system. Houses became multi-storey, there were more than one circuit, and the natural (convection) flow of water through pipelines became inefficient.

With the use of circulation pumps, the distribution of heat throughout the rooms has become much better, the diameter of the pipelines has significantly decreased. In addition, when using a warm floor with liquid heating, the installation of a circulation pump becomes vital.

Pipelines serve as overpasses for the fluid that transfers heat from the source to the consumer. They must withstand high temperatures up to 80 degrees, and at the same time must withstand the pressure created by the pumps. Their walls are required for a long time to create a minimum resistance to the current of the coolant, thereby saving on electricity. After all, pumps run on electricity.

Radiators close the technological process for space heating. They dissipate heat through it, which came from the boiler with the coolant.

The heating system must be backed up. If the boiler fails, for the period of its repair or replacement, there must be a backup source of heat. It should prevent the cooling of the whole house.