Thinking about creating a cozy interior for their apartment, many ordinary people remember such an element as a fireplace. The hearth has always been an obligatory attribute of the dwelling of all peoples of the world. It is hardly possible to make a full-fledged fireplace in a city apartment, but it can be successfully replaced with an imitation. It is possible to perform it qualitatively with the materials at hand, without resorting to outside help. Let's try to figure out how to make a drywall fireplace with your own hands.

Designing a drywall fireplace

Of course, first of all, you need to decide on all the parameters of a false fireplace, find its place in the interior of the room. You can contact a professional designer and get your hands on a ready-made project. But most owners choose the design, shape and location of the fireplace without the help of specialists.

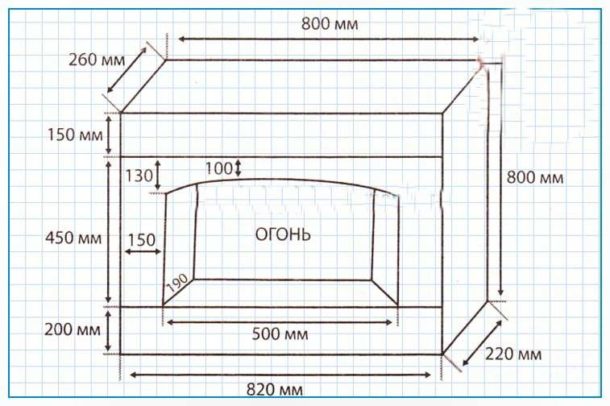

Before you independently make a drywall fireplace, you need to draw up a detailed drawing of the future design. It will be necessary in order to calculate the required amount of material, avoid installation errors, and guarantee that the fireplace you have made will last a long time.

Location options

Typically, fireplaces are located in the living room. There are two options for placing a fireplace portal made of drywall in a room:

- Angular. It is well suited for small dimensions of the room, as it will take up little used space. Corner fireplaces made of drywall can easily fit into the interior of the room. Their design is more rigid, as it is attached to two walls of the room. The shelf of such a fireplace can be used, for example, as a TV stand. The only drawback is that not all rooms can have a corner fireplace in plain sight. Corners can be covered with curtains or occupied by doorways. In this case, it is better to use the second location option.

- Front - the fireplace is located in the middle of the long wall of the room. Ideal for a large living room, which allows you to create symmetry in the interior of the room.

False fireplace functions

A drywall fireplace can carry a different functional load:

- At its simplest, a fireplace is simply a protruding architectural decoration of a room. It can be equipped with a flame imitation in the form of a pattern or a special screen.

- A drywall fireplace can be used for heating when combined with an electric heater. The modern market offers the widest selection of electric fireplaces that combine comfort with fire safety. In this case, the drywall construction will help to achieve maximum similarity with a natural fireplace.

- Inside the portal, you can place various shelves or drawers for storing things. They can be hidden by disguised hinged doors. Thus, at the same time as decorating the room, we will get an original plasterboard cabinet.

The fireplace can have an impressive countertop, which can be used at your discretion. As mentioned earlier, you can place a TV there, install a mirror, or simply use it as a shelf.

Marking and assembly of the frame

The sequence of work will be as follows:

- Marking of the future structure is applied to the floor and walls. For this operation, a level and a square must be used. In addition to the contours of the portal, the furnace hole should also be marked.

- Attached according to the intended contour guide profiles. For concrete surfaces, dowel-nails are used; on wooden surfaces, fastening is carried out with self-tapping screws.

- The depth of the fireplace will be determined by the horizontal crossbars.They are fixed between the guide profiles on the wall and the vertical posts that form the outer ribs of the structure. For fixing, small self-tapping screws for metal are used, called by craftsmen "bugs" or "fleas". The distance between the jumpers is determined by the drawing of the product under construction. The optimal step is 20–25 cm.

The more horizontal jumpers, the more rigid the structure will be. So it’s better to make them with a margin, but at the same time take into account the design features: extra jumpers can interfere with the installation of some parts of the fireplace.

- Vertical racks are also fastened with jumpers to each other. The upper crossbars of the front and rear walls must be located strictly in the same plane.

- In the same way, part of the frame for the parapet is mounted.

- If the combustion chamber has a curvilinear outline, then the profile will need to be bent. To do this, the side shelves are cut with scissors for metal, after which the guide will easily take the desired shape. It remains only to securely fix it with the help of "bugs".

- After assembling the frame, the location of all its elements is controlled using a level and a plumb line. It is easier to correct the flaws at this stage, much worse if they are found when lining the fireplace with drywall.

If it is planned to install an electric fireplace or lighting elements in the portal, then the electricity supply must be carried out before the plasterboard sheathing of the frame.

Fastening and finishing drywall

Drywall cutting is carried out according to the dimensions indicated on the drawing. Drywall is cut in a straight line with a paint knife:

- An incision is made on one side of the drywall sheet, resting the knife against a ruler or rule located on the line.

- Having laid a sheet of drywall along the cut line, for example, on the edge of the table, break it.

- The sheet is turned over, folded and cut off to the end, cutting through the second cardboard shell with a knife.

Curvilinear drywall parts are cut with an electric jigsaw. Holes for fixtures are obtained using a crown of the desired size.

Installation is carried out in such a way that plasterboard elements located in perpendicular planes cover each other's ends. That is, if the dimensions of one sheet coincide with the distance between the profiles, then the sheet perpendicular to it should be larger by the thickness of the drywall.

Fastening drywall elements is carried out on self-tapping screws, slightly sinking their hats into the material.

The optimal fastening step for self-tapping screws is 20 cm, but when installing curved drywall surfaces, such as a firebox vault, it may be less.

In order to bend drywall element, parallel cuts should be made on one of its sides. The smaller the radius of curvature, the more often the cuts should be located.

In the final part, all the seams of the drywall construction are glued with a reinforcing mesh and puttied, not forgetting to cover the heads of the self-tapping screws with putty. After drying, the surface of the drywall is primed completely.

It is recommended to reinforce the outer ribs with perforated corners.

In the future, a drywall fireplace can be finished in accordance with the design idea: paint, paste over with wallpaper or decorative tiles.