Metal pipes for water supply and heating are in less and less demand among consumers, giving way to modern analogues. The choice in favor of metal-plastic and polypropylene communications is not just a tribute to fashion. Pipes made of these materials are indeed superior in some respects to traditional cast iron and steel structures. It is difficult to say unequivocally which pipes are better - metal-plastic or propylene. The preference for one of these materials depends on the particular situation. In order not to make a mistake and make the right choice, you need to know their characteristics and differences.

Polypropylene pipes

Raw materials for manufacturing polypropylene pipes and fittings is a random polypropylene copolymer of the third type. This modified material has many positive properties, which makes it possible to use such pipes in hot and cold water supply. In addition, due to its chemical resistance, polypropylene is used in the construction of process pipelines used to transport substances with a wide variety of properties.

It is immediately worth noting that polypropylene belongs to a group of materials called thermoplastics. This means that it softens and melts under the influence of high temperatures. Its melting point is 170 degrees, and at 140 degrees Celsius it loses its hardness.

The nominal temperature that high-quality polypropylene products can withstand varies within 75 ° C with short-term jumps up to + 95 °. For this reason, polypropylene products are not recommended for use in heating systems. An exception - reinforced polypropylene pipesthat belong to a separate category.

Polypropylene products do not bend, so all turns of the pipeline are carried out using special connections - fittings. The elements of the system are fixed using a special welding machine. It heats up the material of the parts that are securely glued together.

Advantages of polypropylene

- tightness of connections - thanks to this, such pipes can be used in hidden heating and water supply systems, embedding them in the floor or walls, without fear that they will leak;

- resistance to corrosion and long service life - 50 years;

- high mechanical strength;

- constant inner diameter throughout the entire service life - the smoothness of the inner walls prevents the appearance of scale and various deposits;

- good sound insulation - you can not hear the noise of water in the pipes;

- fairly simple and quick installation - the process of welding joints takes a minimum of time;

- no interaction of the material with chemically active substances - does not affect the composition of water, without changing its taste, smell and color;

- environmental friendliness - polypropylene is absolutely harmless to humans, and its processing does not harm the environment;

- high plasticity and ability to expand - the pipes endure freezing and, after thawing, return to their original shape and size without deforming or bursting;

- relatively low cost.

Flaws

- the impossibility of using conventional non-reinforced polypropylene products in systems with a constant high temperature;

- big thermal expansion – it is necessary to take this into account when installing hot water supply and heating system. It is impossible to hide pipes under the finish close, otherwise, when they expand, it will be damaged;

- the need to use a large number of various fittings for wiring, the cost of which in total can be quite high;

- the impossibility of connecting pipes without a special soldering iron and handling skills.

Reinforced polypropylene pipes

If we are talking about reinforced polypropylene pipes, then they are distinguished by improved technical properties. Such products have an additional layer of aluminum foil or fiberglass.

The operating temperature regime provides for a liquid temperature of up to +95°C with a short-term increase to + 120°C. In addition, these products withstand high pressure. Thanks to these characteristics, reinforced pipe products can be used in the heating system in an apartment.

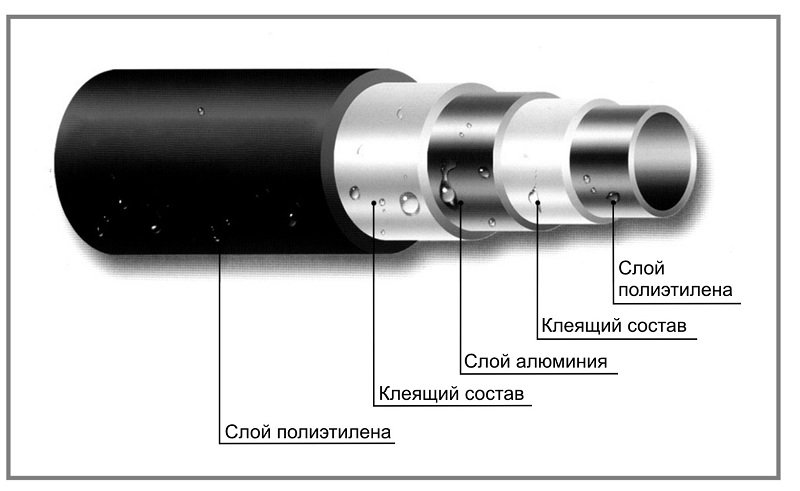

metal-plastic

Pipe products made of metal-plastic are multilayer reinforced structures, the frame of which is an aluminum pipe with a thickness of 0.2 to 2 mm. Outside and inside the product has a shell made of PE-X polymer. The plastic layers are bonded to the aluminum with an adhesive.

Due to the smoothness of the plastic surface, they do not clog like steel and cast iron. The aluminum layer prevents the penetration of oxygen into the pipes, increasing their service life, and significantly reduces the thermal expansion of plastic.

The working temperature of metal-plastic products is +95C, the maximum is +130C. The pressure that they are able to withstand at 95 ° C - 10 atmospheres, at 25 ° C - 25 atmospheres.

Pipes made of metal-plastic can be easily installed and changed independently. They are connected by compression fittings with threaded adapters. However, the reliability of such connections may be insufficient, especially with a non-professional approach. It is better to invite a master for these purposes. A press fitting is considered a much more reliable method, but it requires a special tool - press tongs.

Advantages of metal-plastic pipelines

- light weight;

- flexibility - allows you to do without a large number of connections and does not require accurate measurements of linear dimensions;

- quick and easy installation;

- high temperature resistance;

- low thermal expansion;

- ability to withstand high pressure;

- impossibility of occurrence of corrosion;

- high throughput and no deposits on the walls - as well as polypropylene pipes;

- rather low thermal conductivity;

- resistance to various substances.

Many of the advantages of polypropylene and metal-plastic tubular products are similar, so the choice of material will be more influenced by their disadvantages.

Disadvantages of metal-plastic

- combustibility;

- intolerance to direct sunlight;

- low resistance to mechanical stress and damage;

- the need for mandatory providing access to connections to control possible leaks;

- narrowed flow section of fittings;

- poor tolerance for temperature changes;

- higher than polypropylene, the risk of a breakthrough at the junction.

Thus, there is no single answer to the question of which pipes are better. The main thing to be guided by when choosing is the operating conditions of the water supply.