The problem of good hearing is relevant both for residents of new buildings and for owners of apartments in old houses. It can be solved by arranging high-quality sound insulation. An important element of the soundproofing structure is a special vibration suspension for drywall. Let's see what it is and how to choose and use such devices correctly.

What is a vibration suspension

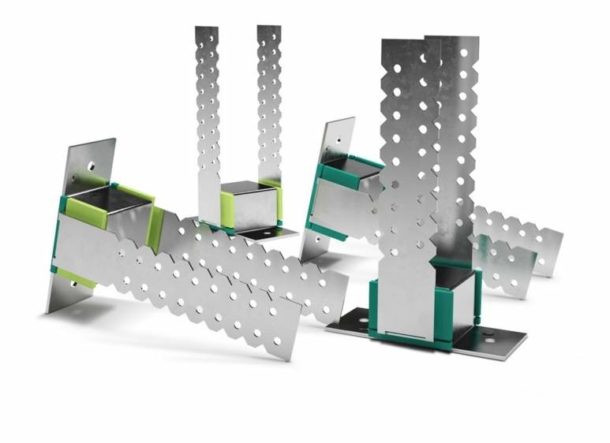

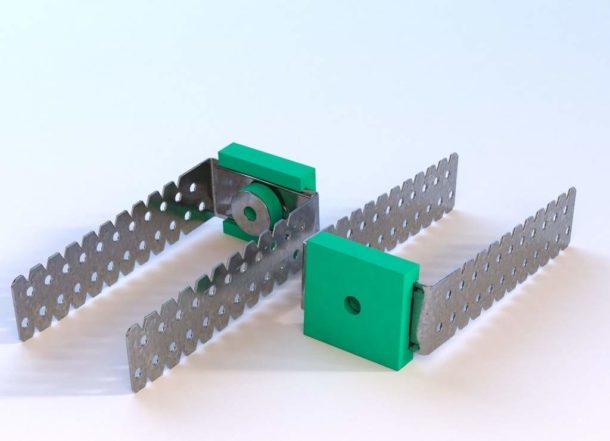

The vibration suspension is a metal U-shaped carrier profile, on the crossbar of which there is an elastic element made of rubber or elastomer based on rubber or polyurethane. This element - a vibration isolator - which plays a key role in the design of the product, allows you to exclude direct contact between the bearing plasterboard profile and the base to which it is attached. Its main task is to dampen vibrations and reduce the transmission of structural noise from the wall or floor slab to the structure frame.

On such fasteners, as well as on conventional hangers, rack profiles are mounted on the wall, and ceiling carriers - on the ceiling.

Vibration dampers are distinguished by the following characteristics:

- By application - wall, ceiling, universal.

- In size - standard, designed for mounting on a metal profile with a width of 60 mm, and "economy", designed for narrower profiles with a width of 47 mm.

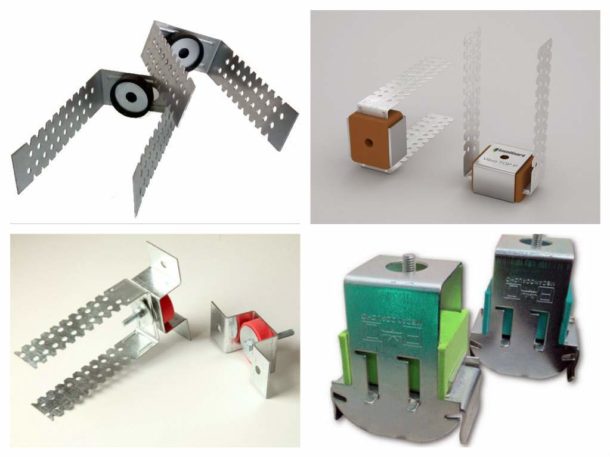

- According to the material from which the vibration isolating element is made.

- According to the fastening system.

The absolute leader in the market of special vibration damping suspensions is SoundGuard.

Advantages of products manufactured under this brand:

- High vibroacoustic efficiency, prevent the transmission of low-frequency noise.

- Effective decoupling with vibration design.

- Ease of installation.

- Versatility, many products are suitable for both walls and suspended ceilings.

- Durability, moisture resistance.

- Devices with an insulating element made of elastomer do not shrink during the entire period of use.

All SoundGuard vibration isolation mounts are compatible with Knauf profiles.

How to choose

The most important characteristic of vibration suspensions is their strength. You must be sure that they will withstand the GKL construction. These elements help metal profiles to hold drywall sheets, soundproofing material, and a layer of putty on the ceiling.

The simplest product is designed for a weight of up to 12 kg for the ceiling and 15 kg for the wall, more massive reinforced suspensions can withstand loads of up to 25–30 kg for walls and up to 20 kg for the ceiling.

The second important characteristic is the degree of sound insulation. The suspension must dampen vibrations well and suppress noise. This indicator depends on the properties and thickness of the soundproofing material on the suspension itself.

Vibrosuspensions differ in the area of soundproofing material. The larger the surface area, the better the noise and vibration isolation. They also differ in the number of mounting holes. If there is one hole on the suspension frame, the installation time is reduced by 50%.

U-shaped plates on the vibration suspension have several holes that allow you to adjust the depth of the frame. But note that these holes may vary in size from manufacturer to manufacturer. Some brands produce hangers that only fit certain screws.

How to do it yourself

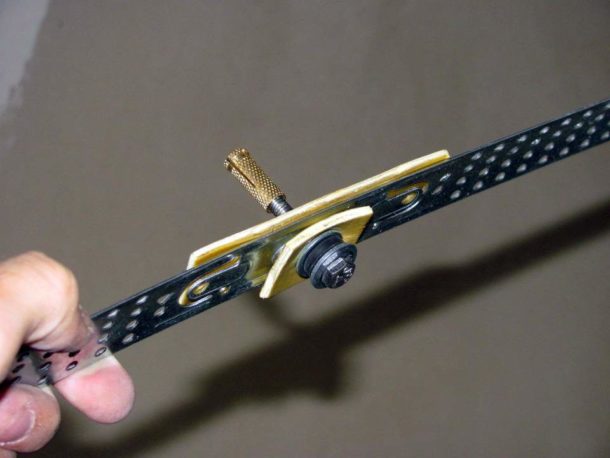

Vibrating hangers can be made by hand. This will require perforated metal plates and soundproofing material, such as foam rubber.

Such suspensions are made simply: rubber rectangles are attached to the middle of the plate from above and below. After that, the edges of the plate are bent. The hanger is ready to use.

You can use one layer of rubber, but practice shows that such suspensions are not effective enough. You can check the quality of the resulting vibration suspension using a wooden block. Hangers are fixed on top of it. After that, the bar is hit on the floor and the oscillations of the U-shaped plates are observed. The faster they decay, the better the vibration isolation characteristics of the material.

Mounting the vibration suspension

Stages of installation of a soundproof structure with vibration suspensions on the ceiling:

- The ceiling is measured using a level and the lowest angle is determined, from which the distance retreats, by which the surface will fall, taking into account the fixtures, the thickness of the sound insulation.

- Mount guides for the frame, pasted over from the side adjacent to the ceiling with sealing tape.

- They make markings for the ceiling profile with jumpers, as well as for suspensions.

- Vibratory suspensions are fixed with dowel-nails and their edges are lowered.

- Bearing profiles are inserted into the guides, fixed with hangers, jumpers are made.

- Soundproofing material is laid on the frame.

- The ceiling is sheathed with plasterboard.

The number of vibration suspensions depends on the area of the room. For one square meter of the ceiling, it is recommended to mount 3-4 suspensions. Thus, for a room of 15 sq. m you need 40-50 pieces.

Wall vibration isolation mounts are mounted according to the same principle as conventional direct suspensions.

Vibration hangers are necessary for ensuring high-quality sound insulation premises during the installation of plasterboard structures. Do not neglect these elements, they will help make the apartment quiet and comfortable. If you are doing your own repairs, follow the installation technology.