Issues during installation

Many questions arise for those who do not have the opportunity to build a house on their own and decide how to insulate their premises, what material to choose and what to do with the floor?

When there is a question about the vapor barrier of an existing room with its original data, you need to take into account the state of the ceiling. There are cases when owners stick isospan on a plastered ceiling and expect that condensation will not appear on the loggia or in another room, thanks to the magical properties of the membrane. They make a mistake in advance, isospan does not fit on structures that are already plastered or insulated with mineral wool.

Insulation of this kind does not require a vapor barrier flooring, and plaster is already a type of interior decoration. Flooring will lead to consequences that will then have to be eliminated.

To insulate the roof from the outside, a different type of material is required, type A. It will be laid for other principles and reasons. And for the insulation of the roof from the inside of the room, the flooring technology remains the same.

If during installation there was a rupture of the film, then you can seal it with construction tape. This must be done very carefully so that the sealed layer is not broken subsequently.

In addition to the vapor barrier of ceilings, such work must be carried out with respect to the floor or walls, but completely different types of membrane film and technologies for its laying can be used for this. The main thing is to figure out what type of film is needed for construction or repair work, so as not to purchase something that turns out to be unnecessary.

The use of isospan for the ceiling is described in detail in the instructions for use. If there is any doubt about the choice of material, it is best to consult with specialists. Mounting isospan on the ceiling is easy to do on your own if you study the necessary information in advance.

Briefly about the choice of materials

Above, we stopped a little at a rather important point, the better it is to insulate the ceiling of the bath. Now we want to tell you a little more

First, let's look at basalite and isospan, designed for saunas.

Basalite is an excellent material for thermal insulation of a bath ceiling. Click on the photo to enlarge.

Basalite is a lightweight and flexible tile insulator. It is made from basalt fiber, hence the name.

The scope is quite extensive. In addition to insulation, basalite is used for sound insulation. The main thing is that there are no significant loads on the surface to be coated.

As for isospan, it is divided into two varieties. Izospan A performs the functions of hydroprotection and vapor barrier. In fact, it is a membrane that counteracts the influence of moisture.

The material is often used in the construction of wall structures and roofs of buildings. Not to mention the protective properties that prevent premature damage to the insulation.

Izospan B refers to universal vapor barrier products that include two layers. The main task is a vapor barrier for thermal insulators.

Installation of the material is carried out from the inside of the insulation.

Sawdust is also suitable, covered with an earthen layer on top. Frankly, not the best way, as it has many drawbacks.

There is also expanded clay. The material is made in the form of clay capsules, fired at high temperatures. When swelling of the feedstock occurs, it is sent for heat treatment. This is how finished products are obtained.

Despite the presence of many other insulators, the insulation of the bath ceiling with expanded clay is not without meaning. The excellent thermal insulation qualities of the products are explained by the cellular structure. In addition, expanded clay is an affordable material that almost everyone can afford.

The only thing to consider is the thickness of the insulation layer. It should be at least 30 cm. Plus, do not forget about the vapor barrier and hydroprotection, otherwise the efficiency of the system will leave much to be desired.

How is it with other parts of the building?

If you are new to the insulation business, the above information may have been misleading.

We examined the ceiling in detail, but did not touch other elements of the building at all. In fact, it is necessary to insulate not only the ceiling surface, but also many other parts of the bath. These include the foundation, walls, floor, roof, etc.

And do not expect to do something quickly. In the end, you get a building, from where the heat is extremely slowly released to the outside. It will not be possible to completely block the leak. Yes, this is not necessary. Any building should be well ventilated, including a bathhouse.

In steam rooms, the warmth does not disappear immediately after the rooms are warmed up, but lasts for a certain time so that you can take a good steam bath.

Do you want to know what's to come? Check out the photo of how to insulate the ceiling of the bath, and other images presented in the article. Be sure to read our other publications on the topic. Hot steam for you!

Which side is correct to lay isospan

The first question that arises for beginners is choosing the right side of the material. The main purpose for which isospan is laid on the ceiling is to protect the insulation from moisture penetration. Therefore, for maximum efficiency in performing the required tasks, a smooth layer of material should always face the insulation. Along with this, outdoor and roofing work with this insulator has some differences. When choosing which side to put and isospan, remember that it is more important for the roof to ensure the unhindered removal of steam to the outside and protect the insulation and ceilings from precipitation. In this case, the smooth side of the material should be facing out.

Independent vapor barrier of the bath room

The steam moves up and to the sides, which means that the ceiling and walls are more affected by it. However, with poor-quality vapor barrier, it can rush into any loophole, causing damage to the material and freezing. Without waterproofing the floor in the washroom, all insulation measures will not be enough. When the floor is sealed and the walls are insulated, they start laying the vapor barrier in the sauna or bath.

Vapor barrier and insulation of the bath ceiling protects it from maximum thermal loss. There are two variants of the insulating "pie":

- The surface is sewn up with a board or a die from 5 cm thick.

- From above (outside the room) a vapor barrier is mounted.

- A layer of clay 1-2 cm is applied and mineral insulation is laid (foam glass, expanded clay, mineral wool, etc.).

- A boardwalk or a cement-sand screed is made on top.

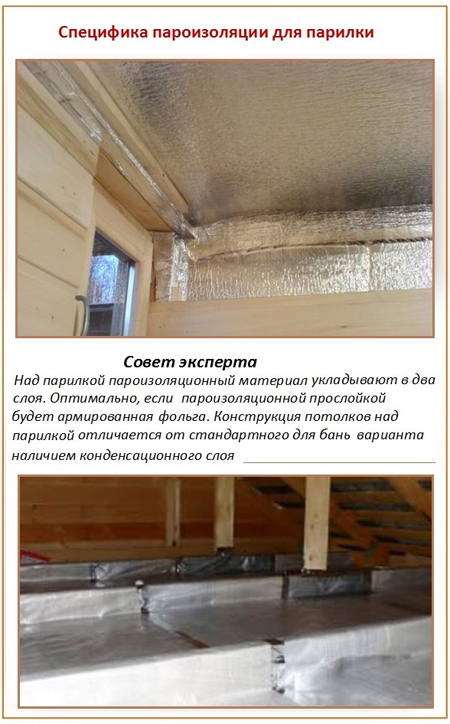

Particular attention should be paid to the vapor barrier in the steam room, where the temperature under the ceiling is maximum. Even with thick sheathing, polyethylene film can melt and impregnated materials begin to release toxic or pungent odors.

It is better to use hardwood lining, for example, aspen. When heated, resin protrudes and drips from the needles. A quality product made of expanded polypropylene is able to withstand +100 °C, film foil insulation - up to +140 °C.

The second option provides for an air gap:

- A finishing panel is assembled from a grooved board 2-3 cm thick and fastened to thick beams with a section of 20 x 20 cm.

- Boards are twice rubbed with drying oil for water resistance.

- Over the beams, transverse boards of the crate are stuffed.

- The vapor barrier is laid with foil inside the room and fixed with mounting rails. Joints are sealed with aluminum tape.

- Sand, slag or specialized insulation is poured on top.

Save money with reflective film

Installation of foil vapor barrier on the walls of the bath also requires an air gap. If it comes into contact with a sheathing or other surface, heat is conducted by aluminum, like any metal. This rule answers the frequent question of home craftsmen: which side to lay the vapor barrier? Obviously, you need to reflect heat inward, and not cold outward. With proper use, this option pays for its cost twice.

If you want to save money by choosing cheap materials for the dressing room and washing room, remember that the service life of polyethylene is very short. First of all, it cracks on the folds left from the factory packaging. They should be reinforced with adhesive tape when installing the vapor barrier. If the film has lost its tightness, the insulation will begin to dampen, so it is better to use hydrophobic products in advance. It will be more profitable to buy a vapor barrier for Isospan baths due to its exceptional durability and unique properties.

Foil vapor barrier Izospan FB is designed specifically for rooms with elevated temperatures. Its technical characteristics allow laying the film directly on the wall without additional thermal insulation. The rolled web is stretched in transverse strips and fixed with vertical slats. The sheets are mounted from the bottom up, overlapping, with a margin of 15 cm and the joints are glued with heat-resistant aluminum tape. A wooden crate for sheathing is stuffed over the vapor barrier. The gap between it and the foil should be at least 4-5 cm.

Insulation material options

The schematic diagram of the device of the insulated ceiling pie is applicable to all types of insulating materials. True, depending on their ability to pass steam, there may be some deviations, for example:

- When using extruded polystyrene, it is not necessary to lay a vapor barrier on the ceiling located above rooms with a “dry” operating mode. This type of insulation is characterized by almost zero vapor permeability, therefore it does not need additional protection.

- When arranging the ceiling of rooms with a “wet” operating mode, vapor barrier is arranged in any case, regardless of the insulation used in the construction of the pie and its characteristic properties.

- When using mineral wool of all degrees of hardness and foam plastic, the ceiling slab is necessarily protected by a vapor barrier layer.

The vapor barrier material is laid in the form of a kind of pallet, the "walls" of which should be higher than the thickness of the insulation layer. If the shield ceiling is assembled from boxes with insulation, then the vapor barrier material in this form is placed in each of them. If the thermal insulation is planned to be laid in the space between the lags, then they are wrapped with a vapor barrier membrane.

When using a polyethylene film or glassine as a barrier, a ventilation gap of 2–3 cm should remain between the insulation and vapor barrier. To do this, rails are fixed on the ceiling from the side of the premises, which at the same time serve as the basis for lining it with clapboard, decorative panels or drywall.

It is necessary to think about how best to lay vapor barrier on the ceiling during the design of the house. It is at this stage that you need to choose the best installation option and think over the mounting scheme.

However, now there is always an opportunity to correct the flaws of builders and designers, which have already appeared during the operation of the house. For example, you can correctly glue a polypropylene membrane to the ceiling. You just need to understand the characteristics and technological features of suitable materials.

Recommendations for installation and use

Vapor barrier film Izospan B is placed indoors. It is used for insulated roofs, floors, ceilings for the attic, walls. The manufacturer's instructions and information about the material give an idea which side to the heat insulator to turn the panel during the fastening process. A flat surface always adheres to the thermal insulation, while a fibrous surface remains on the outside and stops moisture from steam, preventing it from penetrating into the structure.

The vapor barrier is laid with an overlap of panels of 15-20 cm, installation is carried out from the bottom up. The connecting places require good sealing; specialized adhesive tape produced by the company and labeled FL is used for gluing.

Ribbon will work too. Izospan SL. Areas of adjunction to the structure, lathing, engineering holes and niches are sealed with a self-adhesive sealing tape, which is simultaneously pressed against the protective sheet and the contacting surface.

Installation of the film when insulating a roof with an inclined surface is carried out according to the following scheme:

- the roll is cut into strips of the required size;

- the first strip is attached from below parallel to the floor, with a smooth part to the heat insulator;

- the next tape is installed, covering the fixed film by 15 cm;

- the panels are fixed with a stapler for construction work or with galvanized nails to the rafters of the building;

- joints are covered with sealant with specialized SL tape;

- a frame frame is stuffed on top of the vapor barrier, forming a gap of 40-50 mm;

- cladding material is attached to the wooden slats.

Izospan B is fastened during floor (ceiling) insulation in stages:

- canvases creep with the rough side to the base floor (ceiling);

- the places of adjunction to the surface of the walls and the joints of the tapes are smeared with glue with SL tape;

- heat insulator lays down on a smooth film surface;

- waterproof Izospan C spreads from above;

- floor covering is being installed.

When fixing the vapor barrier on the internal walls and partitions, the panel lies directly on heat insulator and attached to wood slats. First of all, a frame frame is stuffed on top of the film, forming a gap for ventilation of at least 30 mm. With further cladding with gypsum, the installation is performed on a zinc profile.

The use of Izospan B, protecting heat insulator and wall surface from the manifestation of moisture, extends the operational life of thermal insulation and the entire structure of the building.

Vapor barrier laying Technology, mistakes

Some features of the pie device on the ceiling

In general, when constructing an insulated ceiling pie, the same ceiling vapor barrier scheme is used, regardless of the type of materials used for insulation.

However, their throughput can make some changes, so it is important to know how to properly lay the vapor barrier on the ceiling.

In particular, we are talking about the following:

- The use of extruded polystyrene foam in rooms with a low level of humidity allows you to skip the vapor barrier layer. This is explained by the fact that a heater of this type practically does not allow moist warm air to pass through, therefore, it does not require additional protection.

- In rooms with a high level of humidity, a vapor barrier layer must be present, regardless of the type of thermal insulation material and its characteristics.

- The laying of mineral wool of any hardness and foam plastic is always accompanied by the use of a vapor barrier material.

In the process of deciding how to put isospan on the ceiling, it is necessary to ensure that the edges of the insulating material are located at a higher level than the upper edge of the insulation. In other words, the thermal insulation is placed in a kind of bowl made of vapor barrier material.In the case of a panel ceiling, a vapor barrier material is placed in each box under the insulation. When laying thermal insulation in the space between the ceiling joists, they should be wrapped with vapor barrier material.

The method of using vapor barrier material must be considered at the design stage

At the same time, it is important to choose the right laying method and options for fixing the material. With the advent of new technological materials for insulation on the market, it became possible to correct the mistakes made during the installation of the vapor barrier layer.

The main thing is to know the characteristics of the insulation used, how to put isospan on the ceiling, as well as the technological features of the selected material.

Izospan B characteristics and specifics

Regardless of the purpose of the building being erected, protection against steam and moisture should be installed. It is for this purpose that the Izospan B film was developed. It is a propylene panel, one side of which is smooth, and the other is covered with perforations that create roughness. After unfolding the material, the question arises of which side to the heat insulator it is necessary install? To properly fix the vapor barrier film, you need to figure out how it works.

The main purpose of the film is to protect the heat insulator from getting wet, and the room from the penetration of small particles of material for thermal insulation. This is all the more necessary when placed as insulation min. cotton wool, which is more sensitive to moisture manifestations and has an unpleasant characteristic of distributing small fibers.

The flat surface of the canvas forms a sealed vapor barrier, and not a slippery coating is a place to collect condensate, which is later eroded. The film has the following technical properties:

- resistance to direct ultraviolet exposure for 3-4 months;

- steam resistance - 7;

- density - 72 g / m2;

- breaking load - 130 (longitudinal), 107 N / 5cm (transverse);

- composition - 100% polypropylene;

- moisture resistance - 1000 mm aq. pillar;

- operating temperature - from? 60? up to +80? C.

Membrane fabric stands out for its reliability and elasticity, it well protects metal structures from corrosive processes, and heat insulator and wooden elements from fungus and mold. The product is produced in a roll with a width of 1.4 and 1.6 m, area - 35, 70 m2.

Floor vapor barrier instruction

Mounting Izospan on the floor

Everyone knows that moisture is the enemy of wooden buildings. It has a significant, sometimes negative effect on wood. Disastrous results can be avoided only through high-quality vapor barrier.

Why Izospan

The advantages of using Izospan in comparison with other methods of vapor barrier are obvious:

- on the one hand, it isolates wood from moisture;

- on the other hand, it in no way affects the flow of air, without which, of course, the wood will not last long.

Types of Izospan for the floor

This material has gained popularity among consumers as a non-alternative option for floor insulation. Which Izospan is right for you? It is unambiguously difficult to answer, but let's imagine the varieties that are most suitable for isolating the floor from moisture.

- Izospan AM is a universal tool that can act as insulation for both roofs and walls, and for floors to protect insulation in unheated attics. It is mounted with the white side to the heater.

- Izospan AS is a three-layer membrane, durable, suitable for floors. It is applied similarly to Izospan AM.

- Izospan V is a two-layer material that does its job perfectly. The best option for indoor floor vapor barrier.

Preparatory work before the direct laying of Izospan

You need to start with the fact that all the boards that make up the floor are treated with a special mixture, which does not allow them to rot, attract the attention of insects, and so on.

If the floor has already been rebuilt, then this action will need to be carried out by dismantling the floor.

After dismantling, it is necessary to replace especially worn materials, processing new ones according to the already announced scheme.

Vapor barrier installation

Izospan laid on the floor

Even a non-specialist can carry out this procedure, guided by the presented sequence of actions.

When vapor barrier interfloor ceilings, Izospan B is laid on top of the insulation, fixing it with a stapler and sealing it by gluing the joints. Be sure to provide an overlap of 15–20 cm.

Application in certain areas

The use of a vapor barrier material greatly extends the service life of the insulation and, as a result, the entire building structure. Its main task is to prevent the penetration of condensate and the formation of fungus.

insulated roof

A membrane or plastic film is an indispensable element in the construction of an insulated roof. It is mounted on the elements of the supporting frame, less often - on the rough finish. It is necessary so that the moisture formed during the temperature difference does not fall on the insulation. To enhance the characteristics of the joints (overlap), Izospan SL is glued.

|

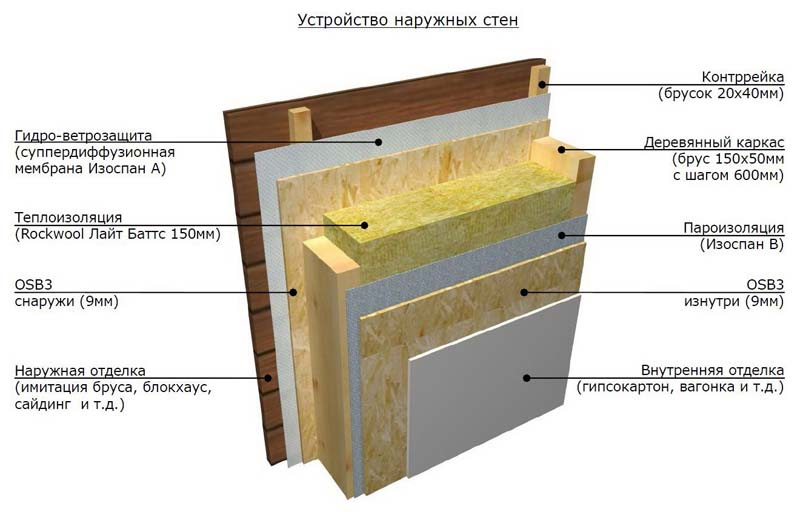

External wall insulation

The structure of the product is such that it is equally successfully used for both external and internal insulation. The main thing is that direct sunlight does not fall on the film - they significantly reduce the service life and generally negatively affect the canvas. For exterior finishing, the smooth side also faces the heat insulator.

|

Floor structures

Installation of Izospan is recommended when arranging interfloor and basement ceilings to isolate the insulation from moisture and at the same time to prevent its fibers from entering the living space.

Polyethylene is placed between the cladding and the draft ceiling with the perforated (reverse) side down and directly above the insulation itself, while the rough surface is facing it.

For tight joints, it doesn’t matter if the B or FX series is used, when butted, glued with KL or SL tape

|

Floor arrangement

When laying any floor covering on a concrete, brick, cement and other base (with the exception of wood and its derivatives), a layer of vapor and waterproofing must be laid to compensate for temperature differences and absorb condensate. The canvas is laid directly on the screed, they can be laid with insulation if the decorative coating is thin or immediately lay parquet or laminate on the substrate.

|

The choice of materials for creating a vapor barrier layer

The main property of a vapor barrier material that you should pay attention to when choosing is the ability to pass a minimum of steam. This criterion is calculated by the amount of steam that passes through 1 m 2 per day

Some materials have an indicator of 3-5 g / m 2, but most are characterized by a vapor permeability of less than one. To know which vapor barrier to choose for the ceiling in your particular case, you need to explore the options.

The first vapor barrier material was glassine, its vapor permeability was 80 g/m 2 . However, modern insulation in some cases has an index of about 0.02 g/m 2 . The appearance of materials that are used as surface insulation from steam and atmospheric moisture is almost the same

Therefore, it is very important when choosing to carefully study the information that is indicated by the manufacturer. Otherwise, you can purchase not a vapor barrier, but a waterproofing material, the use of which will lead to damage and mandatory replacement of the heat-insulating layer

To protect the ceiling, it is recommended to use the following types of vapor barrier for the ceiling:

- The vapor barrier polymer membrane refers to rolled materials, one side of which is completely smooth, the other is rough. When laying the rough side, it should be directed downwards so that a minimum amount of evaporation penetrates the cake. The presence of roughness prevents the accumulation of condensate on the surface.

- Film polypropylene and polyethylene materials can be reinforced and non-reinforced. This type of insulation requires the mandatory creation of a ventilation gap between the vapor barrier and the insulation. Ceiling vapor barrier film is used when the construction budget is limited, installation can be done by both sides.

- The foil membrane on the ceiling is recommended for use to create a barrier to the path of moist warm air, as well as to reflect heat rays and return them to the room. In both cases, laying is carried out with foil towards the steam and the flow of warm air.

In most cases, vapor barrier materials have accompanying documentation, which, along with technical and operational characteristics, describes which side to attach the vapor barrier to the ceiling, and the fastening technology itself.

To avoid unpleasant moments during operation, when choosing a material, you should pay attention to the possibility of direct contact between the vapor barrier and the insulation.

The formation of rolls of a vapor barrier polymer film is carried out in accordance with how the material will be rolled out to create a vapor barrier layer. Along the long edge of the strip there is a mark of the recommended overlap, so that the insulating carpet on the building structures is continuous.

The direction of the strips of insulating material does not play a special role, the roll can be rolled along or across the ceiling. The main condition is the creation of an overlap and a strong fastening of the strips into a solid web using adhesive tape.

It is recommended to choose bonding materials and vapor barriers from the same manufacturer. Otherwise, it is impossible to guarantee complete tightness at the gluing points. Due to the features that each manufacturer endows its products with, deformation of the material and even its destruction can occur.

Among a large number of manufacturers of rolled roofing materials, TechnoNikol should be singled out. It produces building materials for use in the CIS countries, including polymeric vapor barrier membranes, polyethylene and polypropylene films.

Vapor barrier membranes are available in several innovative self-adhesive options, as well as materials that are installed using bituminous mastic or fusing with a gas burner.

No less popular are the products of the Izospan manufacturing company. Its product range includes materials from a standard vapor barrier film to foil insulation with a layer of insulation and a self-adhesive coating on the back.