Characteristics of polyurethane foam

PPU is popular not only because applying polyurethane foam with your own hands is a fairly simple process. This material has excellent characteristics:

- thermal conductivity coefficient 0.019-0.028 W / m * K;

- vapor permeability tends to zero;

- density 30-60 kg/m. cube;

- does not burn - according to GOST 12.1.044 refers to slow-burning materials;

- does not absorb moisture - the percentage of closed cells is from 85 to 95.

The efficiency of floor insulation with expanded clay under the screed is lower than with foam plastic or mineral wool.

This also applies to the insulation of frame walls with expanded clay. Plus, it's quite heavy.

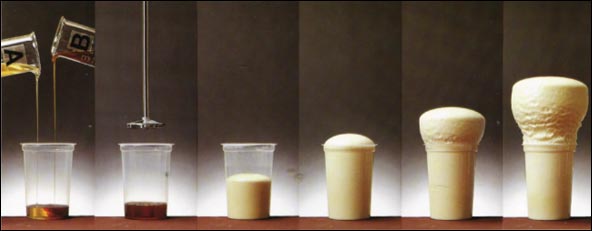

It has good adhesion (adhesion) with all materials. Due to the almost complete water tightness, PPU protects metals from corrosion. In the characteristics of polyurethane foam, there is also such a thing as start time. This is the number of seconds it takes for foaming to occur. The start time for different types of work is slightly different. For horizontal surfaces the foaming time should be in the order of 5-10 seconds. To insulate the ceiling, this period is reduced to 3 seconds.

Polyurethane foam application equipment

Polyurethane foam sprayers come in high and low pressure. The main elements are a compressor and a spray gun in which the PPU components are mixed. In low-pressure equipment, mixing occurs at 5-10 atmospheres, and in high-pressure equipment, at 100 atmospheres or more.

Different pressure affects the mixing method:

- at low pressure, the components are mixed by swirling;

- at high pressure, mixing is carried out by diffusion of the components.

Fibrous insulation Isobox, according to reviews. performed well in use.

And the leader in this niche is Rocklight stone wool insulation. made from basalt.

Low pressure units are smaller, cheaper, easier to operate. In them, you can set the mixing ratio (1:1 or 1:2) and smoothly adjust the performance directly in the process. High-pressure installations allow you to create a more even layer of thermal insulation, you can work at a distance from tanks with mixed components up to 125 meters. The productivity of such equipment is much greater (up to 500 square meters in 8 hours). These are professional installations, and therefore they are quite expensive.

Interesting on the topic:

- How to make a styrofoam crusher

- Mineral wool Rocklight: characteristics

- Isobox insulation: technical specifications

- Insulation Penoplex: technical characteristics.

Basement floor insulation

Basements, especially damp ones, also need high-quality insulation. In order to properly insulate the floor in the basement, you first need to isolate the surface from excessive moisture. Roofing material and bituminous mastic are suitable for waterproofing the floor.

Step 1. Waterproofing device

The floor in the basement is covered with roofing material, leading its edges 20 cm onto the walls. At the joints, the material is overlapped and the seams are coated with bituminous mastic to make the base as airtight as possible. Along the perimeter of the basement, the roofing material should fit very tightly to the walls, so their surface is also covered with mastic and the waterproofing is pressed.

To avoid deformation of the protective layer, a screed is poured over the roofing material

If the basement is not too damp, for waterproofing, you can coat the brick walls with mastic to a height of 10-15 cm, paying special attention to the joints of the floor and walls

PPU basement insulation

Step 2. Applying polyurethane foam

After mixing the insulation components and connecting the hoses, they begin to apply thermal insulation from the corner to the exit. Spraying must be done in 3-4 layers, adhering to the same level over the entire area of \u200b\u200bthe basement.

Step 3. Pouring concrete screed

The surface of the insulation is checked with a level, areas with large differences in height are leveled. A screed solution is prepared and applied over the polyurethane foam in equal portions. Using the rule, the mortar is leveled over the entire area so that the thickness of the screed is at least 5 cm. After hardening and drying of the mortar, tiles, linoleum or other topcoat can be laid on the screed.

Scope of polyurethane foam

There is soft foam and hard foam. Soft polyurethane foam is a foam rubber used to make mattresses, pillows for furniture, etc. Rigid PPU is used for the production of car seats, parts in military equipment. Recently, PPU has been gaining more and more popularity as a heater in civil engineering.

For spraying you need a compressor and a special gun.

It is sprayed on vertical and horizontal surfaces, used for the production of thermal insulation boards. For spraying polyurethane foam with your own hands, special equipment is required, we will talk about it later. PPU is also used for pipe insulation. There are special steel pipes that are covered with polyurethane foam and a protective polymer casing. Such products are used for laying communications in the ground. In addition, the production of shells of different diameters for thermal insulation of communications has been launched.

Panels are made from polyurethane foam:

- sandwich - when the insulation is covered on both sides with profiled tin;

- facade - a decorative layer is applied to the thermal insulation. In appearance, it is indistinguishable from natural stone or clinker tiles.

In civil engineering, liquid polyurethane is blown into cavities between walls. This can be done both at the stage of erection of the enclosing structure, and at the end of the work. The advantage of this material is that it fills all the cavities, creating a monolithic heat-insulating carpet.

Properties and characteristics

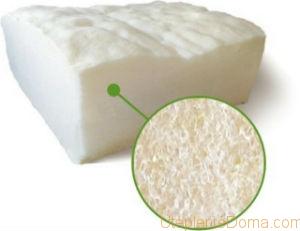

Polyurethane foam is made from two polymers - polyol and polyisocyanate. Before applying to the surface, the components are mixed, heated, and carbon dioxide is added. They spray insulation under high pressure, which makes it possible to effectively isolate even hard-to-reach places under the roof or between communications. After hardening, the material is a durable hard coating without seams with a bumpy surface.

Appearance of polyurethane foam

This heater has many positive properties:

- low thermal conductivity;

- complete tightness;

- environmental friendliness;

- resistance to chemicals;

- light weight;

- durability.

In addition, the material has excellent sound insulation, does not allow moisture to pass through, is easily applied to any surface and is very firmly attached to it. Due to its high adhesion, the insulation is securely held even on the smoothest surfaces. Polyurethane foam does not ignite, it is not afraid of mold, insects and rodents, it tolerates sharp temperature fluctuations without consequences.

The use of this insulation makes it possible to do without additional fasteners, waterproofing materials and primers, which significantly reduces the cost of the heat-insulating process.

The scope of polyurethane foam is quite extensive:

- internal premises of residential buildings;

- exterior walls of buildings;

- roofing;

- attics;

- loggias and balconies;

- baths;

- garages;

- sewer systems;

- floors and foundations.

To perform thermal insulation with polyurethane foam yourself, you must have skills in working with a spray installation. To begin with, you can practice on some section of the outer wall under the guidance of an experienced master. Subject to safety precautions, you can work with the installation without fear. Of course, professional equipment is not so easy to master, but now there are compact disposable installations on sale, the principle of which is much simpler.

PPU production technology

Closed cell structure.

So, polyurethane foam, what is it? This is a polymeric two-component composition with a closed cell structure, a relative of the foam. The first component (A) consists of several chemical elements such as polyesters, emulsifiers, foaming agents.All these elements are non-toxic and non-explosive, they are stored in metal barrels, which are treated with special protection from the inside.

The second component (B) is a mixture of diisocyanate and polyisocyanate. These are poisonous substances, you need to be especially careful with them. At 215 degrees they ignite. Lose their characteristics upon contact with air or water. When mixing components A and B, a reaction occurs, resulting in polyurethane foam. The technology for the production of polyurethane foam may differ in the ratio of components, and this, in turn, determines the polymerization time, thermal conductivity, and density.

Making polyurethane foam with your own hands at home is unrealistic.

It's about preparing the components. All you can do is mix the already prepared reagents (which were made in the factory) before applying to the work surface. And then, for this you will have to purchase a special installation.

Portable polyurethane foam kits Foam Kit, Touch n Seal

|

№ |

MATERIAL |

SHORT DESCRIPTION |

PACKAGING |

Price with VAT |

|

rub/PC |

||||

|

1 |

Penoglas Kit 400(1 m3) |

Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 30kg/m3, >85% closed cells. Hoses, pistol, 10 nozzles included. The weight of the set is 30kg. |

PC |

19900,00 |

| 2 | FOAM KIT 200 (0.45 m3) | Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 28kg/m3, >85% closed cells. Hoses, pistol, 10 nozzles included. The weight of the set is 17.2 kg. | PC | 18700,00 |

|

3 |

FOAM KIT 300 LD (0.7 m3) |

Two-component portable set (2 steel cylinders) for the production of polyurethane foam, density 16-20kg/m3, |

PC |

18990,00 |

|

4 |

FOAM KIT 600 (1.4 m3) |

Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 28kg/m3, >85% closed cells. Hoses, pistol, 10 nozzles included. The weight of the kit is 49kg (2 x 24.5kg). |

PC |

31800,00 |

|

5 |

FOAM KIT 1000 LD (2.33 m3) |

Two-component portable set (2 steel cylinders) for the production of polyurethane foam, density 16-20kg/m3, |

PC |

38200,00 |

| 6 | FOAM KIT 200 SR (0.45 m3) | Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 28kg/m3, >85% closed cells. Hoses, pistol, 10 nozzles included. The weight of the set is 17.2 kg. | PC | 16800,00 |

| 7 | FOAM KIT 600 SR (1.4 m3) | Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 28kg/m3, >85% closed cells. Hoses, pistol, 10 nozzles included. The weight of the set is 48kg. | PC | 28600,00 |

|

FROTH-PAK Portable Polyurethane Foam Kit, Dow Chemical |

||||

|

№ |

MATERIAL |

SHORT DESCRIPTION |

PACKAGING |

Price with VAT |

|

rub/piece |

||||

|

8 |

Froth Pak 180 (0.4 m3) |

Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 28-30kg/m3, >85% closed cells. The weight of the set is 11.7 kg. |

PC |

19500,00 |

|

9 |

Froth Pak 600 (1.35 m3) |

Two-component portable kit (2 steel cylinders) for the production of polyurethane foam, density 28-30kg/m3, >85% closed cells. The weight of the set is 41kg. |

PC |

37000,00 |

|

10 |

INSTA-FLO Gun + Hose (2.3m) |

Spray gun INSTA-FLO. Contents: foam hose (length 2.3 m), 10 nozzles |

PC |

4000,00 |

|

11 |

INSTA-FLO Gun + Hose (4.6 m) |

INSTA-FLO gun Includes: foam hose (length 4.6 m), 10 nozzles |

PC |

4500,00 |

|

12 |

Wide Cover Nozzle Set |

Set of cone spray nozzles with a wide round spray, 25 pcs. |

PC |

2500,00 |

|

13 |

Set of nozzles with medium coverage |

Set of cone spray nozzles with medium round spray, 25 pcs. |

PC |

2500,00 |

|

Two-component polyurethane foam |

||||

|

14 |

PurFoam-2K, (0.012 m3) |

Two-component quick-hardening polyurethane foam, 400ml can, foam density - 35kg / m3, 80% closed cells, expansion 1:30. |

PC |

300,00 |

|

Insta-Stik Polyurethane Adhesive |

||||

|

15 |

INSTA-STIK, 750 ml |

Polyurethane adhesive for gluing heat-insulating materials |

PC |

430,00 |