Preparatory work before drilling a well

The first stage of preparation is the conduct of geodetic reconnaissance. It is carried out in several ways:

- assess the terrain, the proximity of natural reservoirs;

- interview neighbors and old-timers;

- use reference literature;

- trying to determine the drilling site by dowsing;

- invite experts in geodesy.

The latter option is the best if it is planned to drill a powerful well that will last for more than a dozen years.

The scientist who is cited for his exquisite research on hydraulics, and who worthily upholds the honor of the name illustrated by so many engineers, M. de Caligny, explained this fact by the sudden collapse of matter that flows from the water supplying the Grenelle well, or from a discharge of gas collected near the bottom holes of this well, and which will go into the tube. One or the other of these two reasons would lead to understanding, due to the sudden fall of the rising water column. This way the copper tube will no longer be pressed from the inside to the outside, and the mud water that surrounds it should then smooth it out right away.

Exploration drilling is an effective way to determine the depth of a future well

The next step is to obtain permits if the drilling depth exceeds 30 m. However, the first water-resistant layer rarely lies deeper. But you should not relax: the well will need a document - a passport, which indicates all the parameters of the source.

This explanation is very plausible, and we do not realize that this was not indicated in the recording of the sessions of the Academy. Of course, this silence cannot be due to the opposition of this point of view and the gaze of the eternal secretary. Other explanations for the same phenomenon have been given, but they all have their weak points, and we will pass them on silently.

From the explanation presented by M. de Caligny, there was an indication of the means to be used to prevent further flattening of the inner tube, which had to be replaced by the one that had just been removed. It was necessary to give this tube a thickness proportional to the pressure, which could once again deform it. The old copper tube could only resist 10 atmospheres; The new one can carry seventy; instead of copper, beaten iron will be used.

If the hydraulic structure was drilled independently, obtaining a passport is impossible and additional difficulties will arise in case of operational problems. To avoid this, as well as to accurately determine the drilling location, depth and potential power of the source, it is recommended to use the help of specialists in the installation and launch of hydraulic structures.

Professionals will perform a full range of work, share recommendations for efficient operation. The source will last a long time and will regularly supply water, no matter how deep the aquifer is.

sand wells

Schematic of a sand well.

They are drilled using a screw method - penetration is carried out in soft rocks: loam, sand and pebbles. Excavation diameter ≥100 mm.

There are 2 types of sand wells by depth:

- up to 40 m - on the upper layer with a flow rate of 1 m³;

- 40-90 m - deep trunks with a water flow rate 2 times greater.

A casing string made of metal or plastic pipes with a filter in the bottomhole part of the well is lowered into the drilled working. The water is lifted by a submersible pump.

Advantages and disadvantages

The main advantage is the auger drilling method, which allows you to build a well in 1-2 days without much effort. The mechanization of all operations is ensured by the design of the drilling rig on a self-propelled or mobile chassis.

Other advantages:

- water purity;

- a permit for the construction of a water intake is not required;

- service life - up to 30 years.

Disadvantages are noted in wells of shallow depth: the dependence of the flow rate on precipitation, the sensitivity of the water composition to surface contamination at the location of the mine. Another minus has already been identified - the tendency to silting of the water intake.

The concept of a well

A well is a mine working in the earth's crust, which has a small diameter compared to its length. The base of the well (on the surface) is the mouth, the bottom of the well is the bottom. Wells fall into two categories:

— exploration (drilled to calculate oil reserves at a new field);

- operational (for extracting oil from the reservoir).

An oil well is a capital structure, which is being built according to a pre-compiled technical specification. project. The basis of the project is the design of the well.

Well design refers to the number of casing strings that must be lowered into the well for successful drilling and subsequent long-term operation. The concept of well design also includes the optimal lifting height of the cement slurry in the annulus. The diameter of the well should be minimal, but at the same time sufficient to ensure the descent of casing strings to the designed depth, as well as to ensure reliable isolation of productive formations from aquifers and from the mutual influence of formations from each other. The drilling speed and the cost of well construction depend on the chosen well design.

Well design is selected based on factors:

— geological;

— technical and technological;

- economic.

How to make a well in the country

Almost every owner of a country house, and even a villager, wants to have a well on his site. Such a source of water from which it would be possible to constantly obtain high-quality water.

It is worth noting that if the water is at a depth of up to ten meters, then such a well can be drilled independently. This is not such a laborious process as it might seem at first glance. We need a standard pump. It will pump out water and at the same time, in a sense, drill a well.

Video-how to drill a well in the country

Let's move on to the drilling process itself. It should be noted that the pipe that we will lower into the well must be located vertically. Water will be pumped into this pipe using a pump. The teeth should be located at the bottom end of the pipe. Such teeth can be made by hand. Water, which is under pressure from the lower end, erodes the soil. Since the pipe is heavy, it sinks lower and lower, and soon reaches the aquifer.

Video-how to drill a well under water

In order to really get drilling, we need only a pipe made of steel. The radius of such a pipe must be at least 60 mm (preferably more). Such a pipe will serve as a casing pipe. The length of such a steel pipe must not be less than the depth of groundwater. The end of the pipe, which we close at the top with a flange and a special fitting.

To do this, we use a pass-through fitting. Through this element, water will pump through the hose. We also need to use a welding machine. With it, we will weld four "ears" with special holes. These holes should fit the M10 bolts.

As a water tank, we will take a barrel with a volume of 200 liters. In order for us to somewhat speed up the drilling process, we need to shake the pipe and turn it a little either clockwise or counterclockwise. Thus, we will wash out a large amount of soil. For the convenience of pipe rotation, we can use a gate. To do this, take two metal tubes and attach them to the pipe. For these purposes, we can use special clamps.

For drilling, several people are needed (two are possible). In the place allotted for the well, a hole is dug. The depth of such a pit must be at least 100 cm. A pipe is lowered into this pit. And the jagged end down. Next, using the collar, deepen the pipe. It is worth noting that the pipe must be in a vertical position. Next, we turn on the pump. The hole will fill with water. We scoop it out. Then it can be spilled through a sieve and poured back into the barrel. It is quite possible to drill six meters in a few hours.

Here you can read:

how to drill a well for water, how to drill a well for water video, how to drill a well, how to make a well for water, how to make a well for water on the site video

When is it more profitable to carry out drilling seasonal features

The seasonal peak in demand for drilling is summer and the first month of autumn. Indeed, the conditions are ideal, the ground is solid and it is possible to equip a source of any type, regardless of depth.

In spring and late autumn, demand is minimal, there are no queues. This is due to the large amount of precipitation and the specifics of the technology. In winter, there are more chances to save money: but in cold weather it is better to only drill, and postpone the arrangement until warmer weather.

In the off-season, you can drill artesian wells: in spring or autumn, work is carried out to slaughter deep sources for sand and limestone. Can be drilled:

- If there is a good road to the site.

- When the site is not landscaped.

From surface sources in the off-season, it makes sense to equip an igloo or an Abyssinian well. The casing pipe is installed during drilling, being at the same time a drill - shedding of the walls does not slow down the work. Usually, the slaughter is carried out manually: in wet soil, the passage is facilitated and occurs faster.

Flaws:

- There is severe damage to the area.

- The extracted wet soil is difficult to dispose of; during rains, the dirt spreads throughout the site.

- High risk of errors in determining the depth, difficulties with the installation of equipment.

The best conditions for drilling any well are summer and autumn. The groundwater level is the lowest. The soil is compacted, the equipment is easy to deliver even off-road. After completion of work, only dry soil from the trunk will remain on the site, which is easy to remove.

Advantages:

- It is easier to choose a time without precipitation to organize work.

- There is no risk of collapse or flooding of the trunk with perched water.

- It is possible to carry out work in the complex: drilling with simultaneous arrangement.

- Ideal conditions for all types of sources: surface and deep.

Of the shortcomings, it is worth noting the heavy workload of drilling crews. It is better to order summer drilling in advance: 4-5 months before the planned procedure. It is also better to negotiate the cost in advance and make an advance payment. Increased demand stimulates seasonal price increases. Equipment should be purchased in advance: at the peak of the construction season, prices for materials for arrangement also increase.

The winter period is ideal for slaughtering deep artesian wells. Advantages:

- Clean area after work.

- The lawn is not damaged.

- The integrity of the soil is not violated.

- Drilling will cost less - there is a seasonal decline in demand.

- Minimal risk of depth errors.

The disadvantage of winter drilling is the uncomfortable working temperature for the craftsmen and restrictions on the installation of equipment: it is impossible to install a pipeline and connect pumps at temperatures below -5o. There is a way out: assemble the pump group in an isolated room or basement, or postpone the piping until warmer weather.

In winter, not only heavy equipment works: you can make a sand well without unnecessary dirt and at a bargain price. On the video: how a compact installation works on a landscaped area in winter.

Drilling is a job for specialists. You need to choose the type of source and the season for work not on your own, but after a complete analysis of all the initial data. Masters will tell you which type of water intake will be cheaper, when it is faster and more profitable to carry out

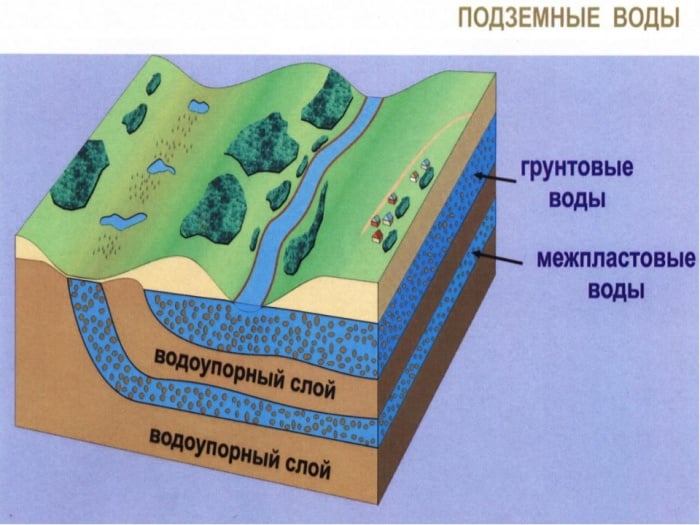

What sources underground

Geological sections for land plots are not the same, but there are patterns in aquifers. With a deepening from the surface into the subsoil, underground water becomes cleaner. Water intake from the upper levels is cheaper, it is used by owners of private housing.

Verkhovodka

A water resource located in the ground near the surface above a water-resistant layer of rocks is called a perch. Waterproof soils are not available in all areas; it is not always possible to find a suitable site for organizing a shallow water intake. There is no filtration layer above such lenses, harmful substances, organic and mechanical impurities penetrate the soil with rain and snow and mix with the underground reservoir.

Verkhovodka is characterized by such indicators:

- Depth. On average 3-9 m depending on the region. For the middle lane - up to 25 m.

- The reservoir area is limited. Manifestations are not found in every locality.

- Replenishment of reserves is carried out due to precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If there are no harmful chemical contaminants in the composition, the water is improved to drinking water by the filtration system.

Verkhovodka is well suited for watering the garden. When drilling shallow wells, you can save money: sinking is available for self-execution. Option - the device of the well with the strengthening of its walls with concrete rings. It is not recommended to draw water from the upper deposits, if fertilizers are used near the land plot, an industrial zone is located.

Primer

Verkhovodka is a disappearing resource, unlike the primer, which is the first permanent underground reservoir. The extraction of perched water from the bowels is carried out mainly by means of wells; wells are drilled to take the primer. These types of groundwater have similar characteristics in terms of depth −

Ground features include:

- The filter layer of rocks. Its thickness is 7-20 m, it extends directly to the layer located on the impervious platform of the rocky ground.

- Application as drinking water. Unlike top water, for which a multi-stage cleaning system is used, the removal of mechanical impurities from the primer is done by a downhole filter.

Groundwater recharge is stable in forested and temperate regions. In dry areas, moisture can disappear in summer.

Sources between layers

Groundwater scheme.

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled at this level.

Signs of lenses interspersed with rocks:

- pressure water, because it takes on the pressure of the surrounding rocks;

- there are several productive water carriers, they are dispersed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Stocks of individual lenses are limited.

The quality of water in such deposits is better than in the upper levels. The depth of distribution is from 25 to 80 m. From some layers, springs make their way to the earth's surface. Groundwater exposed at great depth due to the stressed state of the liquid rises along the wellbore to its usual proximity to the surface.This allows for water intake by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular in the arrangement of water intakes for country houses. The flow rate of a sand well is 0.8-1.2 m³/hour.

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³ / hour. This amount is enough to provide several country houses.

- Purity of water: penetrating into the bowels through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The enclosing rocks determined the second name of water intake workings - wells for limestone. The statement refers to porous varieties of stone.

On an industrial scale, the extraction of artesian moisture is carried out for commercial purposes - for the sale of drinking water. In areas located in lowlands, it is possible to find a pressure deposit at a depth of 20 m.

Well design elements

The upper part of the well is called the mouth, the bottom is called the bottom, the side surface is called the wall, and the space bounded by the wall is the wellbore. The length of the well is the distance from the wellhead to the bottom along the axis of the wellbore, and the depth is the projection of the length on the vertical axis. Length and depth are numerically equal only for vertical wells. However, they

do not match for deviated and deviated wells.

Figure 5.2 Well design. 1 - casing pipes; 2 - cement stone; 3 - layer; 4 - perforation in the casing string and cement stone; I - direction; II - conductor; III - intermediate column; IV - production string.

Well design elements are shown in Fig. 4.1. The initial section I of the wells is called the direction. Since the wellhead lies in the zone of easily eroded rocks, it must be strengthened. Therefore, first they drill a pit - a well to the depth of stable rocks (4 ... 8 m). Then a pipe of the required length and diameter is installed in it, and the space between the walls of the pit and the pipe is filled with rubble stone and poured with cement mortar 2.

The downstream sections of the well are cylindrical. Immediately behind the direction, a section is drilled to a depth of 50 to 400 m with a diameter of up to 900 mm. This section of the well is fixed with casing pipe 1 (consisting of screwed steel pipes), which is called conductor II.

The annular space of the conductor is cemented. With the help of a conductor, unstable, soft and fractured rocks are isolated, which complicate the drilling process.

After installation of the conductor, it is not always possible to drill a well to the design depth due to the passage of new complicating horizons or due to the need to cover productive formations that are not planned to be exploited by this well. In such cases, another column III, called intermediate, is installed and cemented. If the productive formation, for which the well is intended to be developed, lies very deep, then the number of intermediate columns may be more than one.

The last section of the IV well is fixed with a production string. It is designed to lift oil and gas from the bottom to the wellhead or to inject water (gas) into the reservoir in order to maintain pressure in it. In order to avoid oil and gas flows into the overlying horizons, and water into productive formations, the space between the wall of the production string and the well wall is filled with cement mortar.

Technology of drilling an artesian well for water

When ordering the drilling of an artesian well, it is desirable to control the entire drilling process from start to finish in order to understand what the drillers are doing and whether they are cheating, simplifying their work. This article is intended to make it clear to the owner of the land the technology of drilling artesian wells for water (for limestone), in order to properly accept work from drillers and not waste money.

The technology of drilling an artesian well for water includes 3 stages:

- The destruction of the rock.

- Removal of rock from the well.

- Arrangement of the walls of the well with casing pipes.

For drilling wells, mobile drilling rigs based on MAZ, ZIL and KamAZ trucks are used (imported drilling rigs are also based on tracked vehicles for difficult terrain). The method of drilling is called rotary, because a rotor on a drilling rig is used to rotate the bits.

As a drilling tool, a cone bit of different diameters is used. Transportation of drilled rocks to the surface is carried out using a special solution that enters the well through the drill rod.

The upper rocks are drilled with a large bit (it is not known whether one, two or even three pipes will have to be used to casing an artesian well, and to place them one inside the other, a larger drilling diameter is needed, so they are drilled with a large bit first).

In the process of removing soil rocks, the driller must record changes in the rock in the drill log.

When passing unstable rocks, a clay solution is used to flush the well. If drilling starts immediately with clay layers, then the solution itself will turn out to be clay. To make clay mortar artificially, bentonite clay is used (sometimes with a little cement added).

When the drill reaches solid limestone, drilling is stopped for a while and the well is equipped with a casing pipe of the largest diameter to protect the walls of the well from shedding and penetrating surface water from the overlying soil layers.

Depending on soil types, up to three casing pipes can be used to equip an artesian well (for example, if clay veins are present in hard limestone rock). The design of three casing pipes is called telescopic.

After the well is cased to limestone in the casing, the limestone is drilled with a smaller diameter bit (in this process, the limestone is flushed with clean water so that the dirty solution does not enter the clean aquifer after drilling is completed). Then, a production perforated pipe is lowered into the drilled hole. Pipes are washed until clean water appears.

A very important point when drilling an artesian well is the isolation of the lower clean layers of water from the upper ones. Compactonite material is used for high-quality insulation. These are granules of dry clay, which, when meeting with a moist environment, swell several times, preventing the penetration of moisture into the well. This method of isolation is reasonably more expensive than the others. Before ordering drilling, be sure to check what kind of insulation the drilling company uses.

Upon completion of all work on drilling an artesian well, drillers make all the necessary measurements and check the well. Then the owner is issued a passport, which indicates the depth of the well, the debit, the height of the water level and other characteristics.

Pipes for artesian wells

For artesian wells, as a rule, steel pipes are used as casing, but metal-plastic pipes are also becoming popular now. Welding was used to connect pipes, but it has proven to be a risky connection method. Therefore, pipes with threaded connections are now being produced. Pipes made of plastic and its types, as well as steel pipes, are used as operational pipes.

Abyssinian well

Abyssinian well for water.

The tubular well got its name from the territory in Africa, where the technology of extracting groundwater from the bowels of the earth was first used without the use of special equipment.

Self-drilling of wells is performed in this old way. Water intake is carried out from a depth of 8-13 m.

Sequence of work:

- A drill string is assembled from 1-2 m pieces of pipes Ø2 ″, it will also serve as a casing.The drill filter is made by flattening the downhole end of the first pipe or a nozzle on the cone rod for better penetration into the ground. Holes of 6-8 mm are drilled in the walls of the drill, so that water enters them, they are wrapped with a metal filter mesh.

- A shock headstock is made from a guide pipe Ø100 mm 1 m long, weighted with metal weighing 10 kg, handles are welded on both sides.

- The drill filter is driven entirely into the ground, after which the next section of the column is attached to it by welding or threaded connection. Having hammered the pipe after the drill, the operation is repeated until the filter penetrates into the aquifer.

- A manual or electric vacuum pump is connected.

The tube well is pumped until clean water appears. The quality of the liquid is checked in the laboratory of the sanitary and epidemiological station.

Advantages and disadvantages

The advantage of the Abyssinian water intake is the ability to build it yourself with minimal investment. The well-needle is completely isolated from the perched inflow. A tubular well can be hammered into the ground from the basement of your house.

There are few disadvantages:

- the impossibility of using a submersible pump due to the small diameter of the column;

- the need to clean the well from sand and silt;

- restrictions on soil properties: the method is used on soft rocks and coarse sands.

The service life of the water intake is ≥30 years. A prerequisite for longevity is the periodic extraction of silt and sand from the casing string. This is done with the help of a bailer - a cylindrical vessel with a valve lock.