Chimney installation

Otherwise, the combustion products will not only damage furniture, but also harm the human body.

Any building of this type is done according to the following principles:

- Regarding the smoke. At the same time, a tee is placed in the network, which removes condensate.

- regarding condensate. In this case, this tee is not used.

First stage

. This is the choice of the project and the selection of materials. At this stage, it becomes clear what kind of building will be (straight or with transitions and folds).

Second phase

. This is an assembly. All butt joints, elbows and tees must be securely fastened with clamps.

Third stage

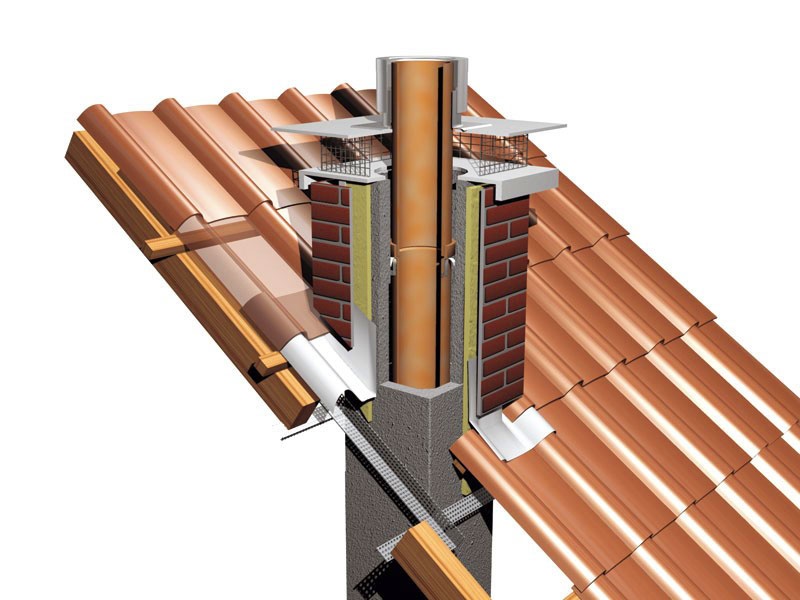

. Roof penetration. Through the roof, the withdrawal occurs with the help of a special section.

It is chosen according to the level of the slope of the roof. Then the place where exactly the workpiece will pass is determined.

The angle of inclination is adjusted by part of the cutting, and its extreme parts are “adjusted” to the ridge. Insulation is laid along the walls of the pipe.

Fourth final stage

. An adjustable apron is attached to the branch pipe and the pipe is extended to the required length. Its edges are covered with a lid - an umbrella. It will protect you from the weather.

Chimney fixture

In this case, the gaps between the roof and the pipe must be closed with waterproofing. It is recommended to raise the building above the roof in accordance with existing rules.

When carried out from the outside of the structure, the problem of how to fix the metal chimney pipe is not acute. Because for this they use a knee, which sets the direction of the vertical position.

When the structure rises to the level of the roof ridge and is securely fixed to the wall, an umbrella must be put on top of it. It protects against clogging by fallen leaves, rainwater and snowfalls.

Transition from a brick chimney to a metal one

How to extend a brick chimney with a metal pipe? This question is asked very often.

This extension pad must be securely fixed. To do this, take dowels and screws. But, such a mount will not be reliable without sealant.

And now all the lengthening actions in order:

- On a brick base, all attachment points must be marked. These places should not be on the masonry seam. Also, they should not be on the edge of the brick.

- Further, holes for self-tapping screws are drilled in the site, and holes for dowels are made in the bricks.

- The site is placed on.

- After that, the platform is evenly attracted along the entire perimeter with self-tapping screws.

- Further, this transition can be mounted only after the sealant has completely dried.

Now a brick building can be extended to any desired distance with a metal blank.

Some installation rules

- If the smoke outlet rises above the roof by more than 1.5 meters, then it is recommended to additionally fix it with stretch marks.

- The length of the pipe from the stove to the head should not exceed 5 meters.

- For cleaning from condensate, special plugs are mounted.

- Outside the roof, the structure should be taken out no less than 1.5 meters.

- When installing a smoke exhaust pipe, its diameter must not be narrowed.

- Nearby structures made of combustible materials should not heat up more than 50 degrees.

- The smoke outlet must be located at a safe distance from the electrical wiring.

When deciding how to insulate a metal chimney pipe, everyone makes a decision based on their preferences and financial capabilities.

The main thing in this business is to do everything in accordance with the norms and requirements, and then the work will please with a quality result.

Almost every private house has a stove or fireplace, which are necessarily equipped with a chimney to remove combustion products. The temperature of this element can reach several hundred degrees, and the only thing that separates it from the room is the wall of the chimney.

Attached from above steel apron

according to the dimensions of the chimney into special grooves. Then all joints are filled with sealant. Sometimes a chimney apron is part of an insulating steel wall, which is necessary in some cases (during the formation of condensate, during conduction). At the same time, the steel sheet in the lower part is bent at an angle and has no joints, which increases the level of reliability against leakage. Metal aprons are also worn on round pipes if the temperature of the combustion products at the outlet over 100 degrees.

Best Answers

Alexander Kudryavtsev OLD . Answer:

At such temperatures, Asbestos is needed ... the best. Wrap the pipe with cord asbestos, and on top you can already use basalt wool .... but it will be easier. Temperature won't be the same

Oksana Shmuchkova:

The air gap is effective, since expanded clay outside the screed absorbs a lot of moisture and becomes a heat conductor. It is a FILLER, not an independent heat insulator.

I love Spitz!

piss, there are no other options

Antonio M:

I wrapped the pipe with non-combustible paper, then 10 cm of heat-resistant mineral wool, then a galvanized iron box. All the same, you can’t touch it with your hand during a good fire. Try expanded clay but at least 15 cm. The pipe will still be very hot

nik:

expanded clay is not suitable for this purpose; it can only be used in a fireproof ceiling cut (around a heat-insulated pipe). Rockwool wired matt and its analogues are best suited as a heat insulator in the pipe, the denser the heat insulator, the lower the temperature of the outer casing, but at the same time the temperature of the internal circuit rises

Leonid Shingarov:

I did this around the pipe. The wooden box inside was upholstered with a glass-magnesium sheet; it dares a temperature of 1100 degrees, and the space was covered with expanded clay.

Oleg A:

vermiculite, what expanded clay. Just so that it is exactly vermiculite. Better is a slab of heat-resistant cement GTs 40. In the case of using a slab, brick when fluffing, the distance from the inner wall of the pipe to the protected tree should be 380 mm, to the unprotected - 500. 380 mm is one and a half bricks, and 50 mm fire butts rockwell stuffed on a tree.

Sauna chimney

When performing insulation of a chimney in a bath, the safety of people should be a priority. The main threat indoors comes from open flames. Therefore, it must be protected, having previously made the overlap resistant to high temperatures.

Basically, baths are built from wood, a highly flammable material. A very common misconception is the belief that sheeting the ceiling with metal sheets is sufficient. But in reality, such protection is not enough. After all, the upholstery will still heat up, which can lead to ignition. A popular solution to the problem is to insulate the chimney with red brick. But this is not suitable for every bath design.

There are currently two good options for chimney insulation:

-

Folgoizol

. A bath with such insulation will not lose heat, everything works like a thermos. At the same time, it warms up quite quickly, keeping the temperature for a long time. -

Teploizol

. The material is used for winding the chimney.

A popular solution is the use of sandwich pipes, which demonstrate a high degree of safety. The construction of the insulation consists of several sections that can be easily combined with each other. This option is also suitable for saunas with a metal stove.

Application of kaolin

Such material is produced using advanced scientific developments.Inorganic binder additives are added to the mullite-silica base in vacuum and subsequent drying of the material. To increase the strength, a clay binder is added to them.

Kaolin fibers have a number of advantages:

- safe for human health. They do not contain asbestos and do not emit harmful substances when heated; a high level of safety against fires; thermal energy losses are reduced; the material is guaranteed not to collapse even at 2001 start or stop of the furnace. It can be used in a country house with occasional use of the oven; plates are easy to process and install; low density with high thermal insulation performance affects the dimensions of the plates and allows to reduce the thickness while maintaining performance.

Chimney fire insulation

For this purpose, a wooden box is constructed from elements of the truss system between the pipe and the roof. The chimney must be located inside the box at a distance of at least 15 cm from its walls. The space between the chimney and the walls of the duct is filled with non-combustible material with low thermal conductivity (usually mineral wool).

Instead of a wooden one, you can make a welded box made of galvanized roofing steel, guided by the same principles.

The inner layers of the roof (vapor barrier, thermal insulation, waterproofing) at the point of passage of the pipe are cut and fixed with staples or nails to the transverse beams and rafters. The waterproofing layer is fixed around the roof passage with a frame. In this way, reliable isolation of the chimney from combustible elements of the roof is ensured.

There are ready-made modular chimneys, the design of which provides for thermal insulation. The modules consist of a ceramic core, a layer of basalt wool and an outer shell made of lightweight concrete. Installation of a chimney from modular blocks is simple. First, an asbestos gasket is installed between the furnace and the chimney, then a layer of mortar is applied to it, the module is placed and leveled. Each next modular block is fixed with a layer of mortar. After erecting a modular chimney, it is necessary to isolate the chimney from leaks at the point of passage through the roof.

The following method of chimney insulation is mainly used in the construction of baths. The metal chimney at the point of passage through the roof is wrapped with several layers of mineral wool and fixed with wire. Then plaster is performed with a clay-sand mixture. The pipe prepared in this way is wrapped with a layer of galvanized steel roofing, fixed with self-tapping screws and the chimney is mounted on the roof.

How to insulate a chimney pipe

With large pipe irregularities, the plaster layer turns out to be quite thick, so it is recommended that you first close up all the cracks and differences with the specified solution, and then wrap the pipe with a reinforcing mesh. A brick pipe can be sewn up with sheet iron using a layer of insulation. The easiest way to insulate a single pipe is to wrap it with a layer of non-combustible insulation, such as basalt wool, and protect it from above with metal or plaster. They wrap the heat-insulated pipe with a reinforcing mesh, fix it, and plaster it according to the technology described above in two layers with a cement-lime composition. It is necessary to isolate the passages when using any chimney: both a sandwich pipe, and brick, and metal in isolation.

Most people naively think that metal sheeting on the ceiling can serve as a fire protection and therefore the chimney is not insulated.

The chimney and stove heat up very quickly and it is therefore important to properly insulate the chimney pipe for fire safety purposes. Folgoizol is also an excellent choice for chimney insulation.

It consists of a foil in two layers and a heat insulator.Insulation helps the roof and hardwood floor to be protected from overheating and fire. It is recommended to insulate the pipe outlet in the area of \u200b\u200bthe ceiling and roof with asbestos sheets. Expanded clay is poured inside the box, which will serve as a good fire protection for the wooden floor. It is recommended that before starting work on insulating a metal chimney pipe, treat its outer part with a heat-resistant sealant.

To isolate any heating elements of the bath, asbestos and tin are usually used. Asbestos in the form of a special cloth, white on a fabric basis, and ordinary thin tin. An iron stove, which is usually used in a bath, is enough to overlay with bricks at the junctions with partitions so that the wood does not touch the iron. A brick wall can handle brick-thick heat quite well. As for the pipe, here you need to be especially careful, since fires usually start exactly at the places where it exits through the ceiling to the outside. All contact surfaces that are in contact with heating - a pipe with a roof and ceiling, a stove with a bath wall - must be insulated with asbestos sheet.

The main danger is live fire. If you do not perform high-quality insulation of the chimney, stove, ceiling and walls, then the ceiling may catch fire.

The best option for the construction of a metal chimney would be to use sandwich pipes. Condensation appears on the inner surface of a metal chimney in the event of a sharp temperature drop. To further reduce it, you need to use pipes with the thickest possible layer of thermal insulation.

The passage section in the ceiling is equipped with a special box made of wood or metal, keeping a sufficient distance to the chimney. For complete tightness of the roof, the pipe in this place must be wrapped with a special sealing tape. Proper installation of the internal waterproofing and the outer hood will ensure reliable sealing after the thermal insulation of the chimney is installed in the roof opening. Experts recommend reinforcing the insulation at the places where the cap is attached - with an elastic heat-resistant gasket. Modern roofing with corrugated board has its own characteristics - here it is better to make the chimney window a little wider. All mating surfaces are also filled with materials with thermal insulating properties.

Advantages of outdoor chimney laying

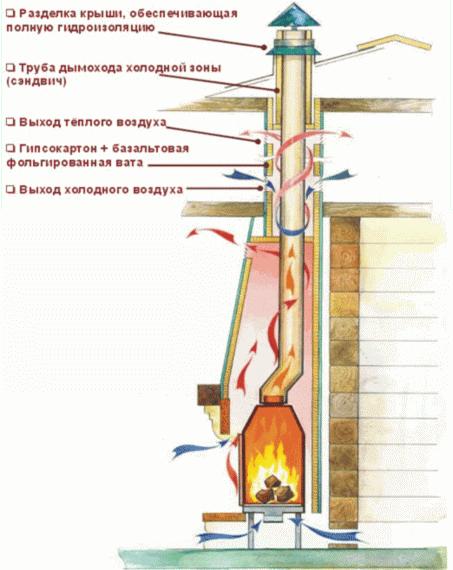

The external method of wiring the outlet pipe has the following obvious advantages:

- The removal of the main part of the outlet channel from the house allows you to increase the usable living space of the room.

- Installation of the combustion products removal system can be carried out upon completion of the main construction activities.

- External laying of the chimney will not require you to spend a lot of time and effort.

Easily eliminated shortcomings of this approach include:

- The need for mandatory insulation of chimney pipes.

- The possibility of significant heat loss with low quality thermal insulation.

- The complexity of combining the design of the chimney with the architectural style of the building.

Despite all these difficulties, when deciding how to make a chimney through a wall, preference is usually given to its external placement (full or partial).

The main methods of insulation

The metal chimney pipe is insulated using various methods.

Steel chimney insulation technique

The chimney is insulated using a special solution. The composition is prepared from a dry mixture and water. The solution is applied with a spatula to the surface, spreading over the entire area. Then a fiberglass reinforcing frame is fixed on it, on which plaster is applied.

Gas boiler chimney insulation

Insulation for pipes of a gas boiler must have a number of increased heat-insulating and heat-resistant qualities.

Sandwich chimney consists of a layer of mineral wool and two metal pipes. The upper element, with a large diameter, is the main sleeve, the smaller one is part of the steam outlet channel.

How to isolate such a chimney pipe with your own hands? You must follow the recommendations:

- In the roof of the roof and ceilings, holes are made with a diameter of 25 cm larger than the chimney channel.

- At this stage, it is necessary to insulate the chimney pipe with a layer of basalt wool. The thickness of the winding must be at least 5 cm.

- The insulation around the pipe is fixed with steel wire.

- A larger casing is put on top.

Upon completion of the work, the chimney is connected to a heating source and the surrounding riser is filled with expanded clay, clay or asbestos.

Sauna chimneys

You can isolate the chimney in the steam room using the following options:

- thermal insulation - a material made of foamed polyethylene, hidden between sheets of foil. Insulation rolls with a thickness of 2 - 10 mm are offered on the market. The foil surface reduces overheating of the pipe. The insulation is wrapped around the chimney, fixed with a wire or metallized tape;

- Filgoizol consists of two balls: a foil that saves more than 90% of the heat in the room and a heat insulator. The material is used to cover the walls and ceilings of the sauna, providing the effect of a thermos;

- sandwich pipe, consisting of several sections. This option is suitable for saunas and baths with an iron stove.

To insulate a metal pipe means to ensure the optimal functioning of the heating system. Proper installation of chimney insulation with your own hands allows you to increase the operational life of the structure and the heat generator, and also prevents fire.

The article will discuss how and with what to isolate the chimney pipe. Several practical methods are presented.

Chimney pipe insulation is required to prevent leaks and overheating. Simply put, it allows you to increase the life of the structure. Experts recommend performing complex work, which includes hydro and fire insulation.

How to insulate a metal chimney

The metal version, and in particular its insulation, deserves special attention. drawing up a construction project.

It is not always possible to isolate an already created scheme without restructuring the roof structure.

If you are building a modern structure, you can use ready-made sandwich pipes. Such designs are carried out quickly, with little expenditure on specialists.

But, they are not cheap. However, this cost justifies the long service life and ease of design.

In them, mineral wool is located between two blanks. Insulation thus comes out at the highest level.

With the help of insulation, they stop or prevent irreversible chemical reactions that take place under the influence of moisture and fuel decomposition substances.

Condensate, reinforced by the action of acid, slowly, but intensively spoils building materials. Condensation brings a particular danger during the thawing period of the pipe after winter.

The choice of material for thermal insulation

The main question of the owners of country houses with an autonomous heating system is how to insulate the chimney. In order to reliably insulate the outlets for the furnace or boiler, materials with a high degree of thermal insulation are used to ensure the thermal balance of the chimney on the roof.

Basalt insulation

Relevant for the insulation of the chimney mineral wool or basalt. Insulation is obtained from a melt of volcanic rock - gabbo-basalt. It is converted into fibers, due to which the insulating material has the advantages of:

- retains up to 95% of heat;

- characterized by good permeability of the outgoing steam;

- different chemical and corrosion resistance;

- prevents the growth of fungus and mold on the surface of the chimney on the roof;

- vibration and heat resistant;

- made of ecological materials;

- not subject to destruction under the influence of ultraviolet radiation.

Stainless steel casing

Metal "armor" in the form of a pipe made of stainless steel is used as an option for insulation. It is able to provide full protection against mechanical damage, moisture and other aggressive factors.

The casing for the chimney is mounted on a pipe on the roof. The annular space is filled with basalt wool, covered with insulation from the outside, 5 cm thick. An asbestos chimney can be wrapped with this insulation.

Wooden shields

Wooden shields are considered one of the simplest options for insulating a chimney pipe. Thermal insulation is made in the form of a wooden frame from plates of the appropriate size. On top of it, slate or other flooring is fixed, from which the roof of the dwelling is made.

After the pipe is completely covered with wood, the empty cavity is filled with felt, slag, sand, mineral wool. Frame seams are necessarily covered with a waterproofing compound.

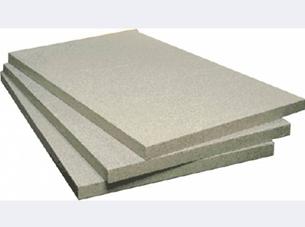

Slag-reinforced concrete insulation slabs

Insulation of the chimney in a private house using iron and cinder concrete slabs provides the smallest distance between the joints on the structure. The space inside and the corners are reinforced with mesh or wire, gypsum, clay and sand are poured in the form of a solution. Plaster is applied over the tiled insulation.

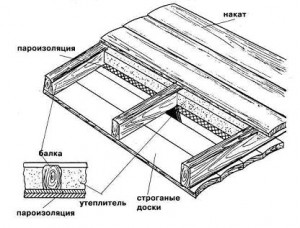

How to build a ceiling in the bath sequence of work

Of all the mentioned methods of arranging the ceiling for a bath, let us dwell in more detail on the false ceiling, since this is the option chosen by the vast majority of homemade ones.

The work includes the following construction steps׃

Installation of load-bearing beams

The beams are installed along the smallest span of the “box” of the structure with an interval of 0.5–1 m. Their height and width depend on two load parameters (permanent + temporary) and the distance between the supporting walls. For selection, special calculation tables by I. Stoyanov are used.

For instance:

Span width - 4.5 meters

Load - 250 kg per linear meter

Result׃ necessary beams with a section of 10 × 20 cm

After mounting all the beams, a hole for the chimney is formed in the formed "ladder" - perpendicular jumpers are inserted in the selected place, cutting them into the beams (by 1/2 thickness) and additionally fixing them with nails.

Vapor barrier installation

The vapor barrier of the ceiling of the bath is attached directly to the beams using a stapler, while it is necessary to leave an overlap on the side walls of 15-20 cm. For these purposes, use a regular film or special multilayer membranes reinforced with foil and a reinforcing "net" (it is recommended to strengthen the thermal insulation above the steam room in this way) . The butt joints are closed with an overlap (15-20 cm) and glued with special adhesive tape.

Interior ceiling boarding

The boards are attached to the beams with nails (2 pcs for each support), the length of which is twice their thickness. The starting crossbar is adjusted to the wall, completely cutting off the mounting groove on one side, and then the sequential laying of the wooden lining begins, helping to put the spike into the mounting hole of the adjacent element with a mallet.

Installing a heat insulator

The selected insulation for the ceiling of the bath is laid directly on top of the vapor barrier film. Please note that wadded heat insulators cannot be stored outdoors without a film, as they quickly absorb moisture. We adjust the mats of mineral or glass wool in such a way that they sit tightly in the "nests", without side slots. It is better to make a pattern with a margin and slightly compress the material than to let it “walk”.

Laying waterproofing

Waterproofing material is laid by analogy with vapor barrier, be sure to provide overlaps on the side walls. There must be at least a minimum ventilation gap between the cotton insulation and the film.

Arrangement of the attic

Edged boards are used for the attic floor, laying them similarly to the ceiling covering inside the bath.

Safety regulations

The passage of the pipe through the ceiling of the bath is regulated by SNiP 41-01-2003. This document states that:

- the passage of the bath pipe in the ceiling must be located at a minimum distance of 350 mm from flammable structures and 250 mm from hardly flammable elements;

- ideal is to leave this distance not closed (air). However, such a design will lose a large amount of heat;

- the specified distance is filled with non-combustible materials;

- the hole must be closed with metal sheets (stainless steel is more often used, which does not spoil the appearance of the room);

- the pipe in the bath through the ceiling and roof should not have joints. This factor must be taken into account when designing a chimney;

- the maximum length of the pipeline passing through the ceiling or roof should not exceed 1 m;

- The chimney must not be rigidly attached to the ceiling or roof.

As the temperature rises and falls, the pipe may expand and contract slightly, respectively. Strong fastening will lead to deformation of the pipe or passable ceiling.

The choice of thermal insulation material

The following materials can be a heat insulator:

basalt or mineral wool. The insulation is able to withstand heating up to 600ºС. The main disadvantages are: the release of formaldehyde, since the composition of the material includes resins and the instability of the protective qualities when wet, which is possible in the event of condensation;

Basalt wool

expanded clay. The material has excellent properties. When wet, expanded clay quickly restores its functions. However, to arrange the floor, you will have to additionally install containers in which the material will be located;

Expanded clay of average fraction

minerite The material consists of cement, cellulose and mineral fillers. Minerite tile is able to withstand temperatures up to 600ºС. When heated, it does not emit harmful substances, and when water enters, it does not lose its properties;

Minerite insulation

- asbestos. It is a good insulating material, however, with strong heating, it emits substances harmful to humans;

- sand or clay. Materials were used as heat insulators earlier, before the advent of modern heaters. However, some experts prefer to use natural materials rather than artificial ones.

Minerite is considered the most optimal insulation.

Pipe joint insulation

To give the joints tightness apply:

- high-strength sealants that can withstand large temperature differences;

- special clamps made of the same material as the chimney.

To ensure draft in the chimney, there should not be more than 3 - 4 pipe connections. A chimney consisting of 3 knees is considered optimal.

Positive factors of an insulated chimney

Before answering the question - how to insulate the pipe, it is necessary to highlight the advantages of an insulated chimney.

An insulated gas outlet provides protection for the heating system from the effects of the external environment and combustion products. Of course, thermal insulation cannot completely protect the structure from destruction, but it will extend its service life. This happens due to the following factors:

- Pipe insulation allows maintaining thermal balance in the middle of the structure, eliminating the possibility of aggressive acids and condensate falling onto the walls. The products of combustion are completely volatilized together with the smoke stream.

- Chimney insulation minimizes the possibility of a temperature difference between the cooled flue and hot steam.

- Increased energy-saving properties that contribute to fuel economy.

- The strength of the steam outlet structure increases due to the reinforcing frame.

Properly selected chimney insulation increases the frost-resistant properties of the system, ensures long-term preservation of the appearance and increases the service life, which is very important

Box manufacturing

Many people are afraid to make a metal box for a chimney pipe on their own. But, it does not contain great difficulties.

When making a box, you need the following tools:

- Metal scissors.

- The sheet is galvanized.

- Self-tapping screws.

- Tsyrkul.

- Drill.

Further sequence of actions:

- A hole is being prepared. Its edges must be fixed with support bars. They will create support for the box.

- A couple of parts are cut out of a galvanized sheet. At their edges, at a distance of five centimeters, a 90-degree fold is made. These U-shaped parts are fastened with self-tapping screws to the prepared holes in the ceiling covering.

- Similarly, two more p-shaped blanks are prepared, and they are overlapped on already standing sheets. As a result, a solid frame of the exit made in the ceiling covering comes out.

- The next part of the action is the bottom for the box. From the same galvanized sheet, an element is cut out that corresponds in size to the opening made. In its center, a circle is drawn with a compass for the entrance of the smoke exhaust blank.

- From the central part of the bottom of the box, 4 fasteners are placed (each of them has a two-centimeter width). Then they are cut and bent at an angle of 90 degrees. As a result, a base is formed with a hole and 4 strips for fasteners.

- The bottom is attached to the walls. A chimney is inserted through the outlet and secured with a clamp. The empty space is filled with an insulating layer.

According to the proposed instructions, it is not difficult to make a box. If you follow everything exactly, the work will not be difficult even for an inexperienced layman.

Asbestos-cement pipe insulation

To complete the entire cycle of work, you will need to perform several operations:

- we clean the remains of mortar, dirt, paint from the surfaces; we assemble a finished steel protective device (casing), which consists of several parts and is put on the pipeline like a simple 2-part clamp; we put on the first part and fill the internal space with a layer of thermal insulation; , the work is carried out according to a similar scheme; at a certain distance, the pipes are fixed to the wall with self-tapping screws with dowels; after reaching the roof and before installing the protective visor, it is necessary to close the internal space between the steel lining and the asbestos-cement pipe.

Options for fire insulation of smoke extraction systems

The simplest and most reliable, but expensive way to insulate a chimney is to install a sandwich chimney made of metal or ceramic.

Kits for prefabricated chimneys include elements for fixing the structure, revision, maintenance and for connecting heating units. Their installation is simple, but you still need to follow the instructions so that safety is fully ensured.

There is another option used when installing a furnace unit - the construction of a brick chimney. Due to the low degree of thermal conductivity of bricks, its walls will not heat up to extremely high temperatures and, as a result, additional measures related to its insulation will not be required (in more detail: “How to insulate a chimney, what kind of insulation to use”). It will only be necessary to correctly perform the fire-prevention cutting of floors and roofs.

In order to save money and reduce weight, sometimes the construction of a brick chimney is completed with the installation of a ceramic or metal pipe. In this case, thermal insulation is produced according to the technology described below.

When such work is performed for single pipes, boxes made of non-combustible materials can be used.Chimneys of this type are allowed to be operated without thermal insulation, but fire protection is required in accordance with the regulations.

The relevance of thermal insulation

Moisture and smoke generated during the combustion of fuel are aggressive factors affecting the brick chimney. The temperature difference in the cold season and the accumulated moisture settling on the walls fills the microcracks with water, and the stone structure collapses from the inside. Small ice crystals press from the inside and destroy it. An insulated chimney allows this to be excluded.

During combustion, condensate is formed on the surface of the flue, which includes a chemical series of oxides. Interacting, the elements form weak acids (carbonic, sulfuric, etc.) that can destroy the metal surface. It is for this reason that chimney insulation is necessary.

Proper installation of thermal insulation helps prevent fires inside the premises and will not allow the roof to ignite. Well-heated chimney pipes improve draft in the fireplace, boiler and stove, there is less tar and burning deposits in it. The efficiency of the heating unit is significantly increased.