Plumbing equipment is subject to intensive operational loads and often fails. When the toilet cistern constantly flows, it brings great losses due to water overruns. It is not advisable to call the masters due to the failure of the device, since the repair mostly consists in setting up the tank mechanism. But in order to understand how to fix a toilet, you first need to know how it works. Let's figure out how to independently repair the toilet flush tank with a button.

Toilet device

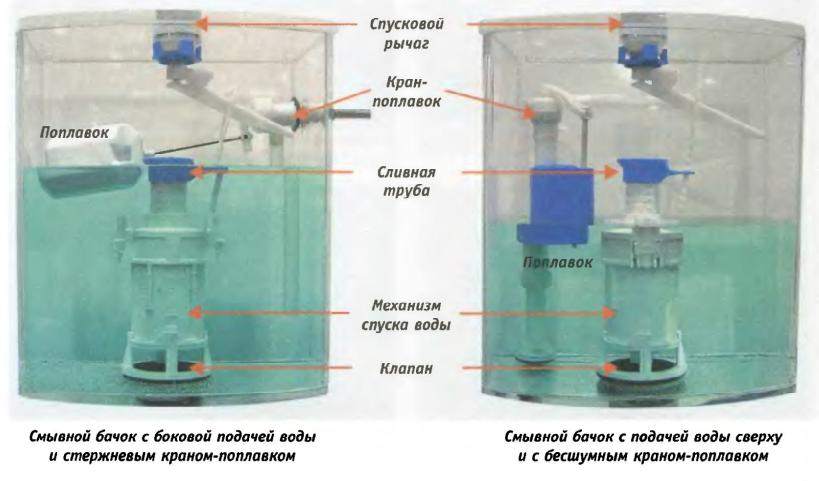

The composition of the toilet includes the following elements:

- A toilet bowl connected to a sewer pipe with an airtight cuff.

- Drain tank with fittings that ensure its filling with water and draining.

A water supply hose is connected to the tank. Depending on the design, it is connected from the side or from below. The bowl and tank are usually connected to each other with bolts and a seal.

Hardware components:

- pull-rod trigger with drain button;

- a shut-off device (inlet valve) connected to the float;

- rubber seals.

The principle of operation of the toilet with a button

The toilet cistern with a button is a water seal filled with a portion of water that is fed into the bowl when the shutter is opened. Flushing is controlled by a button that must be pressed. This opens the valve, and the water under its own weight flows down, washing the bowl. After the tank is released, the shut-off valve at the inlet opens, the container is filled with the next portion to a certain level, regulated by a float. Access to the mechanism is provided by opening the top cover of the tank.

Preparation for repair

Before you fix the toilet cistern, it must be opened. It can only be accessed from above by removing the cover. In many modifications, it is attached with a ring around the button. This ring must be pressed and turned counterclockwise. After a long period of use, the ring may not turn. Then a few drops of oil are applied to the attachment site. After the ring turns, it is unscrewed, and then the button is released from the plastic clothespins and the cover is removed.

Models are supplied with one button or two. In the second case, one of them is designed for a small flush, and the other for a large one. To dismantle the cover, press one button and remove both in turn through the technological groove. After unscrew the fastening screw and remove the cover.

Do-it-yourself ways to repair the tank mechanism

Through the upper hole in the tank, the entire mechanism of the drain valve is visible. It may have the following faults:

- The tank is constantly leaking.

- There is no water pressure at the inlet.

- Uncontrolled drain mechanism.

The causes of these malfunctions can be different, and the way in which the toilet cistern will be repaired depends on them.

- The plug (pear) does not fit snugly against the drain hole. To avoid this, you should purchase high quality plumbing. The possibility of repair can be checked by pressing the stem with a little force. If at the same time the water does not flow, the cork can be slightly weighted with an additional load or the rod can be leveled. You also need to periodically clean the seal from rust and salts, due to which the tightness is broken, and the liquid constantly flows into the bowl.

- The regulator does not shut off the water supply. At the same time, the tank will never overflow, thanks to the presence of an overflow tube. The serviceability of each element of the device is checked: float, inlet valve, fasteners, rod. The failed part is replaced or the float mount is simply tightened.

- Leak from the tank into the room. It may have a crack or the tightness of the gaskets is broken.Particular attention should be paid to the quality of the connection between the current tank and the bowl. It needs to be tightened, and if this does not help, the rubber gasket changes. Another cause of leakage may be the wear of the cuff in the joint between the bowl drain and the sewer pipe. The seal is changed to a new one, having cleaned the connection of contaminants and treating the surfaces with a sealant.

- Weak pressure through the intake valve. This usually happens if it becomes clogged. You can prevent this by cleaning or installing a filter in front of it.

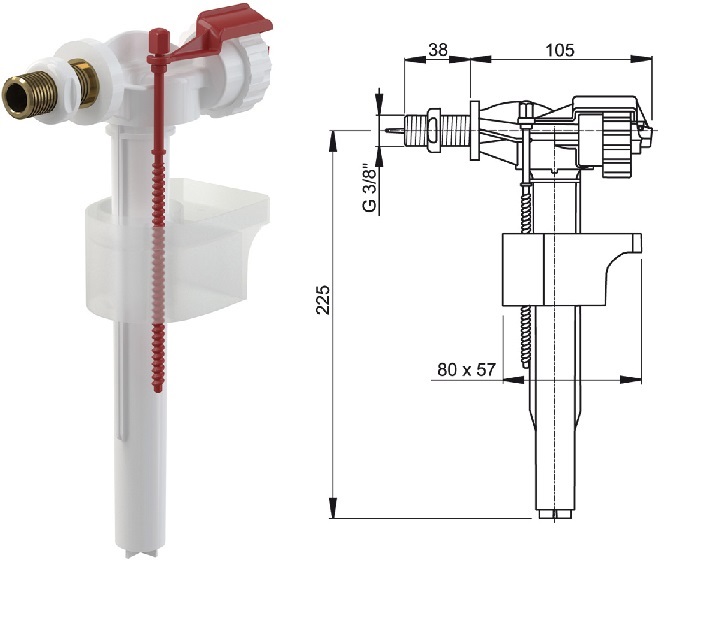

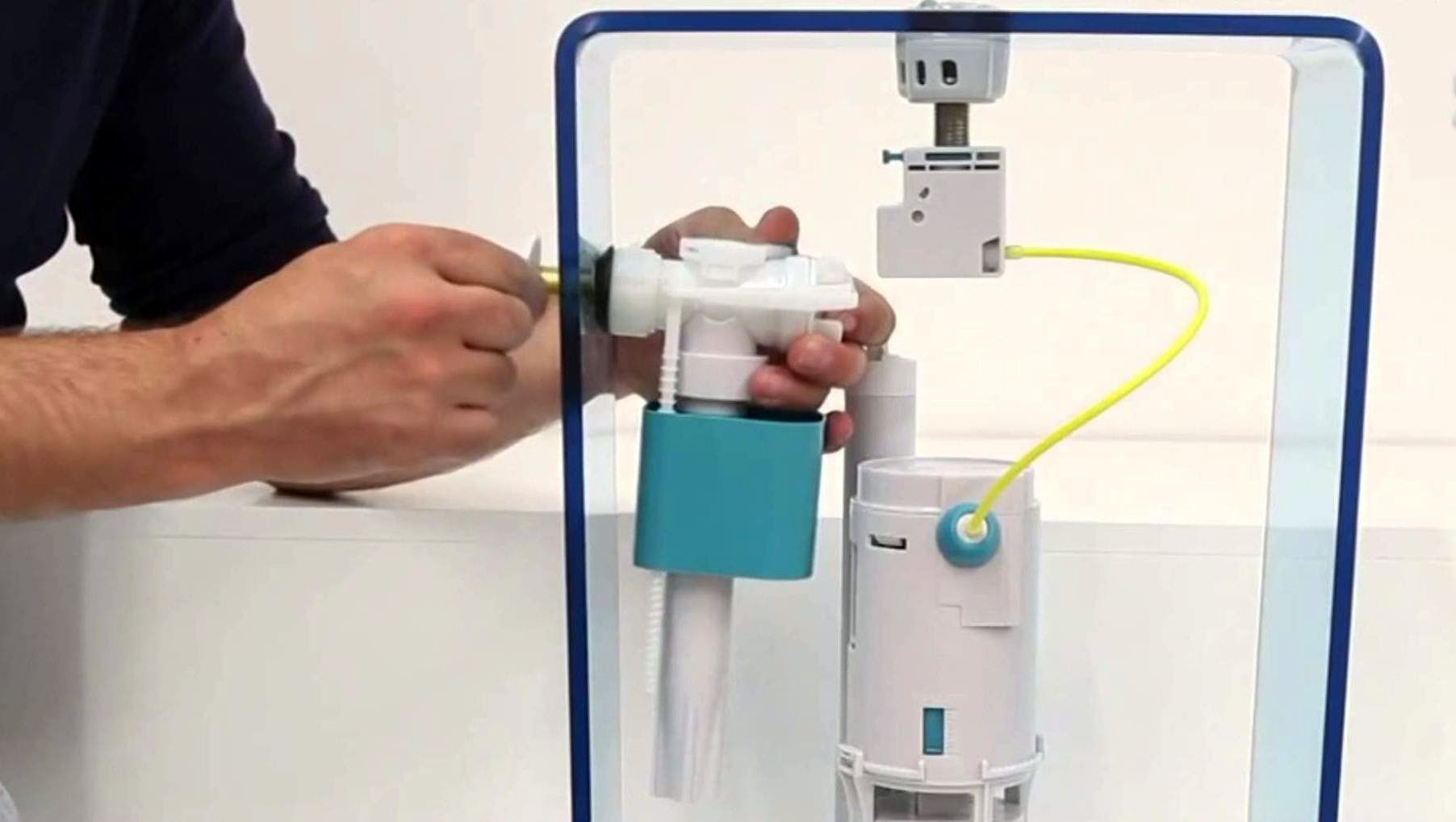

Inlet valve replacement

Before repairing the toilet, turn off the water supply tap. It connects to the pipeline from the riser. After that, the flexible hose is unscrewed from the intake mechanism. It can be easily removed by loosening the fastener. Instead, a new or refurbished one is installed. Assembly is carried out in reverse order. A plastic thread does not require sealing, and a fluoroplastic tape is wound onto a brass one.

Bleed valve replacement

The main reason is the wear of the sealing ring under the valve. To replace it, you need to remove the hardware and install a new gasket. After the assembly is carried out in the reverse order.

The water release button should always be used carefully and pressed without sudden force.

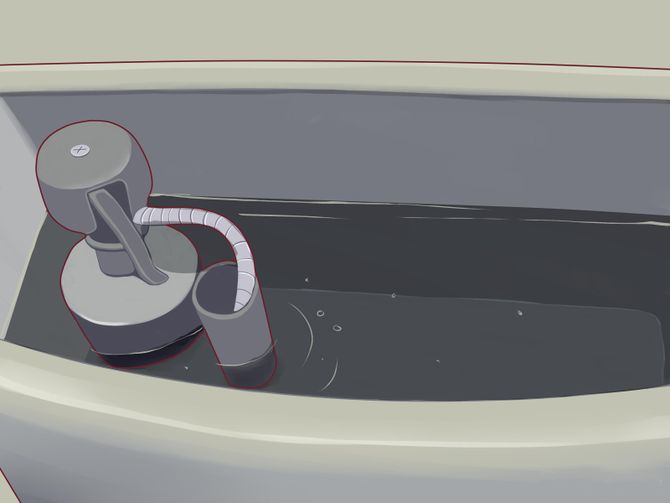

Adjusting the water level in the tank

The water level can be easily adjusted by hand. To do this, the float is set in a certain position.

The optimal level is considered to be when the water supply to the container has stopped, and a few centimeters remain to its upper edge.

The method of adjustment depends on the design of the valve. The simplest is bending a metal bar. If the float moves along a horizontal plastic guide, it is fixed with the help of fasteners in a certain position. With a vertical layout, it is moved with an adjusting screw.

When choosing the fill level, do not forget about the overflow pipe. Its upper edge should be a couple of centimeters above the water level in the filled container. If it is located lower, water will constantly flow through the overflow into the bowl.

Tank Troubleshooting

The tank may leak water due to a crack that has appeared in it. The same applies to the bowl. In this case, the question of how to repair a cistern or bowl is not worth it: the entire toilet is usually changed. A small crack in the upper parts of ceramic products can be repaired. So that it does not spread further, and the seepage of water does not increase, it is drilled at the ends and processed along the entire length with sandpaper. The work is done neatly.

If the crack has gone further during operation, the toilet should be replaced.

The surface is degreased, and the gap is filled with epoxy. After hardening, the seam is polished.

Features of repair of products with a lower water supply

Not so long ago, tanks with a bottom water supply began to be used, which makes them more compact due to the absence of protruding tubes. Typical malfunctions and features of repairing a toilet cistern with a button with a bottom water supply:

- Weak water pressure. For normal operation of the membrane valve, a water pressure of 0.05 MPa is required. Otherwise, water will flow into the tank constantly. The increase in pressure is created by cleaning the intake valve and filter.

- Installation errors. The outlet fitting must not come into contact with the walls of the tank.

Built-in cistern repair (with installation)

It is more difficult to get to the mechanism of a tank installed behind a false wall. First of all, you should purchase a device with high reliability, which rarely requires repair. There should be inspection hatches in the wall through which you can get to the tank and replace the gaskets if the tightness is broken.Do-it-yourself drain fittings cannot be repaired due to the complexity of the design.

A coarse filter is installed in front of the hidden tank, which traps solid particles, which in most cases cause a leak.

How to choose the right plumbing?

When choosing a toilet, pay attention to the following.

- Way of fastening: monoblocks, compact and separate toilet bowls. The choice is made taking into account the size of the room, the design and the complexity of maintaining the tank.

- Accessories. Most of the parts with low strength and reliability are made of plastic.

- The presence of positive reviews, a well-known manufacturer, the availability of a guarantee and a certificate.

Conclusion

The durability of the cistern is ensured by the use of non-corrosive and durable materials. The tank mechanism is simple and can be adjusted and repaired with your own hands. Toilet bowls of common designs should be purchased so that a new part can be easily found.