Installation of plasterboard structures is one of the most popular ways to prepare premises for interior decoration. With the help of GKL, you can level the walls, prepare the basis for the stretch ceiling, and even build interior walls and partitions. In order for these structures to have sufficient strength and evenness, it is necessary to mount a frame from various types of metal profiles for them. For sheathing the surfaces of the ceiling or walls, the frame will be based on guide profiles. Below we will talk about how to choose a high-quality metal profile, what sizes they are and how to fix the drywall guides correctly.

What is a guide profile for drywall

You can guess the purpose of the guides for the GKL from their name. They serve as the basis for fastening rack and ceiling profiles, set the desired direction for the entire drywall construction, and are also used to create jumpers.

Types of guide profiles

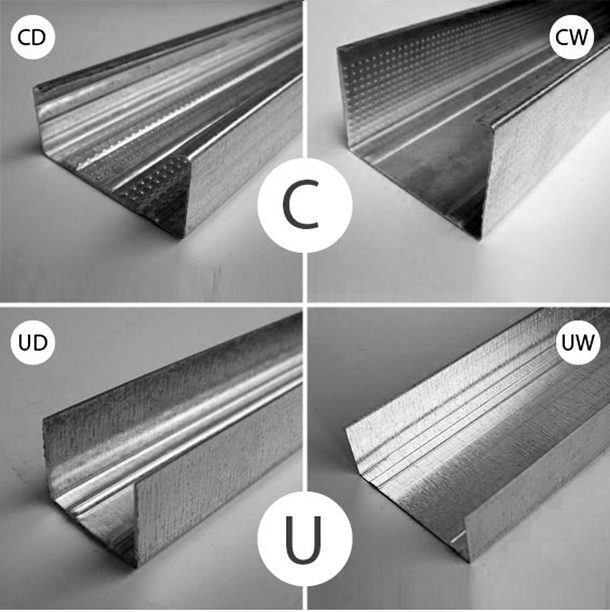

There are two types of guide metal profiles for drywall, used for:

- wall cladding (PN or UW profile);

- laying the groundwork for suspended ceiling installation (PPN or UD profile).

These two species differ in their size.

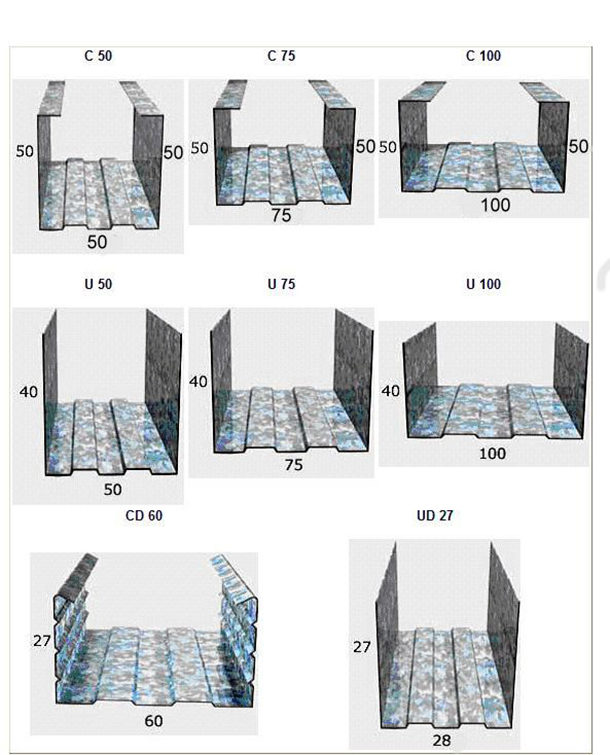

Guide profile dimensions

The dimensions of the guide profiles for walls vary in height (50, 65, 75 and 100 millimeters) and product thickness (from 0.5 to 0.6 millimeters). The width of the shelf remains unchanged - it is 40 millimeters.

The ceiling guide metal profile has a size of 28 by 27 millimeters.

The length of the guides is usually 3-4 meters, as they are used to create structures over large areas. If necessary, the length can be easily reduced by cutting off the excess with scissors for cutting metal.

Price

The price of such profiles depends both on the brand-manufacturer and on their size. A guide metal profile for the ceiling can be purchased for an average of 50-100 rubles, for walls - from 100 to 250 rubles apiece.

How to choose a quality product

In order not to make a mistake when choosing metal profiles in a store, pay attention to the following tips and tricks:

- Check the thickness of the metal and other dimensions of the product. This can be done using a special tool (caliper), or by comparing several metal profiles from different manufacturers. If the thickness of the product is insufficient, during installation, the self-tapping screws will constantly scroll due to the breaking thread, and incorrect dimensions will make it difficult to mount an even frame.

- If rust is visible on at least one product in the package, it is better to refuse such a purchase. This means that the corrosion process has already begun, and such a profile cannot be fixed to the surface.

- Abundantly oiled profiles usually indicate that the seller is trying to hide a low-quality metal coating.

- Beware of products with uneven rolling - any curvature will make it very difficult to work with them. It is quite easy to identify such a defect, because when looking along the profile, any deviations from the straight shape will be immediately noticeable. For the same reason, it is worth transporting metal profiles carefully, as they can easily bend.

- Do not buy products that have burrs and chips. This can lead to cuts during their installation.

Choosing a profile is just the case when you should not save on quality. Any errors will lead to poor-quality work, and subsequently you will have to overpay for correcting all the “jambs”.

How to fix guides

Before installing guides for drywall, you need to prepare the walls or ceiling for work. Namely:

- clean the surface of the old finishing coating;

- remove from the surface all protruding objects such as fittings or screws;

- to putty the ceiling for its preliminary alignment (in the event that there are deep cracks or depressions);

- prime the surface.

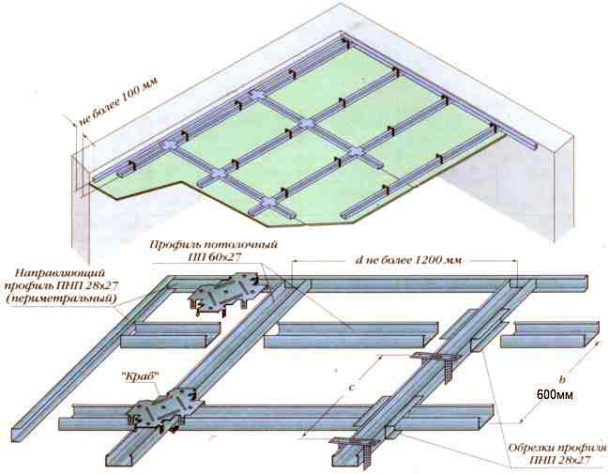

Guides for the ceiling are located on the walls around the entire perimeter of the room, for walls - horizontally along the perimeter of the room on the ceiling and floor. When fastening, they must be turned so that a rack or ceiling profile can be inserted into them.

markup

For the ceiling:

- The lowest point of the ceiling surface is located, the distance is laid off from it, by which the ceiling will fall, taking into account the size of the fixtures, communications, and the thickness of the insulation.

- With the help of a level and a chopping cord, a line is drawn along the perimeter of the room, along which the guides will be placed.

For walls:

- On the ceiling, using a level and a paint cord, mark the location line of the future plasterboard wall, transfer it to the floor with a plumb line.

- The gap between the wall and the profile should be minimal, but sufficient for wiring or insulation, the angles between the lines for adjacent walls should be straight.

Installation

The guide profile for drywall sheets must be fixed as follows:

- We lean the guide against the wall, while focusing on the perimeter line drawn with a plumb line. It is most convenient to start work from below, stepping back from the edge of the profile about 30 centimeters. We drill holes a little deeper than the length of the dowel, and fix it.

- The same holes are made in the middle and at the bottom, dowel-nails are also inserted into them.

- Now we check if the guide profile matches the line, and then we knock out the dowels with a hammer.

- We add a couple more centimeters to the distance remaining to the wall, take the required number of profiles and begin to overlap them. To do this, the sides of the profile are cut off with scissors, then the product is bent in the opposite direction, the middle is cut off, and the edges are aligned with pliers.

- All profiles are set strictly according to the markup, we drill holes at the joints and fix them with dowels.

- By the same principle, the guides are mounted on the remaining walls, as well as on the ceiling.

- Along the perimeter, the structure can be further strengthened by drilling holes in increments of 20–40 centimeters and inserting dowel-nails into them.

Such frame will allow you to easily install a wall or ceiling profile to create the basis for plasterboard sheathing.