The construction of drywall structures begins with the design and calculation of the amount of purchased material. It is easy to find out the number of profiles and GKL, but it is more difficult to determine how much fasteners are needed. Let's find out how to count the number of self-tapping screws per drywall sheet.

What kind of self-tapping screws are used when installing GKL?

For fastening drywall to the frame, screws of different lengths are used:

- 25 mm - when installing GKL in one layer;

- 35 mm - when sheathing in two layers.

The type of self-tapping screws is selected based on the material of the frame:

- the cladding is attached to the profile with metal screws;

- to a bar - on a tree.

It is easy to distinguish between them: hardware designed to work with metal has a more frequent thread.

Do not use one type of screws instead of another: this will definitely affect the strength of the fastening.

Fastener design provides convenience and quality of work:

- The hardware is protected from corrosion by a special coating that gives them a black color.

- The pointed thread spiral ensures easy penetration of the self-tapping screw into the metal profile and securely holds it there in the future.

- The cone head is recessed into the material and does not interfere with subsequent finishing.

- A deep cross-shaped slot on it allows you to screw in a self-tapping screw with a conventional screwdriver or a screwdriver.

When using a screwdriver, you need to act carefully: there is a high risk of drowning the screw too deeply and ruining the material. Facilitate the work special nozzle for drywall: due to its design, it limits the screwing depth of the hardware.

Professionals use screwdrivers with automatic feed. They facilitate and speed up the process of installing drywall sheets at times. But the cost of such a tool is high, so it makes no sense to purchase it for a single repair.

Recommendations for positioning and screwing

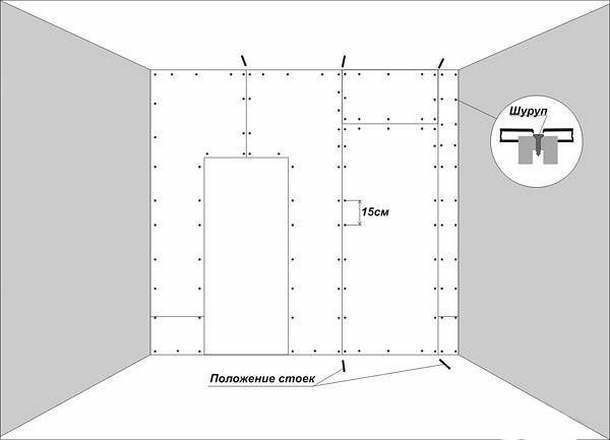

Before calculating how many self-tapping screws will go to the structure, it is logical to familiarize yourself with the rules and regulations for their placement. Here the following nuances are taken into account:

- The distance between adjacent screws must be more than 10 cm, otherwise, when screwing in, the sheet gypsum will begin to crumble.

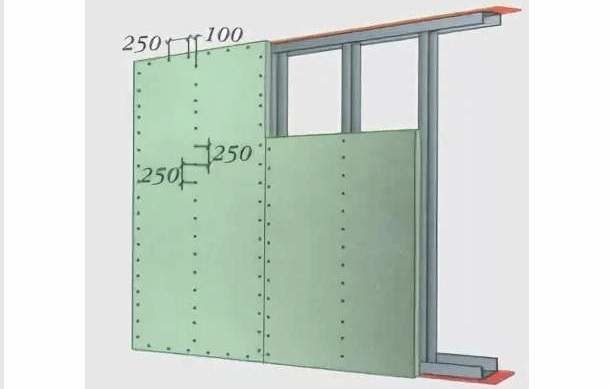

- When leveling walls or installing partitions, a step of 25–35 cm is taken between the attachment points. It is reduced to 15–20 cm if it is planned to cover the surface with heavy material, such as ceramic tiles, in the future.

- More hardware goes to the ceiling sheathing, since they are attached more often: the step is 15–20 cm. The rule works here: the thicker and heavier the drywall, the smaller the distance between the attachment points.

- When installing in two layers, the first one is fastened less often - every 45–60 cm. The screws that fix the second layer are 10 cm longer. When screwed in, they additionally fix the first one. This reduces the consumption of hardware and frees you from unnecessary costs.

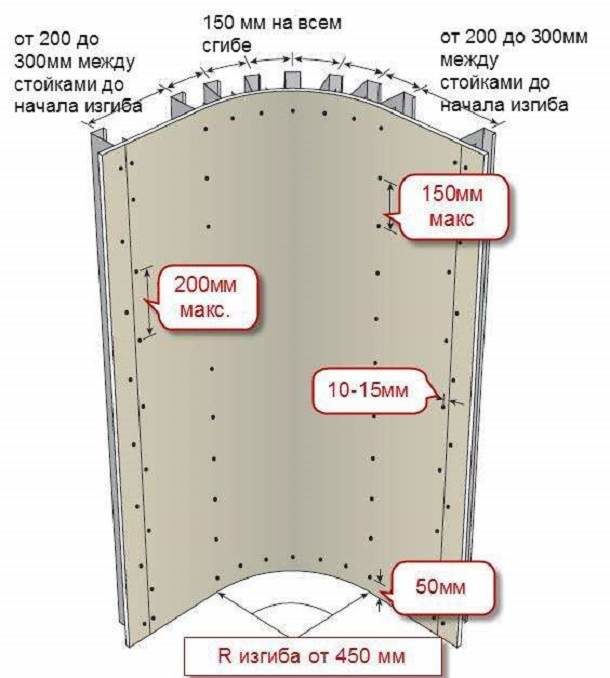

- The number of required attachment points increases with the construction of curved structures. Here the pitch between the screws is chosen so as to fix the desired surface shape.

Calculation of the number of screws

It is produced according to the frame scheme drawn up. It is clear that the number and dimensions of the guides, as well as the jumpers between them, will be individual for each case. General recommendations are as follows:

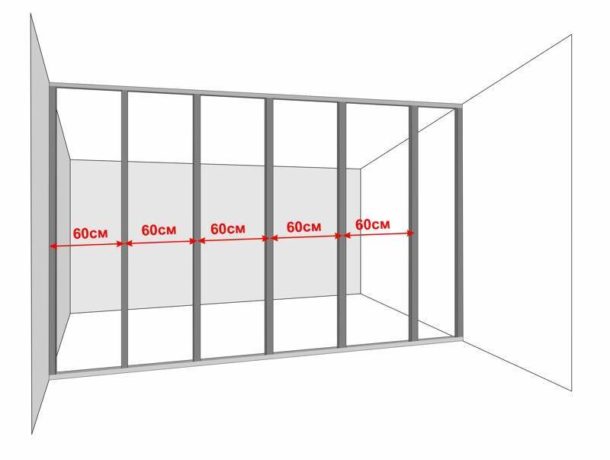

- For walls, the distance between the guides is 40 or 60 cm. This step allows you to place the joints of the sheets on the surface of the profile.

- The number of horizontal jumpers depends on the dimensions of the room (one sheet of drywall is often not enough in height), as well as on the requirements for structural rigidity (required when building partitions, and when leveling walls, they can be neglected).

- For ceiling structures, frames are constructed in the form of cells with dimensions of 40 × 40, 40 × 60 or 60 × 60 cm. This structure ensures a minimum of trimming and joining of elements on the profile.

Having drawn a frame plan, you can calculate how many hardware will be needed to cover it with GKL. For example, to mount one standard sheet to a frame on a wall with a post spacing of 40 cm, you will need:

- 11 self-tapping screws for each post (the sheet is located vertically, its length is 2500 mm, the fastening pitch is 25 mm).

- Based on 4 racks - 44 screws.

- Plus 6 - for fastening to the upper and lower horizontal jumper (three for each - it is enough to place one self-tapping screw between adjacent vertical posts).

- A total of 50 pieces will go to the sheet.

Similarly, the number of screws for fixing individual fragments is calculated, after which all the results are summarized.

Consumption of self-tapping screws per 1 m2

Table of consumption of fasteners for wall cladding in one layer according to the Knauf system (C 623.1):

Name | Quantity per 1 sq. m |

|---|---|

| Dowel-nails K 6/35 | 1,6 |

| Screws for connecting profiles LN 9 | 2,7 |

| Self-tapping screw TN 25 | 17 |

For double wall cladding (C 623.2):

| Name | Quantity per 1 sq. m |

|---|---|

| Dowel-nails K 6/35 | 1,6 |

| Screws for connecting profiles LN 9 | 1,5 |

| Self-tapping screw TN 25 | 7 |

| Self-tapping screw TN 35 | 15 |

For a partition with drywall fastening in one layer (C 111):

| Name | Quantity per 1 sq. m |

|---|---|

| Self-tapping screw TN 25 | 34 |

| Dowel-nails K 6/35 | 1,6 |

For a partition with a two-layer sheathing (C 112):

| Name | Quantity per 1 sq. m |

|---|---|

| Dowel-nails K 6/35 | 1,6 |

| Self-tapping screw TN 25 | 14 |

| Self-tapping screw TN 35 | 30 |

For false ceiling:

| Name | Quantity per 1 sq. m |

|---|---|

| Screw LN 3.5 x 9 mm | 1,4 |

| Self-tapping screw TN 25 | 23 |

| Dowel for mounting profiles PN 28/27 | 0,7 |

| Anchor dowel | 0,7 |

Online self-tapping calculator for a drywall sheet

In order not to do manual calculations or check yourself, it is convenient to use our calculator, which calculates according to the Knauf formula.

Tip from ibuilder.decorexpro.com/en/. Fasteners often break and are lost, which leads to an increase in the consumption of self-tapping screws, therefore, it is better to buy them with a margin of 10-15%. This type of fastener is universal, and the surplus will be useful for subsequent repairs, so the costs are justified.