Types of insulation

When soundproofing sewer pipes in apartments, the following options are used:

Use of "silent" pipes. In the assortment of some manufacturers you can find "quiet" pipes. The material for such pipes is multilayer high-density polypropylene. At the moment, they have only one minus - this is a high cost.

Use of materials for soundproofing. The drain system, with densely applied soundproofing material, works almost silently. Types of material used:

- foamed polyethylene;

- fiberglass;

- roll insulation;

- synthetic rubber;

- soundproof tape;

- mineral wool;

- polyethylene foam;

- various porous materials.

Any of the presented materials is distinguished by its soundproofing abilities, and each has characteristic features that should not be forgotten during installation. Otherwise, soundproofing will not be suitable for your case.

Attention! Soundproofing must be done very carefully in order to avoid damage to the entire sewerage system.

Causes of noise in the sewer

Now in any home you can find a large number of communications that are designed to make the life of modern people easier and more comfortable.

But sometimes there are situations when communications can cause discomfort and inconvenience, for example, noise from a sewer riser.

This problem can occur not only in apartments, but also in private houses, since several factors influence the occurrence of noise in the sewer.

Noise from sewer pipes can cause a lot of trouble

Of course, most often noise occurs in the main riser, since the maximum volume of water passes through it, which creates vibrations and, accordingly, can become a source of noise.

There are several types of noise that can accompany a sewer riser.

- Firstly, noise can occur when the waste stream hits the elements of the pipeline.

- Secondly, the appearance of extraneous sounds can cause the presence of air in the system.

- The last and most intense type of sewer noise is structural noise, which is caused by the contact of parts of the sewer with the wall surface or other elements.

As already mentioned, rapid sewage streams create vibration, which is the reason that the riser begins to come into contact with other surfaces, and this is accompanied by a characteristic knock.

Properly executed soundproofing of sewer pipes will help to get rid of the discomfort associated with noise.

Varieties of soundproofing material

To date, there are quite a few options for soundproofing materials for soundproofing pipes. Among the most common materials are:

foamed polyethylene;

Foamed polyethylene is well suited for soundproofing sewer pipes.

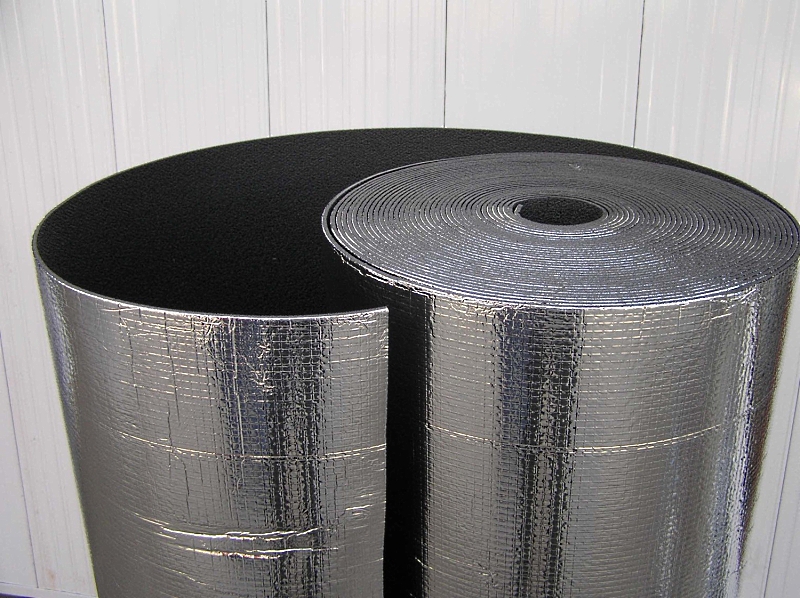

roll insulation.

Roll material is a great way to soundproof

These are the two main types of soundproofing material that are effective and reliable.

But in order to accurately determine the type of material, several factors must be taken into account.

First, it is necessary to pay attention to the level of noise absorption of materials. When choosing a material, consider the amount of decibels it can absorb.

When choosing a material, consider the amount of decibels it can absorb.

The label of any material indicates the number of decibels that it is able to absorb, of course, the higher this indicator, the better.

The second thing to pay attention to when choosing a soundproof material is the outer base, since the harder it is, the longer the material will last without losing its original properties. A lot of people try to make noise insulation with mounting foam, but this is wrong, because it is not able to absorb noise

A lot of people try to make noise insulation with mounting foam, but this is wrong, because it is not able to absorb noise.

NEVER use mounting foam for noise insulation. There will be no effect!

What is the cause of the noise

What can cause this:

- Incorrect installation of the heating system.

- System breakdown.

- Failure to comply with building codes for soundproofing the system.

And now let's take a closer look at the third point, which will help solve one of the most common problems of soundproofing heating pipes in an apartment. It arises due to poor-quality implementation of building codes by developers.

Heating pipes should be laid in the inter-wall and in the inter-gender space using "sleeves".

In practice, it often happens that builders either do not use a “sleeve” or sound insulation, or they may not use either the first or the second.

The hole is simply filled with cement mortar, which after a short time begins to crack and crumble, as a result, extraneous sounds and even smells enter the apartment through such cracks.

To fix this flaw you need:

- Clean out the remnants of the old mortar around the pipe as best as possible.

- Wrap the pipe with soundproofing material (asbestos fabric, fiberglass) or cement this area.

- If the heating system was installed using “sleeves”, then we also perform point No. 1, but we clean only inside the “sleeve” itself! Then we seal the resulting gap with silicone sealant.

Let's talk about soundproofing radiators and heating systems in general.

Application of a special screen

The appearance of such a screen

A screen with soundproofing material is attached in front of the radiator, covering its entire area.

But the top and bottom of the radiator must be left open space for free air circulation. Cold air will rise from the floor to it, heat up and return to the room again, but already warm.

The screen can be made of various materials, choose any color for it, which will easily fit it into the style of any room. The disadvantage of this method of soundproofing is that with the absorption of sound, the screen also absorbs part of the heat.

Vibration compensators for the heating system

Today it is an effective method of combating sound vibration, it also compensates for thermal expansion and deformation of pipes of the heating system, they are made of heat-resistant rubber.

An excellent solution for the correct operation of the entire system as a whole and in particular the sound insulation of the heating system.

Another way is to attach a heavy load to the heating system, the handle of which must be securely fastened to the pipeline, and the load itself can be hidden in the floor.

We use a vibration compressor

A no longer suitable cast-iron radiator or weight can serve as a load, the main thing is that the weight is about 50 - 60 kg. Of course, this method is not suitable for every room.

Now you can safely start soundproofing your heating system!

Do-it-yourself soundproofing of sewer pipes

Noise isolation of sewerage in the house should be carried out on the basis of specific goals. Let's consider several ways:

- 1 way: method using a special shell

- Method 2: using rolled insulating material

- Method 3: soundproofing pipes by installing a drywall and mineral wool box

1 way: method using a special shell

prefabricated shell

Special skills are not needed, you just need to insert the joint into the joint on both sides of the material:

You can use prefabricated polyethylene shells

Method 2: using rolled insulating material

Soundproofing a pipe using insulating material (video instruction):

Method 3: soundproofing pipes by installing a drywall and mineral wool box

If it is necessary to carry out soundproofing of sewer pipes in a house or apartment, then you can give preference to sewing the pipes with a drywall box, additionally wrapping the pipes with rolled material or foamed polyethylene.

This method of isolation is carried out in the following way:

-

- it is necessary to prepare the pipes, namely to paint over and check their tightness, so that after they are sheathed with a box there are no problems with leakage;

- wrap the pipes with soundproofing material (we have already considered their types, choose any);

Wrap the pipes with soundproofing material

make markings for the box on the wall, here you need to take into account that the walls of the box should be at a distance of 5-6 centimeters from the pipes;

Markup for the future box

-

- on the marked places it is necessary to mount the profile using self-tapping screws or dowels;

- the third profile will be attached from the wall to the floor, for this it is necessary to draw lines on both surfaces that will run perpendicular to the already attached profiles and determine the point of intersection of the lines;

- we mount the starting profile in the places of the drawn lines;

- we install the last third profile for the box at the intersection of the lines on the floor and ceiling;

- it is necessary to attach jumpers at a distance of 40-50 centimeters from each other;

It is necessary to make such a design

-

- we fasten drywall to the finished box, it is better to give preference to moisture resistant. When installing drywall, you need to leave a hole for organizing an inspection hatch;

- having screwed one side of the box, it is necessary to fill its space with mineral wool, the denser the soundproofing material will be laid;

The penultimate stage of pipe soundproofing

we sew the second side of the box and carry out finishing work.

Ready. Pipes are lined with a box

Soundproofing of heating radiators

Bimetallic and aluminum heating radiators are good for everyone, except for one thing - they perfectly transmit sound. Sound waves through pipes easily penetrate even through very thick walls. Many new owners of such lightweight radiators have found that communication between rooms is almost as good as over the phone. A crying child, a loud conversation, any noise propagates through metal pipes and causes resonant phenomena in radiators. How to solve a similar problem?

The most radical way to deal with increased audibility in the area of \u200b\u200bradiators is to completely replace them. Heavy cast-iron constructions almost do not vibrate, so the sound that reaches them is perfectly damped. Of course, modern cast-iron batteries look very presentable and stylish, but the disadvantages of this method are obvious: this is a very costly undertaking both in terms of money and time. In addition, you will have to wait until the end of the heating season.

If, nevertheless, a decision is made to replace aluminum radiators with cast iron ones, the required number of sections should be recalculated. For example, for houses with a two-pipe heating system, the temperature in which is controlled depending on the outside temperature, it is recommended to increase the number of sections.

Another way to improve sound insulation is to install a special sound-absorbing screen in front of the radiator. It is made from OSB sheet, chipboard or ordinary plywood. A layer of dense material capable of absorbing sound is attached to the inner side, for example, mineral wool covered with a cloth, etc. The screen is installed in front of the radiator, placing fasteners to the right and left of it.The space above and below must remain open to allow free air circulation. However, it should be remembered that, along with unwanted sounds, such a screen will also absorb part of the heat intended for heating the room, which will lead to an increase in heating costs.

For soundproofing heating radiators, you can use a stylish and convenient screen. Inside it should be covered with a special dense fabric that absorbs sound.

Please note that before starting work on soundproofing, it is necessary to check whether the batteries are really “to blame” for the problem. To do this, radiators are covered with several layers of dense fabric, for example, a warm blanket.

If the noise level has decreased, the reason is really in the radiators. If the voices from the adjacent room remain loud enough, you need to look for another source of problems with unwanted sound.

Vibration can also increase due to insufficiently strong fastening of the elements of the heating system. In this case, you should:

- inspect radiators;

- check the reliability of fasteners;

- clean the area around the radiators;

- close up all the cracks found with a solution;

- reinforce loose brackets;

- check the condition of the openings in the ceilings through which the heating pipes pass;

- fill these holes.

To prevent sound from propagating through the heating system, an obstacle should be placed in its path that will dampen the sound waves. Some craftsmen recommend replacing part of the metal pipe with flexible piping. Perhaps in this way it will be possible to reduce the vibration of the heating pipes. But replacing part of the heating system with non-design material can lead to breakdowns.

You can try to attach a heavy metal part to the heating pipes in the ceiling. It can be a cast-iron weight weighing about 50 kg, the handle of which is rigidly fixed on the pipe, and the rest is hidden under the floor covering. It will be necessary to leave a small hatch to facilitate the removal of additional cargo during repairs.

An effective option for soundproofing heating radiators can be the use of vibration compensators. They are made of durable heat-resistant rubber and perfectly dampen sound vibration.

You should think about sound insulation and protection of the heating system even at the stage of its design and installation. To do this, use special elements - vibration compensators. They are flexible inserts made of composite synthetic rubber. It is a heat-resistant material with a long service life, capable of withstanding high pressure and a sharp change in working conditions. Vibration compensators allow you to protect the heating system from possible water hammer, longitudinal or transverse displacements, compensate for the expansion of the pipeline due to temperature changes, etc.

(0 votes, average: 0 out of 5)

Symptoms and Diagnosis

If a characteristic hum appears in the pipes, it is possible:

- a large amount of deposits accumulated on the walls of the pipes, which led to a narrowing of the lumen;

- there is a water leak from the system;

- there are devices with a too small diameter in the system.

To establish the cause of the noise more precisely, you should inspect all elements of the heating system and find the place of the leak

If the pipes look intact, no steam or streams of flowing water are visible, you need to pay attention to the connecting elements and valves, perhaps the leak occurs here

Sometimes it is difficult to determine the place of leakage, since it is hidden by a layer of insulation. To accurately diagnose the problem, you should invite a professional plumber.

If there are no leaks, and the pipes are buzzing, you need to find the source of the sound. Most likely, it was in this place that the pipe clearance became too small due to accumulated mineral deposits or debris that got into the system. Eliminate the problem by flushing the heating system.This is detailed in the video:

Usually a good plumber can identify parts of the system that are not the right size, causing pipes to hum. It is possible that such an element will have to be replaced or modified. Of course, such work should be done as best as possible, in full accordance with the technology, so that new causes for unpleasant noise in the pipes do not appear.

Note! In the elevator unit of an apartment building, a special washer is usually installed to control the flow of water. Often, one of the residents dismantles this element in order to increase the amount of coolant in the system.

Such unprofessional interference can cause quite a lot of noise.

Clicking sounds and the characteristic sound of bubbling water can be caused by air trapped in the system. To fix the problem, it is enough to bleed excess air from the radiators, for example, using a Mayevsky crane. Clicks can also indicate the presence of foreign objects, debris in the pipes. In this case, you should clean the system.

If air has entered the heating system, it can cause clicking and gurgling sounds. To release air from the system, you should use the Mayevsky crane

For more information on how to remove an airlock from a heating system, read our article: https://aqua-rmnt.com/otoplenie/documents/udalenie-vozdushnoj-probki.html.

Intermittent crackling, knocking and clicking may occur if:

- there are small foreign particles in the pipes;

- parts of the system are worn out;

- the ventilation valve has broken;

- the unstable operation of the system caused the expansion of the metal.

In order for the crackling in the heating pipes to stop, sometimes it is enough to drain some of the water with debris. In other cases, you will need the help of a professional plumber to repair or replace damaged items.

Sometimes the cause of noise in the heating system is a heating pipe overgrown with deposits and particles of rust. This pipe should be flushed or replaced.

It is not uncommon for a vent valve to break due to improper installation, for example, when the valve is installed in the wrong direction. Such an error can lead to significant damage to the entire heating system.

The reason for tapping may also be the condition of the brackets on which pipes and heating radiators are attached. The loosened bracket moves under the influence of metal expansion-contraction processes, which causes knocking. To stop this unpleasant phenomenon, it is enough to strengthen the old brackets or replace them with new ones. Sometimes special gaskets are installed between the pipe and the bracket.

Soundproofing methods

Sound insulation of sewer pipes (as well as gas and water pipes) in an apartment can be performed in several ways:

- Use of soundproof pipes.

- Use of thick-walled pipes.

- The use of pipe shells.

- Damping of vibrations of the pipeline.

The methods mentioned above allow you to nullify the sound that the sewer riser transmits. Ideally, initially find out exactly why the pipe is making noise: these options are suitable for eliminating various causes.

The first 3 will dampen shock, resonant and atmospheric noise, and the fourth will minimize vibration.

By the way, mounting foam, mistakenly considered a good way to deal with noise, is not at all suitable for solving the problem. It practically does not delay the sound, even in large quantities.

Use of thick-walled and/or soundproof pipes

In order for the pipe not to be a source of unpleasant noise, special plastic products are now being produced:

- With thickened walls.

- The composition of which includes a filler that reduces the elasticity of the product.

Limestone, chalk, marble powder or flour are usually used as a filler.

The use of such products is suitable in cases where a complete replacement of the pipeline is planned. You can recognize them by special markings: a silent pipe has a white color, and parallel stripes of red and green are applied along its entire length.

Use of pipe shell

The option mentioned above is suitable in cases where a major overhaul is planned in the apartment with the replacement of risers. If we exclude such serious work, you can do it yourself much faster by using the shell.

Typically, such products are used for thermal insulation, but in addition to heat, the material also retains noise.

The pipe shell is a cylinder with a cross section along the entire length. For putting on a pipe, this section opens. For fastening on the pipe, glue, electrical tape, or wire is used.

The main thing is to get the tightest possible connection so that noise cannot enter the room. This applies not only to the transverse section, but also to the longitudinal joints (between adjacent shells). Any looseness can spoil the effect: the sound will still be heard through the gap.

Grooved foam shell

You should decide on the material of the insulator. Why? Because each of the materials has its own properties, and to a different extent is able to retain noise. Let's make a list in decreasing (in terms of efficiency) sequence:

- PPU.

- Extruded polystyrene foam.

- Styrofoam (regular polystyrene foam).

You need to pay attention to the density and thickness. The denser and thicker the insulator layer, the more effective the result will be.

Alternatively, a cheaper insulator made of foamed polyethylene or rubber can also be used. However, these materials are porous, and they do much worse at damping noise.

It is strongly not recommended to use mineral wool cylinders, since the material itself is not suitable for sanitary standards. Mineral wool causes irritation on contact with the skin.

Also, its microscopic fibers can cause serious harm if they enter the respiratory system. In addition, mineral wool also has a not too high density, which means that it dampens noise worse than the materials from the above list.

Using the shell with your own hands is extremely simple: you just need to fix the cylinder along the entire length of the pipeline, tightly closing the joints.

Damping pipeline vibrations

Another way that you can do it yourself is to prevent the pipe itself from oscillating. Very often, when installing a pipeline, gaps remain between the pipe itself and the wall.

Damper on the pipeline

Even a few free millimeters lead to noise: moving in the hole, the pipe beats against its walls. This not only creates an extraneous sound, but also harms the riser.

To dampen these oscillations, 2 methods can be used:

- The use of a "glass" (used in places where it passes through the ceiling).

- Use of a damper clamp (used in places where it passes through walls).

In the first case, the role of the "glass" can be played by the shell described above. At the point of passage through the ceiling, a cylinder is put on the pipe, which fills the gap and does not allow the structure to move, hitting the walls. This is the easiest way to eliminate noise with your own hands.

In the second case, you can replace the standard clamp with a new one (the old ones become unusable over time, weaken, and cease to hold the pipeline well). As an option, you can not change the damper, but simply seal it by stuffing dense rubber gaskets into the gaps that have arisen.

What to isolate

Insulation needs a sewer riser and pipeline. It is extremely rare for water pipes to be isolated, and in any case, the method of work will be the same. Insulation of a gas pipe in an apartment is almost never required.

By the way, only plastic pipes can be called "noisy".Cast iron sewer, despite its tendency to blockages, is almost silent. Why - we will mention below:

- Cast iron - the material is not elastic, and therefore - not sonorous (due to the peculiarities of its composition).

- The inner walls of cast iron are very quickly overgrown with plaque. This is harmful due to the risk of traffic jams, but such deposits absorb noise.

Types of noise

Conditionally produced noise can be divided into several types:

Pipe sound insulation of risers

- Impact: when flowing water hits the walls of pipes.

- Resonant: when extraneous noise is transmitted through the pipe.

- Vibrating: when the vibration of the building, internal structures, partitions is transmitted through the pipe.

- Atmospheric: when wind is heard in the chimney passing through the ventilation shaft.

Almost always, all these factors are combined. During the day, water passing and beating against the walls will make noise in the pipe. At night, the wind blowing into the ventilation shaft and the vibration of the pipeline will be heard.

By the way, water and gas pipes also transmit vibration and resonant noise. This often happens if the water and gas risers are loose in the holes in the wall (which is quite common) and can move.